DIY oak table: prestigious, beautiful and durable. Table: material, manufacturing technology, diagrams, designs - simple and complex Do-it-yourself oak tables

The interior of any apartment, house or cottage is absolutely impossible to imagine without such important element like a table.

And although it does not seem difficult to select in furniture showroom table of any sizes, shapes, designs and design solutions, it’s still much more interesting to make it yourself.

Firstly, it is much more economical, and secondly, you will not only enjoy the creation process, but are also guaranteed to achieve the desired result - the shape and dimensions that are ideal for your room. Let's consider the process handmade solid wood.

First of all, you need to decide on your goals.

Advice. The choice of species for the tabletop will depend on what functions your table will perform, how durable it should be and what characteristics of structure and color it should have.

Pine, spruce, alder. The main advantage of these types of wood is their low cost. In addition, they have a uniform structure and, accordingly, are very easy to process. However, their safety margin is not very high.

Pine, spruce, alder. The main advantage of these types of wood is their low cost. In addition, they have a uniform structure and, accordingly, are very easy to process. However, their safety margin is not very high.

Oak, beech. These are the options with the strongest wood. If durability is your priority, then optimal choice there will be oak.

It looks very beautiful in cross-section, and the oak tabletop will be very heavy. At the same time, the cost of the material is relatively high. Beech is also different high strength, it is somewhat cheaper than oak, but has practically no relief pattern.

Ash. The structure is practically the same as oak, although it does not look as luxurious. Its main advantage is the variety of color palette.

Birch, larch. Also representatives of hardwood. Their processing is somewhat more complicated, but moisture resistance and strength are at the highest level.

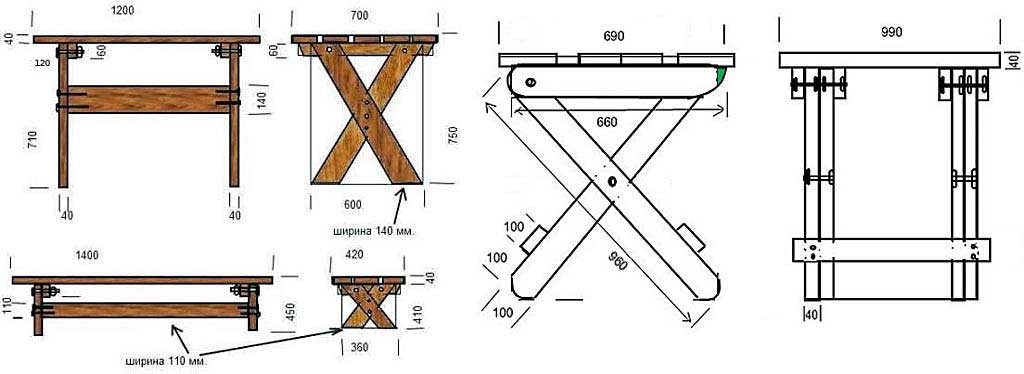

Drawings

Many people think that having a drawing when making a table is not at all necessary. But still, in order to avoid inconsistencies between the future finished product and its intended purposes, it is better to spend some time and protect yourself. Constructing a drawing is necessary for at least two reasons:

- When you decide to make a table, you, of course, think in advance about what functions it will perform and where it will be placed. Dimensions and the shape of the table are, of course, determined based on the availability of free space. But besides this, you need to take into account such nuances as comfortable space under the table for your feet, the distance from the chair to the wall, etc. In order to organically fit your table into the interior of the room and ensure its maximum functionality, you need to have a clear idea of its dimensions. And in this matter you cannot do without a drawing.

- In addition, although at first glance the table is not very complex design, the possibility of making a mistake in the manufacture of any part still exists. To prevent this, a drawing will be useful - a visual reflection on paper of the table components showing all sizes.

Advice. If you do not have specific experience in drawing, you can always choose finished drawing in the Internet. In this case, you will only have to change some parameters, adjusting it to the table functions and interior conditions you need.

