Gas boiler closed combustion chamber. Boiler with a closed combustion chamber

Wall mounted gas boilers With closed camera fuel combustion are modern heating equipment, which is widely used for heating and hot water supply in apartments, cottages, and mansions. Boilers equipped with a closed combustion chamber are more advanced and safer compared to similar equipment with an open combustion chamber.

Advantages of wall-mounted boilers

- 1. High safety during operation - oxygen is taken for gas combustion from outside the room, combustion products are also removed to the street. Therefore, the likelihood of carbon monoxide poisoning is reduced to almost zero. The cycle of combustion and heat production occurs in complete isolation from the room, which is why the level of safety and comfort when staying in it significantly increases.

- 2. Ease of operation - for installation there is no need to allocate a separate room for the boiler room, when compared with boilers with an open combustion chamber of a certain capacity. That is why boilers with a closed chamber can even be installed for heating small apartments dream large area.

- 3. Small size- they are similar in size to a geyser, so they will not take up much space in the room. The installation feature allows you to mount them on the wall in a convenient place.

- 4. High efficiency - gas burns almost completely when compared with boilers equipped with an open chamber. Therefore, you can use fuel more efficiently and economically.

Some features

The cost of heating boilers with a closed combustion chamber is slightly higher than similar devices with an open chamber. There are single-circuit and dual-circuit devices: the first are intended only for heating, and the second - both for heating and for supplying hot water. The water in such a boiler is heated in flow mode; the device will be useful if the household’s needs for hot water are not very large. Most boilers can provide volume hot water 10-15 liters per minute if heating is carried out at 30-35 degrees. There are models

Select a boiler for gas system heating is very difficult. After all, there are many equipment options on the market, among which it is easy to get confused. The characteristics and parameters of modern equipment allow you to select a device according to individual parameters. For example, what type better camera combustion, open or closed. Let's look into this issue.

Open combustion chamber in gas boilers

Gas heating equipment with an open combustion chamber is a classic device with natural draft. That is, the air necessary for the combustion process is taken directly from the room in which the boiler is installed. The fumes and combustion products are discharged through a special opening. Experts recommend installing a chimney for safe use of the equipment.

A gas boiler open type combustion can be installed in any room. But in living rooms it can lead to decreased oxygen levels and stuffiness. And when there was a strong burning, there were also cases of poisoning by combustion products. That is why it is recommended to install such equipment in separate rooms. Before purchasing such a boiler, it is worth preparing a separate room for its installation. This is the main disadvantage of this type of equipment. It is not bought so often, although it costs much less than its analogues.

The use of boilers with an open combustion chamber will require not only separate room, but also the installation of a vertical chimney and ventilation system. A unique mini boiler room will ensure safe use gas boiler in the house.

Closed combustion chamber in gas boilers

Gas equipment with a closed combustion chamber has its positive aspects:

- installation of the boiler does not require a special room. It is enough to allocate a few meters of space for the boiler. This is very important, especially for small country houses;

- the equipment is classified as a high-security device;

- very easy to install;

- has an acceptable cost.

But to be sure of its safety, it is worth understanding where the air is taken from to support the combustion process and where the carbon monoxide goes. Naturally, if you have technical knowledge, you will be able to understand the technological characteristics yourself. If not, we will tell you. So, air is supplied and discharged through the chimney. True, it does not require the installation of a vertical chimney. Boilers with a closed combustion chamber are completely safe for use in the country.

It is worth noting that when using a boiler with a closed combustion type, it is still recommended to remove it horizontally using a powerful fan or cooler. For the ventilation system to function flawlessly, it is necessary to ensure a constant supply of electricity. Boilers closed type have significantly highest coefficient Efficient, but cannot be used without an electrical connection.

Coaxial chimney is a necessary element of boiler performance

A coaxial chimney is a pipe-in-pipe structure. This device provides the supply of air necessary for combustion from the street and the removal carbon monoxide. For air supply provides outer pipe, and for the removal of combustion products - internal.

The main advantages of installing such an additional element are:

- safe use of the heating system. When passing through a coaxial chimney, the fumes cool down and become absolutely harmless to the environment;

- increasing the CPT coefficient, at which the fuel is almost completely burned, converted into thermal energy;

- significant fuel savings. The boiler consumes significantly less quantity and ensures its complete combustion;

- the ability to install in residential premises, since the equipment does not emit fumes.

