What equipment and materials are needed to create a water heated floor? Equipment for installing heated water floors

Today, installing heated floors indoors has become very popular. One option is a warm water floor. The building materials market offers a huge range of equipment for its installation. And do right choice it can be very difficult. Therefore, it is necessary to study the characteristics of each element and figure out whether there is any need for such a structure as a water floor.

Water heated floors are one of the most cost-effective and popular types heating systems. The room is heated by circulating hot water through a pipeline built into the floor.

a is a layered structure, consisting of:

- base layer (wooden floor or concrete slab);

- waterproofing;

- thermal insulation (prevents heat from escaping from a given direction);

- water floor, directly heating the room;

- concrete screed ;

- final coating.

How to choose equipment

The main elements of this heating system are pipes and a boiler. In addition, you may need a manifold and a box for it, a pump, fittings connecting pipes to the boiler, heat and waterproofing materials.

Pipes

Among can be used pipes made of different materials:

- of stainless steel ;

- copper;

- reinforced polyethylene;

- metal-plastic etc.

Today they produce pipes specifically designed for heated floors. They are very flexible and can withstand high pressure. Their service life can reach 25–28 years. But they are quite expensive. The most the best option are pipes made of metal-plastic. They can last a long time and are fairly easy to install. It is better to abandon polypropylene pipes, since they are not suitable for installation in concrete screed. If you take metallized ones, then preferably with an anti-oxidation coating.

For each heating circuit you need to take a separate pipe of suitable length. There should be no connections in the middle of the system. The optimal tube diameter is 2 cm.

How to replace a central heating system with heated floors:

Collector

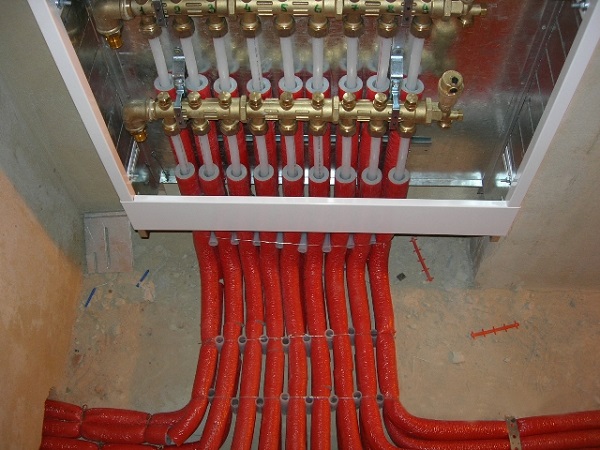

Collectors there are different types . The most simple models They only let the coolant flow through the pipes, and no longer provide other functions. More modern designs make it possible to regulate the water supply to each individual branch of the system and set its temperature. The newest options are equipped with an auto-adjustment system, which automatically sets the desired parameters.

To choose a collector, you should focus on the number of circuits in the house (apartment), and the need for constant monitoring of them. If all rooms must have the same temperature level, you can get by with a simple collector model and not overpay for additional functions.

Thermal insulation

Before installing pipes, thermal insulation should be made. It is impossible to avoid heat loss when using a heated floor. The system will transfer some of the heat outside. Therefore, thermal insulation elements are placed under the tubes. This will preserve heat and speed up the process of warming up the room.

To select thermal insulation material, should be considered:

- thermal power of the heating system;

- load-bearing capacity of the floor;

- efficiency.

Materials for thermal insulation:

- penofol;

- expanded polystyrene;

- Cork tree;

- mineral wool.

For installation in a warm water floor, polystyrene foam is better suited. A layer of it is made of at least 3 cm. To prevent heat from escaping at the joints, they are reinforced with a polymer fabric with a reinforcing mesh. Since polystyrene foam is a highly flammable substance, it is additionally coated with a foil compound.

For a full review of equipment for heated water floors, see here:

Installation options

There are several methods for laying pipes for a water floor.:

- Snake– pipes are laid along the wall, at the end they are bent and directed in the other direction. This covers the entire floor surface. The difficulty of this installation method lies in the design of the bend of the tube. With a small pitch, the pipe bends very difficult, and the large distance between the pipes does not properly heat the surface.

- Double snake– unlike the previous method, 2 pipes running parallel to each other are used here. The distance between them should not be more than 3 cm.

- Spiral(snail) - laying occurs from the outer perimeter of the room moving towards the center. From the center the pipe is turned back, completing the circuit. This laying scheme is very popular because, thanks to the alternation of hot and cooled tubes, uniform heating is ensured over the entire surface.

