Correct installation of plastic windows with your own hands. Technology for self-installation of PVC windows

Buying and installing new windows is not a cheap pleasure, and Substantial part costs are for installation. You can reduce costs by doing this part of the work yourself. We will tell you how to install a plastic window yourself, giving step by step instructions with photo.

Measurements required for the manufacture of a plastic window

The ease with which you will succeed or fail will subsequently depend on how correctly you take the measurements. After all, having made window unit bigger size, you will be forced to increase the opening, and if you make a smaller mistake with the dimensions, you will be forced to increase it.

It is necessary to determine the dimensions of the future frame based on the type of windows, which are:

- with a quarter, i.e. with a half-brick protrusion, which is located outside the opening and against which the window frame rests. Such windows are present in almost all typical buildings;

- ordinary, i.e. without protrusions. This design is used in buildings constructed according to individual projects.

Measurements of a regular window

Using a tape measure, measure the length and width of the window opening, add 5 cm to these indicators (per polyurethane foam) and record the received data. In addition to dimensions window box, you need to measure the depth of the slopes, as well as the depth and length of the window sill. The last parameter is calculated based on the distance between the boundaries of the vertical slopes, to which 8-10 cm are added.

Quarter window measurements

In this case, you will have to measure the distances between the horizontal and vertical edges of the protrusion and add 5 cm per polyurethane foam to the resulting figures.

The video will tell you more about the nuances of measurements:

When ordering a metal-plastic window, do not forget to discuss with the manufacturer the number of double-glazed windows and the profile size, as well as the list and quantity of fittings and fasteners. If the climate of your area is not severe, and the windows do not face the roadway, feel free to order two double-glazed windows and a profile 6 cm wide. The lower the temperature outside the window and the more noise on the street, the greater the number of double-glazed windows and the size of the profile.

The procedure for dismantling the old frame

To install a plastic window yourself, you need to get rid of its wooden predecessor. Dismantling should be done carefully so as not to dismantle half of the wall, which will then have to be restored, wasting time, money and effort. At the same time, remember about safety precautions, because working with glass is very dangerous, and the slightest mistake can land you in a hospital bed.

First, remove the opening parts of the windows from their hinges. Remove the glass by first removing the glazing beads. Using a grinder or hacksaw, make cuts in the frame and other parts of the window unit.

Using a pry bar, remove the elements of the old structure from the opening, which you then thoroughly clean construction waste and dust.

Now it's time to find out how to install a plastic window yourself.

Installing a plastic window with your own hands: instructions

To install a plastic window yourself, prepare the tools and materials you will need during installation:

- self-tapping screws (4x35 mm, 4x25 mm);

- screws (5x60 mm, 3.8x25 mm, 3.9x25 mm);

- anchor plates;

- polyurethane foam;

- waterproofing and vapor barrier tapes;

- mounting wedges;

- low tides;

- windowsill;

- plumb line;

- level;

- PSUL;

- perforator;

- screwdriver;

- screwdrivers;

- a hacksaw with a fine tooth for cutting the window sill;

- tin snips to trim the flashing.

Before installation, remove the sashes from the window block.

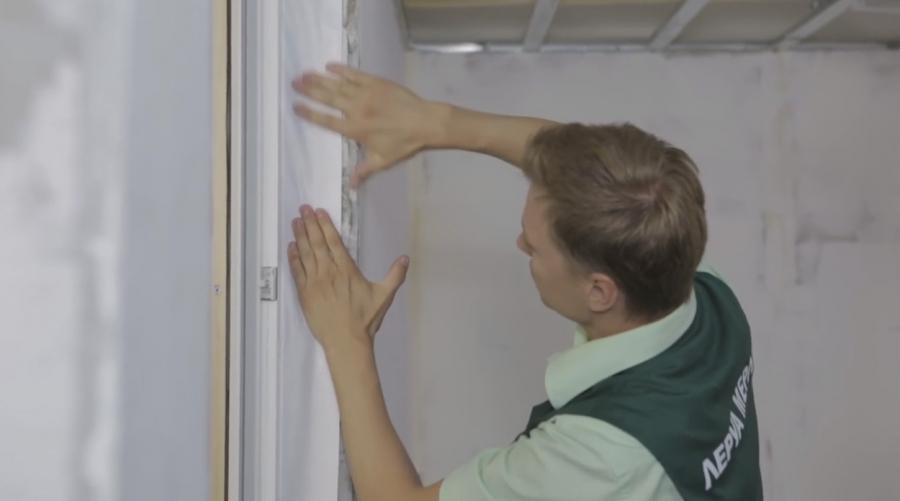

Install the mounting plates. The procedure is as follows: place the plate along the end of the window block, then turn it with the other end towards the room, fix it with a self-tapping screw (4x35 mm).

