Do-it-yourself gas heat gun device. How to make a heat gun

There are hardly any more pressing problems in winter than problems with high-quality heating objects. To solve them, special equipment is used, one of the most common of which is a heat gun, in particular a gas gun. Today we will talk about how to make a gas gun with your own hands and whether this can be done in principle.

Note that thermal gas guns have become very popular in our country. Lately. And the reason for this is not only the specific climate, but also quite a large number of dachas and country houses. In short, such devices have a lot of advantages.

- Fairly quick installation/disassembly.

- They are safe.

- Once installed, they are immediately ready for heating.

- They are mobile and compact.

- The air in the entire room warms up very quickly.

- You can independently regulate the temperature mode.

- Finally, impressive efficiency.

Operating principle and application of a gas gun

If you connect the gun to a centralized gas supply, it turns into a full-fledged stationary device, which in a private home can easily replace an entire heating system without any damage to the quality of heating. Regarding the fuel used, in most cases it is propane-butane.

Note! When the gas burns, virtually no odor is released.

Moreover, the multi-level protection system found in the devices completely eliminates gas leakage. More “advanced” models have a special body coating that protects it from damage.

Thanks to gas guns, you can not only heat, but also quickly dry any surfaces - for example, plaster, freshly poured concrete, etc., and high performance makes it possible to use the device in large rooms - warehouses, hangars - and in crowded places. This device really can be set and forgotten, because temperature control and on/off is initiated by the thermostat. Finally, in terms of quantity carbon monoxide The gas gun is no larger than a regular tile.

About what else can be used to heat industrial premises,

All devices of this kind consist of standard elements:

- heat exchanger;

- automatic device-controller;

- fan

It is characteristic that the device requires very little electricity - after all, it is only needed to rotate the fan. When the gas burns, the heat exchanger warms up. The air driven by the fan passes through the heat exchanger, heats up and spreads throughout the heated room.

Types of gas guns

Air can be heated in one of two ways:

- direct heating;

- indirect.

Gas guns (homemade or factory-made) with direct heating have enough simple design, which is why their cost is low. In them, the burner is not insulated in any way, so that, in addition to heated air, gas combustion products also enter the room. For this reason, the device is compact and demonstrates good efficiency. But if you use it to heat a living space, you must first ensure that it (the room) has good ventilation system, which would remove combustion products.

Guns operating on an indirect principle are equipped with insulated combustion chambers. They have special pipes through which these products are removed and which are connected to the common chimney. They are ideal for any type of premises where many people gather.

All this is a description of stationary guns, but besides them, there are also portable or mobile guns. They are used in conjunction with gas cylinders. To make it convenient to transport and operate the device, it has special wheels and handles.

Note! Mobile guns require strict adherence to safety rules.

The operating time of such devices is dictated only by the volume of the gas cylinder, fuel consumption fluctuates in the range of 0.6-7 l. at one o'clock. In order to extend the battery life, there are special adapters that allow you to connect the device to several cylinders at once. Most economical option is a gun that is equipped with a thermostat. With it, the device turns off after the required room temperature is reached. In a word, heating the room with such guns is an opportunity to save on heating.

What will be required at work?

So, you have decided that you will make your own gas gun yourself. Well, this is understandable because it is economically beneficial. But desire alone is not enough; you will also need the following list of tools and materials.

- Metal pipe for supplying fuel to the system.

- Drill with drills for metal.

- Bulgarian.

- Sheet of steel.

- Strips of metal 2 millimeters thick.

- Eight-millimeter iron pipe required to create a heat exchanger.

- The fan is from a car, its power must be at least 12 volts.

- Reinforcement for the structure on which the cannon will be placed.

DIY gas gun

Devices of this kind are represented today by a wide range of models from different countries. We use them mainly for heating garages. But before you start creating a gas gun with your own hands, let us remind you once again that it consumes a lot of electricity.

You may also be interested in an article about how electrical power works.

So, step-by-step technology manufacturing of the device.

First stage. First, we cut the tube with a grinder - it is through it that the gas will enter the system. These measures are necessary to further lengthen the pipe - in order to do this, we weld any other pipe that has a similar diameter.

Third stage. When this is finished, we increase the length of the body - this is necessary to increase heat transfer. To do this, we need a metal disk (? 8 centimeters), which we will attach directly under the extension. Then a hole is drilled with? 1 centimeter, in total we will need eight holes of a similar nature.

Fourth stage. We make a clamp that will secure the heat exchanger itself. After this, we weld two metal plates of 2 millimeters each in the form of a cross - this is also necessary to increase heat transfer.

Fifth stage. We are building a heat exchanger. We take it for this iron pipe With? 8 centimeters, its walls should not be too thick. After this, we weld the end to the pipe wall, in which, in turn, we drill a hole. We will pass the extension cord from the burner through it, and at the end the clamp must be additionally reinforced with bolts.