- Combined method– several options for installing pipes are used in one room. This is true if the room has a non-standard shape with protrusions or recesses, for example for installation.

Installation

Before production, you need to prepare the surface. It should be perfectly smooth. To do this, you can use self-leveling mixtures for filling.

- Placed on the rough surface waterproofing material . It is secured at the joints with tape. It is secured along the perimeter of the walls with damper tape.

- The next layer is thermal insulation. The thickness of the material depends on the characteristics of the room. For example, in basement or on the ground floor the thermal insulation density should be high. This helps reduce heat loss. For the kitchen, a layer of regular foil will be enough.

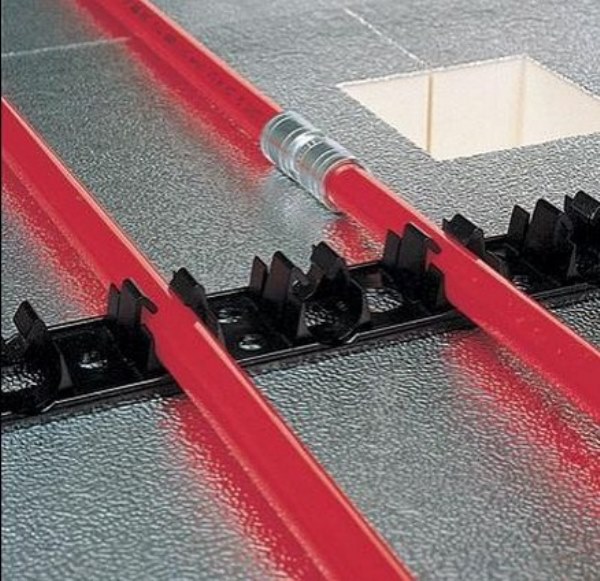

- Next stage - laying pipes according to the chosen scheme. The average distance between them should be about 30 cm. They are attached using plastic clamps to the reinforcing mesh, or with special profiles. They produce insulation with already provided protrusions, with the help of which the pipes are fixed.

- Fittings connect the tubes to the manifold.

- The collector is connected to the system and run it in test mode. The pressure and temperature should be increased gradually over at least 4 hours. If there are no leaks, test as much as possible permissible pressure, supplying water using a pump to the system.

- After testing the design, the pipes are covered with reinforcing mesh and pour cement screed no thinner than 3 cm. allows you to lay tiles directly on the screed.

- After the screed has dried, lay it. The surface humidity should be 2–4%.

Read how to install linoleum in the kitchen.

Video tutorial for installing a heated water floor:

Mistakes of installing heated floors, do not make them:

The installation of a warm water floor should be approached responsibly. Depends on the quality of equipment and installation performance characteristics systems, so choose a reliable manufacturer, for example, . To be confident in the operation of the heated floor, it is better to entrust its installation and connection of the system to the collector to professionals.

Water heated floors are the way to create comfort and coziness in the room. Their production requires special attention. This is especially true when it comes to choice necessary equipment. It must meet modern quality standards, which will ensure good heating dwellings. What components do you need to purchase for a heated water floor? You will get the answer to this question in this article.

What you need to buy

To create heated floors, the first step is to create a project. According to this project, all necessary equipment is assembled. The main purchases should include the following components:

- Thermal insulation of different thicknesses.

- Pipes and fittings.

- Damper self-adhesive tape, thickness from 5 to 10 mm.

- Pipe fastenings: anchor bracket, mounting plate, clamps for pipes, an arc for turning pipes at right angles, etc.

- Manifold cabinet.

- Reinforcement mesh.

- Boiler.

- Material for pouring the screed: sand, cement and plasticizer.

This is perhaps the main equipment that is required to create underfloor heating. Now let's look at some categories in more detail.

Pipes and fittings

Only high-quality pipes can provide a good heated floor. Today you can buy metal-plastic pipes or made of cross-linked polyethylene. This material fully complies with quality standards. They can be filled cement-sand screed.

Considering the fact that the pipes will be filled with screed, their quality should be given Special attention. Otherwise, it will be very difficult to remove them from the floor for repairs.

It is prohibited to use pipes that are used for water supply. Quality pipes must meet the following criteria:

- Tightness.

- Flexibility.

- Protection against oxygen diffusion.

In order for the laid circuit to last as long as possible, it should not consist of two or more pieces of pipe.