Please note: the distance between the plates should not exceed 600 mm.

Before you begin installing the structure in the opening, you need to apply marks for fasteners and PSUL. Align the position of the structure in the opening (this is why a plumb line and level are needed), taking into account the following: the maximum deviation from the horizontal or vertical should not be within 1.5 mm per 1 m of the structure, but not exceed 3 mm over the entire length or width of the product. Secure the frame using mounting wedges.

Bend the plates and mark with a pencil the places on the slope where they will be attached.

If your window is a quarter window, then outside frame, mark the outline of the adjacent opening.

Remove the frame and drill holes in the places you marked, where the anchor wedges will then be inserted.

Drive dowels into the resulting holes.

Use a brush and vacuum cleaner to get rid of dust. Apply sealing tape to the frame. In case you are dealing with a quarter window, the tape is applied to outer part frames at a distance of 3-5 mm from the previously outlined opening contour.

In windows without a quarter, the outer seam is insulated using special moisture-proofing sealants after the structure has been installed.

Secure the window block in the opening using mounting wedges and remembering to check the correct position.

Fix one top side plate at a time and measure the diagonals of the window block. Their difference should be within the following limits:

Screw on the remaining plates and remove the wedges, leaving only the bottom and diagonal ones, then proceed to foaming.

Trim off the excess foam and stick a vapor barrier tape on the side of the room, overlapping the wall by 10-20 mm.

Attach waterproofing tape to the outside.

Set the tide. Insert it into the groove and screw it using self-tapping screws (4x25 mm).

Hang the shutters and then install the window sill. Adjust the handles if necessary.

You see, install a plastic window yourself not that difficult. The main thing is to have the desire and follow our advice.

Take it for yourself and tell your friends!

Read also on our website:

show more

Reading time: 7 minutes.

More recently, in the glazing of residential buildings and industrial buildings, exclusively wooden window frames were used. Today, many consider them relics of the past and are in a hurry to replace them with modern metal-plastic structures. After all, in addition to high performance characteristics, they are much cheaper wooden frames. For installation plastic windows you don’t need to have superpowers with your own hands. Almost any person who can hold a tool in their hands can cope with such a task.

However, do not forget that each job requires certain skills and craftsmanship. Lack of experience in installing windows can lead to a number of troubles. These are systematic breakdowns, loose fit and high throughput street air into the apartment.

To avoid the above points, in this article we will provide step by step instructions, which will help you install your windows correctly and efficiently. If you still decide to trust professionals, know that some of them are not really professionals, and for a number of reasons they openly neglect certain stages of proper installation (some save time, others save money). Having an idea of the work being carried out, you can easily exercise independent control over the entire process. And subsequently you will enjoy the high-quality operation of your windows, which will bring joy to all family members.

The main stages of installing new windows:

- taking measurements;

- dismantling old windows;

- preparing openings;

- installation of a metal-plastic structure.

Not everyone knows that the manufacturer gives absolutely no guarantee for its services when installing windows. on our own. Therefore, if various troubles arise during the installation process, you should not hope for a return or replacement. All metal-plastic structures are manufactured strictly according to pre-agreed dimensions. If you make a mistake, the window may not fit in the opening or may end up being much smaller. And it will only be your fault. The company's employees are solely responsible for the implementation of each stage of product installation.

Also, any inaccuracy made when installing a metal-plastic window will deprive you and your loved ones of all advantages modern design and expected level of comfort.

Window measurements

Carrying out necessary measurements, you need to pay attention to the fact that window openings exist with and without a quarter. Accordingly, their formulas for calculating sizes are different.

For the first case, we must measure the width of the opening between the existing quarters, this is done at the narrowest point. And then add 3-4 cm to the resulting figures - this will be the width of our plastic frame. In addition, it is important to check: the largest distance between the vertical quarters should not exceed the design width of the block.