Sixth stage. We continue to work with the thermal energy exchanger. We make a hole in its body (using a grinder for this), to which a piece of an eight-centimeter tube is attached. Heated air will escape from it into the room.

Seventh stage. Next, we take a regular fan from a car with a power of at least 12 volts and install it at the second end of the exchanger housing. This will be a kind of motor for us, in other words, a device that generates energy for our device, through which heat will be transferred to the heated room.

Eighth stage. The last stage The work will involve drilling the holes necessary to make igniting the gas more convenient. Moreover, you will also need to think over the design where, in fact, the gas gun will be placed with your own hands. You can use iron reinforcement for this, welding a kind of frame from it.

Trial run

To use the gun you need to perform some procedures.

- We light the lighter by bringing it to the fuel ignition hole.

- Open the valve so that gas begins to flow.

- When the gas lights up, put the lighter back.

- Turn on the fan.

If we briefly consider the manufacturing technology of this kind of heat gun, it looks like this:

- We attach a metal extension disk to the burner;

- we extend the pipe necessary for gas supply to the device;

- we install iron plates necessary to improve heat transfer;

- install the clamp on one side of the extension, after which you need to secure the heat exchanger itself;

- We assemble the entire heating device;

- we make holes in the heat exchanger so that hot air can escape through them;

- We weld a metal ring to the second end of the pipe;

- We install a switch on the heat exchanger that will turn the fan on/off;

- fan assembly itself.

Do not forget that a DIY gas gun also needs a housing. This body, as you know, most closely resembles an ordinary pipe, so we can easily make it ourselves. To do this, take a sheet of steel that is not too thick, cut it to give it required sizes, and roll it into a pipe.

In order to connect the edges of the sheet together, you can resort to the connecting lock method. If for one reason or another you cannot do this, then use regular fastening bolts.

Finally

Well, so we looked at the features, operating principle and manufacturing technology of such a device as a gas heat gun. This device is very popular due to its efficiency and the ability to heat rooms with a large area in record a short time. You can do it yourself, just have a list necessary tools, materials, and a little patience.

Among the obvious advantages of a homemade electric heat gun is its mobility and the ability to be delivered to any place at no cost. It is convenient to use and easy to repair. A heat gun, built or assembled with your own hands, has increased performance characteristics.

A homemade heat gun is special device, whose main task is to heat large residential or storage facilities. This heater runs on electricity, but can also be used alternative sources energy - kerosene, gasoline, diesel fuel, etc. Heat guns have different power levels. For domestic use, a unit with a power of 2 to 10 kW is sufficient. But they work at such power simple models, which are not enough to heat a large workroom or warehouse. If you need to heat a large room, then the power of the device must be at least 200 kW. You can order online and buy such a heater, but it’s easier and cheaper to assemble it yourself.

This heating source has its advantages and disadvantages. First, you don’t need a fuel tank. Secondly, electric devices are safer than those running on gasoline and kerosene. They are environmentally cleaner and do not emit harmful substances. There is only one drawback - the electric gun is only suitable for rooms with a central electrical supply.

Yes, you can make any device, even one running on gas and diesel fuel, but achieving the desired level of power is very difficult if you additionally take into account safety regulations.

When assembling a gas gun, you risk causing a fire or a powerful explosion, because assembling such a device requires the skills of a gas technician. The same applies to the diesel variant. Plus, you will have to worry about constantly adding fuel, monitoring its level and complying with safety regulations.

And the process of manufacturing a gun that heats a flow by burning gas will require, at a minimum, quite serious skills in assembling such units.

Mains-powered guns do not have open flame, no flammable fuel is used, and the risk of fire is minimal. If there is a possibility of problems, they will all be related to electrical part, so to know everything about electrical engineering - necessary condition for self-assembly.

Electric models are much easier to assemble, but this does not mean that you can do without specific skills and experience in assembling such structures. In addition to the fact that assembly requires the ability to handle many tools, you must have sufficient experience or work under the supervision of someone who has such skills.

If you do not have knowledge in the field of electrical engineering, then attempting to create such a device yourself is strictly prohibited!

Principle of operation

Any electric gun, even a homemade one, has the same operating principle: air is driven with the help of a powerful fan through a heating device - heating element, which warms up the air, which then goes out into the heated zone.

To have an idea of the operation of this unit, you should carefully study its elements.

There are only five of them in the design:

- Frame;

- Heating element for heating air;

- Powerful fan;

- Control device;

- Wire with plug.

The quality and speed of heating the room depends on the quantity and power of the heating elements. The more heating elements, the more powerful and faster the air mass passing through the apparatus will warm up.