Tools

In order not to be distracted while working by constantly searching for the necessary tools at hand, all the tools should be prepared and laid out in advance. Approximate list something that might be useful to you looks like this:

Manufacturing

Important. Before starting any carpentry work, it is necessary to prepare the wood: thoroughly sand and treat all surfaces with an antiseptic: solid table top, boards for the frame, table legs.

- Making a frame. The frame is a rectangular base that connects to the tabletop and serves to secure and stabilize the legs.

- We turn the tabletop over and measure a few centimeters horizontally and vertically from the corner of the tabletop inward. We make the same marks on the other three corners of the tabletop. The marks should be at the same distance from the corners;

- Let's draw connecting lines. The result should be a rectangle (or square, depending on the shape of the tabletop), inscribed in the center of the table;

- We cut four pieces of wood so that their dimensions exactly match the lines drawn on the underside of the tabletop;

- We glue the frame to the tabletop and install clamps. To strengthen the structure, in addition to gluing, the frame should be screwed.

- Making legs. To do this, we make four bars of the same length indicated in the drawing. We glue the legs to the frame and tabletop so that there is no empty space left in the leg-frame and leg-tabletop joints. Leave it to dry for a while and secure the legs with self-tapping screws at an acute angle to the surface of the board.

- After completing the main work, we move on to processing. All sharp edges of the table top and legs must be sanded by hand. Then we apply varnish evenly over the entire structure. Transparent or colored varnish will not only protect the table from unwanted influence external factors, such as moisture, but will also highlight the natural pattern of the wood. It will look very impressive if you paint some parts of the table with paint.

Sometimes, in order to improve the durability of your product or give the table a brighter appearance, surface varnish(or painted) again.

Sometimes, in order to improve the durability of your product or give the table a brighter appearance, surface varnish(or painted) again.

In this case, it should be remembered that the second layer of varnish or paint can be applied only after the previous layer has completely dried. There is no need to rush, it is better to wait a few extra hours, but be sure that you will not spoil the almost finished table.

- the first time after varnishing and painting, try to avoid contact with moisture and direct sunlight on the surface;

- even after the varnish has completely dried, do not leave the table outside in the rain or at low temperatures;

- Keep the surface clean, treat it with special cleaning agents in a timely manner, and polish it periodically.

Photo

You can design the resulting result in the style of the following photos:

Useful video

An excellent example showing all stages of the process can be seen in the following video:

Conclusion

Based on the above, we can conclude that making a wooden table with your own hands is not so difficult. Especially if we are inclined to the option with a ready-made solid wood tabletop, because... in this case, the “front of work” is significantly reduced.

In contact with

This piece of furniture is one of the most versatile in use. The table can be a dining room, a utility table, or installed in a living room, on a veranda, on a property, in a workshop, and so on. In a word, it is impossible to do without it. But many people are not satisfied with purchased products in terms of a number of parameters - size, design features, form or for any other reason.

Considering that wood is relatively easy to cut and sand, making a table from it according to your own drawing, with your own hands, is not a problem for a good owner. And it will come out much cheaper. Plus - satisfaction from such work.

Room

Ideally, this is an extension, a barn, an empty garage, although a small area under a canopy will do. Working with wood on the site, under open air- means being completely dependent on the vagaries of the weather. If there are suitable ones for making furniture " square meters", then you should worry about quality ventilation in advance. Natural is sometimes not enough (besides, it depends on changes in wind direction and pressure), and a hood is installed.

Arguments that if you use protective equipment, you can work in closed space, do not stand up to any criticism. Wood dust will immediately settle on everything, including the sample with which some action is being performed. Neither precise cutting along the line, nor high-quality surface treatment of wood (not to mention impregnation and finishing coating paint and varnish composition) will not be possible to obtain.

One cannot ignore the fact that many preparations used for wood processing contain toxic components. For example, varnishes, paints, impregnations: if they are not natural, then harmful fumes are guaranteed.

