Temperature regulator for solid fuel heating boiler. Draft regulator for solid fuel boilers

Solid fuel boilers on wood, which allows you to heat the coolant for heating rooms, are becoming increasingly popular. This is due to the constant rise in price electrical energy, gas and oil products. Therefore, more and more are appearing on sale various models boilers burning wood, briquettes and charcoal. There are many videos about such boilers on the Internet.

Basic device information

However, there are also craftsmen who make heating systems using wood with their own hands. The most effective wood-burning heaters are.

Therefore, it is best to take a stove as a basis for a wood-burning boiler long burning and supplement it with the components necessary for heating the coolant. The main task solved during boiler operation is to effectively heat the coolant. But the coolant should not boil. To do this, in a homemade heating system you will need to install a self-made draft regulator. This essential device, without which a long-burning boiler will not be able to operate safely. Therefore, it is recommended that you watch the corresponding video on our website.

For the most efficient work The draft control device must be non-volatile and mechanical. This is required in order for the damper position to be mechanically adjusted, which regulates the air supply to the boiler furnace. When the controlled temperature increases, air supply is necessary. In this case, the long-term combustion process will slow down. And, vice versa - when the controlled temperature decreases, by opening the damper. To better understand the principle of operation of the regulator, you can watch the video on the pages of our website.

For mechanical control The damper will require a product that changes its dimensions quite well when the temperature changes. Most available material for these purposes, aluminum will most likely be used. If we take aluminum, for example, the tube will have a length of 1.5 m, then when heated to 130 degrees Celsius, the increase in length will be at least 4 mm. In the presence of aluminum tubes You can make a draft regulator only using a grinder and an electric drill.

The simplest draft regulator

Materials and supplies you will need:

- two aluminum pipes like ski poles;

- steel spring;

- steel sheet 3-5 mm thick;

- faucet - axle box, which can be removed from the old water mixer;

- a chain that can be removed from a bathroom stopper.

Progress:

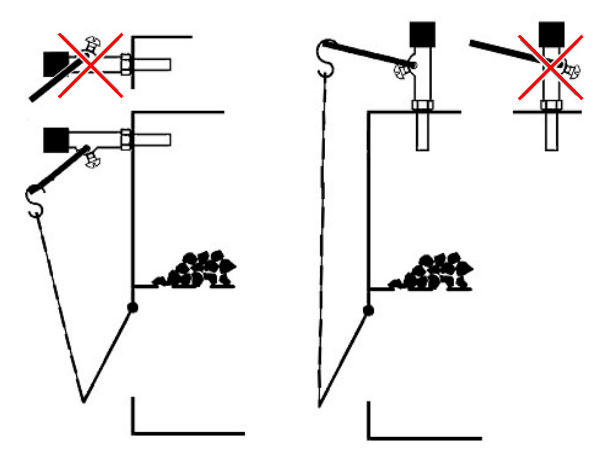

- Two tubes - upper and lower - are located close to the boiler wall.

- The upper tube is located between the first lever and the valve - axle box.

- The lower tube is located between the first lever and the second lever with a spring.

- A chain connects the second lever to the damper.

- The levers and faucet mounts are cut from a steel sheet using a grinder.

- The axis of the lever is located between the places where other parts are attached to the lever.

The resulting design works as follows:

- The tap sets the initial displacement of the tubes.

- The top tube heats up and expands.

- The first lever, pushed by the upper tube, rotates to a certain angle.

- The lower tube, pushed by the first lever, also heats up and elongates. At the same time, she pushes the second lever.

- The second lever turns and releases the chain stretched between the blower flap and the second lever.

- The flap is lowered.

Goal achieved – An increase in temperature leads to a decrease in air supply. However, the process of long-term combustion is most effective when the blower is coordinated with. To prevent the gas released from the wood, which then ignites, from entering the chimney too early, it is also necessary to regulate the flow of smoke in it. To do this, there must be an adjustable damper at the beginning of the chimney. If the ash damper opens and more air flows through it, the chimney damper should also open so that smoke passes through it faster.