For some models, the fan rotation speed changes, and therefore the amount of air blown through the device.

There is a misconception that the rate of heating of a room depends on the speed of air passage through the heating elements. For our device, the power and number of heating elements are important.

The air blowing speed determines only the level of uniform heating of the room - the higher it is, the more uniform the heating. The heating element is responsible only for the amount of air heating.

How to assemble a heat gun with your own hands

Assembly requires the assembler to have knowledge and skills to work with electrical equipment. If you are confident in your knowledge, you can start assembling.

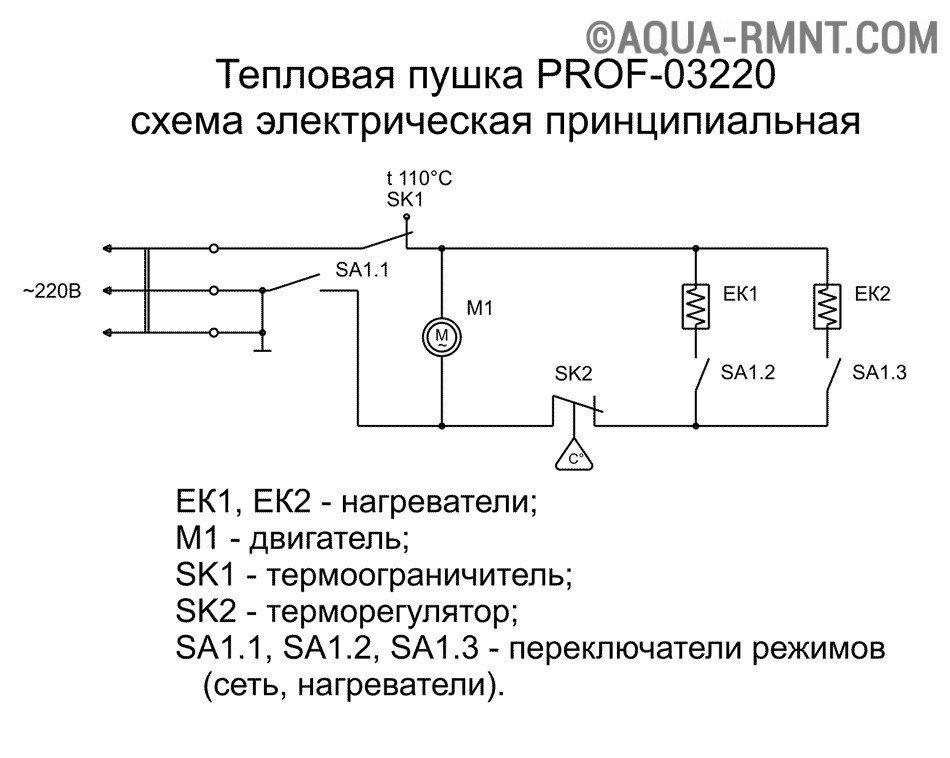

Before the mechanical part, we deal with the electrical circuit. It is needed to take into account all safety regulations and perform correct installation.

A durable one is suitable for the case round pipe or box It must be metal. Metal is the most heat-resistant and wear-resistant material that can withstand temperature changes and external loads. We choose a thick case with low thermal conductivity, since during operation the temperature of the device can be very high.

You can additionally cover the body with materials for thermal insulation. This will save you from burns if you suddenly touch the operating device.

Then we install the heating element. The quantity and power are determined by the master himself; it all depends on your requirements for the heating device. If you mount several heating elements together, this will help warm up the room faster and stronger, but will make the design of the device more complicated.

The temperature in the room depends on the power of the heater - the more powerful it is, the more heat will come out.

We fasten the heating elements in the center of the body and connect the power wiring to them. Make sure that the contacts and connections are insulated.

Everything connects to the switch, or make a control panel. We take the wiring from the heating elements and the fan and connect it, add switches and power wiring.

Before turning on for the first time, check all connections and circuits of the device for short circuits, all wires and contacts must be insulated, open contacts are prohibited.

If you have taken into account all the safety requirements, you can carry out the first start-up of the heat gun.

Assembling an electric heat gun with your own hands is very difficult. This requires experience with electrical equipment, knowledge and skills.

Without knowledge you will not collect heating device, but only triple the fire. We recommend just purchasing factory model rather than risk your own safety.

It seems that the heater collection on our own will help you save a lot of money. But homemade devices cannot be safe, especially if you make them for round-the-clock operation. The minimum that can happen is an electrical overload and a short circuit. Homemade apparatus quickly pumps oxygen out of the room. For your own safety, we advise you to buy a heater in a company store.