Tools

Their selection depends on the extent to which it is planned to “ennoble” simple design made of wood, what shape to give it and a number of other nuances. If the master does not lay claim to the elegance of a wooden table and does not aim to achieve its originality, then an ordinary carpenter’s set will be enough.

For more “delicate” work in the process of making a table of unusual shapes, external design will be needed special devices.

El/jigsaw

Sander

Many of the listed devices can be rented if making furniture is not a hobby, but a necessity.

Impregnating and other compositions

Rot protection:

- Working off machine oil– an effective, and also free, remedy. But not for dining tables.

- Flaxseed oil. A natural and effective product that penetrates deeply into the wood structure and protects it from mold and mildew. The downside is the high cost. But if the table is intended for eating - great option. The drug has no color, therefore, after processing lumber, it does not leave any traces in the form of darkening, stains, or streaks, unlike processing.

- Water-polymer emulsion. It is characterized by long-lasting action and safety for health.

- Acrylic varnishes. They have practically supplanted their predecessors in the “NC” category, since they are harmless and in many respects better compositions, which are diluted with solvents.

- PVA, bone glue and a number of others. More detailed information about carpentry compositions - .

To decorate a tree:

- Clear varnishes are used not only to protect the material from moisture. With their help, you can preserve the texture of the wood and shade it.

- Stains.

- Varnishes with a coloring effect (tinting).

- Paints (but only for wood!).

- Putties.

Using colorless varnish and pigments, you can make a coloring composition of any shade. It is enough just to correctly determine the proportion of components. This is easy to do by experimenting with mixing and applying a sample to a discarded board. This will allow you to choose an acceptable tone. It is more than advisable, since it is not always possible to purchase exactly what you need on the market.

Fasteners

It is better to ignore all advice on assembling a wooden table using nails (the reasoning is simple, quick and cheap). The reasons are as follows:

- The nail easily pricks dry wood (and this is exactly what is used; more on that below).

- It is quite difficult to direct its leg correctly (strictly vertically). In some cases, it is even more difficult to redo your mistake.

- A tree, even the most protected from rot, succumbs to it over time. The maintainability of a table knocked down with nails is extremely low. Practice shows that it is rarely possible to remove such fasteners without damaging adjacent structural parts. As a result, instead of the planned replacement of one element, 2–3 will have to be changed.

- When assembling a wooden table, if glue alone is not enough, you should use only self-tapping screws.

- Sometimes its individual parts (at joints) require reinforcement. Strengthening the strength with hardware with a thicker and longer leg is impractical. The reason is the same - the likelihood of the tree splitting. For these purposes, metal strips, brackets, and corners are used.

Features of choosing wood

Some people focus on the cost of lumber, others care about the wood’s resistance to rot, and for others, its texture. What can you recommend to a novice furniture maker? Do not use the same type of wood for a table unless it is intended to be installed somewhere in a utility room or garage. This is exactly what many novice “craftsmen” do, selecting the same type of boards and bars from what is left from construction or renovation and gathering dust in the barn.

When making a wooden table for a living space, veranda, etc., you need to take into account the properties of individual species. Naturally, if you do not have sufficient experience in assembling furniture, you should pay attention to cheaper wood. The first table (chair, stool) in your life is just a kind of training in making and gaining experience.

TabletopIf the size of the countertop is small, then you can use wood-based slab products (OSV, OSV and the like). But only with lamination to prevent the material from swelling when liquid gets on the table surface. For example, chipboard.

Low-grade lumber is not used in the furniture industry. This is not economically feasible, since pre-treatment of wood increases the production cycle time. But when making anything, wood of lower grades, substandard wood is just right. The same pallets left over after using stacks of foam blocks or bricks.

And not just because it is free or relatively cheap. Many of the disadvantages of such wood can be turned into advantages with the right approach. For example, after coating with colorless varnish, the tabletop acquires a unique, original look.

The main thing is that the boards do not have obvious defects in the form of rot, cracks, falling knots and wormholes.

