Creation of the first steam engine. History of the invention of steam engines. Creation of a steam engine.

Article published on 05/19/2014 05:36 Last edited on 05/19/2014 05:58The history of the development of the steam engine is described in sufficient detail in this article. Here are the most famous solutions and inventions of the times of 1672-1891.

First work.

Let's start with the fact that back in the seventeenth century, steam began to be considered as a means for driving, all kinds of experiments were carried out with it, and only in 1643 Evangelista Torricelli discovered the force action of steam pressure. Christian Huygens, 47 years later, designed the first power machine, powered by an explosion of gunpowder in a cylinder. It was the first prototype of an internal combustion engine. On a similar principle, the Abbot Otfey's water intake machine is arranged. Soon Denis Papin decided to replace the force of the explosion with the less powerful force of steam. In 1690 he built first steam engine, also known as a steam boiler.

It consisted of a piston, which, with the help of boiling water, moved up in the cylinder and, due to subsequent cooling, lowered again - this was how force was created. The whole process took place in this way: under the cylinder, which simultaneously performed the function of a boiler, a furnace was placed; when the piston is in top position the oven was retracted to facilitate cooling.

Later, two Englishmen, Thomas Newcomen and Cowley, one a blacksmith, the other a glazier, improved the system by separating the boiler from the cylinder and adding a tank of cold water. This system functioned by means of valves or faucets, one for steam and one for water, which were alternately opened and closed. Then the Englishman Bayton rebuilt the valve control into a truly clocked one.

The use of steam engines in practice.

Newcomen's machine soon became known everywhere and, in particular, was improved by the double action system developed by James Watt in 1765. Now Steam engine turned out to be sufficiently complete for use in vehicles, although due to its size it was better suited for stationary installations. Watt offered his inventions to industry as well; he also built machines for textile factories.

The first steam engine used as a means of transportation was invented by the Frenchman Nicolas Joseph Cugnot, an engineer and amateur military strategist. In 1763 or 1765, he created a car that could carry four passengers at an average speed of 3.5 and a maximum of 9.5 km / h. The first attempt was followed by the second - a car appeared for transporting guns. It was tested, of course, by the military, but due to the impossibility of long-term operation (continuous operation cycle new car did not exceed 15 minutes) the inventor did not receive support from the authorities and financiers. Meanwhile, in England, the steam engine was being improved. After several unsuccessful Watt-based attempts by Moore, William Murdoch and William Symington, Richard Travisick's rail vehicle, commissioned by the Welsh Colliery, appeared. An active inventor came into the world: from underground mines, he rose to the ground and in 1802 presented mankind with a powerful a car, reaching a speed of 15 km / h on flat ground and 6 km / h on the rise.

Preview - Click to enlarge.

Preview - Click to enlarge.

Ferry-powered vehicles were also increasingly used in the United States: Nathan Reed in 1790 surprised the people of Philadelphia with his steam car model. However, his compatriot Oliver Evans, who fourteen years later invented the amphibious vehicle, became even more famous. After the Napoleonic Wars, during which "automobile experiments" were not carried out, work began again on invention and improvement of the steam engine. In 1821, it could be considered perfect and quite reliable. Since then, every step forward in the field of steam-powered vehicles has definitely contributed to the development of future vehicles.

In 1825, Sir Goldsworth Gurney, on a 171 km long section from London to Bath, organized the first passenger line. At the same time, he used a carriage patented by him, which had a steam engine. This was the beginning of the era of high-speed road carriages, which, however, disappeared in England, but became widespread in Italy and France. Such vehicles reached their highest development with the appearance in 1873 of the "Curts" by Amede Balle weighing 4500 kg and the "Mansel" - more compact, weighing just over 2500 kg and reaching a speed of 35 km / h. Both were forerunners of the technique that became characteristic of the first "real" cars. Despite the high speed steam engine efficiency was very small. Bolle was the one who patented the first well-functioning steering system, he arranged the controls and controls so well that we still see it on the dashboard today.

Preview - Click to enlarge.

Preview - Click to enlarge.

Despite the tremendous progress in the field of internal combustion engine, steam power still provided a more uniform and smooth running of the machine and, therefore, had many supporters. Like Bollet, who built other light cars, such as the Rapide in 1881 with a speed of 60 km/h, the Nouvelle in 1873, which had a front axle with independent wheel suspension, Leon Chevrolet launched several cars between 1887 and 1907. with a light and compact steam generator, which he patented in 1889. De Dion-Bouton, founded in Paris in 1883, produced steam-powered cars for the first ten years of its existence and achieved significant success in doing so - its cars won the Paris-Rouen race in 1894.

Preview - Click to enlarge.

Preview - Click to enlarge.

Panhard et Levassor's success in using gasoline, however, led De Dion to switch to internal combustion engines. When the Bolle brothers took over their father's company, they did the same. Then the Chevrolet company rebuilt its production. Steam-powered cars disappeared faster and faster from the horizon, although they were used in the USA even before 1930. At this very moment, production ceased and invention steam engines

The principle of operation of the steam engine

Contents

annotation

1. Theoretical part

1.1 Timeline

1.2 Steam engine

1.2.1 Steam boiler

1.2.2 Steam turbines

1.3 Steam engines

1.3.1 First steamboats

2. Practical part

2.1 Building the mechanism

2.3 Questionnaire

Conclusion

Appendix

steam engine useful action

annotation

This scientific work consists of 32 sheets. It includes a theoretical part, a practical part, an application and a conclusion. In the theoretical part, you will learn about the principle of operation of steam engines and mechanisms, about their history and the role of their application in life. The practical part details the process of designing and testing the steam mechanism at home. This scientific work can serve as a clear example of the work and use of steam energy.

Introduction

A world submissive to the whims of nature, where machines are driven by muscle power or the power of water wheels and windmills- this was the world of technology before the creation of a steam engine. Even in ancient times, a person drew attention to the fact that a jet of water vapor, escaping from a vessel put on fire, is able to displace an obstacle (for example, a sheet of paper) that is in its path. This forced a person to think about how steam can be used as a working fluid. As a result, after many experiments, a steam engine appeared. And imagine factories with smoking chimneys, steam engines and turbines, steam locomotives and steamships - the whole complex and powerful world of steam engineering created by man. The steam engine was practically the only universal engine and played a huge role in the development of mankind. Invention the steam engine served as an impetus for the further development of vehicles. For a hundred years, it was the only industrial engine, the versatility of which allowed it to be used in factories, railways and the navy. The invention of the steam engine is a huge breakthrough, standing at the turn of two eras. And after centuries, the whole significance of this invention is felt even more sharply.

Hypothesis:

Is it possible to build with your own hands the simplest mechanism that worked for a couple.

The purpose of the work: to design a mechanism capable of moving on a pair.

Research objective:

1. Study the scientific literature.

2. Design and build the simplest mechanism that worked on steam.

3. Consider the possibilities efficiency increase further.

This scientific work will serve as a manual in physics lessons for high school students and for those who are interested in this topic.

1. T eo R e tic part

Steam engine - a thermal piston engine in which the potential energy of water vapor coming from a steam boiler is converted into mechanical work of the reciprocating movement of the piston or rotational movement of the shaft.

Steam is one of the common heat carriers in thermal systems with a heated liquid or gaseous working fluid along with water and thermal oils. Water vapor has a number of advantages, including ease and flexibility of use, low toxicity, the ability to bring to technological process significant amount of energy. It can be used in a variety of systems that involve direct contact of the coolant with various elements of equipment, effectively contributing to lower energy costs, reducing emissions, and a quick payback.

