Repair of mounted boilers. In what cases is it possible to independently repair gas boilers?

Wall-mounted boilers came into use several decades ago and immediately gained popularity in the household market. heating devices. This is due to the fact that they are quite simple to install, they do not take up usable area dwellings are compact and economical. Average term Boiler service life is 20 years. And yet, due to insufficiently good quality of water, gas and voltage drops in the electrical network and other factors, boilers often fail earlier and require Maintenance and repairs.

Main types of gas boilers

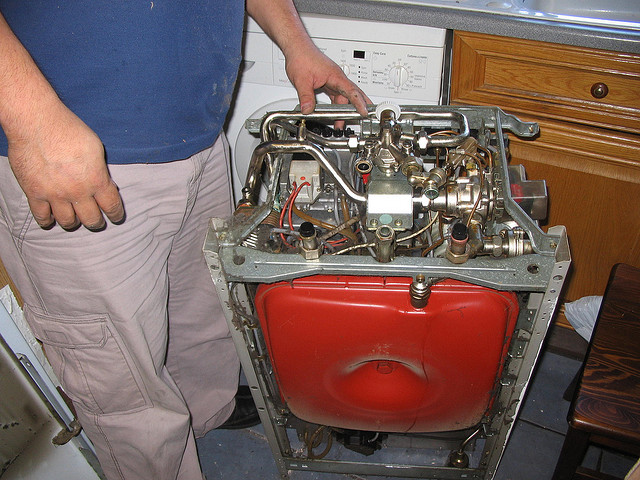

A modern wall-mounted gas boiler is a complex combined device that combines an electronic control system, electrical system ignition, electric pump and gas heating circuits.

Based on their capabilities, boilers are divided into single-circuit boilers - those that are only capable of providing heating and double-circuit boilers, in which there is a hot water supply circuit. Double-circuit boilers, in turn, are divided according to the type of water circuit heat exchanger into bithermal and plate boilers.

According to the type of draft, boilers are chimney boilers (with open camera combustion) and forced draft (with closed camera combustion).

How to repair gas wall boilers

Let's consider cases when it is possible do-it-yourself repair gas boilers:

- The first step is to record and sketch the readings of all instruments that are displayed on the front panel of the boiler. After this, it is necessary to assess the type and extent of damage.

- Next, you need to check the flame, which usually burns in standby mode. If you see that the reed has faded, then you are quite capable of fixing this problem. If your boiler does not have a special window, then, following the operating instructions and observing all safety rules when working with gas appliances, you will have to turn off the electricity, turn off the gas and water supply and carefully remove the front casing of the boiler. After this, try to understand the boiler circuit and determine the cause of the problem. Sensors and alarms will help you with this. You also need to check if your boiler is clogged.

- If you have a chimney boiler, check the chimney draft. Take a thin strip of paper and hold it up to the chimney. If there is no traction, the paper will not flutter. In this case, you need to seek help from the housing office as soon as possible or call a private chimney cleaning specialist.

- Check if the boiler is poisoning. To do this, just smell the air near it and determine if there is a smell of gas. Firstly, if the boiler or gas pipes are leaking gas, you will also need the help of a gas specialist. Secondly, this way you will know whether the sensors have spontaneously triggered.

- If the boiler gets very hot when turned on, its heat exchangers may be clogged. At the same time, overheating sensors are triggered and the boiler turns off. In this case, the boiler must be allowed to cool by turning it off. If the boiler continues to heat up when you turn it back on, you can try to wash the heat exchanger tube yourself with a chemical that can dissolve scale.

All other boiler malfunctions are more serious, so you should not try to eliminate them yourself. Contact service center for heating equipment maintenance or directly to the manufacturer. They will provide you with repairs to gas wall-mounted boilers in the event of a breakdown.

Ways to prevent gas boilers from failing

Electronic systems of gas boilers are very sensitive to voltage drops and surges. Install stabilizers before entering the boiler. Also install gas and water filters at the gas and water inlet to the boiler, respectively.

In a private home, the main place among household appliances is heating boilers . There comes a time when wall mounted boiler like another similar technical product, suddenly stops working. The owner is faced with the question: where and how to repair. Logic dictates that it would be better and with a guarantee to do such work in a specialized certified service.

But customer emotions prevail. Trying to save money leads to a private master, where an inexperienced repairman acts as a sort of ace of the matter. To make matters worse, invite a scammer home. Such “savings” on the service always result in additional costs and repair wall-mounted boiler adds up to a round sum.