If pine is chosen for the tabletop (this also applies to many other conifers), then you need to pay attention to the location of the annual rings. These arches are called humps. The cuts of the boards show how they are oriented, and this is taken into account when laying them in a row. Samples obtained by tangential cutting are arranged alternatingly (one top down, the next one up); radial cutting - the same (with arcs in the same direction). The nuance is insignificant, but compliance with this recommendation eliminates the risk of warping and splitting of the boards.

For furniture, if you think about its durability, you should take only dry lumber. As wood shrinks, it will become deformed; This is a natural process, and its consequences in the form of twisting, warping, and bending are inevitable. Such a table will quickly become warped, and you will have to repair it. And here you need to decide whether to purchase highly dry wood or rid it of moisture yourself. The first option is simpler, but such a tree is more expensive. The second one will cost less, but there are a number of purely technical difficulties.

- Firstly, it is necessary to ensure stable temperature regime at the place where the workpieces are stored. Changes in its value will lead to uneven evaporation of moisture, which will negatively affect the strength of the tree.

- Secondly, good ventilation must be organized.

- Thirdly, and perhaps this is the most unpleasant moment - you will have to wait up to about six months, depending on the initial moisture content of the tree. But this is not a guarantee that the result will be as expected; Even this requires practice.

This once again confirms the idea that when starting to make furniture from wood for the first time, you should focus on simple table for household needs from cheap lumber, without pretensions to its sophistication and originality of design. For example, for a barn, garage and the like.

Options and patterns of wooden tables

It should immediately be noted that any work related to the design and self-assembly- the process is creative. There are no stereotypes in this matter, so you can only take the model you like as a basis, and everything else - linear parameters, shape, manufacturing specifics - depends on the purpose of the product and your own imagination. Here are just a few examples of what wooden tables can be like. For example, for summer cottages For small utility rooms, you should choose structures whose geometry can be easily changed - folding, camping, hanging, garden, level, and so on.

Tables that are supposed to be used for eating, games, as coffee tables for installation in living rooms intended purpose, they are made stationary, that is, unchangeable in size. These assemblies are more “solid”, since all articulated parts are rigidly fixed; no hinge joints.

Features of assembling wooden tables

If a person undertakes to make something, it means that he knows how to use tools, read blueprints and work with lumber. Such a home craftsman does not need to be taught the basics of carpentry. But it would be worth noting a number of nuances when making a wooden table. These notes will only help in the process.

Let's start with the types of connections. There are quite a few of them, but for a table that you assemble with your own hands, the ones listed below are quite enough.

On the dowels

In this case, the parts are fastened by placing them on an adhesive composition (Fig. 1 – 3).

The nuance is that to make the “cylinders” that are inserted into pre-drilled “channels”, a tree of a denser structure than the table elements is taken. This is what ensures the strength of the connections. Before installing them, chamfers are removed from the edges of the dowels and holes.

These round sticks are available for sale in any furniture showroom in several sizes. Grind them out, even having carpentry machine- an irrational waste of time. It is not recommended to purchase plastic dowels for the table; they are used for detachable connections. For example, frame furniture (walls, multi-level shelving, etc.).

You should not use nails to fix table elements (Fig. 4). Metal and wood differ in the degree of thermal expansion. Such a connection will not last long - it will begin to “shatter”, especially if the table is intended to be installed on the territory or in an unheated room.

On the kings

It is advisable to make such connections if the table either has to be disassembled periodically, or without this it is impossible to move it through the doorway. Although not all drawers require dismantling the structure. The most commonly used options are shown in the figures.

Bolted

Such connections are used mainly for garden furniture or those installed in extensions; for utility tables. An example is shown in the figure.

The nuance of working with fasteners

In order for the self-tapping screw to be easily screwed in and “go” in the desired direction, a hole is first made at the point of its installation using a drill with a diameter slightly smaller than the fastener leg. The main thing is to withstand the coincidence center lines, that is, to prevent distortion. In this case, to “plant” the screw, you can do without a screwdriver.