Goal achieved – An increase in temperature leads to a decrease in air supply. However, the process of long-term combustion is most effective when the blower is coordinated with. To prevent the gas released from the wood, which then ignites, from entering the chimney too early, it is also necessary to regulate the flow of smoke in it. To do this, there must be an adjustable damper at the beginning of the chimney. If the ash damper opens and more air flows through it, the chimney damper should also open so that smoke passes through it faster.

In order for both dampers to move simultaneously, a force distributor is needed. The force distributor can be made of a thin cable stretched between the second lever and the damper in the chimney. A corresponding weight must be connected to the damper in the chimney, which will turn the damper when the cable is released. The cable can be used from a bicycle brake or gear shifter.

After the draft regulator has been made and tested, it would not be a bad idea to make instructions for its use. Now you can quickly and easily record a video, which will serve as instructions for viewing. This will allow someone other than the creator of the mechanism to operate the heating system correctly and therefore safely. Safety issues when operating any heating systems should be paramount.

Traction force can be considered a rather heterogeneous and complex concept that includes several factors. To guarantee stable operation of the equipment, this parameter must be maintained at a certain level. This applies to the functioning of any boiler equipment, because the deviation in draft force from standard indicators affects fuel combustion and energy generation.

Often violations occur during the installation of equipment that runs on solid fuel. You can cope with the problem using a draft regulator, which is used in conjunction with solid fuel boiler equipment.

Instead of a preface

Today high tech allow you to create different means automation, thanks to them, boiler equipment works independently, and there is almost no need to pay attention to it. But most of them use electricity, which is not very convenient. Along with power outages, the house is filled with cold; this situation cannot be called rare. The reason is the shutdown heating device automation.

However, on sale today you can find quite a lot simple remedies automation systems that do not require electricity to operate; this includes a draft regulator, which is used in conjunction with mechanically driven boilers.

Description of traction force

This parameter depends on many factors, including:

- weather;

- chimney section;

- gas temperature.

All this can affect the operation of the device, so specific conditions must be considered individually. Another parameter that may escape the attention of consumers, but has a great influence on traction force, is the type of equipment. Using gas device the traction force may vary slightly, but the final value is stable. This is due to the fact that the flue gases have almost the same temperature.

The deviation occurs only when the chimney warms up, and the value changes briefly. Solid fuel equipment shows different data. It is impossible to judge the influence of models on traction. This is due to the use different types fuel. The heterogeneity of indicators also depends on the variety

Design and description of operating principle

Installation of the draft regulator is quite simple, as is the design, as evidenced by the example of the RT 10 regulator, which consists of:

- handles;

- temperature corrector;

- rod;

- actuator;

- guide;

- housings;

- immersion sleeve;

- temperature sensitive element;

- springs;

- lever;

- chain drive;

- chains;

- handle fastening screw;

- lever securing screw.

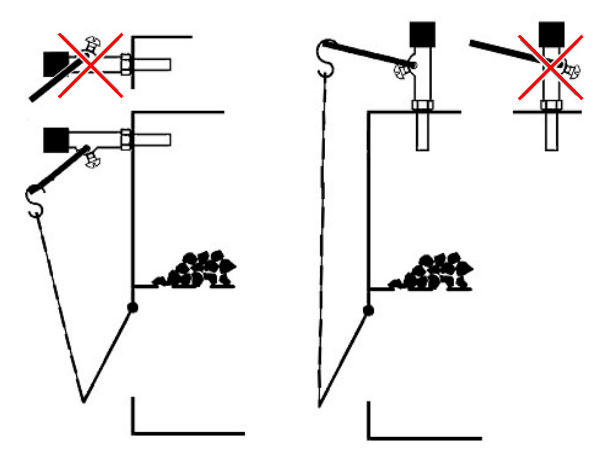

Depending on what boiler design is used, the regulator can be installed in different places. The main condition for this is that the immersion sleeve must be in contact with the coolant. It contains a heat-sensitive element that is filled with gas or liquid; it expands when heated. As soon as the water temperature begins to rise, the thermoelement will begin to act on the mechanism that releases the chain drive lever. The chain will cover the valve. The air supply in this way will be limited and the combustion intensity will be reduced. When the temperature of the water in the jacket drops, the thermoelement will open the door, which will resume the air supply.