There are no signs of anything when a desperate owner, unable to find a suitable boiler repair service, decides to fix the breakdown himself. Ends on your own wall-mounted boiler repair deplorable. IN best case scenario to no avail. At worst, the device is already Can not be repaired and you have to raise money to buy a new one. We recommend not to tempt fate and, at the first appearance of a malfunction, contact a specialist.

Repair of a wall-mounted gas boiler at the GazService company

The GazService company will help residents of Moscow and the Moscow region solve heating problems and repair a wall-mounted boiler at a professional level. We are available by phone every day, including holidays and weekends.

The company's specialized services employ trained engineers who have received specialized education and pass annual exams to improve their skills. Special diagnostic equipment is available. We install new official spare parts. with a technician visiting the installation site. The warranty period for the repaired part is 12 months.

Boilers are produced with design differences and dimensions. These are portable wall-mounted devices or stationary monsters, stuffed with sophisticated electronics. Sometimes even to an experienced master having specialized knowledge and experience in this matter, it is difficult to immediately determine the breakdown. We offer wall-mounted boiler repair with a professional approach:

- Visual inspection with determination of cost at the installation site;

- Troubleshooting with a work guarantee;

- Parts from official dealers of the manufacturer;

- Free call back due to the technician's fault.

You shouldn't take things to extremes. It's better to call your nearest one in advance. wall-mounted boiler repair service and sign maintenance contract necessary devices. The master periodically pays a visit and checks the condition. This approach and the conclusion of an annual contract will save you from constantly searching for masters.

Specialists will solve all problems

When purchasing a gas boiler, we most often think about the advantages of using it - the possibility of rationalizing heating and year-round hot water supply. Meanwhile, a gas boiler is a complex household appliance that works simultaneously with two energy sources - electricity and gas. Moreover, the latter, in the event of a malfunction of the boiler or gas pipeline, poses a considerable danger to both the life and health of the owners of the house, and to property. This is why regular maintenance of gas boilers is so important. Periodic inspection allows you to identify emerging problems and not bring the equipment to a state where its use can lead to dire consequences.

What is meant by gas boiler maintenance?

What should the capacious concept of “service” include to ensure safety and serviceability? gas boiler? The answer to this question largely depends on the complexity of the device and on what functions it performs - heating only, hot water supply only, or both. It also matters which protection systems and additional functions included in the design.

A complete list of necessary checks and the frequency of their implementation are usually indicated in the operating instructions on specific models boilers It is this document that should be used as a guide when concluding service contracts with a service organization. Be prepared for the fact that not everything specified in the instructions fits within the narrow framework of mandatory “free” procedures. Cunning operators perform some checks as additional services for an additional fee. Don't skimp. Ask them to also be included in the contract list. After all, not only the “weather in the house” depends on the serviceability of the boiler, but also the health of the people living in it.

Sample list of maintenance work

In the most general case, maintenance of gas wall-mounted boilers should include:

- Cleaning burners, during which you need to pay attention Special attention details that determine the intensity, composition and direction of the flame:

- retaining washer - a device that regulates the position of the burner torch and the degree of its contact with the heat exchanger

- the pipe supplying gas to the burner - it must be removed, disassembled, blown out and cleaned all parts, if necessary, replace failed filters and reinstall them

- flame sensor and ignition device electrodes

- air sensor responsible for the parameters of preparing the gas-air mixture

- Cleaning the combustion chamber, during which all parts of the boiler that are exposed to open flames during operation are freed from dirt.

- Checking the integrity of the structure, correct operation and, if necessary, adjusting the built-in hot water boiler (in storage models).

- Cleaning the gas supply and exhaust channels inside the boiler.

- Checking the chimney for contamination, which is usually done for a fee.

- Checking the built-in electronic devices that support the operation of the boiler.

- Adjustment of all adjustable units of the unit to set the parameters recommended by the manufacturer.

- Checking the composition of the gas in the combustion chamber. This is necessary to assess the compliance of the burner settings with the composition of the supplied gas, the completeness of its combustion and the amount of emitted carbon monoxide.

- Checking the serviceability of circuit breakers. During this test, various emergency situations are simulated and the operation of the corresponding devices is checked.

- Checking the tightness of the shut-off valve - the most important of the safety circuit breakers.

- Checking the integrity of the gas supply pipeline throughout the entire section located in an apartment or house and on an estate (in a private house) in order to identify and prevent damage to the gas pipeline. Particular attention is paid to the outer sections of pipes and their joints.

Don't experiment on your own

Don't do the repairs yourself

There is nothing complicated in the above list. And at first glance it may seem that anyone can cope with such work. But this impression is deceptive. The first signs of a boiler and gas pipeline not meeting certain requirements may escape the eyes and nose of an inexperienced person. And in the event of unforeseen situations, not everyone is able to react quickly and correctly, without causing irreparable consequences.