Features of wood processing

Everyone knows that a plane is used first, an abrasive with a large grain, and then a fine one. But sometimes it turns out that the last stage, grinding has to be done many times. Much depends on the type of wood and the degree of drying. After applying the first layer of varnish, the fibers may “stand up”. Nothing wrong with that. You should wait for the workpiece to dry and repeat its processing with abrasive. The work is painstaking and takes time. But it is precisely this method that can bring “problem” wood to ideal “smoothness.”

To eliminate the risk of injury to a person, all edges and corners of the table should be slightly rounded.

Features of external decoration

- Minor defects in the form of cracks and chips are eliminated with putty.

- Once sanding is complete, all wood dust must be removed. In this case, the usual one will help out household vacuum cleaner with the appropriate nozzle. It is recommended that after such cleaning, wipe the entire table with a slightly damp cloth, let it dry and repeat removing any remaining dust. After this, you can safely start applying stain or varnish - there will be no “pellets” on the wood.

- You can add originality to the table not only with the help of curly cutouts, unusual shape tabletops or legs, combination of textures different breeds and so on. One of good options– artistic painting.

And finally. Work on self-production something made of wood (the same table) - just First stage mastering the skill of “designer-assembler”. Having developed technologies and techniques on wood and acquired the necessary skills, it is enough to simply switch to other materials - metal, plastic, glass. So the benefits of a wooden table made even by yourself simple drawing(besides the pleasure of work and the money saved) is obvious - time well spent.

After making a gazebo with a canopy, the forum participant was faced with the question of making the necessary furniture. The owner decided to start with what seemed to be the simplest, but at the same time complex product - a table. It had to be outside for a whole year and, importantly, the design would match the entire interior of the gazebo.

Table

Looking for oak boards ttttt came across an advertisement for the sale of timber at a good price. I called the seller and drove 35 km. However, when he saw a stack of oak beams overgrown with moss and rooted into the ground, the forum member was taken aback. The timber was prepared by the owners back in the 80s, but they never needed it. At first he was upset, but later it turned out that it was in vain: after the logs were cut into boards and beams of the required cross-section at the sawmill, a tree of amazing beauty was revealed to the owner.

When the material was ready, the forum member conducted several experiments on finishing– I wanted to achieve a beautiful coating that would protect the wood from moisture. Ott treated the wood with colorless Belinka glaze and linseed oil, and then exposed it to aggressive media: poured water, vinegar, soup, orange juice, vodka.

“Belinka” turned out to be more durable, but the drying oil looked more natural and beautiful. In addition, this coating had one more advantage: discoloration under the influence of any liquids can be corrected by wiping the wood a couple of times a season with a cloth soaked in drying oil.

Then the forum member did a test fitting and marked all the legs.

After the onset of cold weather, the work had to be moved indoors. A weight tie-down strap was used for assembly. The owner glued the legs with elastic polyurethane adhesive-sealant. I tightened everything with a belt and tapped the connections with a rubber hammer. After hardening (after three days), I carefully cut off the excess glue.

The wood was pre-treated with a mixture water stains walnut and oak colors (1:1), then soaked in drying oil mixed with turpentine in the same ratio. I achieved the color of greasy wood, darkened by time.

After drying, I went over all surfaces with 180-grit sandpaper to remove the lint and “wipe” the edges and texture. With the onset of spring, the table was taken out and collected. The forum member connected the boards with a gap of 2-3 mm, leaving allowances for swelling. Fastened with oak blocks.

This connection will allow the board to “play” to the sides a couple of millimeters without splitting.

Finally, the owner treated it with several layers of a weak solution of drying oil in turpentine. The table turned out to be about 84 cm high, so the legs had to be shortened.

Bench

Ottt made the corner bench without a back in two days off. The legs were made from a 7 cm block. For the seat, a 25 cm board was used. Since it was thin, the owner made five jumpers on the long side so that the product could support all the guests.

Blanks: I made the eyes with a milling cutter to fit the template, and then glued them with polyurethane sealant.