The law of conservation of energy is a fundamental law of nature, established empirically and consisting in the fact that the energy of an isolated (closed) physical system is conserved over time. In other words, energy cannot arise from nothing and cannot disappear into nowhere, it can only pass from one form to another. From a fundamental point of view, according to Noether's theorem, the law of conservation of energy is a consequence of the homogeneity of time and in this sense is universal, that is, inherent in systems of very different physical nature.

1.1 Timeline

4000 BC e. - man invented the wheel.

3000 BC e. - the first roads appeared in ancient Rome.

2000 BC e. - the wheel has become more familiar to us. He had a hub, a rim and spokes connecting them.

1700 BC e. - the first roads paved with wooden blocks appeared.

312 BC e. - The first paved roads were built in ancient Rome. The thickness of the masonry reached one meter.

1405 - the first spring horse-drawn carriages appeared.

1510 - a horse-drawn carriage acquired a body with walls and a roof. Passengers have the opportunity to protect themselves from bad weather during the trip.

1526 - German scientist and artist Albrecht Dürer developed interesting project"horseless cart" driven by the muscle power of people. People walking on the side of the carriage rotated special handles. This rotation was transmitted to the wheels of the carriage with the help of a worm gear. Unfortunately, the wagon was not made.

1600 - Simon Stevin built a yacht on wheels, moving under the influence of the force of the wind. She became the first design of a horseless cart.

1610 - carriages underwent two significant improvements. Firstly, the unreliable and too soft belts that rocked passengers during the trip were replaced with steel springs. Secondly, the horse harness was improved. Now the horse pulled the carriage not with its neck, but with its chest.

1649 - passed the first tests on the use of a spring, previously twisted by a person, as a driving force. The spring driven carriage was built by Johann Hauch in Nuremberg. However, historians question this information, since there is a version that instead of a large spring, a person sat inside the carriage, who set the mechanism in motion.

1680 - the first samples of horse-drawn public transport appeared in large cities.

1690 - Stefan Farffler from Nuremberg created a three-wheeled cart that moves with the help of two handles rotated by hands. Thanks to this drive, the wagon designer could move from place to place without the help of his legs.

1698 - Englishman Thomas Savery built the first steam boiler.

1741 - Russian self-taught mechanic Leonty Lukyanovich Shamshurenkov sent a “report” describing a “self-running carriage” to the Nizhny Novgorod provincial office.

1769 - French inventor Cugno built the world's first steam car.

1784 - James Watt builds the first steam engine.

1791 - Ivan Kulibin designed a three-wheeled self-propelled carriage that could accommodate two passengers. The drive was carried out using a pedal mechanism.

1794 - Cugno's steam engine was handed over to the "repository of machines, tools, models, drawings and descriptions of all kinds of arts and crafts" as another mechanical curiosity.

1800 - there is an opinion that it was in this year that the world's first bicycle was built in Russia. Its author was the serf Yefim Artamonov.

1808 - The first French bicycle appeared on the streets of Paris. It was made of wood and consisted of a crossbar connecting two wheels. Unlike the modern bicycle, it had no handlebars or pedals.

1810 - the carriage industry began to emerge in America and European countries. In large cities, entire streets and even quarters populated by master coachmakers appeared.

1816 - German inventor Carl Friedrich Dreis built a machine resembling a modern bicycle. As soon as it appeared on the streets of the city, it received the name "running car", since its owner, pushing off with his feet, actually ran along the ground.

1834 - a sailing crew designed by M. Hakuet was tested in Paris. This crew had a mast 12 m high.

1868 - It is believed that this year the Frenchman Erne Michaud created the prototype of the modern motorcycle.

1871 - French inventor Louis Perrault developed a bicycle steam engine.

1874 - a steam wheeled tractor was built in Russia. The English car "Evelyn Porter" was used as a prototype.

1875 - Amadeus Bdlly's first steam engine was demonstrated in Paris.

1884 - American Louis Copland built a motorcycle on which a steam engine was mounted above the front wheel. This design could accelerate to 18 km / h.

1901 - in Russia, a passenger steam car of the Moscow bicycle plant "Duks" was built.

1902 - Leon Serpollet on one of his steam cars set a world speed record - 120 km / h.

A year later, he set another record - 144 km / h.

1905 - American F. Marriott on a steam car exceeded the speed of 200 km

1.2 Steam engine

An engine powered by steam. The steam produced by heating water is used for propulsion. In some engines, the steam forces the pistons in the cylinders to move. This creates a reciprocating motion. The connected mechanism usually converts it into rotational motion. Steam locomotives (locomotives) use reciprocating engines. Steam turbines are also used as engines, which give direct rotational motion by rotating a series of wheels with blades. Steam turbines drive power generators and ship propellers. In any steam engine, the heat generated by heating water in a steam boiler (boiler) is converted into motion energy. Heat can be supplied from burning fuel in a furnace or from nuclear reactor. The very first steam engine in history was a kind of pump, with the help of which they pumped out the water flooding the mines. It was invented in 1689 by Thomas Savery. In this machine, quite simple in design, the steam condensed into a small amount of water, and due to this, a partial vacuum was created, due to which water was sucked out of the mine shaft. In 1712 Thomas Newcomen invented piston pump steam powered. In the 1760s James Watt improved Newcomen's design and created much more efficient steam engines. Soon they were used in factories to power machine tools. In 1884, English engineer Charles Parson (1854-1931) invented the first practical steam turbine. His designs were so efficient that they soon began to replace reciprocating steam engines in power plants. The most amazing achievement in the field of steam engines was the creation of a completely closed, working steam engine of microscopic dimensions. Japanese scientists created it using techniques used to make integrated circuits. A small current passing through the electric heating element turns the drop of water into steam, which moves the piston. Now scientists have to discover in which areas this device can find practical applications.

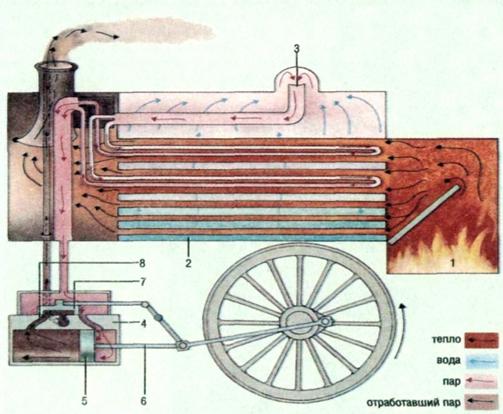

Steam engines, such as those formerly used in locomotives, run on steam produced by heating water. Fig(1.) shows a coal or wood burning furnace (1) heating a boiler filled with water (2) which produces steam. The steam rises and is forced through the steamer (3) through the pipes into the cylinder (4), where it causes the piston (5) to move back. Linked to the piston is a lever (6) that is a spool valve (7) which first allows steam to enter the cylinder (as shown) by closing the exhaust port (8). This creates pressure which pushes the piston forward and causes the spool valve to be in a position where the outlet port opens and steam escapes. The movement of the wheels causes the piston to move backwards and everything starts again.