At the same time, the specialist is not only trained to find faults. He is also personally responsible for the quality of the inspection performed. This is confirmed by his signature in the boiler certification documents, which must be requested from him upon completion of the work.

We remind you that the service life and the health of your family depend on how well the service is carried out, and even more so.

Today systems have become very popular autonomous heat supply. The main component of such a system is the heat source. Most often this is a gas boiler. Such equipment has good quality and decent characteristics.

Modern boilers have their own protection system:

- Lack of traction;

- Burner goes out;

- Heat exchanger overheating.

If malfunctions occur, you can use the equipment only after they have been eliminated.

In some cases, repairs can be done yourself. But in order to prevent breakdowns from occurring, you need to observe and carry out:

- Operating rules;

- Preventive actions.

Compliance with these measures will allow you to operate the equipment for a long time without breakdowns.

Having heating system and hot water supply, you can fully experience the benefits self-adjustment temperature regime. But in order for operation to be completely safe and the services received to be of high quality, it is necessary to periodically repair the heating boiler.

What you need to know about the system design

Any heat generator can break down, this can happen for several reasons, for example:

- Damage expansion tank;

- The instructions and operating rules have been violated;

- Poor quality elements or components.

Whatever the malfunction, repairs must be carried out carefully and in accordance with established standards.

When repairing, you need to pay special attention to the serviceability of the sensors. For example, if a carbon monoxide sensor fails, there will be a high probability of inhaling dangerous gases.

Any master or person who decides to carry out repairs on their own should know what safety groups there are and what they consist of:

- Traction sensors along with plates. They are rated at seventy-five degrees. This device helps to monitor the state of drafts in the chimney or their exit into smoke eliminators. In the latter, the sensor heats up and triggers. It is best if a gas alarm is purchased in conjunction with this sensor;

- A monostat is installed to protect turbo boilers from poor removal of flue gases. May be due to a contaminated heat exchanger or chimney;

- Limit thermostat. It controls the water in the boiler. If it boils, the overheating sensor turns off the boiler;

- Ionization electrode. Installed to monitor the presence of flame. Often, repairing a heating boiler begins with checking the electrodes, because operating gas boilers without a flame can lead to an explosion;

- Burst valve. Serves to monitor pressure. At a pressure above 3 bar, the boiler discharges dangerous excess.

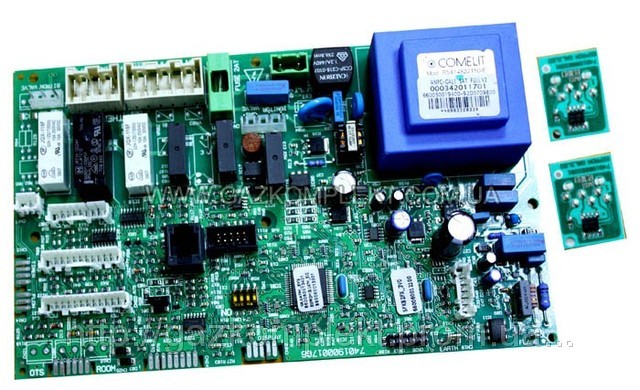

Fulfill renovation work Control boards can only be installed by specialists. Because they have the experience and the necessary equipment.

Important! In most cases, the control panel fails due to electrical surges, so care must be taken to install a voltage stabilizer.

The repair work itself for such boards is in most cases the same for all brands of manufacturers, but there may be slight differences. Therefore, there is no need to get into the “brains” of your boiler, as you can cause trouble.

Repair Notes

Never immediately supply full voltage to the equipment, because repairs of heating boilers may stop there due to failure of the automation and wiring.

For installation, you need to use only sensors that are correct for the job, as recommended by the manufacturer. Use stabilizers to avoid damaging wiring and sensors. Most manufacturers' instructions indicate all sorts of problems with the operation of the boiler and what errors it may show. Carefully studying the instructions is already half the battle!

Self-repair – important point, on the quality of which your life will depend. People have been studying this work for many years.

Do I need to do the repairs myself?

All heating boilers are complex systems. Their main danger is the use of explosive fuel. To control the operation of the heat source, automation is used. In addition to maintaining optimal performance it also signals problems with the equipment.

We agree with the opinion of experts and argue that boiler repairs should only be carried out by professionals, but in some cases (replacing a small unit) you can limit yourself to repairs yourself.

Let's look at the most common problem with flame loss. The reason for this may be:

- Damper clogged;

- Emergency valve activation.