Read also: "Kärcher" for washing windows: features of use and advantages

The height is determined by measuring between the top quarter and bottom surface of the window opening.

If the window opening is without a quarter, the required values can be obtained by subtracting 5 cm from the vertical dimension (to place a window sill) and 3 cm from the horizontal dimension.

When determining the size of the window sill and ebb, it is worth considering the following details:

- Often the size of a window sill is chosen based on its functionality. It should cover the heating radiators and house flowers should be placed on it;

- The length of the window sill is taken to be 8-10 cm longer than the window opening, its edges should be recessed into the cavity of the slope by approximately 4-5 cm;

- The dimensions of the ebb are calculated taking into account the planned insulation. It is recommended to leave it protruding 5-10 cm from the wall.

Features of measuring balcony windows

When calculating the width balcony windows The length of the parapet is taken as the basis; the entire structure will rest on it. Also, on both sides it is necessary to subtract 6-7 cm, which will be needed for installing the corner profile; it is used to connect the window blocks of the front and side parts. The distance from the roof to the railing, with the exception of the difference of 2.5-3 cm, which is important to set aside for gaps for fastening, will be the height.

Regarding the side balcony frames, their dimensions are determined in the same way. The only thing is that you need to subtract 6-7 cm from the width to install the corner profile, as well as 2.5-3 cm for the gap from the wall to the window.

Features of window measurements in private houses and old buildings

When taking measurements of windows in private houses and old buildings, it is recommended to first knock off part of the slopes on both sides (in the measurement areas). This is done in order to see what the space occupied by the window opening is like. It often happens that there are dilapidated cement mortar And various insulation materials, which can crumble during disassembly of an existing window. The positive thing here is that the new plastic construction it will be possible to increase it somewhat by expanding the cleaned window opening.

Ordering a metal-plastic window

Before contacting a company with an order, you should think about what type of double-glazed window is right for you. It can be one-, two- or three-chamber. As for fittings and fasteners, you can also choose them yourself.

WITH technical characteristics The manufacturer's consultants will help you figure out which plastic windows will be preferable for your home at the time of ordering.

Some important points during installation

When installing windows yourself, you should pay attention to the following:

- the metal-plastic structure must be well secured;

- The mounting foam used to fix the windows must be plastered on both sides (this will prevent it from sagging and deforming the frame in the future);

- It is very important to align the structure vertically and horizontally using a level (this will help avoid warping).

How to install metal-plastic windows with your own hands

Before starting installation, prepare everything you need for work:

- Window frame with fasteners;

- Building level;

- Polyurethane foam;

- Mount;

- Bulgarian;

- Windowsill.

The process of preparing a window block

Window preparation is important stage installation work that you do with your own hands. If necessary, the double-glazed windows and hinged sashes themselves are dismantled from the window structure. To release the double-glazed window, a chisel is used; very carefully, you need to use it to pick out the glazing bead (fastening) and after a light blow on the tool it will come out of the grooves. Then the vertical fasteners are removed, top and bottom. The released glazing beads will need to be marked; sometimes their sizes can differ significantly, which will lead to the formation of gaps of several millimeters. The glass unit will come out of the grooves on its own if you tilt the frame a little. Gently lean it against the wall, creating a slight angle.

Installing plastic windows is not a very labor-intensive job. Therefore, each person can independently begin installing plastic windows. But anyone who decides to install windows themselves is faced with the problem of choosing fasteners. After all, there are many types of fasteners on the product market. And every novice builder wonders.

What fasteners are best to choose for window installation? To answer this question unambiguously, let's look at this issue thoroughly. And we will consider the types of fasteners for plastic windows, as well as installation rules and characteristics.

Types of fastening elements for windows

- Anchor dowel

- Anchor plates

- Nog

Now let's pay attention to their features.

Anchor dowel

This type of fastening for plastic windows is very reliable. The principle of operation is designed in such a way that when the screw is tightened, the bushing expands the walls of the sleeve and the element is securely fastened.

Size. Dowel sizes exist great amount from 100 to 200 mm, and their thickness is from 7-12 mm. To calculate your dowel length, you need to measure the thickness of the window and opening from the frame and slope.