While the glue was setting, I pulled it in with the corners. In order to save effort and time, I attached the seat with screws into drilled and countersunk holes. I puttyed it and treated it with walnut and oak colored stain, and soaked it in drying oil and turpentine.

Subsequently it turned out to be more a good decision than varnish coating. When the table was scratched with screws, the forum member soaked the damaged areas natural drying oil. Even without sanding, the scratches became less noticeable. In addition, the table was made for the street, and any film coating would begin to peel off under the influence of seasonal fluctuations in humidity in the wood.

Equipment used:

- trimming machine (trimming machine) – allows you to make perfect corner cuts;

- I used a router to select the lugs and make a beautiful semicircular chamfer;

- Since the boards used were uncalibrated, all adjustments were made using a plane.

Based on materials from a participant in the "House and Dacha" forum

You can become the owner of a magnificent oak table without even having the money to buy it. It is enough to have a little free time, minimal carpentry skills and small funds to purchase materials. No experience in making solid wood furniture? Read - we'll teach you.

Good preparation is half the success

What do you need to make an oak table with your own hands? Confidence in own strength, good tool and a cozy place for equipping your home “carpentry”.

- Self-confidence comes after assembling the first stool, because the design of the table is not much more complicated. To “get into the swing of things,” we can recommend first making a table for country house, then for the kitchen, and then start making furniture product, designed to decorate the living room.

- Ordinary carpenter's tool should always be at hand. However, without the achievements of modern technical thought, the work will take much longer. Below we will look at this topic in more detail.

- Without separate room for carpentry workshop home handyman not enough. The work of cutting wood is dusty, and after using stains and nitro-varnishes, a persistent smell appears, which is not the most beneficial for health. Therefore, work requires a separate, well-ventilated room, preferably with forced ventilation. You can use the garage, but it is better for the car that it is not there at that time.

Varnishes, paints, impregnations, and adhesives deserve a special mention. This topic is large and requires separate consideration, but here we will outline the main thing: without 2-fold impregnation with a water-polymer emulsion, with a break of 3-5 days, an oak table will last less.

Carpenter's "weapon"

The use of a rotary miter box makes it possible to make cuts exactly to size and angle in 2 planes. This universal device, it may come in handy more than once; it is better to purchase it rather than borrow it on occasion. It is wise to take a miter box with the included bow saw: the result of the work will be more accurate, and the costs will not be much higher.

Rice. 1. In the left half: a – mallet; b – carpenter's ax; c – bow saw; g – hacksaw; d – tools for crushing; 1 – chisel, 2 – chisel; e – plows. WITH right side there are: 1 – rotary miter box; 2 – jigsaw with a tilting shoe; 3, 4 – disc sander, 5 – belt sander, 6 – hand-held wood router.

A jigsaw is useful for making cuts at an angle to vertical plane. Application of disk grinder allows a beginner to compete with an experienced carpenter. The result achieved by a master in an hour or more, a person armed with a grinder receives in 5-15 minutes.

Without tape grinding machine You can’t even dream about fast end processing. There are, in addition, belt sanders for grooves and recesses, equipped with a protruding part that interacts with the material being processed. Their purchase will not soon pay off if you do not assemble furniture regularly: the tool is specialized and unsuitable for other work (except for brushing - artificial aging wood).

A manual wood router with a set of cutters is useful for processing shaped edges, making holes and grooves. You can also rent one, and over time, systematically doing “carpentry,” you can purchase your own.

Rice. 2. Woodworking machine UBDN-5

Good help a master can use a universal household woodworking machine of various modifications. Its advantages are:

- small sizes;

- power supply 220 V;

- Possibility of installation on any stable surface (table);

- versatility (the ability to perform cutting and jointing of lumber, drilling holes, milling grooves, turning of workpieces, tool sharpening).

Craftsmen often improve it by lengthening the caliper (the operation is simple). This will make it possible to turn the table legs on the machine. When purchasing a combined device, pay attention to power, configuration, functionality, ease of adjustment and safety.