The need to quickly heat a large or small room does not arise very rarely. Sometimes you need to heat the garage and dry cement wall, warm up the cellar, barn, garden house, dacha, etc. In this case, a do-it-yourself heat gun may be the best solution. Making such a device is not so difficult, but you can choose suitable look fuel: electricity, diesel fuel, liquefied gas in cylinders, etc.

It is difficult to name a more convenient and simpler device for heating rooms than a heat gun. It is a powerful heating element and fan enclosed in one housing. Such a device heats the air and quickly distributes it throughout the room. To warm up small room It will take just a few minutes, and heating a large room will not take too much time.

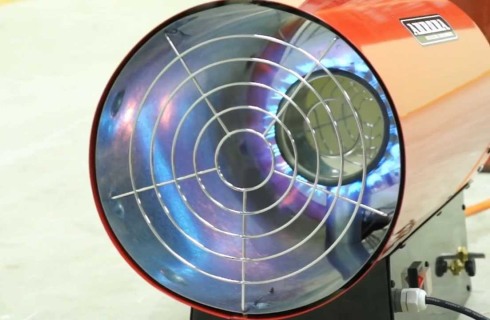

The body of the heat gun must be covered on both sides with grilles that will allow air to pass freely. This is a mandatory element of all industrial models

The design of a heat gun is very simple, so a properly manufactured device almost never breaks. Various fuels can be used to operate the device:

- electricity;

- liquefied gas;

- diesel fuel;

- kerosene;

- gasoline, etc.

The efficiency of a heat gun depends on the power of the device. For household use A device with a power of 2-10 kW is quite suitable. For large rooms you will need a heat gun with a power of 200-300 kW.

Unit #1 - electric heat gun

An electric heat gun is perhaps the simplest and safest heater option. If there is access to electricity on the site, you should make just such a unit. It will be useful both during construction work and later, for various household needs both in the house and on the site.

Materials and tools

To make an electric heat gun you will need:

- the frame on which the structure will rest;

- metal case;

- heating element (heating element);

- fan with electric motor;

- switch or control panel;

- cable for connecting the device to the mains.

The body of the heat gun can be made from a suitable piece of pipe or from a sheet of galvanized iron. To work, you will need a metal tool and, possibly, welding machine. This device received the name “cannon” due to the similarity of its cylindrical body to an ancient weapon. However, the heater body may also have a square or rectangular section, if it is easier to make.

Please note that the body of the product can become quite hot during operation. You should choose a heat-resistant or fairly thick metal for the housing. In addition, it makes sense to apply a thermal insulation coating to its metal parts.

When choosing a suitable heating element and fan, you should remember that the heating temperature depends on the power and number of heating elements. The fan rotation speed does not affect the amount of heat, but the higher it is, the more evenly the resulting heat will spread throughout the room. Thus, the heating element is responsible for the heating temperature, and the fan rotation speed is responsible for the quality.

To reduce costs, the heating element can be removed from an old iron or other household appliance. Sometimes it makes sense to shorten the heating element to increase the heating temperature. A suitable electric motor with an impeller can be found in older models of vacuum cleaners.

Build process

To assemble an electrical heat gun That's right, it is recommended to first draw up a diagram of the electrical circuit of the device. You can already use ready-made circuit, one of the options is presented below:

For correct installation electric heat gun before starting work, it is recommended to draw up electrical diagram, reflecting on it the connection of all elements to the electrical network

The electric heat gun should be assembled in the following order:

- Prepare the body and support.

- Install a heating element (or several heating elements) in the center of the body.

- Connect the power cable to the heating elements.

- Install the fan and connect power to it

- Connect the power wire, wiring from the heating elements and the fan to the control panel.

- Place a protective grille on the front and back of the housing.

During the assembly process, all electrical connections must be carefully insulated. After assembly is completed, a test run of the device is performed. If it works without failures, you can use the gun for its intended purpose.

Unit #2 - diesel fuel heat gun

Where access to electricity is limited or impossible, diesel fuel heaters are often used. It is somewhat more difficult to make such a heat gun yourself than an electric model. You will need to make two buildings and work with a welding machine.