1.2.1 Steam boiler

The first steam boiler was built by the Englishman Thomas Savery in 1698. It was an iron tank, under which a fire was made in the furnace. After some time, instead of a tank, they began to use a long (up to 10 m) cylinder with a diameter of about 1.5 m. It was surrounded by masonry, and a fire was lit under it. The surface washed by hot gases in such boilers was very small. Therefore, they produced very little steam, and due to the fact that hot gases mainly went into the pipe, the efficiency of such a boiler was very low. Most of fuel was burned in vain. At the beginning of the 18th century. the design of the steam boiler has been changed. Hot gases began to flow through pipes, surrounded on all sides by water. Such boilers were called "gas-tube" and began to be widely used in steam locomotives and steamships. At the end of the 19th century. once-through boilers were invented. The water in them turned into steam as it moved through the pipes: on the one hand, water is supplied to the pipes, and on the other, steam comes out.

1.2.2 Steam turbines

A steam turbine is a series of rotating disks fixed on a single axis, called the turbine rotor, and a series of fixed disks alternating with them, fixed on a base, called the stator. Rotor disks have blades on outside, steam is supplied to these blades and turns the disks. The stator discs have similar blades set at opposite angles, which serve to redirect the steam flow to the following rotor discs. Each rotor disc and its corresponding stator disc is called a turbine stage. The number and size of the stages of each turbine are selected in such a way as to maximize the useful energy of the steam of the speed and pressure that is supplied to it. The exhaust steam leaving the turbine enters the condenser. Turbines rotate at a very high speed, and therefore, special step-down transmissions are usually used when transferring rotation to other equipment. In addition, turbines cannot change their direction of rotation, and often require additional reverse mechanisms (sometimes additional reverse rotation stages are used).

Turbines convert steam energy directly into rotation and do not require additional mechanisms for converting reciprocating motion into rotation. In addition, turbines are more compact than reciprocating machines and have a constant force on the output shaft. Because turbines have more simple design, they tend to require less maintenance. The main application of steam turbines is power generation (about 86% of the world's electricity is produced by steam turbines), in addition, they are often used as ship engines (including those on nuclear ships and submarines ). A number of steam turbine locomotives were also built, but they were not widely used and were quickly replaced by diesel and electric locomotives.

1.3 Steam engines

Theoretically, the task of building a car, that is, a wagon that would drive itself, was already almost solved. It was only necessary to build a carriage with a control mechanism set in motion by the engine in it. In the XVIII century. only a steam engine could become such an engine.

For the first time this idea was expressed by Denis Papin and Thomas Severi - the authors of the unit of power "horsepower", but, unfortunately, they could not confirm their thoughts in practice. The implementation of the English projects of Severi and Watt, which remained in theory, was succeeded by the Frenchman Nicolas Joseph Cugno. Cugno was born in 1725 in Lorraine. He was well educated and from childhood showed an exceptional interest in technology. The engineer was interested in detail in the adaptation of a steam engine to drive a "horseless crew", he thoroughly knew the design of the Papin engine and a number of Watt steam engines. Unfortunately, the too large dimensions of these structures did not allow them to be placed on a wagon. Cugno started building his own steam engine small size. But since the resulting designs were still too large, the inventor was soon forced to stop work, for which there were no longer enough funds, and attempts to obtain additional funding from the government did not work.

The figure (2.), made by an unknown artist according to the instructions of Isaac Newton, shows the device of a simplified carriage that uses the jet of steam to move. However, in 1764, when the inventor was ready to completely abandon the fulfillment of his dream, luck smiled at him. The repeated request for an audience with the Minister of Defense was granted. Naturally, the minister did not intend to be interested in the work and projects of Cugno, but instructed General de Gribiev, who knew a lot about mechanics, to get acquainted with the invention. General, exceptionally intelligent and smart man, immediately realized what a revolution a "mechanical mule" could make in the army as an artillery tractor. He supported the idea of building prototype Cugno machines. However, the first test drives had to wait five years. They were held in Brux with complete success in the presence of a small number of spectators. The result of these tests made it possible to arrange a demonstration of the machine in Paris, to which the French Minister of Defense was invited.

The first car, the so-called small cart of Cugno, with its own name "Fardier", developed a speed of 4.5 km / h on the road, but only for 12 minutes, since there was not enough water or steam for more. It was necessary to fill the boiler with water and re-ignite the fire under it, since the first car did not even have a firebox. Despite its shortcomings, the Minister liked the cart so much that he ordered immediately to begin the construction of an improved and enlarged copy, which could be produced in large quantities for use in the troops for transporting cannons. Fig. (3.) shows the world's first steam car, built in 1769 by Cugno.

The famous French inventor Nicolas Joseph Cugno was one of the first to try to use a steam engine for transport needs. Built by Cugnot in 1769, the steam carriage is now kept in the Museum of Arts and Crafts in Paris, and its image has become the emblem of the French Society of Automobile Engineers.

Having received at his disposal 20,000 francs as a reward for the first design, Cugnot enthusiastically set to work. At the end of 1770, Cugno's new, more powerful steam car was tested in the presence of official military experts. They gave a commendable conclusion when the tractor fully completed the tasks assigned to it, although its speed did not exceed 4 km / h instead of the required 15. The movement was continuous, since the boiler had its own firebox and it was not required to kindle a fire on the ground. In addition, Cugno had already figured out how to increase the speed at least to the speed of the march of military columns so that the artillery would not be left behind. Only in the 20s. In the 19th century, after a significant improvement in the quality of roads, steam wagons began to appear again in England. Over time, a wagon with fuel and water supplies was attached to the stagecoach. This allowed fifteen-seater steam stagecoaches to make about 700 flights and overcome almost 7 thousand km at a speed of 30 km/h. The government imposed taxes on steam cars. A crushing blow to the owners of any mechanical carts was the “Law on Road Locomotives” adopted by Parliament, which destroyed the most important advantage of steam transport - speed, limiting it to 15 km / h. A steam locomotive is a locomotive with an independent steam power plant (steam boiler and steam engine), moving along the laid rails. The first steam locomotives were created in Great Britain in 1803 by R. Trevithick and in 1814 by J. Stephenson. In Russia, the first steam locomotive was built in 1833 by the father and son Cherepanovs. Figure (4.) shows the "road locomotive" built by Trevithick and Vivant in 1803. In 1865, when the railways covered the main part of England with their network, their owners, together with the owners of horse transport, dealt a final blow to steam carriages. Starting this year, steam engines were to be suburban areas roads move at a speed of 7 km/h, within the city - up to 4 km/h. In addition, a special person with a red flag had to run in front of the steam wagon, warning everyone of the approaching danger. So, in England, such a mode of transport as steam stagecoaches was destroyed for several decades. However, steam locomotives, driven by the same steam engine, continued to roll along the rails without hindrance and to the benefit of their owners. The adopted law was softened only in 1878 and completely repealed in 1896, when tens of hundreds of cars with gasoline engines drove along the roads of Europe. The first steam wheeled tractor in Russia was built in 1874 at the Maltsevsky plant in Lyudinovo. The English car "Evelyn Porter" was taken as a prototype, but the Russian tractor turned out to be more powerful and heavier. In addition, it was adapted to work on wood, and not on coal. In total, seven such tractors were built. As in France, the military department showed great interest in steam tractors in Russia. As soon as the first rutier, acquired by Baron Buxgevden for his estate near Riga, appeared in Russia, the military tested it. The steam tractor of the “Thomson system” withstood the test, and in 1876, after testing several more models of rutiers, it was decided to purchase them for the needs of the Russian army. In Fig. (5.) - Rutier is a steam tractor capable of towing special cars, platforms or trailers.