These requirements also apply to all purchased fittings that connect the pipe system in the manifold cabinet. To avoid getting caught by a counterfeit, it is better to purchase all such equipment from trusted suppliers..

Control system equipment

Each warm water floor is equipped with a control system. As a rule, it is located in the collector. The following equipment should be present here:

- Pumping and mixing unit. It is used to control and regulate the temperature. Control is performed in the direct cold water addition line.

- Manifold with flow meters. This equipment evenly distributes the coolant throughout the circuits. It is desirable that it be made of stainless steel. For the convenience of monitoring coolant flow, an individual upper meter is installed. The existing viewing window allows you to monitor the water flow.

- Nickel plated ball valves.

- Manifold cabinet. This is where the entire control system is located.

- Servo. The servo drive closes and opens the heating circuit, which is connected to the temperature controller. The thermostat is installed in a heated room.

- Eurocone connections. They are intended for joining pipes to the collector.

These components for a warm water floor will allow you to create a reliable control system.

The key link of the system is the collector!

The main equipment of the entire underfloor heating system is the collector. It can be purchased either ready-made or disassembled. Moreover, some decide to make it homemade. But for this it is important to understand the principle of its operation and choose only high-quality equipment. Additionally, the collectors are equipped circulation pumps, pressure stabilizers, thermostats and the like. It contains different quantities outputs for heating circuits. Each circuit is equipped with shut-off valves. This allows, if necessary, to block a certain heating area.

Thermal insulation material

For a warm floor, the thermal insulation layer is important requirement. It is laid under the pipes. The thickness can be around 50 mm.

Exists a large number of types of thermal insulation. For example, foil, polystyrene foam, mats, waterproofing boards and the like.

Some people use foam. But in this case, an additional waterproofing layer of film will be required. It completely eliminates the appearance of condensation.

All the equipment listed in this article will allow you to create a full-fledged heating system floor system. We hope this material will help you in choosing and collecting necessary components. We encourage you to leave comments on this article if you need other additional equipment.

Still have questions?

There are several options for heating systems called “warm floors”. Considering the fact that film and cable versions of products have the most simple system installations and are accompanied by minimal use of additional equipment, it is worth considering in detail the equipment for heated floors based on the use of liquid as a heat carrier, because it is much more complex.

Water floor systems look like this: a pipeline is laid between the rough base and the finishing floor covering, in which a heated coolant—liquid—moves in a closed loop.

Note! With this heating method, not only regular water, but also other types of liquids, for example, ethylene glycol or antifreeze.

General form

Such systems have many advantages:

- When compared with radiator-type heating systems, such heating saves about 12% of thermal energy.

- Maintaining a comfortable human habitation temperature regime. The temperature at the floor level is 22-24 degrees Celsius, and in the head area – 20.

- Due to the small difference between the temperature of the air and the floor, the speed of movement of convective flows is low, as a result, dust does not rise into the air.

- Uniform heating of the room is ensured, in which there are completely no overheating zones or cold areas.

- The heating efficiency does not affect the air quality; an optimal level of humidity is maintained, which creates the most comfortable conditions in the room. optimal conditions for a person. No dampness or dry air.

- When the liquid circulation is turned off, the heated coolant will continue to give off heat for several hours, maintaining a favorable air temperature in the room.

- The effective operational life of the pipeline laid during the development of the system is about half a century.

Pipeline on insulating layer

- There is no need for special maintenance, since the equipment practically does not break down during operation.

- During use, the system does not emit electromagnetic fields.

- The presence of a water heated floor in the room does not impose any restrictions on the subsequent formation of the interior.

Installation of water-type floors

There are several types of water floor installation:

- Concrete type - requires a concrete screed, which dries within three weeks. This is how long it takes for concrete to completely harden. Due to all elements general design The height of the room with this installation method is reduced by at least 10 cm.

- Layered type - in this version, the pipes are simply covered with a special gasket that absorbs moisture. This gasket is made of polyethylene foam, sometimes cardboard is used for its production, covered with aluminum plates. The finishing coating, for example, parquet, tiles, laminate, etc., is subsequently laid on these plates.

Installation on polystyrene foam board

- Wooden type - installation is carried out on wooden joists or wood floor.

The list of equipment necessary for installing a water heated floor system includes manifolds and fittings that are used to connect to a common heating system, as well as a pump that circulates the coolant, polymer or metal-polymer pipes and the thermal insulation on which they are laid. In addition, fasteners are used to secure system parts.