Typically, the thickness of the frame varies about 4-6 cm, and the dowel should enter the wall at a distance of 4 cm. If your distance from the wall to the window is about 3-4 cm, then you need a 110 mm dowel, if 8-10, then 160- 190 mm.

Flaws. The disadvantage of any type of fastening is that once the dowel is installed, it can no longer be dismantled. Therefore, you need to take window alignment very seriously, because... correcting your mistakes will cost you a lot and take a large number of time.

Also, if you hit the reinforcement with a drill, you can break the drill and have to drill a new hole.

Important. Before installing a plastic window in an apartment panel building, you need to find out its type and wall structure. Because in many panel houses Builders install insulation inside the walls. Therefore, during installation you may get caught in the insulation and the dowel may fall out. Also, do not install the dowel in soft building materials.

The depth of drilling inward for the dowel depends on the material from which the wall is made. IN concrete wall the depth is 4 cm, and in brick wall 7-8 cm.

Nog

A dowel is a simple screw that is screwed into the wall to secure a window. This type of fastener is also very reliable. Unlike a dowel, the dowel can be easily unscrewed in any case.

Dimensions. There are a huge number of dowel sizes from 100 to 250 mm, and thickness from 5-12 mm. To calculate the length of the dowel, you need to measure the width of the window and opening from the frame and slope. If your distance from the wall to the window is about 3-4 cm, then you need a 110 mm dowel, if 8-10, then 170-200 mm.

Flaws. Before installing a plastic window in an apartment panel building, you need to find out its type and wall structure. Because in many panel houses, builders install insulation inside the walls. Therefore, during installation you may get caught in the insulation and the dowel may fall out.

You should also not install the dowel in soft building materials.

Important. The depth of drilling inwards under the dowel depends on the material from which the wall is made. In a concrete wall the depth is 6 cm, and in a brick wall 7-8 cm.

Anchor plates

This type of window fastening is suitable for panel houses in which there is insulation and the use of anchors and dowels is impossible. It is also perfect for wooden houses and baths, where it is not possible to fix windows in the wall. By filling the free space with polyurethane foam, this design will be very reliable and warm.

Dimensions. The length of this fastening element varies from 150-200 cm. One edge of the plate is secured with a self-tapping screw to the frame from the outside, and the other is secured to any load-bearing structure for two self-tapping screws. The length of the second part should be around 10 cm.

Flaws. This type of fastening is not the most reliable.

Important. This method of fastening is the most common, because... it is the simplest. It is mainly used by beginning builders. The anchor plates should be located at a distance of 15-20 cm from the corners of the window opening and at a distance of 60 cm from each other.

I cannot say which type of fastening of plastic windows is the best. Each type has its own disadvantages and advantages. You must choose the type of fastening yourself, depending on the technical features your house.

Photos of fasteners for plastic windows

PVC windows have long proven themselves with the best side. They are multifunctional, reliable and durable. However, these indicators directly depend on how well the installation was carried out window system. There are only two methods: installing windows on plates and the unpacking method. With the first method, you do not need to remove the glazing bead and remove the glass unit from the frame. The window structure is secured using anchor plates, which allows you to install the window without any special skills.

Window installation methods

Both methods have their own nuances, positive and negative qualities.

Unpacking or fastening through the frame using self-tapping screws

This fastening method is characterized by the fact that before installation, the frame must be completely disassembled: the blind and opening doors are removed, and only then installation is carried out through the profile with self-tapping screws.

The unpacking method is mainly used when installing large windows

After installing the profile, the system will have to be assembled and adjusted again. This option is used for large windows with an area of 4 square meters for reliable fastening of such a large structure.

Straightening plates are installed between the glass unit and the profile

Straightening plates are installed between the glass unit and the profile Here it would be appropriate to mention the straightening plates, which are installed to avoid contact between the edge of the glass unit and the window profile. Their presence will ensure uniform distribution of the weight of the glass unit and ventilation of the rebated space. The plates are made of plastic, the width of the element corresponds to the width of the glass unit.

Installation using plates

When installing PVC windows on plates, there is no need to remove the glass unit

When installing PVC windows on plates, there is no need to remove the glass unit Installation of windows on plates begins with the acquisition of these same plates. There are models universal purpose and manufactured for use with a specific profile system. They are usually supplied with structures of complex shapes. Their peculiarity is that they have special “ears” and can be inserted into existing grooves on the surface of the frame.