The next steam car after the rutiers of the Maltsevsky plant was built in 1901 by the Duks passenger steam car of the Moscow bicycle plant. On a car of this rather successful design, not only a run to the Crimea and back was made, but also an ascent to Ai-Petri. However, steam cars did not manage to take root in Russia. The last attempt in this direction was the construction at the end of 1949 of two steam trucks NAMI-012. Tests confirmed the performance and durability of the machines, while their driving performance was no worse than that of a diesel truck. A timber road train with a NAMI-012 tractor is shown in the figure. (6.). The maximum speed is 42 km / h, the supply of firewood in the bunkers was enough for 80 km of run.

Let's go back to France at the end of the 19th century. Here at this time, steam cars experienced their second birth. The engines were equipped with kerosene burners instead of coal furnaces, now they did not need a supply of coal and a long warm-up. Leon Serpollet (1858-1907) in his model of a steam carriage replaced the water boiler with a long, repeatedly bent pipe - a serpentine. It was a real success, since such a replacement made it possible to reduce the amount of water used. In addition, elastic tires were installed on the Serpolle wagon, which increased the comfort of the trip, and a special mechanism connecting the shaft of the steam engine and the drive wheels - a cardan. It got its name from the Italian inventor Gerolamo Cardano and made it possible to transfer rotation from a fixed steam engine to wagon wheels swaying on springs. In 1875, Bolli's first steam engine was demonstrated in Paris. It was a steam stagecoach, designed for 12 seats, and was called "Obediant". With a total mass of 5 tons, the steam engine consumed 2.5 kg of coal and 14 liters of water per 1 km. According to these indicators, Bolly managed to get ahead of similar steam omnibuses of the British by 1.5-2 times. Ahead sat the train manager (according to the terminology of those years - the conductor), and behind - the stoker (driver), who serviced the steam boiler. A four-cylinder steam engine (more precisely, two two-cylinder ones) made it possible to reach speeds of up to 40 km / h on a flat horizontal road. new model made in the 80s. 19th century and dubbed "New", had even higher rates. The mass of the omnibus was 3.5 tons, while for 1 km of the way it needed 1.5 kg of coal and 7 liters of water. In terms of its speed characteristics, Bolly's car could compete even with the newly appeared gasoline cars. By the way, if we discard the steam engine, then by design and appearance Bolli's wagon looked more like modern car than the first gasoline "horseless carriages", officially considered cars. Its design even included elements such as independent wheel suspension and metal body, which became widespread on cars only in the mid-30s. XX century. In the future, a steam engine was often used as an engine for light three- and four-wheeled carts. In France, this was done by Leon Serpollet and the factory "De Dion-Bouton and Trepardou". The use of a much smaller vertical tube boiler than conventional ones has reduced the mass of the engine, simplified maintenance and eliminated the risk of explosion. The resulting small, cart-like four-seat steam carriages were very popular in the early 20th century. in France and especially in the USA, where steam cars were produced until the beginning of the 30s. But despite all the improvements, steam cars of the second half of the 19th century. remained very inconvenient to use. The driver had to have the same knowledge and skill as the driver on the railway.

This led to the fact that the steam engine was practically inaccessible to the mass consumer. Despite this, it was she who played important role in the development of automotive technology. Thanks to this machine, the real possibility of mechanical movement of the crew was proved, tested and improved various mechanisms future car. Since the days of steam cars, the word “chauffeur” has also remained with us (it used to be written through two “f”), which means “stoker” in French. And although there is no longer a boiler or a firebox on a car, a modern driver is often called a driver. By the beginning of the 20th century. steam engines could reach a power of 15 million W, and the speed of rotation of their shaft was 1000 rpm. On one of his later cars, Serpollet in 1902 set a world record for car speed - 120 km / h. A year later, he set another record - 144 km / h. And two years later, in 1905, the American F. Marriott on a steam car exceeded the speed of 200 km / h. In the 80s. 19th century gasoline-powered vehicles appeared. Their main advantage was their low weight and quick launch, although they were not without a number of shortcomings from which steam engines had already been “cured”.

Despite all the efforts of scientists and engineers to save steam engines, they no longer met modern requirements. Steam engines were heavy, bulky, required large amounts of fuel and water, and did not promise further improvements in efficiency. In transport, they were increasingly supplanted by those that appeared at the end of the 19th century. internal combustion engines.

1.3.1 First steamboats

The beginning of the use of steam engines "on the water" was 1707, when the French physicist Denis Papin designed the first boat with a steam engine and paddle wheels. Presumably, after a successful test, it was broken by boaters who were afraid of competition. After 30 years, the Englishman Jonathan Hulls invented the steam tug. The experiment ended unsuccessfully: the engine turned out to be heavy and the tugboat sank. In 1802, the Scotsman William Symington demonstrated the Charlotte Dundas steamer in drawing (7.) Robert Fulton. From the 1790s, Fulton took up the problem of using steam to propel ships. In 1809, Fulton patented the Clermont design and went down in history as the inventor of the steamboat. Newspapers reported that many boatmen turned a blind eye in horror as the "Fulton monster", belching fire and smoke, moved along the Hudson against the wind and current. Already ten or fifteen years after the invention of R. Fulton, steamboats seriously pressed sailing ships. In 1813, two factories for the production of steam engines began operating in Pittsburgh, USA. A year later, 20 steamboats were assigned to the port of New Orleans, and in 1835 there were already 1,200 steamboats operating on the Mississippi and its tributaries. US river steamer 1810-1830 - in Fig. (8.) By 1815 in England on the river. Clyde (Glasgow) already operated 10 steamers and seven or eight on the river. Thames. In the same year, the first sea steamer "Argyle" was built, which completed the passage from Glasgow to London. In 1816, the steamer "Majestic" completed the first voyages of Brighton - Le Havre and Dover - Calais, after which regular sea steam lines between Great Britain, Ireland, France and Holland began to open. In 1813, Fulton turned to the Russian government with a request to grant him the privilege for the construction of the steamboat invented by him and its use on the rivers Russian Empire. However, Fulton did not create steamships in Russia. The beginning of the 19th century in Russia is also marked by the construction of the first ships with steam engines. In 1815, the owner of a mechanical foundry in St. Petersburg, Karl Bird, built the first paddle steamer "Elizaveta" in Fig. (9.) A Watt steam engine with a capacity of 4 liters was installed on a wooden "Tikhvinka". With. and a steam boiler that powered the side wheels. The car did 40 revolutions per minute. After successful tests on the Neva and the transition from St. Petersburg to Kronstadt, the steamer made voyages on the St. Petersburg - Kronstadt line. The steamer passed this way in 5 hours and 20 minutes at an average speed of about 9.3 km / h. By the 20s of the 19th century, there was only one steamer in the Black Sea basin - the Vesuvius, not counting the primitive steamer Pchelka with a capacity of 25 liters .s., built by Kiev serfs, which two years later was carried through the rapids to Kherson, from where it made flights to Nikolaev. Big Siberian gold miner Myasnikov,. who received the privilege to organize a shipping company on the lake. Baikal and the rivers Ob, Tobol, Irtysh, Yenisei, Lena and their tributaries, in March 1843. launched the steamship "Emperor Nicholas I" with a capacity of 32 liters. s., which in 1844 was brought to Baikal. Following him, the second steamship with a capacity of 50 hp was laid down and in 1844 completed with the construction. s., called “Heir to the Tsesarevich”, which was also transferred to the lake. Baikal, where both steamships were used for transportation. In the 40-50s of the 19th century, steamboats began to regularly sail along the Neva, Volga, Dnieper and other rivers. By 1850 there were about 100 steamships in Russia.