Features of floor equipment

The most important element of the system is the fittings and piping. In order for heated floors to last a long time, and their operation to be comfortable and problem-free, it is necessary to install plastic pipes high level quality.

Note! Poor-quality pipes can quickly become unusable, and replacing or repairing them will require breaking up the entire concrete floor. It is unacceptable to use products intended for cold and hot water supply.

Another way to fix pipes

High quality the pipe has the following properties:

- 100% tight;

- flexibility, allowing the product to be bent by hand;

- special protective layer, which will create an obstacle to the development of oxygen diffusion;

- integrity;

- the service life must be commensurate with the service life of the building.

Most often, plastic or metal-plastic pipes are used. The optimal diameter of the products is 1.6-2 cm. The distance in the coil should be at least 10 cm and no more than 30 cm. It is very important that the pipeline is not at risk of corrosion damage, and inner diameter must be preserved throughout the entire service life of the pipes themselves.

Ball valve

Used for thermal insulation various materials. As a rule, this is polystyrene foam and its other derivatives (pressed or extruded polystyrene foam). The thickness of the insulation stand must exceed 2.2 cm. If the room is poorly heated or has a dirt floor, then the minimum value is 3 cm. To prevent a thermal bridge from forming between the heating plate and the wall, a thin sheet of foam plastic is laid in this area. You can use damper tape.

In order to ensure uninterrupted operation, the underfloor heating system, in addition to the pipeline and related materials, is equipped with additional equipment.

Such equipment includes:

- ball valve, of which there are several included;

- a collector equipped with flow meters;

- connecting element - “eurocone”;

- servo;

- collector cabinet;

- a block that acts as a pump and mixer.

Collector block

The collector, which has adjustable flow meters, is designed to distribute the coolant throughout all elements of a closed circuit - a pipeline. Stainless steel is used to produce this part. Each heating circuit has an upper meter, which is located on the supply line. Thanks to this, the consumer can regulate the water flow without using any tools at all. The viewing window allows you to control the volume of liquid consumed.

Ball valves are supplied with a pair of balls coated with a layer of nickel-plated material. Due to the servo drive, the heating circuit is closed and opened. This drive is connected to a thermostat installed in a room that is heated.

Servo

"Euroconus" is used to connect the pipeline to the collector. And the pumping and mixing unit allows you to regulate the temperature on the direct line. This control is achieved by adding water to the system, which comes from the return pipe.

A distributor belonging to heating circuit. The central unit is located here, due to which the temperature in individual rooms is regulated.

Euroconus

In order for the warm water floor system to function fully, it must be provided with an energy source, preferably an autonomous type, which will heat the water. Most often used in such cases gas boilers. Their efficiency results in significant savings. Money. And if you use a type of condensing boiler, they can reduce consumption by about 35%. Therefore, the equipment used to install heated floors pays for itself fairly quickly.

The quality of heating no longer depends on utility services. Many homeowners are upgrading standard heating circuits. One of the types of such heating in the house is warm floors. It comes in electric and water.

Electric underfloor heating has an operating principle suitable for heating small rooms: baths, toilets, kitchens and hallways.

The water floor is intended for heating residential and public premises with an area of more than 20 m2. For uninterrupted operation you need high-quality equipment for heated floors, selected according accurate calculation for a specific room.

The article will talk about equipment for water heated floors of different types and design features each of them.

A water heated floor is a system of circular circulation of hot water through pipes laid in the floor. Through them, heat is transferred to the cement-sand screed, and from it spreads throughout the room. The water floor is connected to central system heating or gas boiler. This heating method has its pros and cons.

Pros:

- It is used as the main heating method. Ratio measurements useful action showed that the efficiency of heated floors is 12-14% higher than that of radiator heating.

- Thermal energy is distributed evenly throughout the room. At a level of 20-30 cm from the floor, the temperature is 22-24°C. At a height of 200-240 cm – 20°C.

- Low speed of air convection. Thanks to this, dust practically does not rise from the floor.

- Heating eliminates the appearance of “dead zones” where heat from the heating elements does not reach.

- The water vapor content is always within normal limits. A water floor does not dry out the air. At the same time, it prevents strong humidity from appearing.

- A water heated floor accumulates some of the energy. When the heating is turned off, the room will not freeze for several hours.

- Polypropylene pipes do not rot. Their trouble-free service life is 30-50 years.

- Such a floor does not create an electromagnetic field around it.