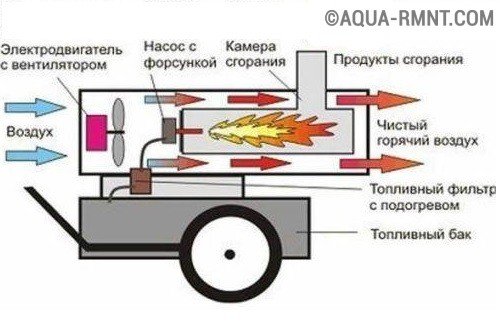

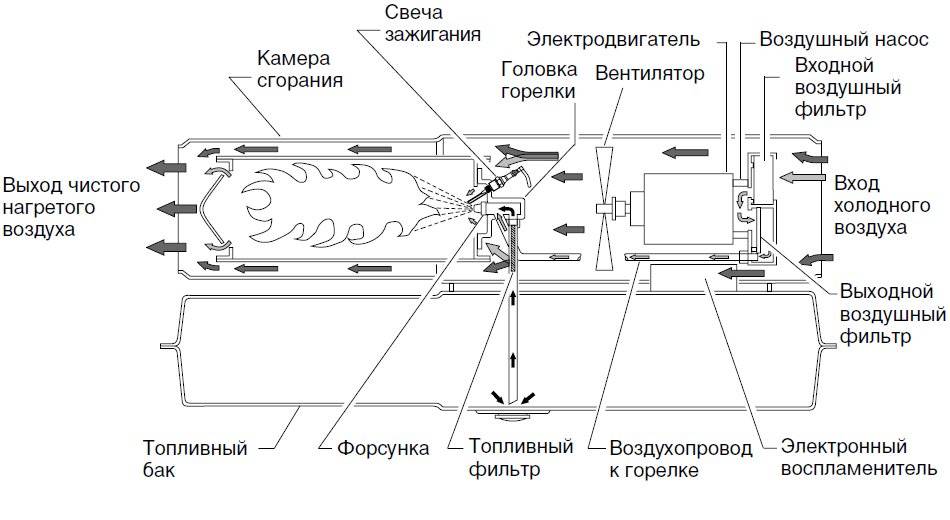

How does this design work?

The bottom part of a diesel heat gun is the fuel tank. The device itself is placed on top, in which the combustion chamber and fan are connected. Fuel is supplied to the combustion chamber, and a fan blows hot air into the room. To transport and ignite fuel, you will need a connecting pipe, fuel pump, filter and nozzle. An electric motor is attached to the fan.

The combustion chamber is mounted in the center of the upper body of the heat gun. It is a metal cylinder, the diameter of which should be approximately two times smaller than the diameter of the body. Diesel fuel combustion products are removed from the chamber through a vertical pipe. To warm up a room of about 600 square meters. m may require up to 10 liters of fuel.

Build process

The lower housing must be at least 15 cm from the upper part. To prevent the fuel tank from overheating, it should be made of a material with low thermal conductivity. You can also use a regular metal tank, which will have to be covered with a layer of heat-insulating material.

The diagram clearly shows the design of a heat gun running on diesel fuel. The device should be mounted on a strong, stable frame

The upper body must be made of thick metal, this can be a suitable piece of wide steel pipe. The following must be secured in the housing:

- combustion chamber with vertical outlet;

- fuel pump with nozzle;

- fan with electric motor.

Then a fuel pump is installed, and a metal pipe is removed from the tank, through which fuel is supplied first to the fuel filter and then to the injector in the combustion chamber. The ends of the upper body are covered with protective nets. The power supply for the fan will have to be taken care of separately. If you don't have access to electrical network, the battery should be used.

When using a diesel heat gun, it is important to adhere to safety regulations. Even at a distance of a meter from the body, the directed flow of hot air can reach 300 degrees. It is not recommended to use this device in enclosed spaces as diesel fuel combustion products may pose a health hazard.

In addition to the unit running on diesel fuel, other types of liquid combustible materials are used for heat guns, for example, waste machine oil. Interesting option such a device being tested is presented in the following video:

Unit #3 - gas heat gun

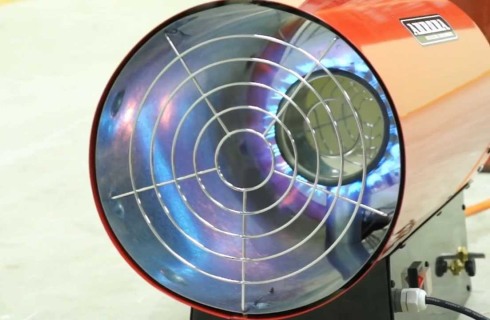

The design of a gas heat gun is in many ways similar to the design of a diesel unit. There is also a combustion chamber built into the housing. Instead of a tank with liquid fuel, a liquefied gas cylinder is used.

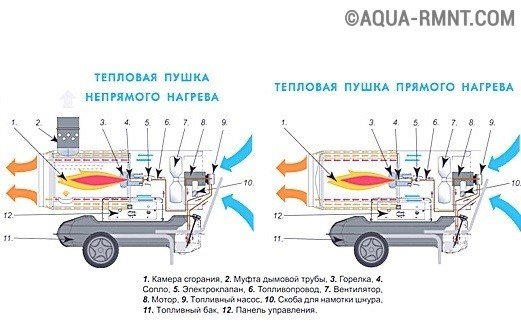

As with diesel fuel, great importance has a removal of combustion products, since in homemade devices it is impossible to ensure complete combustion of gas. The air that enters the room heats up upon contact with the combustion chamber. Exhaust gases leave the device through an outlet led to the street. This indirect heating system is safer than open flame heating.