In 1819, the American sailing mail ship in Fig. (10.) - "Savannah", equipped with a steam engine and removable side wheels, left the city of Savannah USA for Liverpool and crossed the Atlantic in 24 days. The Savannah was powered by a single-cylinder low-pressure steam engine, simple action. The power of the machine was 72 hp, the speed during engine operation was 6 knots (9 km / h). The steamer used the engine for no more than 85 hours and only within the coastal zone. The Savannah flight was carried out to assess the required fuel reserves on ocean routes, because supporters sailing fleet it was argued that no steamship could carry enough coal to cross the Atlantic. After the ship returned to the United States, the steam engine was dismantled, and the ship was used until 1822 on the New York-Savannah line. The legendary giant Titanic. In the boiler rooms of the ship, 29 steam boilers were installed - each weighing 100 tons, which were heated by heat 162 furnaces. Coal stoves heated water in boilers to produce steam. The steam was then fed to piston engines. As soon as steam entered one of the four cylinders of the engine, the necessary force was generated to rotate one of the propellers. Excess or lost steam condensed in the evaporators and the resulting water could be returned to the boilers for reheating. Changing the amount of steam supplied to the thrusters controlled the ship's speed. Smoke from furnaces and engine exhausts were thrown out through the first 3 pipes. The fourth chimney was fake and was used for ventilation. Everything on the Titanic was state of the art. The first military steamship was built in the USA according to the design of R. Fulton in 1815. It was intended to protect the waters of the New York port and was a battery catemaran. Naval sailors called it a steam frigate, but R. Fulton preferred to call it a steam battery and gave it the name "Demologos" ("Voice of the people"). In 1829, the ship exploded in the roadstead of New York due to the careless handling of fire by sailors. In Russia, the first steam frigate "Bogatyr", which became the forerunner of cruisers, was built in 1836. The use of a steam engine in a submarine was postponed for many years. The main problem was the supply of air for burning fuel in the furnace of a steam boiler when the boat was in a submerged position, because. during the operation of the machine, fuel was consumed and the mass of the submarine changed, and it must be constantly ready to dive. Despite the obstacles in the history of the invention of submarines, there have been many attempts to build a submarine powered by a steam engine. The project of a submarine with a steam engine was first developed in 1795 by the French revolutionary Armand Mézieres, but he failed to implement it. In 1815, Robert Fulton built in New York a large submarine, equipped with a powerful steam turbine, eighty feet long and twenty-two feet wide, with a crew of 100 people. However, Fulton died before the Mute was launched and the submarine was scrapped. In the summer of 1866, a submarine was created by the talented Russian inventor I.F. Aleksandrovsky. It was tested for several years in Kronstadt in Fig. (11.). A decision was made about its unsuitability for military purposes and the inappropriateness of further work to eliminate the shortcomings.

1.3.2 The birth of two-wheelers

In parallel with the development of the first cars, inventors continued to improve the design of motorcycles and the engines installed on them. The most interesting works in this area were the devices of the French engineer Louis Guillaume Perrault, who created his own steam motorcycle. He began, like his compatriot Erne Michaud, with a bicycle, equipping it in 1868 with a large flywheel, thanks to which the rider could move by inertia for a certain time. A year later, Perrault began to use a single tubular frame in his designs. A bicycle designed by Louis Perrault, with an electric drive on the rear wheel, became revolutionary. But it was at a time when electrical engineering was just in its infancy and there were no good electric motors, so the teak project, which was fantastic for that time, remained on paper. The result of all these inventions was a steam engine for a bicycle, developed by Perrault in 1871. After some time, the motorcycle was built and tested on the fly. The fuel for the burner was to be alcohol, kerosene or vegetable oil. The engine is a single-cylinder steam engine. A working cylinder was attached along the frame, and tanks for fuel and water were located across the frame. With the help of a special regulator, it was possible to change the amount of steam supplied to the cylinder, thereby changing the speed of the motorcycle. There were no brakes on Perrault's car. The frame was based on a thick curved tube that was attached to the steering column and passed to the rear wheel. The rims of the wheels were wooden, covered with metal on the outside. The needles were also metal. The saddle was attached to a long spring and could move along the car - forward in the summer to move away from the hot engine, and back in the winter to warm up from it. In Fig. (12.) -Perrot offered his offspring for three thousand francs. But, unfortunately, the day before Franco-Prussian War his invention could not win fans and make a profit. Perrault's motorcycle had a tubular frame with a working cylinder fixed to it and tanks for fuel and water, which can be seen in the figure (13.). It is worth mentioning another inventor of "steam cycles" - American Louis Copland. In 1884, he placed a second motor in front of the driver over a small front wheel to relieve the rear (driver's weight plus engine weight). This motorcycle could accelerate to 18 km / h, rushing through the streets like a "hell fiend", and scaring the citizens. Copland later founded his own motorcycle manufacturing company. In the future, the development of motorcycles stopped. The people involved in their manufacture faced the same problem as the car masters - with the lack of a light and economical engine. Only the advent of the internal combustion engine radically changed the situation, giving a powerful impetus to the further development of this original look transport.

1.4 The use of steam engines

Steam engines were used as a driving engine in pumping stations, locomotives, steam ships, tractors, steam cars and other vehicles. Steam engines contributed to the widespread commercial use of machines in enterprises and were the energy basis of the industrial revolution of the 18th century. Later, steam engines were supplanted by internal combustion engines, steam turbines and electric motors, the efficiency of which is higher. Steam turbines, formally a type of steam engine, are still widely used as drives for electricity generators. Approximately 86% of the electricity produced in the world is generated using steam turbines.

1.4.1 Advantage of steam engines

The main advantage of steam engines is that they can use almost any heat source to convert it into mechanical work. This distinguishes them from internal combustion engines, each type of which requires the use of a specific type of fuel. This advantage is most noticeable when using nuclear energy, since nuclear reactor is unable to generate mechanical energy, but produces only heat, which is used to generate steam that drives steam engines (usually steam turbines). In addition, there are other heat sources that cannot be used in internal combustion engines, for example, solar energy. An interesting direction is the use of the energy of the temperature difference of the World Ocean at different depths. Other types of external combustion engines also have similar properties, such as the Stirling engine, which can provide very high efficiency, but have significantly larger weight and dimensions than modern types of steam engines. locomotives perform well at high altitudes, since their efficiency does not drop due to low atmospheric pressure. Steam locomotives are still used in the mountainous regions of Latin America, despite the fact that in the flat areas they have long been replaced by more modern types locomotives. In Switzerland (Brienz Rothhorn) and Austria (Schafberg Bahn), new steam locomotives using dry steam have proven their worth. This type of steam locomotive was developed from the Swiss Locomotive and Machine Works (SLM) models of the 1930s, with many modern improvements such as the use of roller bearings, modern thermal insulation, burning light oil fractions as fuel, improved steam lines, etc. d. As a result, these locomotives have 60% lower fuel consumption and significantly lower maintenance requirements. The economic qualities of such locomotives are comparable to modern diesel and electric locomotives.

In addition, steam locomotives are significantly lighter than diesel and electric locomotives, which is especially true for mountain railways. A feature of steam engines is that they do not need a transmission, transferring power directly to the wheels.