Anchor plates with lugs are used with complex window structures

Anchor plates with lugs are used with complex window structures Plates without ears are fastened with bolts, and with ears - with self-tapping screws. Requirements for bolts: 4.5*25 and the presence of a metal drill.

Installation rules

A standard window requires at least five plates. One plate is fixed in the central part of the frame, and two on both sides: one on top and one on bottom. In this case, you should retreat 20 cm from the border of the frame.

To install a standard shaped window, 5 plates are enough

To install a standard shaped window, 5 plates are enough Installing windows without unpacking involves fastening the frame with anchor plates with outside window opening. In this case, there is no need to remove the glazing bead and glass unit. When unpacking, fasteners are provided through the frame with preliminary disassembly of the window system into constituent elements: sashes, double glazed windows.

Fastening with plates is appropriate for use on windows of medium and small size, more often these are standard windows of residential buildings and apartments. Large window systems (more than 4 square meters) are attached to anchor dowels through the frame, since the weight of such a structure is significant and the plates will not support it.

Large window systems are installed using anchor dowels

Large window systems are installed using anchor dowels Using anchor dowels they also secure door frames. In professional circles among installers metal-plastic structures This installation method is considered the most reliable, but it has some disadvantages:

- This type of installation is difficult even for professionals. There is a high risk of damage to the glass unit when removed from the frame;

- This type of fixation by one person is often not possible;

- This is a labor-intensive method that takes considerable time and requires appropriate skills.

When installing windows on dowels, there is a high risk of glass damage

When installing windows on dowels, there is a high risk of glass damage If you want to install the window yourself using this method, you will need to buy 10*132 mm dowels. Among the tools, you will need a powerful hammer drill - this device is professional and expensive equipment that is rarely used on the farm, so it is not advisable to purchase it for the installation of one or two windows. You can look for a company that rents out construction equipment; usually hammer drills are the most popular product.

By installing the window on plates, all these problems will not have to be solved. You just need to buy the plates themselves.

Difficulties associated with bolt-on installation

A few more reasons why you shouldn’t bother with bolt-on mounting when installing it yourself, but prefer plates. In order to attach the anchor bolt, it will be necessary to drill a hole in the PVC window frame. As a result, depressurization of the glass unit chamber is possible.

As a result of the fact that during drilling, the reinforcement of the system may be disrupted, problems are observed in the future when the window system freezes. As a result, excessive moisture formation occurs inside the room and mold appears on the surface of the slopes.

When fixing a PVC window with bolts, depressurization of the double-glazed window may occur.

When fixing a PVC window with bolts, depressurization of the double-glazed window may occur. If you lack experience and do not know the properties of the material from which the structure is made, it may happen that it will stretch if installed incorrectly. Correct geometry window frame will be almost impossible.

Positive qualities of mounting plastic windows on anchor bolts everything is just like that:

- reliability of fastening of the structure - in order to dismantle it, it will be necessary to carry out the reverse order of work that was done during installation;

- After fixing the window system there is no need to additional work how it happens with fixation with polyurethane foam: time for hardening, leveling, cutting, finishing;

- the structure can begin to be fully exploited immediately after it is installed;

- This connection method is reliable and durable, and fastening materials in the form of bolts are widely available and have an affordable price.

Features of fastening to anchor plates

This method of attaching a window system is as simple as possible and accessible to everyone.

Compared to the unpacking method, the method is considered absolutely safe for the window system, but the only disadvantage is that some fastening elements (plates) will remain visible after installation. However, they can also be cleverly camouflaged by hiding them under slopes during their finishing.

Inserting a plastic window using plates is easier and safer than fixing it with bolts

Inserting a plastic window using plates is easier and safer than fixing it with bolts There is another recommendation from experts: if the window has an opening sash that will be used very often, then the window may fail. This type of fastening is recommended for moderate opening or for fixed windows.

An alternative method of fastening is considered: top part The structure is mounted on plates, and the bottom one is fixed with anchor bolts.

Rules for attaching windows to plates

Self-tapping screws should be used as a fixing element. Glue or foam are not suitable. Application impact mechanism to create holes is only possible for concrete surfaces.