Indirect heating heat guns are equipped with closed camera combustion, which prevents contact between open fire and air - this design is more complex, but safer than direct heating models

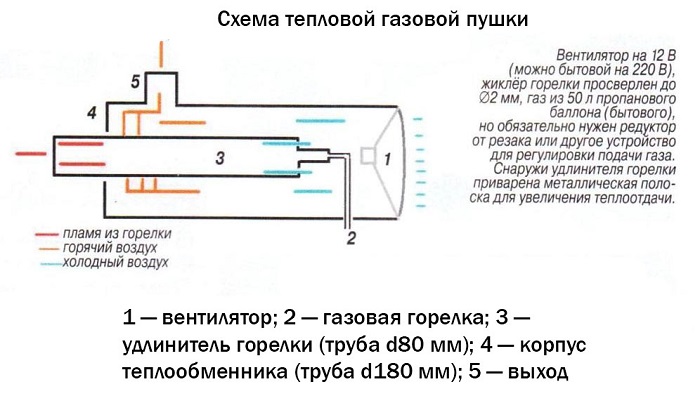

To increase heat transfer, longitudinal plates can be welded to the combustion chamber body; usually 4-8 of them are made. In this case, the dimensions of the combustion chamber with additional plates must be smaller than the diameter of the housing so that the chamber does not touch its walls and does not overheat the body of the heat gun.

The body of a gas heat gun becomes very hot during operation, so it must be covered with a layer of thermal insulation to avoid possible burns or fire.

To create a gas heat gun you will need the following elements:

- liquefied gas cylinder;

- burner;

- gearbox;

- metal case;

- fan;

- device for remote ignition;

- frame for mounting the housing.

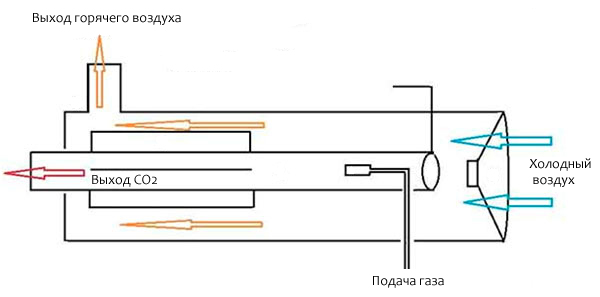

The gas cylinder is connected to a reducer, which ensures a uniform supply of fuel to the burner. The air around the combustion chamber heats up and the fan blows it into the room. The procedure is almost the same as in the manufacture of a diesel heat gun. The device is clear gas heater presented in the diagram.

Necessity fast heating premises most often occurs among owners of spacious production premises, warehouses and garages not connected to central heating.

Auxiliary Source heat may also be required during a period when the temperature in the premises no longer becomes comfortable for work, but the existing heating system not yet operational.

Heat gun powered by gas fuel, becomes excellent option space heating devices in the most economical way.

If it is possible to connect such a heat gun to the gas main, it becomes a stationary device. The use of bottled gas provides mobility to the gas heat gun.

Heat guns connected To gas cylinders , are often used by builders when it is necessary to carry out work at a certain temperature. To do this, the space requiring heating is covered with a thick film, and then, using a heat gun, the heat necessary for work is provided.

Using this heating method allows you to continue construction works even in frosty weather. Heat gun dries perfectly In the spring, damp rooms in the basements will prevent farm animals from freezing in cold weather.

There are heat guns that use alternative energy sources for operation, but gas is much cheaper than electricity and diesel fuel, also often used in heating devices.

Important: The design of the heat gun includes a fan, so its operation requires a connection to a constant source of electricity.

Regardless of the design of the gas gun, the same fuel is used for their operation - gas.

Regardless of the design of the gas gun, the same fuel is used for their operation - gas.

However, the method of heating the air flow for each of the two available types of heating devices has fundamental differences. For this reason, their requirements for operating conditions also differ.

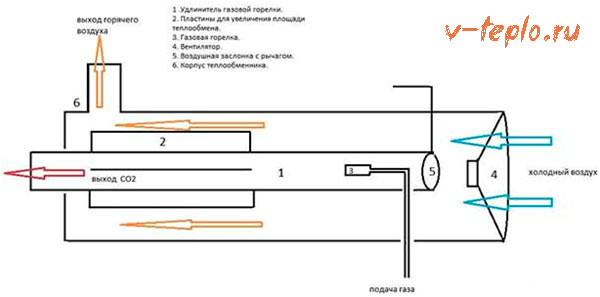

In a heat gun made with direct heating, the heated air contains fuel combustion products. The design does not provide for purification of the air flow from impurities. In fact, the contaminated air obtained after being forced by a fan directly onto the flame is distributed throughout the room.