One of the simplest designs

Table length 140-150 cm, width up to 70 (32 mm board, from which, after leveling, a classic tabletop 28 mm thick is obtained). You will need: boards 1400x100x32, 1400x100x50, sanding belt/discs, paints and varnishes, furniture clamping screws, plane, hacksaw, sanders, screwdriver and good lighting.

Rice. 3. It was - it became

After leveling (getting rid of “helicopters”, “bridges” and slabs) best board selected for the tabletop. The flatter material will be used for connections and supports.

Rice. 4. We begin to put the board in order

When making a table with your own hands, be sure to check the perpendicularity along 3 planes. If difficulties arise, saw off with a margin and use a belt sander to bring it to a right angle.

Rice. 5. Semi-assembled table support

We screw the tabletop boards onto the supports and level them all together. We work with a belt sander, first grit 60, then 120. The direction of movement of the machine is in the direction of the fibers. Afterwards we use an eccentric sander, grit 120, 240, 320. The better the grinding is done, the more beautiful it looks ready product.

Rice. 6. Sanding

Before painting, the table is completely disassembled, the room is covered with film, and mounted forced exhaust. The floor is protected with cardboard secured with tape. For safety, it is best to work with a gas mask.

After the stain has dried, apply primer (follow the official instructions of the manufacturers), 2 layers are laid at intervals of 20 minutes. After it dries, sand it with 400 sandpaper until matte, then apply varnish.

Rice. 7. Placing the workpieces in a heated steam room will speed up drying

How to make a table perfect? Just don’t rush to assemble it, the varnish takes several days to dry. Be careful and patient.

Rice. 8. Ready table

Of the abundance of furniture on offer, wooden tables and chairs remain popular everywhere. Natural materials ensure environmental friendliness, safety and durability of the models. Solid wood furniture can be found in any country house, apartment or office.

In addition, you can make wooden furniture yourself.

Wooden kitchen tables

There are a few things to consider before purchasing a table. The comfort and mood of household members in the kitchen depends on them.

Ergonomics

Due to the fact that in small apartments usually there are kitchens small sizes, do not forget about ergonomics. First of all, when choosing a wooden dining table, you should take into account the comfort of being around kitchen items furniture.

It’s not comfortable when you rest your elbows or feet on your neighbor or on the legs of the table. In addition there should be optimal distance from the table to other pieces of furniture. The table should be approximately 80 cm away from walls and other objects in the kitchen.

The height of the table also plays an important role. It should be selected depending on the height of the people sitting behind him. Low (70-74 cm) tables are recommended for short people. Those whose height is between 1.6 m and 1.7 m should buy tables with standard sizes(75-76 cm).

Appearance of the tabletop

Before choosing a tabletop design, you need to calculate how many people typically need to be seated at it. Shapes are found: oval, round and rectangular and square.

Tables that do not have corners should be placed in spacious kitchens. Tables with a square or rectangle shape fit perfectly into small spaces. You should see if the appearance of the table matches the overall interior.

Practicality

There are many models that provide additional functionality, namely, they replace a cabinet and can be folded and unfolded if necessary.

A wooden extendable table is an excellent solution for those owners who suffer from a lack of space in the room for eating.

Like any furniture, these products have a number of positive and negative qualities. Wooden tables for the kitchen have the following advantages:

- uniqueness and originality of wood texture, which cannot be recreated;

- ability for a long time withstand shock and everyday use;

- environmentally friendly, thanks to natural material that does not contain glue and does not emit harmful substances in atmosphere.

Negative characteristics include: high cost, vulnerability to moisture and dampness. At elevated temperatures, the material can dry out, thereby causing cracks and loosening of the table. Over time, the surface may darken or be attacked by pests.

Wood table in the living room

IN Lately It has become fashionable to decorate living spaces in white colors. A combination of white furniture and light-colored walls and windows is actively used. Dark and White color can also be combined in furniture.