To deal with the first reason, you need to make sure that the room does not smell of gas and check the chimney draft. In the event that flue gases enter the premises, it is prohibited to operate the equipment. You need to urgently contact a repair shop.

If the equipment overheats, then it is quite possible that the heat exchanger is dirty (you can find its photos and videos in our gallery) or the automation has failed. You need to ventilate the room well and seek help from specialists.

Important! If you smell gas in the room, turn off the boiler, turn off the gas and leave the room. In this case, repairs can only be performed by professionals.

Your actions:

- We wait until the boiler cools down and check the draft and the smell of gas;

- If there is draft and there is no smell of gas, we try to start the boiler;

- If the startup fails, then it is quite possible that the combustion sensor has broken down. There may also be contamination in the pipe through which the gas flows.

Bottom line

It is better not to repair the boiler yourself, because this can lead to serious consequences. It is best to have periodic inspections performed by professionals; the cost of these services is negligible.

There is hardly any need to explain why a breakdown of a heating generator in the middle of a frosty winter requires the most urgent measures to be taken. But the ability to quickly get help qualified specialist It is not always available and not for everyone. And not every breakdown is so serious that you have to pay a specialist to fix it. One way or another, the owner of a gas or solid fuel boiler It’s worth learning how to repair such equipment yourself, which our article will help you with.

What can happen to a gas boiler

Here are the most common failures in gas heaters:

Typical malfunctions of solid fuel boilers

These units usually have a simpler design, but they are not immune to breakdowns. Here's what can happen:

- The heat exchanger has leaked.

- A dirty puddle constantly appears near the boiler.

Another trouble: smoke poured into the room.

Troubleshooting instructions

Now let's see how to act in this or that case.

DIY gas boiler repair

So, let's look at ways to troubleshoot gas equipment.

The burner does not ignite or constantly goes out

Problems with the burner may be due to the following reasons:

With a draft, everything is clear - you need to close the window or door. Other points need to be considered in more detail.

A lack of oxygen is quite easy to identify: you need to open a window in the boiler room and see if the boiler operation stabilizes.

Volume of receipts fresh air may decrease for the following reasons:

- regular windows with wooden frames replaced with modern, more airtight ones;

- a door was installed in the boiler room, tightly blocking the opening (it matters if the air entered through the adjacent room).

The airtight door must either be cut from the bottom so that there is a gap of 20 mm wide, or replaced with one that has vent, usually closed with a decorative lattice. With sealed windows, things are more complicated: you need to install a supply valve. There are models that need to be embedded into the wall (you will have to punch a hole), but there are also devices for installation directly into the window, and for this you only need to cut out part of the seal.

If the boiler room is installed plastic window, you'll have to put supply valves to provide required quantity indoor air

Auto gas valve connected to several emergency sensors, which cause it to close in potentially dangerous situations. One of them - the flame sensor - is triggered when one of the events described above (burner extinguishment due to lack of air or strong draft).

In addition, sensors are installed in the boiler that block the gas supply under the following conditions:

- the pressure in the gas supply line has dropped;

- the draft in the chimney has worsened;

- the coolant temperature has exceeded the permissible value.

The pressure in the gas supply line may drop due to blockage mesh filter, so first of all you need to check its condition and clean it if necessary. Another bottleneck - gas meter, but it is impossible to eliminate the blockage in this device on your own - you need to call gas workers.

Pressure in the network may also drop due to excessive gas consumption, when the supplier does not have time to compensate for increased demands from consumers at the beginning heating season or during a sudden cold snap. All the user can do in such a situation is to call gas service and report your problem.

To check whether gas is supplied from the main line at the appropriate pressure, you need to do the following:

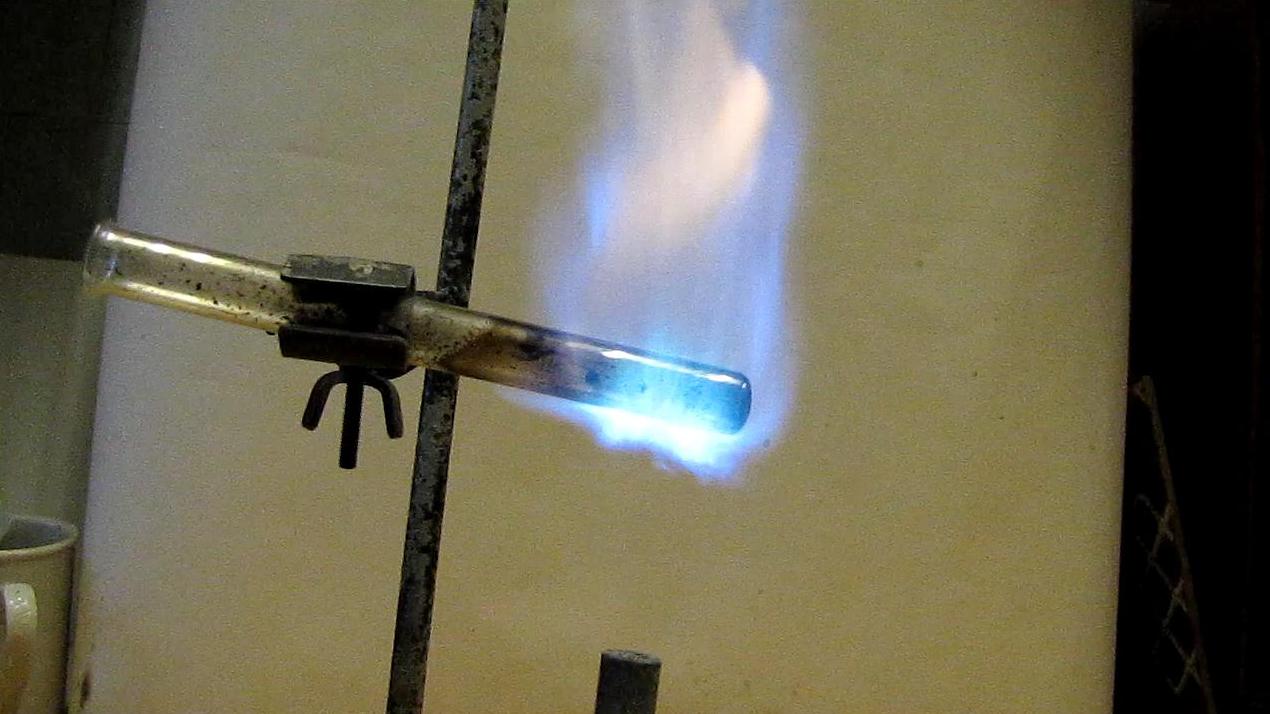

If the culprit for turning off the boiler is the draft sensor, you need to make sure that there is draft or not. To do this, you need to hold a match to the inspection window of the boiler or to the firebox and look at how the flame behaves.

The presence or absence of draft can be determined by the behavior of the flame from a lit match

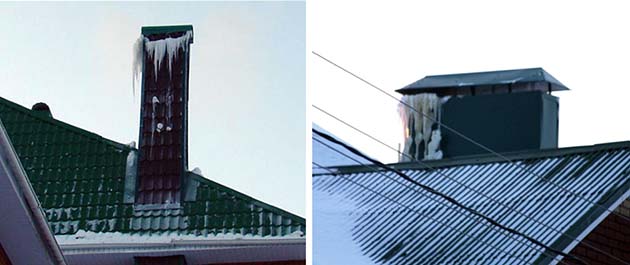

A decrease in the flow area of a chimney sometimes occurs due to the activity of birds that are trying to build a nest in it. But a much more common cause is condensation. The fact is that modern boilers are very economical, so their exhaust gas temperature is quite low.

Moving through the pipe, the flue gases have time to cool to the dew point, at which the water vapor they contain (water is formed by the oxidation of hydrogen present in the fuel) turns into condensate. If the chimney is made of brick, moisture can cause destruction of its walls, as a result of which the channel becomes clogged with fragments of masonry.

In inexpensive sandwich chimneys, the internal zinc coating may peel off, which also becomes an obstacle to the flue gases. Finally, condensed moisture can form an ice plug at the pipe head.

Traction may noticeably deteriorate due to the formation of an ice plug in the head of the pipe

The chimney, of course, needs to be brought into good condition. To clean it from debris, use different kinds brushes with extendable handles and a round steel ball on a cable called the core.

You cannot throw dumbbells, weights, or other heavy objects not intended for this purpose down the chimney instead of a real core. Their center of gravity is usually shifted, so they are more likely to turn unsuccessfully during a fall and get stuck in the canal.

It is better to invite a specialist to clean the chimney, since with a lack of experience the pipe can be seriously damaged.

The ice plug can be removed mechanically, or you can warm it up with gas burner, the nozzle of which must be inserted into the inspection hatch. In the future, at the first opportunity, you should insulate the chimney by wrapping it with glass or basalt wool(if the chimney is located externally, such insulation needs waterproofing).

However, it also happens that the chimney is in perfect condition, but the draft, meanwhile, clearly leaves much to be desired. This problem is usually due to one of two reasons:

- In the next room - usually a kitchen or bathroom - a powerful exhaust fan operates, drawing the air flow towards itself.