The disadvantages of such equipment include the cost, which is an order of magnitude higher than similar equipment with open combustion, and the presence of noise. The chimney of a closed combustion chamber reduces fuel consumption, thereby reducing heating costs.

Equipment on which an additional chimney can be installed

The coaxial type of chimney can be used with turbocharged and condensing boilers. The chimney pipe is ideal for parapet devices. It can be mounted on a boiler with atmospheric burner. But with such an installation, it is worth remembering that only chimneys made of stainless steel can be installed on such boilers.

The coaxial chimney system can be used for double-circuit and single-circuit gas boilers, regardless of the type of combustion chamber.

Types of pipes for coaxial chimneys

The choice of coaxial pipes should be approached with special responsibility. After all, many boiler manufacturers produce non-standard equipment that requires the same materials.

Universal pipes are made from:

- plastic. Today two-channel plastic chimneys made from heat-resistant material. Such pipes can withstand temperatures of more than 200 degrees. Their advantages are low weight, reasonable cost, and easy installation. The disadvantages of plastic chimneys are their fragility and limited opportunity use with many gas boilers;

- of stainless steel. This material can withstand temperatures up to 550 degrees. Such products are produced in two types: non-insulated, with a simple design, and insulated with high aerodynamic properties. Such a chimney can last for a long period, which is more than 30 years.

- aluminum These designs are not used as often, since they do not have such high technological characteristics than stainless steel products and excellent appearance than plastic chimneys. But nevertheless, they are preferred by many summer residents, since in such places they ideally fulfill their purpose.

Possible difficulties of closed combustion equipment

When installing the boiler, it is worth remembering that gas devices for heating with a closed combustion chamber requires special care:

- a kind of lubrication of units, Maintenance, inspection of the turbine will significantly extend the operational period of operation;

- replacing the turbine, if necessary. Like any moving mechanism, it is subject to wear and has a certain period of use;

- Low temperatures may reduce the functionality of the equipment. Freezing in the fuel combustion area can damage the device. It is almost impossible to eliminate this phenomenon. But for trouble to happen, the frost must be very strong;

- providing electricity. A turbine simply will not work without a connection to a power line.

Requirements for installing a coaxial chimney

To create safety of use, the legislator regulates the installation coaxial chimney. These requirements must be followed as they reduce existing risks to a minimum:

- the coaxial chimney must be located at a height of at least 2 meters from the base of the house;

- the hole through which the chimney is brought out should be several centimeters larger diameter chimney pipes;

- the chimney can be created horizontally and vertically;

- it needs to be serviced annually.

Horizontal installation of a coaxial chimney

The horizontal arrangement of the chimney provides for the pipes to be led out through the wall of the house. This is the simplest option for installing a heating system element in a country house. For horizontal installation required:

- calculate the height of the pipe. This is the size from the outlet pipe gas equipment to the hole in the wall of the house. For example, for boilers installed on the floor, it is at least 1 meter. It is strictly forbidden to lead the pipe directly - from the pipe to the street.

- calculate the turns and change the drawing if necessary. According to the requirements, the number of knees cannot exceed 2 turns;

- calculate the length of the horizontal section, which should not exceed more than 5 meters. To connect the sections, it is necessary to use a special coupling, which will allow for a smoke outlet if necessary. The use of silicone glue and sealants is strictly prohibited.

For creating favorable conditions operation in winter time It is recommended to insulate the horizontal chimney. This will eliminate the formation of condensate and significantly increase the service life of the pipes.

Vertical installation of a coaxial chimney

Installation of a coaxial chimney provides for the exhaust of combustion products in a vertical direction. Maximum length such a chimney is no more than 7 meters. This chimney option can be used for houses with a solid foundation and walls. But for a dacha, this option is used very rarely, since the horizontal method is much simpler and safer.  When installing modern equipment, it is also necessary to adhere to the manufacturer’s recommendations. The manufacturer of gas boilers must indicate the installation principle of the heating system. It is almost impossible to make a mistake if you follow professional recommendations.