To avoid damaging the window frame with the drill, it must be of sufficient length. Additionally, you can protect the surface of the frame by installing a piece of PVC near the hole to be drilled.

Self-tapping screws are used as fastening elements

Self-tapping screws are used as fastening elements When installing a window in brick opening having vertical voids, holes for fasteners are formed in the interblock seams. To control the immersion of the self-tapping screw into the body of the frame, it is necessary to use a screwdriver with an appropriate function that limits the torque.

The process of attaching a window to plates

The first step is to fasten the anchor plates in increments of no more than 1 meter. In order for the frame to maintain a stable position, the fastening elements relative to the corners of the frame should be located at a distance of no more than 25 cm.

The distance from the plates to the corners must be at least 25 cm

The distance from the plates to the corners must be at least 25 cm It is important to remember that the distance from the border of the window structure to the opening must be at least 2 cm. If this condition is not met, it is necessary to make recesses in the surface of the opening to accommodate fasteners. To do this, the plates are installed on the frame, then it is installed in the opening.

On the surface of the wall, use a pencil or chalk to mark the future location of the fasteners. Then the frame is removed and in place of the marks, using a chisel, a recess is made into which the plate should fit and be tightly fixed. This will allow you to subsequently effectively mask the plates when finishing the slopes.

On next stage a window structure is placed in the opening and its position is leveled using wooden blocks prepared in advance. Their thickness should not exceed 3 cm and their installation occurs only horizontally, while vertical alignment occurs, which is controlled using a level.

Vertical alignment is done by level

Vertical alignment is done by level When the position of the frame is leveled, you can begin to secure the plates using 6*40 dowels at concrete base or self-tapping screws in other cases.

Gaps are sealed using polyurethane foam

Gaps are sealed using polyurethane foam To avoid frame distortion, the plates are secured in order. First, fix the lower left corner, then the right, monitoring using a level. The top plates are secured last. At the final stage, the seams are sealed using polyurethane foam.

Technology for installing plastic windows in brick house differs from the rules for installing PVC profile products in concrete or panel walls. It is important to understand these differences and avoid mistakes before starting installation work.

Installation of plastic windows requires a set of tools and consumables.

Plastic windows in a brick house can be installed on anchor plates or bolts. Their size depends on the depth of the quarters into which the product will be attached, as well as the quality of the brick from which the walls are laid. It can be gas silicate, foam concrete, etc.

//www.youtube.com/watch?v=PkRy0THGINA

If the installation is carried out in a secondary housing stock, before installing the window, you must first remove it from the opening old frame. To do this you will need:

- removing the sashes from their hinges;

- deleting the old one;

- dismantling the window sill and ebb;

- removal of roofing felt and tow, once used to insulate the opening;

- chipping old plaster if it is necessary to align the geometry of the opening.

To dismantle you will need a small crowbar. If the frames are quite massive, then to facilitate the breaking process you can use hand saw on wood or with a jigsaw.

To drill holes for fasteners, you will need a hammer drill, and to attach the frame to anchors, you will need a screwdriver. Will still be needed construction knife with replaceable blades, level, good quality construction guns for foam and sealant.

What materials are needed to install a plastic window?

Installing plastic windows is a multi-stage process. At each stage it is necessary to use various consumables:

- mounting wedges;

- professional foam;

- PSUL or acrylic sealant;

- water vapor barrier tapes;

- anchor plates or bolts.

- cyacrine;

- sealant.

Mounting wedges are needed to level the level; if necessary, they are placed under the stand profile.

Polyurethane foam — insulating material for filling the assembly seam, i.e.

space between the wall and window frame. Professional pistol foam must meet temperature conditions season in which it is planned to install a plastic window.

PSUL (pre-compressed self-expanding sealing tape) is glued along the perimeter of the window frame and expands on the street side of the seam - from the edge of the frame in a quarter. By appearance resembles gray foam rubber. If there are no quarters, you will need a special acrylic sealant.

Waterproofing tape made of membrane material placed under the ebb for ventilation and protection of the bottom seam from moisture.

Sealant is necessary to fill the seams where the window sill joins the slopes and the window frame.

How to attach a window to an opening?

The rules for installing plastic windows are explained in detail by GOST R 52749-2007 “Window installation seams with vapor-permeable self-expanding tapes. Specifications" This state standard prescribes that before you begin installing a window in an opening, stick PSUL around its perimeter.