1.4.2 Efficiency

Coefficient useful action(EFFICIENCY) of a heat engine can be defined as the ratio of useful mechanical work to the expended amount of heat contained in the fuel. The rest of the energy is released into the environment in the form of heat. The efficiency of the heat engine is

,

Wout - mechanical work, J;

Qin is the amount of heat consumed, J.

A heat engine cannot be more efficient than the Carnot cycle, in which heat is transferred from a high temperature heater to a low temperature cooler. The efficiency of an ideal Carnot heat engine depends solely on the temperature difference, and the absolute thermodynamic temperature is used in the calculations. Therefore, steam engines require the highest possible temperature T1 at the beginning of the cycle (achieved, for example, by superheating) and as much as possible low temperature T2 at the end of the loop (for example with a capacitor):

A steam engine venting steam to the atmosphere will have a practical efficiency (boiler included) of 1 to 8%, but an engine with a condenser and expansion of the flow path can improve efficiency by up to 25% or even more. A thermal power plant with a superheater and regenerative water heating can achieve an efficiency of 30 - 42%. Combined-cycle plants combined cycle, in which the energy of the fuel is first used to drive the gas turbine, and then to the steam turbine, can reach an efficiency of 50 - 60%. At CHP plants, efficiency is increased by using partially exhausted steam for heating and production needs. In this case, up to 90% of the energy of the fuel is used and only 10% is dissipated uselessly in the atmosphere. Such differences in efficiency occur due to the peculiarities of the thermodynamic cycle of steam engines. For example, the largest heating load falls on winter period, so the CHP efficiency increases in winter.

One of the reasons for the decrease in efficiency is that the average temperature of the steam in the condenser is slightly higher than the temperature environment(the so-called temperature difference is formed). The average temperature difference can be reduced by using multi-pass capacitors. The use of economizers, regenerative air heaters and other means of optimizing the steam cycle also increases efficiency. A very important property of steam engines is that isothermal expansion and contraction occur at a constant pressure. Therefore, the heat exchanger can be of any size, and the temperature difference between the working fluid and the cooler or heater is almost 1 degree. As a result, heat losses can be kept to a minimum. For comparison, temperature differences between the heater or cooler and the working fluid in Stirling can reach 100°C.

2. Practical part

2.1 Building the mechanism

In the practical part, an attempt was made to design a mechanism capable of moving on steam.

For work we used various materials which you can buy at the hardware store.

The mechanism consisted of various improvised means.

The materials used were:

iron platform,

air freshener jar,

various metal fasteners,

metal screw,

various tube diameters

various holders,

metal wire,

dry alcohol.

First of all, in order to assemble the mechanism, we prepared the base, on which our mechanism will stand, we chose a metal platform with dimensions (11 * 23) cm.

The metal platform in terms of its qualities and properties: durable, able to withstand long-term loads and a decent weight of the mechanism, as well as able to withstand prolonged heat and not deform under its influence.

Then we prepared a container into which water will be poured and further heated. For the container, we used an air freshener jar measuring 12cm high and 7cm in diameter.

Since we need to heat it up, the outer metal casing was ideal for this. And also the advantages of this container were that it was practically airtight. Air supply and steam exit occurred through one hole. A narrow metal tube was attached at the outlet of the vessel in order to increase the pressure in it when heated and create the largest possible steam flow at the outlet of the vessel.

In order to install the container on a metal platform, metal fasteners were used.

The metal fasteners were specially made of thick metal, so that they were able to support the weight of the water container, as well as fire resistant.

Since when the container is heated, the steam coming out of it is concentrated in one place and creates a hot air stream. It is this feature that we decided to use according to the law of conservation of energy, that energy can pass from one form to another.

And the idea arose to turn steam into mechanical energy.

To do this, a metal screw was used.

The flow of steam directed to the propeller blade would make it rotate the propeller around its axis, which clearly indicated the transition of energy into mechanical energy.

The axis of the screw on one side should be with an extension of 2-3 cm. Since an elastic band will be attached to it, connecting it to the mechanism wheel. And due to the fact that the screw will spin under the pressure of steam, then through the rubber band this movement will pass to the wheel. Which, of course, should make the mechanism move slowly.

One of key features of this mechanism is the heating of water in a container. 2 types of heat source were used: the first is an ordinary candle, which does not give enough heat to make water boil, and dry alcohol, which gives much more heat, but is also not able to quickly evaporate water.

2.2 Ways to improve the machine and its efficiency

In the previous prototype, we favorable conditions could get from 1-3% efficiency, but with this improvement, the efficiency should increase to 3-6%. The idea is very simple and works due to the pressure of the steam formed in the tank.

The improvement lies in the fact that the position of the container and the way the energy is transferred are changed. On the container in the place where the steam comes out, a tube is attached inside which there is a metal ball that closes the container. The ball is supported by a spring that connects the ball and the piston. Holes are formed in the tube itself so that the steam has somewhere to go. And the principle is that steam is formed in the container when heated, and at the moment of pressure increase, when the pressure increases to a certain point, the pressure displaces the ball. The displaced ball, through a chain reaction, activates the spring, and it, in turn, passes to the piston, and so through the levers, the mechanical energy passes to the wheels. And so it continues until pressure can form in the container to displace the ball. Thus, if we adjust the mechanism, we can get a frequent rise of the ball, and this will lead to the creation of speed.

2.3 Questionnaire

The results of the survey showed that out of 20 students of grade 2, 65% of students correctly answered 10 questions.

For the most topical issues a table was made in Fig. (20.) for visual comparison.

Asked questions:

1. What do you think the efficiency of this machine will be and why? in the picture (21.)

2. What industrial enterprises use a steam engine?

3. In what year did the French inventor Cugno build the world's first steam car?

4. Who is the Englishman Thomas Savery?

5. What was the maximum speed developed by the steam car?

Conclusion

After writing the work, it was concluded that steam technology still surrounds us and is used to this day: steam locomotives are comparable to modern diesel and electric locomotives, pumping stations and many other places. After analyzing the scientific literature, it became obvious that it was the steam engine that changed our world, and our lives, since it was from its discovery that the era of technology development and different kind transport.

Having studied the principle of operation of steam engines, they designed and built the simplest mechanism that worked on steam. We considered the possibility of increasing the efficiency in the future.

While creating the mechanism, we encountered a number of problems that prevented us from achieving the desired result and, ultimately, led to the low power of our mechanism. This partly refutes our hypothesis. Excessive Influence external factors and a great loss of heat, wasted energy, were the reasons for the failure. Also, not enough fast and small amount of steam formation led to the fact that it was not created the right pressure and that subsequently led to a lack of power.

When designing the next generation mechanism, most of the factors were taken into account in order to avoid the same fate. The drawings were based in order to improve the mechanism and achieve the desired result.

Based on this work, it can be judged that in the world of steam technologies to this day, there is room for improvement and development. And maybe this technology will become the most economical, ecological and powerful in the future in the world.

Bibliography

The article is based on materials from the Bolshoy Soviet encyclopedia 2nd Edition.eo:Vapormaŝinohu:Gőzgéplt:Garo mašinann:Dampmaskin

Definition

Steam engine- an external combustion engine that converts steam energy into mechanical work.

Invention...