Such design feature A direct heating gas gun requires good ventilation in the room. However, this does not prevent them from remaining popular. The reasons for the high demand for this design are obvious - rapid heating of the room with minimum consumption fuel allows you to get almost 100% efficiency heat gun.

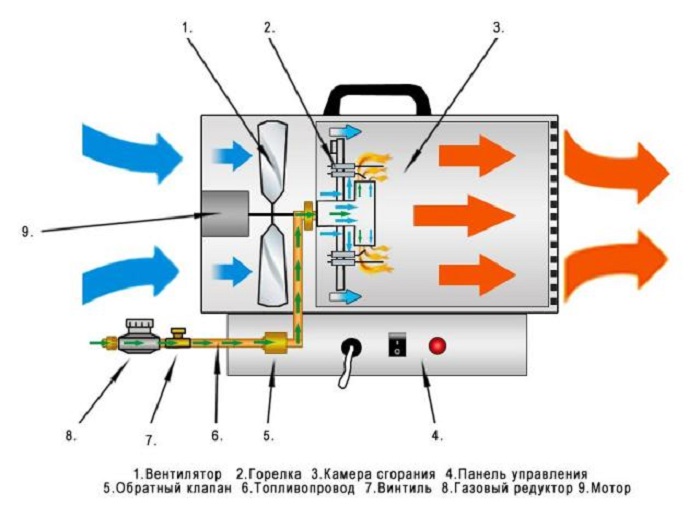

In indirectly heated gas guns The heating element is a ring heat exchanger. All combustion products remain in the heat exchanger and are then removed through the chimney. At the same time, the heat exchanger heats up, air flows with the help of a fan flow around its outer walls and also heat up. Air devoid of harmful impurities enters the room.

In the design of such heat guns it is necessary there is a chimney, through which combustion products are removed from the room. This feature makes it difficult to move the heating device, so these models of heat guns are usually used as stationary heaters.

Important: To ensure safe operation of gas heat guns, manufacturers supply them with protective devices, controlling the presence of flame and body temperature.

Making a gas heat gun with your own hands

Available for sale various models

gas guns, but many home craftsmen construct such devices on their own. There are no particular difficulties in the design of a gas gun.

Available for sale various models

gas guns, but many home craftsmen construct such devices on their own. There are no particular difficulties in the design of a gas gun.

To make such a heating device, you need to understand the principle of its operation, have skills in working with welding equipment and take care of the availability of the necessary materials,

Since most home craftsmen plan to use a homemade heat gun to heat garages, they choose the design of an indirect heating gas gun, connected to the chimney. This design allows you to be in a heated room during its operation.

To create a gas gun you will need following materials:

- a pipe 1 meter long, 180 mm in diameter, intended for the manufacture of the body;

- a pipe of the same length, but with a diameter of 80 mm for the combustion chamber;

- a pipe 0.3 meters long, 80 mm in diameter for the heated air outlet pipe;

- gas-burner, equipped with piezo ignition;

- any axial fan having a round flange.

Schematic diagram gas heat gun see below.

Assembling a homemade gas gun, equipped with a combustion chamber, is carried out in the following order:

- On opposite sides of the pipe larger diameter drill two holes. One of them, intended for welding the heated air outlet pipe, must have a diameter of 80 mm. The second hole is drilled with a diameter of 10 mm. It will include gas hose, connected to the burner.

- The combustion chamber is made from a pipe of smaller diameter. To firmly attach it to the pipe, it is necessary to weld plates that hold the structure in the center of the body.

- Then you need to prepare a plug cut from metal sheet so that it closes the gap between the combustion chamber and the housing. In this case, access to the chamber must be provided to connect it to the chimney.

- The next step will be to assemble the structure. The fins of the combustion chamber must be welded inside the housing, and a pipe must be welded from the outside of its part, through which heated air and a plug will flow into the room. Then the gas burner is installed and firmly fixed, and the fan is mounted.

Assembling a gas gun with direct heating It is much simpler to perform, since it consists of a pipe, at one end of which only a burner and a fan are attached. Hot air along with combustion products exits from the opposite side of the pipe.

Main malfunctions of gas heat guns

Most gas gun malfunctions can be fixed independently, without going to a workshop. Most often they fail:

- fan;

- piezoelectric element;

- burner;

- security elements.

Typically, owners of these devices are faced with following problems:

- Can't light gas. This is how the piezoelectric element malfunctions. It should be cleaned, and if this procedure does not help, then replace the part with a new one.

- Gas does not enter the combustion chamber. The cause of this malfunction is a clogged burner. The problem is solved by blowing the burner with a powerful air jet.