This self-expanding material is independent mounting layer, which cannot be covered with plaster, putty or painted over. Otherwise, the insulating material will not perform its functions.

When inserting a frame into a window opening, you should adhere to the tolerances. Deviation of the window frame in horizontal and vertical plane should be no more than 1.5 mm per 1 m of length, but no more than 3 mm over the entire height of the window.

//www.youtube.com/watch?v=J4zdj8hP5As

The frame is attached to the brick wall along following rules:

- from internal corner the vertical distance between the frame and the first fastening element should not exceed 150-180 mm;

- from the impost to the horizontal fasteners, this distance is recommended to be 120-180 mm;

- vertical placement of anchors - with a gap of 700 mm for windows made of white plastic and 600 mm for laminated profiles.

The inserted block must be checked for deviation from the level and foamed around the perimeter.

Assembly seam construction

PSUL around the perimeter and foam insulation are only 2 parts of the three-layer filling of the installation seam described by GOST.

After foaming the frame, it is necessary to remove the installation mounting wedges from under the stand profile and fill the resulting voids with foam. For better adhesion, the inner surface of the window opening can be moistened with a spray before foaming.

Before installing the drip sill, a waterproofing, vapor-permeable tape should be applied to the outside. The ebb is screwed to the stand profile with self-tapping screws. The edges of the ebb should be folded onto the outer slopes to avoid moisture getting under it.

WITH inside a vapor barrier is glued around the perimeter of the window (except for the lower horizontal part of the frame), which provides an additional sealing layer assembly seam and insulates it from moisture. This tape is available in various widths and can be applied both under wet finishing of slopes (plaster) and dry finishing (slopes made of polystyrene foam or plastic). They also produce universal tapes for slopes.

A vapor barrier is also installed under the window sill board: full-butyl tape with a foil layer.

Assembling the installed window

The frame installed in the opening and foamed around the perimeter must be assembled.

The frame installed in the opening and foamed around the perimeter must be assembled.

Double-glazed windows are inserted into blind, non-opening parts. To glaze (fasten) installed double glazed window, you will need a medium sized Plexiglas hammer. The beads are cut at an angle of 45° and inserted into the frame around the perimeter of the glass unit with some force. In order for the glazing bead to finally snap into place, it must be lightly knocked down with a hammer.

If the window unit being installed has opening sashes, it is necessary to hang them on their hinges. This task is not difficult to cope with, since modern window fittings are very easy to use.

But putting the sash in place is not enough. You should check its functionality and, if necessary, adjust it in the hinge part using a special adjusting key.

To check how accurately a plastic window is level, you need to open the sash. If it does not slam shut or open wider by inertia, it means the block is installed correctly.

Installing the window sill and slopes

The installation of wooden windows, like plastic ones, cannot be considered complete if the window sill is not installed. The window sill board snaps into place and is attached to the stand profile.

If, during dismantling, voids are identified under the window, you can fill them with insulation, for example, rolled or tiled, and then install a window sill.

For final finishing opening, you need to understand how to properly install the slopes. They can be plastered or assembled from sandwich panels made of expanded polystyrene foam.

With the latter option, the panels are cut to size locally, taking into account the geometry of each slope. A U-shaped plastic profile, otherwise called starting. A panel is inserted into it. The voids foam.

Foam is a polyurethane foam sealant that, due to its properties, requires a certain amount of time to fully expand and harden. Typically from 1 to 24 hours.

Where they adjoin the wall, the sandwich panels are covered with a decorative profile, most often F-shaped.

The junctions of the slopes and the frame to the window sill are sealed with sealant.

Who should you trust to install the window?

Mount a PVC profile window and install wooden window- not the same thing. Installing windows in a brick house involves certain nuances. You need to have everything on hand necessary tool, including adjustment keys for window fittings, as well as a supply of fasteners and special mounting tapes.

It is equally important to choose the right mounting foam and sealant. As an alternative to the latter, so-called liquid plastic can be used. This is a special adhesive-sealant that hardens very quickly, but also creates a particularly strong sealed seam.

If you are not sure that you can handle the installation yourself, it is better to seek the help of specialists.

//www.youtube.com/watch?v=qMBqdgWXysU