History of the invention of steam engines begins its countdown from the first century AD. We become aware of the device described by Heron of Alexandria, and powered by steam. The steam coming out of the tangential nozzles fixed on the ball caused the engine to rotate. The real steam turbine was invented in medieval Egypt much later. Its inventor is the Arab philosopher, astronomer and engineer of the 16th century Tagi al-Dinome. The skewer with blades began to rotate due to the steam flows directed at it. In 1629, a similar solution was proposed by the Italian engineer Giovanni Branca. The main disadvantage of these inventions was that the steam flows were dissipative, and this certainly leads to large energy losses.

The further development of steam engines could not take place without proper conditions. It was necessary and economic well-being and the need for these inventions. Naturally, these conditions did not exist and could not exist until the 16th century, in view of such low level development. At the end of the 17th century, a couple of copies of these inventions were created, but were not taken seriously. The creator of the first is the Spaniard Ayanz de Beaumont. Edward Somerset - a scientist from England in 1663 published a project and installed a steam-powered device for raising water to the wall of the Great Tower at Raglan Castle. But since everything new is difficult for a person to perceive, no one dared to finance this project. The Frenchman Denis Papin is considered the creator of the steam boiler. In the course of experiments on the displacement of air from the cylinder, by means of an explosion of gunpowder, he found out that a complete vacuum can be obtained only with the help of boiling water. And for the cycle to be automatic, it is necessary that steam is produced separately in the boiler. Papen is credited with inventing the boat, which was propelled by jet power in a combination of the concepts of Taghi-al-Din and Severi; the safety valve is also considered his invention.

All described devices have not been used and found to be practical. Even " fire installation”, which was designed by Thomas Savery in 1698, did not last long. Because of high pressure created by steam in containers with liquids, they often exploded. Therefore, his invention was considered unsafe. In light of all these failures history of the invention of steam engines could stop, but no.

Preview - Click to enlarge.

Preview - Click to enlarge.

The pictures show the Cugno steam tractor. As you can see, it was very bulky and inconvenient to manage.

An English blacksmith, Thomas Newcomen, demonstrated his "atmospheric engine" in 1712. It was an improved model of the Severi steam engine. It got its use as pumping water from mines. In the mine pump, the rocker was connected to a rod that descended into the mine to the pump chamber. The reciprocating movements of the thrust were transmitted to the pump piston, which supplied water upwards. The Newcomen engine was popular and in demand. It is with the advent of this engine that it is customary to associate the beginning of the English industrial revolution. In Russia, the first vacuum machine was designed by I.I. Polzunov in 1763, and a year later the project was implemented. It powered blower furs at the Barnaul Kolyvano-Voskresensky factories. The idea of Oliver Evans and Richard Trevithick to use high pressure steam has brought significant results. R. Trevithick successfully built high-pressure industrial single-stroke engines, known as "Cornish engines". Despite the increase in efficiency, the number of cases of explosions of boilers that could not withstand the enormous pressure also increased. Therefore, it was customary to use a safety valve to release excess pressure.

French inventor Nicolas-Joseph Cugnot demonstrated in 1769 the first working self-propelled steam vehicle: the "fardier à vapeur" (steam cart). His invention can be considered the first car. A self-propelled steam tractor used as a mobile source of mechanical energy proved to be effective, it set in motion various CX machines. In 1788, a steamboat was built by John Fitch, which provided regular service along the Delaware River between Philadelphia and Burlington. He had a capacity of only 30 people, and moved at speeds up to 12 km / h. On February 21, 1804, the first self-propelled railway steam train was demonstrated at the Penydarren Iron Works at Merthyr Tydfil in South Wales, which was built by Richard Trevithick.

How a steam engine works

Heat engines

Machines that produce mechanical work as a result of the exchange of heat with surrounding bodies are called heat engines. In all types of such engines, continuous or periodically repeating work is possible only if the machine that does the work not only receives heat from some body (heater), but also gives off part of the heat to another body (cooler).

The drawing, made by an unknown artist according to the instructions of Isaac Newton (1642-1727), shows the device of a simplified carriage using the reactive power of a jet of steam for movement.

steam engines

In the middle of the 17th century, the first attempts were made to switch to machine production, which required the creation of engines that did not depend on local energy sources (water, wind, etc.). The first engine to use thermal energy chemical fuel was a vapor-atmospheric machine, made according to the designs of the French physicist Denis Papin and the English mechanic Thomas Savery. This machine was deprived of the ability to directly serve as a mechanical drive; a water mill wheel (in modern terms, a water turbine) was “attached to it”, which rotated the water squeezed out by steam from the boiler of the steam engine into the tank of the water tower. The boiler was either heated by steam or cooled by water: the machine operated periodically.

How a steam engine works

A real steam engine works like this: water in a closed boiler is brought to a boil. Steam can only escape through a hole that leads to a special pipe.

This tube, called a cylinder, contains a movable piston. Steam presses on the piston, and it moves the connecting rod, which turns the flywheel.

After the steam has done this work, it exits through the valve and enters the piping system.

Powerful steam engines, of course, have an extremely complex design.

The principle of operation of the steam engine

The piston forms one or two cavities of variable volume in the cylinder of the steam engine, in which the processes of compression and expansion take place.

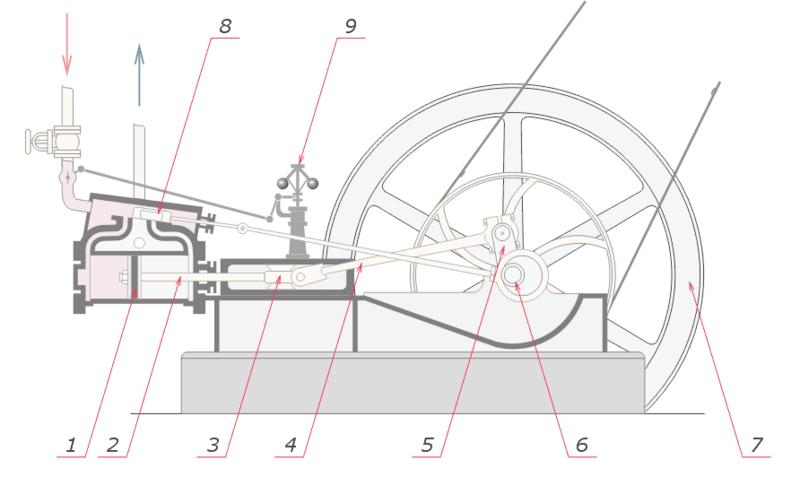

The work of the piston 1 through the rod 2, the slider 3, the connecting rod 4 and the crank 5 is transmitted to the main shaft 6, which carries the flywheel 7, which serves to reduce the uneven rotation of the shaft. The eccentric, sitting on the main shaft, with the help of an eccentric rod, drives the spool 8, which controls the intake of steam into the cylinder cavity. Steam from the cylinder is released into the atmosphere or enters the condenser. To maintain a constant number of shaft revolutions under a changing load, steam engines are equipped with a centrifugal regulator 9, which automatically changes the cross section of the passage of steam entering the steam engine (throttle control, shown in the figure), or the filling cut-off moment (quantitative control).

Steam engine classification

Steam engines are divided:

by appointment

stationary

non-stationary (mobile and transport)

according to the steam used

low pressure (up to 12 kg/cm²)

medium pressure (up to 60 kg/cm²)

high pressure (over 60 kg/cm²)

according to the number of shaft revolutions

low-speed (up to 50 rpm, as on paddle steamers)

high-speed

according to the pressure of the released steam

for condensing (pressure in the condenser 0.1-0.2 atm)

exhaust (with a pressure of 1.1-1.2 atm)

cogeneration with steam extraction for heating purposes or for steam turbines with a pressure of 1.2 atm to 60 atm, depending on the purpose of the extraction (heating, regeneration, technological processes, operation of high drops in upstream steam turbines).