When installing modern equipment, it is also necessary to adhere to the manufacturer’s recommendations. The manufacturer of gas boilers must indicate the installation principle of the heating system. It is almost impossible to make a mistake if you follow professional recommendations.

Problems autonomous heating and hot water supply can be solved using this specialized equipment. A modern gas wall-mounted double-circuit boiler with a closed combustion chamber performs its functions with rational consumption of energy resources. It is well protected from temperature rise and other negative impacts. This technique does not require careful control by the user. If you follow basic operating rules, it will retain excellent consumer characteristics for many years.

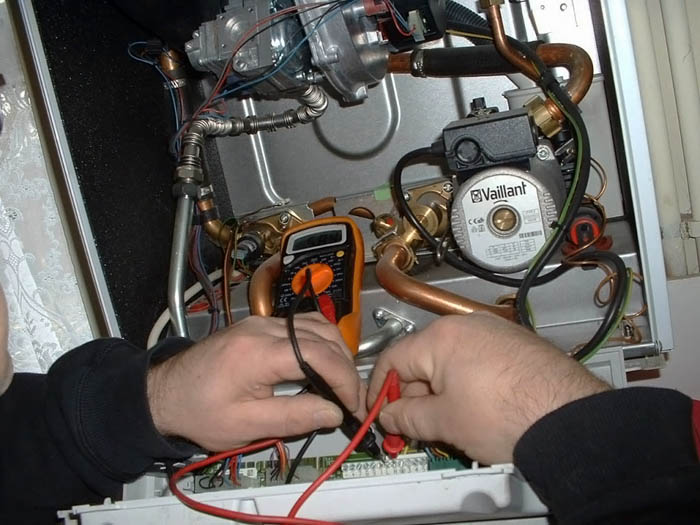

A modern domestic boiler contains complex mechanical components and electronics units

Gas wall-mounted double-circuit boiler with a closed combustion chamber: principles of operation and selection criteria

If when purchasing a complex technical equipment If you pay attention only to the cost and basic characteristics, it will be difficult not to make mistakes. Any attentive person will benefit from a detailed analysis. It should include familiarization with the principles of operation, research of various modifications and coordination of parameters with a specific room and operating conditions. This is exactly the procedure used to consider gas wall-mounted double-circuit boilers with a closed combustion chamber.

What is this equipment for?

This type of technology is universal. It provides water heating in two different circuits. can be divided into several separate sections and connected through a plumbing “comb” in parallel.

Thus, after installing the appropriate equipment, it will be possible to leave only the input line with cold water. This is not only convenient for users. District heating systems are generally less efficient. They heat up environment. To increase productivity, it is necessary to better isolate the routes, which in turn increases the cost of the engineering system. To this should be added the optionality of domestic maintenance services and the increased costs of municipal repairs.

All general economic losses in some form are translated into payments to producers. This explains why investing in a high-quality gas wall-mounted double-circuit boiler with a closed combustion chamber pays off over time.

What is the difference between a closed combustion chamber and an open combustion chamber in gas boilers?

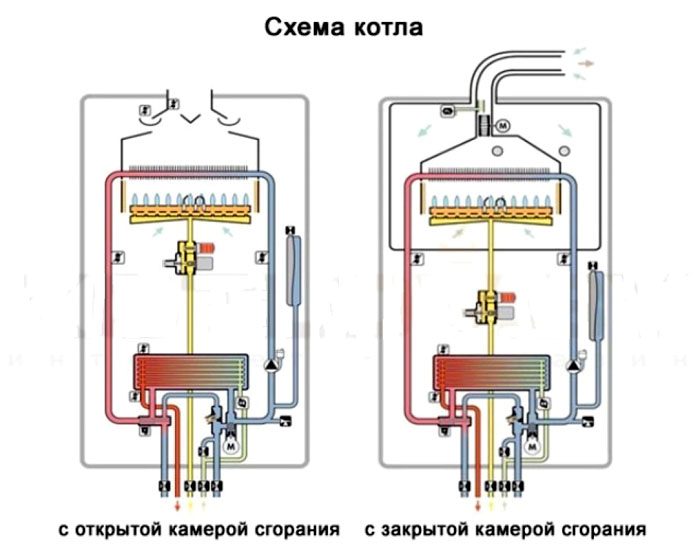

The general principles of operation are the same for all types of double-circuit boilers. This picture shows the main elements of the standard design.