- A tall object appeared near the house (a building was built or trees grew), due to which the aerodynamic situation in the chimney area changed: the head of the chimney, in a certain wind direction, finds itself in a zone of support (increased pressure), which is why the draft deteriorates or even overturns .

A user who encounters such changes will have to extend the pipe, bringing its head above the newly appeared object.

Tall trees or recently constructed buildings may cause poor traction

Now let's consider a situation where the valve closed due to overheating of the coolant. This usually occurs due to the circulation pump stopping. Problems that you can fix yourself are air getting into the working chamber of the pump or sticking of its rotor. In the first case, you need to add water to the chamber to squeeze out air lock, in the second, the housing is disassembled (you need to unscrew the large screw in the center) and the rotor is turned by hand.

It should be taken into account that the safety automation can record the operation of the pump not directly, that is, using a flow sensor, but indirectly - by the pressure in the circuit. But the pressure can drop not only due to problems with the pump, but also due to the fact that the membrane expansion tank (at modern models boilers (it is built-in) did not pump in enough air.

The air pressure in the tank can be checked using a regular car pressure gauge: it should be 0.2 atm less than the operating pressure in the system. If necessary, air is pumped up with a conventional pump.

Air pressure in expansion tank can be checked with a pressure gauge and, if necessary, increased using a car pump

The electronic control module cannot be turned on

It is unlikely that an untrained person will be able to repair burnt electronics, but such troubles can be easily prevented. The fact is that the electronic filling, especially in imported boilers, is very sensitive to the quality of the power supply. Therefore, the voltage surges and dips characteristic of our networks quickly disable it. To protect the boiler, it must be connected through a voltage stabilizer.

The stabilizer protects the boiler electronics from voltage surges in the network

Some manufacturers require that the boiler be connected through a stabilizer, otherwise the user is denied warranty service.

Note that the incapacity of the electronic module does not indicate the need for serious repairs. Perhaps the fuse has simply blown. By the way, do not forget to check the circuit breaker in the panel - maybe it has turned off and now there is simply no power supplied to the boiler.

To check the fuses, you need to remove the front panel by unscrewing the screws holding it with a screwdriver (usually a Phillips head is required). The condition of the fuses is checked visually or using a multimeter. As a rule, manufacturers equip boilers with a spare fuse - glue it to inside front panel.

Electronics failure may be due to a completely banal reason: for almost all imported boilers, it matters which side the plug is connected to the phase. Before doing anything, take it out and turn it on again, turning it 180 degrees, and the heater may work properly.

Fan problems

Boilers with a closed chamber are not able to draw air into themselves due to natural traction- for this the fan must be running. If the latter cannot develop a sufficient rotation speed, the flame will go out due to lack of oxygen. Therefore, in turbocharged boilers, when the burner goes out, you should first check the ease of rotation of the fan and lubricate its bearings.

For this you can use the usual machine oil, but a special heat-resistant carbon-based composition is more suitable.

Igniter malfunctions

The igniter may go out even if the user holds the power button long enough. Problems of this kind indicate failure of the igniter thermocouple.

The thermocouple performs the function of protection against flame loss. If it fails, the boiler will not turn on.

Normally, this element, being well heated, should hold the valve open. There are two types of thermocouples:

- Electrical. They contain an element that transforms thermal energy V electricity. This current flows into a coil (solenoid) mounted on the valve, which draws in the locking mechanism core.

- Mechanical. Such thermocouples consist of a flask containing oil and a capillary tube connected to a valve. When heated, the oil expands and acts on the valve stem through a capillary tube.

If the electrical thermocouple fails, it makes sense to check the integrity of the wiring. The mechanical thermocouple can only be replaced.

If the gas burns with a yellow flame and popping noises are constantly heard, indicating interruptions in operation, it is necessary to clean the nozzle. To do this, you need to disassemble the gas burner device, which is strictly not recommended for a non-professional to do. If you still decide to do the cleaning yourself, pay maximum attention to safety issues:

Low performance of the DHW circuit and the inability of the boiler to sufficiently warm up the coolant

Such problems arise due to the deplorable state of heat exchangers. The main heat exchanger, connected to the heating system and washed by flue gases, becomes covered with soot over time, and it has heat-insulating properties. That is why the boiler, even working with all its might, cannot provide the proper coolant temperature.

Very little soot is formed in a gas boiler, so the heat exchanger has to be cleaned from it quite rarely - once every few years. The exact frequency is indicated in the instructions for the heater. Steel and cast iron heat exchangers can be cleaned wire brush, copper ones require a softer approach: use a dishwashing sponge.