According to the location of the cylinders

horizontal

oblique

vertical

by number of cylinders

single-cylinder

multi-cylinder

twin, triple, etc., in which each cylinder is fed with fresh steam

multiple expansion steam engines, in which steam expands sequentially in 2, 3, 4 cylinders of increasing volume, passing from cylinder to cylinder through the so-called. receivers (collectors).

According to the type of transmission mechanism, multiple expansion steam engines are divided into tandem machines and compound machines. A special group is made up of once-through steam engines, in which the release of steam from the cylinder cavity is carried out by the edge of the piston.

steam engine

It is an engine powered by steam. The steam produced by heating water is used for propulsion. In some engines, the steam forces the pistons in the cylinders to move. That. reciprocating motion is created. The connected mechanism usually converts it into rotational motion. Steam locomotives (locomotives) use reciprocating engines. Steam turbines are also used as engines, which give direct rotational motion by rotating a series of wheels with blades. Steam turbines drive power generators and ship propellers. In any steam engine, the heat generated by heating water in a steam boiler (boiler) is converted into motion energy. Heat can be supplied from burning fuel in a furnace or from a nuclear reactor.

Steam engines, such as those formerly used in locomotives, run on steam produced by heating water. A coal or wood firebox (1) heats a boiler filled with water (2), which produces steam. The steam rises and is forced through the steamer (3) through the pipes into the cylinder (4), where it causes the piston (5) to move back. Linked to the piston is a lever (6) that is a spool valve (7) which first allows steam to enter the cylinder (as shown) by closing the exhaust port (8). This creates pressure which pushes the piston forward and causes the spool valve to be in a position where the outlet port opens and steam escapes. The movement of the wheels causes the piston to move backwards and everything starts again.

4.1 (82.73%) 88 votes

The invention of the steam engine was a turning point in the industrial and general history of mankind. At the turn of the 17th-18th centuries, prerequisites appeared for replacing low-power and inefficient living "engines", windmills and water wheels with mechanisms of a completely new type - steam engines. It was steam engines that made possible the industrial revolution and the achievement of the modern level of technological development.

It is considered that invented the first steam engine Scottish mechanic James Watt - after all, it is not for nothing that the international unit of power Watt is named after him! However, in reality, Watt made a lot of improvements and proposed new type engine, and the history of steam engines dates back much earlier.

The use of steam to actuate a mechanism was first described by the ancient Greek scientist Heron of Alexandria, who worked around the 1st century AD. e. It was Heron who invented the famous Eolipil (or "Eol's ball") - a sphere fixed on an axis with nozzles coming out of it. A ball filled with water was heated on fire, and the steam coming out of the nozzles caused the sphere to rotate.

Of course, all this is nothing more than a toy, but it has been forgotten for more than a millennium and a half. For the first time after Heron, the Arab engineer and philosopher Tagi al-Dinome tried to use the power of steam - in the 16th century he created a prototype of a steam turbine that rotated a spit. Almost a century later - in 1615 - the Frenchman Solomon de Caux describes a device that, with the help of steam, can raise water. And in 1629, the Italian Giovanni Branca also creates turbine-like machine, - heated steam came out of the tube and hit the blades on the wheel, thereby causing this wheel to rotate.

Around the same time, the Spanish engineer Jeronimo Ayanz de Beaumont created steam engine with cylinder- this mechanism had some influence on the development of events in the field of improving steam engines. And in 1663, the Englishman Edward Somerset describes a steam engine for lifting water from wells and mines, and subsequently receives a patent for this invention. The machine created by Somerset worked for some time in one of the English castles, but showed far from the best results.

Two people played a huge role in the development of steam engines: the Frenchman Denis Papin and the Englishman Thomas Savery. Pa-pen invented a cylinder in the mid-70s of the 17th century, in which a vacuum is created by the explosion of gunpowder, and then (in 1680) he adapted this cylinder to work from steam. By the end of the century, a French scientist approached the creation of an industrial model of a steam engine, but Savery was ahead of him - in 1698 an Englishman received a patent for a machine, and in 1702 the mechanism of its design began to be used to lift and pump out water. However, these steam engines received a very limited distribution - they were too imperfect.

But if the devices of Papin and Savery were little used in practice, then why did these people play an important role in the history of technology? The thing is that the ideas of these engineers-inventors formed the basis of the steam engine, created in 1712 by the Englishman Thomas Newcomen. The inventor combined a Savery-designed machine with a Papin cylinder, resulting in a fairly perfect steam-powered engine. An interesting detail: the machine was controlled manually - for this purpose a special person was hired, whose task was to open and close the valves at certain intervals. According to legend, in 1713, a boy named Humphrey Potter, who worked on one of the machines, figured out how to make the valves work on their own. And only in 1715 on steam engines Newcomen's system appeared completely automatic system steam distribution.

Here you need to do two important notes. First, all of the above steam engines are vacuum(or atmospheric). In machines of this type, steam was used only to heat the cylinder in which the piston moved. The principle is simple: steam enters the cylinder, heating it to a high temperature, after which cold water is poured onto the cylinder. As a result, a sharp cooling occurs, and a rarefaction (vacuum) is formed in the cylinder, due to which, under the action of atmospheric pressure, the piston enters deep into the cylinder, while doing work. Secondly, all these machines were used only for lifting and moving water - it never occurred to the inventors that various mechanisms could be set in motion with the help of steam. So even Newcomen's car often referred to as a steam pump.

For more than half a century, Newcomen's steam engines were the only machines suitable for industrial use. It was only in the early 1760s that progress occurred in this area - Humphrey Gainsborough created improved steam engine, which, however, has not received significant distribution. And the Scottish engineer and inventor James Watt was destined to make a real revolution in this area.

In 1765, Watt put forward the idea that it is not necessary to cool the cylinder, but it is better to use the force of steam pressure, and not vacuum. Already in 1769 he received a patent for this invention, but the machine itself new design was created only in 1776 - Watt at that time was tight with money and he simply had nothing to implement his ideas.

But the most important invention of James Watt, which made him famous, appeared only in 1781: it was then that the engineer created a steam engine capable of doing any job. This was made possible by converting the reciprocating motion of the piston into the rotation of the flywheel using the so-called planetary mechanism. And in 1784, Watt's steam engine acquired its final form - a more convenient and simple crank mechanism and many minor improvements appeared in it. It was this development that became known as universal steam engine, and not in vain: the machine soon appeared in factories and plants, and at the beginning of the 19th century, the Watt system engines were installed on the first steam locomotive and steamboat.

It is interesting that a functioning steam engine (and not even one) was also created in Russia - these are the well-known machines of Ivan Polzunov, built in the period from 1763 to 1766. Polzunov's first engines showed good results, and in 1764 construction began on a large steam engine for a metal foundry. Construction ended in 1766, and the launch was made after the death of the inventor. Unfortunately, Polzunov's steam engine worked for only 42 days - after a breakdown, it ceased to be used, and after some time it was dismantled.

As you can see, the history of steam engines does not begin with the discovery of James Watt, but it was this inventor who created a truly efficient and comfortable car which had a huge impact on the development of industry and technology. For these merits, in 1882, the unit of power, known to us as the watt, began to be named after Watt.