Installation of the draft regulator

The draft regulator can be installed by you yourself. This element must be located in the front or side of the equipment. The device must be installed in a special hole. The installation work is carried out using screw connections that can be adjusted, this aligns the element in the correct position, which can be horizontal or vertical.

Once all the screws can be aligned, they need to be secured and sealed using special means. The lever must be installed in such a way that the hole through which the chain will come out is located above the damper. As soon as the draft regulator is installed, the boiler equipment can be heated and the coolant can be brought to 60 °C. This temperature should be set on the regulator. The regulator lever is connected using a chain, and the damper should be open approximately 2 mm or less. When calibrating the device, the damper must be closed; this must be done manually or by shortening the chain.

When installing the draft regulator, next stage need to install more high temperature- at around 80 °C. If the device is calibrated correctly, then when this indicator is reached, the damper will close automatically. A mechanical traction control is not as accurate as an automatic one, and the difference can reach 5 °C. Automatic devices can be installed on the boiler, and they will not require additional human intervention.

Carrying out the adjustment

The draft regulator for the boiler has two types of markings, which are used in different positions. If we are talking about the RT 10 device, then we can say that its red scale is used for working in a horizontal position, and the yellow one for working in a vertical position. You can adjust the product by disconnecting the lower end of the chain from the air damper. This loosens the screw. After choosing the scale color, you need to set the desired temperature value.

The heat generator ignites and warms up, during which the temperature of the coolant is controlled. As soon as the temperature level reaches the desired value, you should put the end of the chain on the ash pan door. When calibrating the chimney draft regulator, the chain must be tensioned and its free play should not be more than 1 mm. The handle is then secured with a screw.

Conclusion

Once the setting is complete, you should check the operation of the thermostatic regulator, and the temperature can be changed by moving the handle. The operator should compare the value with the thermometer readings.

Honeywell GmbH 21 MU1H-1515GE23 R0709

Description of work

The combustion regulator is designed to regulate the supply of combustion air. The built-in thermostat measures the temperature in the heat generator and, based on this, regulates the air supply of the solid fuel boiler using a lever using a chain by opening or closing the air damper.

1. Safety instructions

1. Follow installation instructions

2. Use according to

In accordance with the purpose

In good condition

In accordance with safety requirements and possible dangers

3. Use exclusively and exactly in accordance with these instructions. Any other use is considered unreasonable and will void the warranty.

4. Please note that all installation, commissioning, maintenance and repair work must be carried out by qualified personnel

5. Correct any problem that poses a safety risk immediately

2. Application

For heating systems in accordance with DIN 4751 with solid fuel and universal boilers.

The combustion regulator FR124 should not be used in particular in the following cases:

Explosive environment. In case of operation in explosive areas Sparking can lead to rapid flame spread, fire or explosions.

3. Specifications

Connection size G 3/4"

Immersion pipe length 53 mm

4. Scope of delivery

The combustion regulator consists of:

Tuning knob

Immersion sleeve

Linkage

Solid thermostat

Return spring

5. Delivery options

FR124-3/4A = standard version

6. Installation

6.1 Installation Guide

Horizontal or vertical installation position

Install a combustion regulator in the boiler water circulation

Install only the one intended for this purpose. threaded coupling

6.2 Installation instructions

1. Seal the threads with Teflon or hemp tape.

2. Screw the immersion pipe (G3/4 thread) into the boiler threaded coupling

3. Fix the linkage

4. Secure the chain to the linkage and air damper. The chain hangs freely and the linkage moves freely when the adjustment knob is turned

7. Commissioning

Combustion regulator calibration:

1. Light the boiler with the air supply damper manually open

2. Set the combustion control knob to 60T

3. When the water temperature reaches 60 C and remains stable, adjust the length of the chain so that the door remains open 2 mm.

Control range 30...90 C

Permissible sensor temperature max. 115 C

Temperature environment Max. 70 C at switch head

Connection size G 3/4"

Immersion pipe length 53 mm

8. Malfunctions and their elimination

|

|