For example, the tabletop may be white, while the legs and edging of the table are dark. Such furniture is often used when decorating a room in a minimalist style. In a spacious living room or studio, a white wooden table will be an excellent solution.

The glass and wood table is often found in front of the sofa, comes in a low size and is used as a fashionable piece of furniture in the living room. It is intended for drinking tea in front of the TV, storing books and magazines, and also for working in front of a laptop.

Solid wood table in the country house

On personal plot the most important place for gathering loved ones and guests there is a gazebo or outdoor space.

In nature, one is drawn to everything natural, so a wooden table for a garden is a combination of beauty and practicality in one item. In addition, this piece of furniture goes well with the overall rustic style.

Wooden tables for a summer cottage should not only be durable, but also moisture resistant. If the table will often be exposed to moisture, you should choose a product made of larch.

Country tables should have the ability not to deteriorate under the scorching sun. Due to its density, the best material For country table considered walnut or oak. This wood is considered hard and expressive. To resist pests, oak is stained, that is, kept in water for some time. Such material is more expensive than its counterparts.

You can save money if you choose a table from coniferous species tree. They are lightweight, pleasant in color, smell and moisture resistant. The increased resin content resists water absorption.

How to make a wooden table yourself?

Some summer residents make tables themselves. Creativity and hard work will allow you to save money and create a unique thing on your summer cottage. Making a wooden table with your own hands is not at all difficult. Enough to have in your arsenal necessary materials, tools and some time.

Tools and materials needed for manufacturing:

- plane;

- sanding machine or paper;

- screwdriver with a set of bits;

- jigsaw or saw;

- chisel;

- staining and varnishing agents;

- metal corners;

- yardstick;

- building level;

- accessories for fastening (screws, bolts, self-tapping screws);

- boards 40 or 50 mm thick;

- 4 blocks for wooden table legs measuring 50x50 mm;

- auxiliary boards 40 mm thick for attaching the tabletop.

Procedure (step by step instructions)

- Decide on the dimensions of the future homemade product. If the table length is greater than the standard values, it is necessary to install at least four racks.

- Pre-plane the boards for the tabletop and saw them to the required size.

- Place five boards in parallel, fasten them from below with self-tapping screws to the auxiliary cross boards. It is necessary to leave space for the table legs.

- Install the bars for the legs using metal corners and secure them to the tabletop.

- To prevent distortions and stability of the legs, pass the strips around the perimeter under the tabletop. If the table has more than four legs, an additional cross bar must be strengthened in the middle.

- Clean the edges of the table top with sandpaper on all sides.

- Cover the product with pest repellents (stain) and, if desired, apply a layer of varnish.

There are many ways to create a table with your own hands. The final version of the homemade wooden table we proposed can be seen in the photo.

Wooden tables for kids

When a young child grows up and begins to sit independently, the time comes to feed him various complementary foods.

Wooden table IR for feeding - the most good option furniture designed for comfortable eating. Tables are usually made together with chairs and have a common design.

There are several types of children's chairs:

- transformable chairs

- chairs with adjustable backrest.

In the first case, the seat height is adjusted according to purpose. A child can not only eat at the table, but also play if you remove folding table made of wood and lower the seat.

In the second case, the adjustable seat height allows you to raise the baby higher or lower it to a safe distance from the floor. Even if the maneuver is unsuccessful, the child will not be able to harm himself and will give the mother the opportunity to do everyday chores in the kitchen.

Buying wooden tables for feeding, parents do not have to worry about the health of the child - he will not have allergic reactions. Therefore, natural wood material is most often used to make children's furniture.

When buying a table, you should pay attention to sharp corners, which can cause unwanted damage to its little owner.

Finally, I would like to say that thanks to wooden furniture There are many possibilities to arrange your home for different design. Particularly popular country style using natural materials and copying antique interiors.

Safety and your own health directly depend on the type of materials that are in your home.

Another important fact is that wood is a material that can be worked with without using complex tools and equipment. Thus, any man is able to create beautiful things on his own for reasonable money.

Photo of a wooden table