Repairing a heat exchanger is a complex and expensive operation. It must be performed by a certified specialist

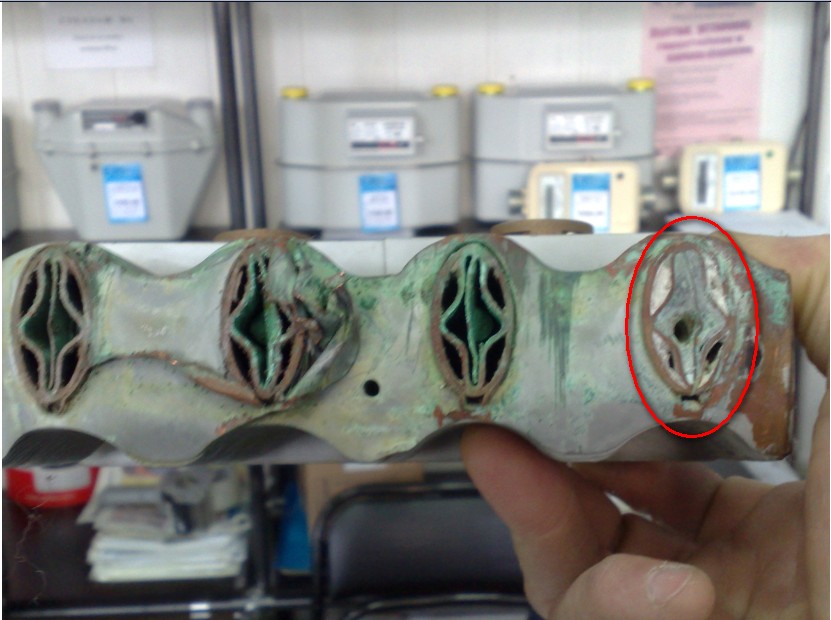

Another “damaging factor” is scale. The main heat exchanger almost never suffers from it, since the water used as a coolant is usually desalted. But according to the secondary heat exchanger, which is available in double-circuit boilers and is used for preparing hot water in flow mode, the most ordinary flows tap water. The hardness salts contained in it (calcium and magnesium salts) gradually crystallize, forming a loose heat-insulating layer - this is scale. The heat exchanger is a lattice of thin tubes, the flow area of which quickly decreases - that’s why hot water and it flows barely. If a scale plug has formed somewhere at the outlet of the secondary circuit, then the water in it will overheat due to low flow.

Due to the presence of salts in water, chemically active metals the heat exchanger channels become overgrown with scale and its operating efficiency decreases

If the water has increased hardness, it is recommended to carry out the descaling procedure annually. If the hardness index is close to moderate, washing can be performed less frequently - once every three years. To do this, you can use a solution of vinegar or citric acid, but special anti-scale compositions available on the market are more effective. In most cases, they are based on soda ash or inhibited hydrochloric acid.

Prepare effective remedy you can do it yourself: dilute in water hydrochloric acid, so as to obtain a solution with a concentration of 3-5%, and add for each liter 2 g of an anti-corrosion additive, for example, wood glue, Unicol, formaldehyde or methenamine. This composition is used as follows:

- Pour it into a container located 0.5–1 m above the heat exchanger and connected to it using a hose, after which washing begins. The washing time is from 8 to 10 hours.

- Next, rinse the heat exchanger with water.

- The next stage is alkalization: a 1% solution of soda, sodium phosphate and caustic soda is boiled in a heat exchanger for 10 hours.

Then the heat exchanger must be rinsed thoroughly with water again.

DIY solid fuel boiler repair

Repairing these units is often more difficult, which is determined by the peculiarities of the fuel combustion mode in the combustion chamber.

A solid fuel boiler, unlike a gas boiler, cannot be extinguished urgently - even after the air damper is completely closed, the flame will continue to burn for some time. Therefore, overheating of the coolant in such units is a fairly common occurrence. In case of boiling working environment A safety valve is installed in the boiler piping in the immediate vicinity, but it can fail: from long downtime the plate pressed by the spring sticks to the seat and the valve does not operate at the right moment.

The heat exchanger in a solid fuel boiler often overheats due to the fact that the fire cannot be extinguished instantly

As a result, excess pressure ruptures the heat exchanger. To prevent this from happening, you need to install a safety valve model with a special handle that allows you to open it forcibly. You need to open it at certain intervals when disabled circulation pump- then the plate will not stick.

Only a steel or copper heat exchanger can be repaired. The first one needs to be brewed thoroughly, the second one needs to be sealed. The cast iron heat exchanger will have to be replaced.