- There was a smell of gas. This problem is usually caused by gas leaking from the hoses. Either tightening the fasteners or replacing the hoses is required. The most in a simple way To identify gas leaks, use a soap solution.

- Gas consumption has increased– the gearbox needs to be replaced.

- When the burner is burning, no air flows into the room. warm air – you should check the serviceability of the fan. If there is power supply and serviceability contact group it needs to be replaced.

Purchase of a gas heat gun equipped with all necessary elements safety, will cost the buyer in a substantial amount. Such an acquisition is justified when there is a constant need to heat large areas.

Therefore, many people make heat guns that run on gas fuel on their own. In this case should be remembered that such devices should not be left to operate unattended under any circumstances.

Find out how to make an indirect heating gas heat gun with your own hands from the video below:

A do-it-yourself heat gun is made when it is necessary to heat a room that does not have central heating, but there is no opportunity to purchase an industrial heating device. In addition, a homemade heat gun will be an excellent way out of a situation when the owner needs to maintain non-residential premises, for example, a workshop or hangar, a certain temperature in order to ensure the operability of production.

The principle of operation of a heat gun is that using heating element The fuel element is heated.

How to choose a heat gun? Depending on the method of heating the fuel element and air, there are the following types heating devices:

- gas;

- diesel;

- electrical;

- multi-fuel;

- aquatic.

Each type has its pros and cons. For example, a gas heat gun is good because the energy carrier in it burns completely. This allows you to save cash for heating. It is also good because it can be easily moved to another place of work.

The disadvantages include the need to create a stationary gas installation if space heating is required large area. A gas heat gun, in addition, has a high degree of fire hazard, since it works with an open fire, so it cannot be used in buildings where flammable substances are stored and fire-hazardous industries are located.

Another type of mobile heater is a water heat gun, which is good because it can long time heat the room when turned off. In addition, it is fireproof. However, it also has a drawback - it is quite difficult to maintain, as it requires water as a coolant.

In order to finally decide on the choice of a heat gun, you need to know what the heating scheme is in the required room. The owner of the premises can order such a diagram from specialists or draw it up himself, if available necessary knowledge. Therefore, if it is difficult to decide on the choice of a heat gun, it makes sense to turn to professionals.

In the process of choosing it, you should pay attention to the following points:

- price;

- power;

- ease of maintenance;

Usually, in terms of all these parameters, an electric gun is the most profitable. Such a device can operate from a regular household electrical network, so it can be used in everyday life, for example, to heat a garage.

Making your own heater

Despite what the industry may suggest a large assortment mobile heaters different models, an electric homemade heat gun is still popular among homeowners. The fact is that this device, assembled independently, will cost its owner several orders of magnitude cheaper than a similar device purchased in a store.

Repairing a heat gun assembled independently will cost mere pennies to its owner, since there will be no need to visit official service centers, working at fairly high prices.

A do-it-yourself heat gun is created from scrap materials, which allows you to have a wide range of spare parts in case of repair. It is not difficult to make a heater design that takes into account all the features of the room.

If the owner decides to create a heater with my own hands, then the electric gun will become for him optimal choice. The fact is that you can find out how to make a cannon with your own hands in almost any electrician’s reference book, and for the work you will need to have some available materials.

Heat gun diagram

In this case, you will definitely need drawings of the device and its diagram. Their use guarantees the build quality and compliance of the device with the rules fire safety. Typically, the design of this heater includes:

- frame;

- heating element;

- powerful fan;

- control device;

- wire with plug.

To make the housing during installation you will need metal pipe or box It is advisable to choose a thick body with low level thermal conductivity, which will protect the device from mechanical influences.

Ten is usually taken standard, sold in the store. Moreover, its power is calculated depending on the area of the heated room and the load on the electrical network. Electric gun if necessary, it can be equipped with several heating elements.

When mounting a fan into the housing, you need to remember that it will be more convenient to install a device on the gun that regulates the rotation speed of its blades, and it makes sense to place the control system for the fan and the entire heating device in a separate box.

In order to get additional savings, you can coat the body of the electric gun with heat-insulating paint. You can apply it to other elements of the device. This saves energy when heating the room.

What should you pay attention to during manufacturing?

When independently assembling a heating device such as a heat gun, it is worth remembering a few points. The average power of such devices ranges from 1.5 kW to 45 kW. If you need more power, then it is recommended to design a diesel heat gun with your own hands.

During manufacturing, all connections should be carefully checked to ensure they are insulated. It's not worth studying self-assembly electric heater in the case where there is not even basic knowledge of electrical engineering.

A self-made heat gun must be registered with the fire authorities. This will save the owner from a fairly large fine for failure to comply with fire safety rules.