This technique works as follows:

- Cold water enters the heat exchanger of a closed chamber, where it is heated by the flame of a gas burner.

- Then it not only goes to consumers, but is also used to heat the liquid in the second circuit.

- To ensure fluid circulation at the required speed, they are used.

- Since the liquid expands as the temperature rises, a special compensating tank has been added to the standard equipment.

- The sensor system is used to quickly obtain information about the operation of equipment, automated adjustments and blocking of dangerous modes.

- In addition to the elements indicated in the diagram, boiler designs include valves for air removal, mechanical and electronic settings, control, and indication devices.

Designs with an open and closed combustion chamber of a gas boiler are distinguished by the method of supplying air and removing combustion products. In the first option, traction is provided naturally. An obvious disadvantage is the consumption of oxygen from the room atmosphere. To recover the corresponding losses, a sufficiently good .

Note! IN winter period frequent ventilation worsens economic indicators and creates the preconditions for the occurrence of colds. It is for this reason that experts recommend installing equipment of this type in a separate technical room, boiler room.

The differences between closed chamber techniques are given below:

Related article:

A special element that allows you to save up to 20% of fuel resources. What kind of regulators there are, what to look for when choosing how to connect the device to the boiler, we will look at in the article.

Modifications of wall-mounted gas heating boilers: which one is better for a city apartment

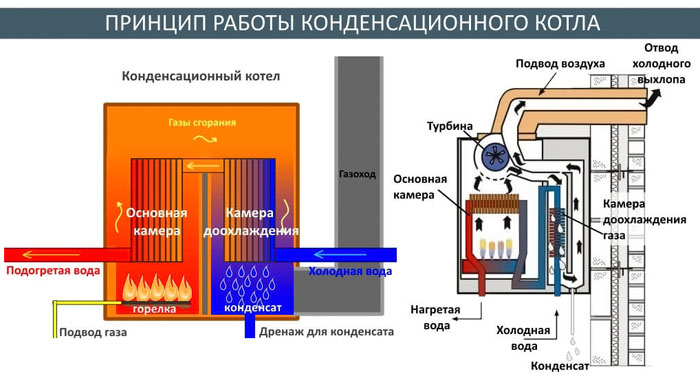

To improve performance, classic circuits are modified as follows:

For standard city apartments, fairly compact ones are better suited wall models. Floor modifications – more. They are used for heating large objects with an area of more than 150 square meters.

Related article:

The principle of operation, advantages and disadvantages, popular models and prices are in a special publication on our portal.

Purchasing a double-circuit wall-mounted gas boiler: how to choose the right model

The table shows data on current market offers.

| Image | Name | Power | price, rub. | Peculiarities |

|---|---|---|---|---|

| Aton AOGV MNE-7E | 7 | 14 200 - 15 400 | The simplest model with mechanical control and an injection type burner, without a circulation pump | |

| Electrolux GCB 11 Basic Space Fi | 11 | 32 800 - 33 600 | Modulating burner, connectivity external unit control using wireless technologies. | |

| Bosch ZWBR 35 | 10,2 | 99 800 - 105 300 | Condensing model equipped with a multifunctional electronics unit. It is used to connect solar collector, temperature control in rooms taking into account weather changes. |

It is difficult to find data to determine the rating of wall-mounted double-circuit gas boilers. The differences in model parameters are too great. It makes sense to select equipment to solve specific problems. Comparison of several options must be objective. So, the first option is cheaper. But the standard package does not include a pump to move water.

Installation and operation

The installation of equipment of this type must be approved by the municipal service gas industry. It is trusted by specialized specialists of an authorized service center. This will allow you to maintain the factory warranty and avoid making an accidental mistake.

The boiler is mounted at a distance from the walls and heating devices. Certain standards limit the slope of the chimney pipe and the method of connection to the power supply network. Some service companies provide regular equipment inspection services. Cleaning heat exchangers and other routine measures will help extend the life of the equipment and prevent emergency situations.