- When designing and creating a design, a water-heated floor does not serve as a hindrance. All elements are hidden under a screed of sand and cement.

Minuses:

- The initial costs for purchasing materials and installation are higher than when using electric heating elements.

- It works like one system. It will not be possible to replace a separate section of a leaky pipe. All pipes will have to be dismantled for replacement.

- High labor and financial costs for installation. Long installation period.

- The heat load per 1 m 2 area is lower than with electric heating.

Types of floors

There are three water heating systems for residential premises:

- Classic - heating elements made of polypropylene pipes through which circulation hot water. They are mounted in concrete base floor.

- Electric-water heating fluid circulates through pipes in which an electrical cable is installed. The pipes are recessed into the concrete floor.

- Flooring – polypropylene pipes With hot water. They are stacked in prefabricated wooden or plastic blocks.

Classic

A common method of heating residential and public buildings. The coolant is heated from the boiler or supplied from the central heating system.

The classic water floor is a universal system that can be connected to any heating plant. This can be done both during the construction of the facility and after its completion.

Design features:

- This floor can be installed in a private home or public building.

- IN multi-storey buildings installing a water floor is associated with a high risk of a decrease in pressure in the general house system and a violation of the hydraulic integrity of the coolants.

- Thermal energy comes from below and is evenly distributed over the entire area of the room. Wooden interior items will not dry out.

- The floor consists of plastic pipes, which do not corrode. This makes the design reliable for many years of use.

Classic heated floors are installed in two ways:

- First. The pipes are filled with concrete or cement-sand screed. In this case, the stone base acts as a shield for heat distribution. Installation additional elements not required.

- Second. The pipes are placed in plastic cassettes. Each has a trough framed by an aluminum heat-reflecting plate. Polypropylene pipes are inserted into the gutters and covered on top sheet material type GVL or OSB.

U classical system there are a number of advantages and disadvantages.

Advantages:

- Suitable for laying all types of modern flooring.

- The installation can be done by hand in a short time.

- It can be connected to any autonomous system heating.

Important! Before connecting, it is necessary to perform a thermal engineering calculation. The water floor should fit smoothly into the overall heating cycle without overloading it.

- The classic system can completely replace electric and radiator heating. The main thing is to produce additional insulation doors and window sealing. This will reduce heat loss through the building envelope. Energy savings are 25-30%.

The disadvantage is that the system is not recommended for installation in apartments multi-storey buildings. Any emergency situation will lead to a disconnection of heat from the entire entrance and flooding of several underlying floors.

Water floor with electric heating

This is a block system consisting of pipes with heating element. Instead of water, a special liquid is used.

Design features:

- An electrically heated water floor that operates autonomously does not need to be connected to the boiler. The liquid is heated using a cable. It does not circulate through pipes, so there is no need to connect pumps.

- The floor is sold in ready-made blocks, consisting of a base, polypropylene pipes with electric cable and heat transfer fluids.

- It works from the network. No need to do a test run. Just plug the plug into the socket.

- The electrically heated water floor is equipped with temperature control sensors. Therefore, the system does not overheat, and the room maintains the same temperature.

Advantages:

- To heat the room you need a small amount of liquid.

- The surface of the floor warms up evenly, unlike a water floor, where air pockets periodically appear in the pipes.

- It is possible to zonally install heating circuits. This means that within one room there can be several zones of independent heating.

- The system can be installed in multi-storey buildings.

As a disadvantage, energy costs significantly exceed those of classic water heating.

Laying system

This water heating floors when pipes are laid in wooden or plastic trays. They are covered from above with gypsum fiber boards.

- The wooden system is popular. Pipes are laid on wooden base. Aluminum heat-reflecting plates are installed around them. There are modular designs where the floor is assembled from ready-made modules.

- The polystyrene system works on the same principle as the wooden one. Polystyrene slabs with grooves for pipes or with bosses are used as the base.

Advantages:

- The thickness of water floors is less than other types.

- The weight of the structure allows it to be installed even in old wooden houses.

- It takes less time to warm up than classic water floors.

The disadvantage is that it cannot work the way the main heating works. This is due to the low power of the heating elements.

Floor project

Eat clear boundaries when designing a water heated floor should be carried out, and when not. If it is not the main source of heating, and the area of the room does not exceed 20 m2, then it is not necessary to order the project.