Puddle near the boiler

A lack of heat is just as likely as its excess: the user does not always have time to add a fresh portion of fuel in time. As a result, the coolant cools down, and if its temperature in the “return” drops to 55 o C or lower, the water vapor contained in the flue gases (water is formed during combustion, that is, the oxidation of hydrogen, regardless of the moisture content of the fuel) condenses on the relatively cold surface of the heat exchanger. This moisture appears in the form of a small puddle near the boiler.

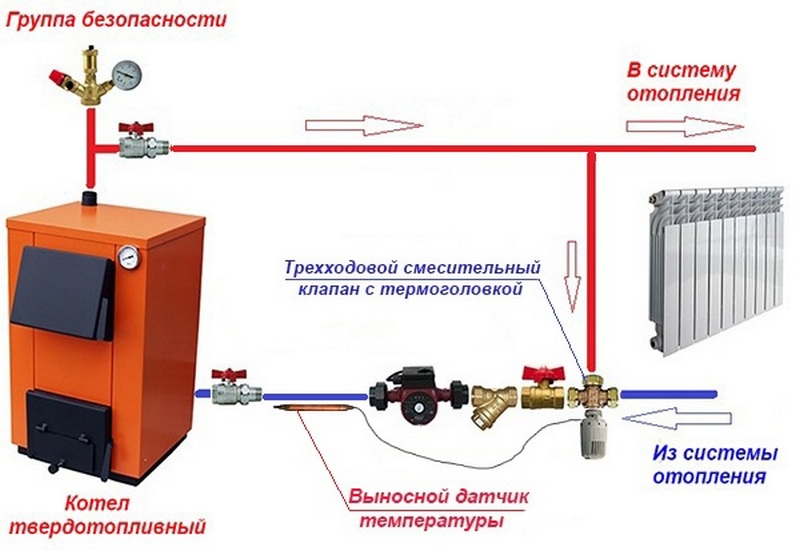

Condensation formed from flue gases is dangerous, and in the case of solid fuel- in particular: the oxides of various elements contained in the smoke, including sulfur, react with water and form an acid cocktail that corrodes the walls of the heat exchanger and poisons the air. To prevent the formation of condensation, it is imperative to install in the piping of a solid fuel boiler mixing unit: between the “supply” and “return” there is a bypass with a 3-way automatic valve.

The thermal head of the valve is connected to a temperature sensor installed on the “return”, so if it detects a temperature drop below a critical value, the valve will switch and pass a certain amount of hot coolant through the bypass into this part of the circuit.

The mixing unit prevents the formation of condensation when the coolant temperature drops

Smoke in the room

Another scourge of solid fuel boilers is soot. It is actively formed during the combustion of not only wet fuel, but also dry fuel, when the user reduces the intensity of combustion by closing the air damper. Due to a lack of oxygen, the fuel does not burn completely and unburned particles settle in the boiler and chimney in the form of soot. Bandwidth the chimney decreases and smoke begins to pour into the room.

But most of all, soot is dangerous due to its ability to ignite. Such an incident not only shortens the service life of the chimney, but can also lead to a fire in the entire house - a fire breaks out wooden elements, adjacent to hot walls chimney. Therefore, it is extremely necessary to promptly remove soot from both the chimney and the boiler. In addition to the mechanical cleaning agents described above, chemical ones are also used, for example, “Log” or “Chimney Sweep”.

Soot is removed from the walls of the boiler and chimney using special preparations, such as Chimney Sweep

The flue gases generated when burning such products contain substances that cause soot to fall off and prevent it from sticking to the walls of the chimney in the future. Some have a similar effect folk remedies, For example, potato peelings that are needed in large quantities(near the bucket) burn in the firebox.

The chimney should be cleaned of soot annually.

Boiler Maintenance

The durability and performance of the heater will depend on how competently and timely its maintenance is performed. WITH solid fuel boilers It's simple, you just need to do the following:

- annually clean the chimney of soot and promptly remove ash from the grate;

- periodically open the safety valve manually to avoid sticking of the plate;

- remove scale from the heat exchanger if untreated water is used (see above).

Servicing a gas boiler is a more complex process that requires the participation of a specialist. But it is desirable for the user to know which works must be carried out without fail, and which are imposed in order to unjustifiably inflate the cost of the service. A specific list of operations is set out in the instructions for the heater, but in general the following should be done:

On last stage an inspection of the gas pipeline section for which the customer is responsible is carried out. The tightness of connections is checked and areas damaged by corrosion are identified. If necessary, the pipeline is painted.

Video: DIY boiler repair

Despite all its complexity, a modern boiler can in some cases be repaired by an untrained user. It’s just important not to overestimate your capabilities and not take on work that you won’t be able to do. to an ordinary person. After studying our recommendations, you will know exactly when to pick up the tools and when to call the technician.