To apply open chamber combustion was as efficient as possible, the equipment is installed in the boiler room. A separate chimney is required to remove combustion products. Such a solution for equipping a standard city apartment will be associated with increased costs. In some situations it is completely impossible.

It is much easier to install a boiler with a closed chamber. Its installation can be approved by official authorities without much difficulty. The work operations themselves also don't cost much.

When choosing, you should pay attention to modern models. It provides better performance and interfaces well with the latest systems management and control category " smart House" For accurate calculations of the required power, in addition to the volume, the insulation characteristics of the premises should be taken into account. Comprehensive analysis gas wall-mounted double-circuit heating boilers should contain prices and consumer reviews.

Installing a gas boiler (video)

Turbocharged boiler is a heating unit used in systems with forced circulation coolant. Its distinctive characteristic is the presence of a closed combustion chamber and a coaxial chimney. The assortment of the TeploExpert online store includes boilers with a closed combustion chamber brands EVAN, RusNIT, ZOTA, ACV, Proterm, Ferroli, Vaillant, SAV, Savitr, Kiturami and others from Russian and foreign manufacturers. When purchasing from us, you receive a full range of services for the delivery and installation of heating units.

Advantages of boilers with a closed combustion chamber

A boiler with a closed combustion chamber has a number of advantages, including:

High performance. Coefficient useful action boilers with a closed combustion chamber is 90-95%, which indicates economical fuel consumption and the generation of a large amount of heat. Thus, you can significantly reduce the cost of purchasing or paying for fuel.

Use of outdoor air. Since the combustion chamber of turbocharged boilers is closed, air is taken from the street and not from the room.

Undemanding presence of a vertical chimney. To install these heating devices a conventional vertical chimney is not needed, since a coaxial pipe is used here. This ensures ease of installation of the boiler.

Safety. Thanks to the tightness of the combustion chamber, your safety is ensured when operating turbocharged boilers. Combustion products do not penetrate into the room.

Modern heating boilers provide heating of buildings and buildings, in particular city apartments, country cottages or dachas not connected to centralized system heat supply from CHP. In addition to its main task, many devices (double-circuit) are used as a boiler, heating running water. "Garantkomfort.ru" offers its customers to buy a boiler for heating their home. In this case, you can take advantage of the opportunity to deliver the boiler in Moscow to the specified address.

Types of heating boilers

By fuel used:

- solid fuel - used in buildings not connected to electrical and gas networks. The fuel is charcoal, firewood or peat. To install such equipment, a chimney is required;

- gas - cost-effective devices with high efficiency, which use as fuel natural gas. A chimney is required for correct operation;

- electric - modern, environmentally friendly boiler models for private homes that do not require a chimney. They are characterized by high energy consumption, so they are often backup source heat.

By number of circuits:

- single-circuit – only for space heating;

- double-circuit - to provide a private home with heat and hot water.

What to look for when choosing

Location. Available in wall mounted and floor options, each of which has certain advantages. The first ones are compact, which allows optimizing the use of free space in the room. They are fully equipped and do not require purchase additional elements. The latter are characterized by high performance and power, which is important for buildings with a large area. In this case, the price of heating boilers for a private home will be slightly higher.

Power. Heating installations can have different power, which must be taken into account when choosing equipment for your living space. The footage of the premises and the height of the ceilings should be clarified. Garantcomfort.ru specialists will help you select a heating boiler in Moscow - to do this, contact them by phone listed on the website.

Performance. When choosing a double-circuit heating boiler, you should determine the number of consumers. The recommended performance indicator of the water supply circuit depends on this. So, this parameter for a family of three will be about 10 l/min for one tap. To be able to use two sources of water at once, you should install a boiler for heating your home with a capacity of at least 15 l/min.

Security and automation systems

Built into modern heating boilers a large number of various systems security. Among the most common are the following:

- overheating protection – this module stops heating the coolant when the temperature reaches a critical value;

- Freeze protection – monitors the temperature of the coolant, preventing it from freezing;

- draft control system – checks the presence of draft in the chimney. If backdraft occurs, turns off the heating to prevent combustion products from entering the room;

- water pressure control – controls the pressure in heating system using a pressure switch.

You can check prices for heating boilers for a private home by calling the phone number listed in the “Contacts” section.