When a water floor is planned as the only source of heating, and the area of the room exceeds 20 m2, the design of a water heated floor is mandatory. The project is needed for a number of reasons:

- To commission a facility where a heated floor is installed, design documentation is needed. A simple calculation on a piece of paper will not work. The documentation indicates all the calculated loads on the heating system.

- To conclude an official contract for the installation of water heated floors, design documentation will be required. Otherwise, it will be difficult to prove the marriage.

- Without project documentation the costs of paying for work and purchasing materials are rising. There are no exact data; all volumes are determined by eye.

On the pipe installation plan and auxiliary equipment All dimensions and materials must be specified.

Equipment and materials

Despite the design features different types water heated floor, the main components are the same:

- Pipes and fittings. This is the basis of everything. As a rule, pipes are laid in concrete. Their service life must coincide with life cycle building. Any leakage leads to the dismantling of the entire coating. Regular water pipes are not suitable. For water floors, elastic and sealed plastic and metal-plastic pipes with a diameter of 16-20 mm are used. They should not rust or be destroyed by oxygen diffusion. The inner surface should be finely porous so as not to trap algae and other microorganisms.

- Thermal insulation materials. These are basalt mineral wool and extruded polystyrene foam. The thickness of the sheets is at least 30 mm. They must be durable and withstand mechanical loads from furniture and people.

- Damper tape. This polymer material, which is glued around the entire perimeter of the room. The tape dampens changes in floor dimensions due to temperature fluctuations and insulates corners.

- Collectors. These systems automatically regulate water flow and temperature. They are equipped with sensors to determine the temperature, pressure and flow rate of water in the system.

- Manifold cabinet. Basic equipment is installed in it to ensure the operation of the water floor. Shut-off valves, heat and water consumption meters - all this is installed in it. The manifold cabinet can be hung on the wall or installed on the floor. It is also equipped with a door with an internal lock. This is protection from strangers and children. The cabinet must be covered with a layer of polymer that will protect it from corrosion. There is a viewing window on the door to control the main parameters of the devices.

- Mixing unit. In it, the liquid is mixed to the desired temperature. It is equipped with temperature and pressure sensors. Shut-off valves are installed on it to regulate hot and cold water.

- Control system. It can be installed in any convenient location. It consists of a panel with buttons that can be used to adjust the temperature. Modern systems are equipped remote controls control or even the function of working via the Internet.

A good option is polypropylene pipes from Western European or Scandinavian manufacturers.

- To supply water, you must use seamless, durable and flexible pipes. Any additional connection is a source of leakage.

- Thermal insulation made from extruded polystyrene is the best option. It has the lowest coefficient of thermal conductivity and water absorption.

- Pipes “play” when heated and cooled. It is better to use elastic wire to secure them.

- Ball valves are better suited for shut-off valves.

Video

Warm floor is easy way create comfortable conditions in residential premises at reasonable costs. If you follow all the rules and recommendations, there will be no problems with operation.

It is generally accepted that a warm floor is modern system heating. At the very least, such a statement is a misconception and a historical error, since underfloor heating systems have been known since the times of the Roman Empire and were actively used to heat Roman baths, which are called thermae. Then hot smoke was supplied through the pipeline, which was the main coolant. Today, for a warm water floor system, several coolant options are used, in particular antifreeze, ethylene glycol solution or just water.

Why has such heating not only remained relevant for so many years, but also received a number of improvements and unlimited trust and popularity among homeowners? Of course, all this is thanks to numerous positive characteristics.

Let us dwell in some detail on the advantages of a warm water floor.

The comfort of such a heating system has already been mentioned several times. However, most buyers are always interested in the question of the cost-effectiveness of such heating, so it must be said that in comparison with a radiator system, heat savings are about 12%, regardless of the area of the room. The complete absence of convection currents ensures a complete absence of dust in the air, which is a significant advantage compared to a radiator heating system. One cannot help but mention the creation optimal humidity, which affects not only the physical well-being of residents, but also the appearance of fungus or mold on decorative floor covering. A special advantage of a warm water floor is its ability to accumulate heat and then gradually release it over several hours, thus maintaining optimal temperature in room. An important fact is that such a heating system does not require maintenance and has a fairly long service life. It should be noted that there is no electromagnetic radiation that is created by an electric or infrared floor, which makes the water heated floor system absolutely safe and environmentally friendly for human health.

So, what equipment should be purchased to install such a heating system.

Here is the actual list of necessary equipment for a water heated floor.

Be sure to watch two very useful and interesting videos about the construction of a water heated floor and the equipment used for its operation: