Who invented the first steam engine in the world. History of steam engines. Invention of steam engines. Great discoveries.

The invention of steam engines became turning point in the history of mankind. Somewhere at the turn of the 17th-18th centuries, the replacement of ineffective manual labor, water wheels, and completely new and unique mechanisms began - steam engines. It was thanks to them that the technical and industrial revolutions, and indeed all the progress of mankind, became possible.

But who invented the steam engine? To whom does humanity owe this? And when was this? We will try to find answers to all these questions.

Even before our era

History of creation steam engine begins in the first centuries Heron of Alexandria described a mechanism that began to work only when steam acted on it. The device was a ball on which nozzles were attached. Steam came out of the nozzles tangentially, thereby causing the engine to rotate. This was the first device that was powered by steam.

The creator of the steam engine (or rather, the turbine) is Taghi al-Dinome (Arab philosopher, engineer and astronomer). His invention became widely known in Egypt in the 16th century. The mechanism was designed as follows: streams of steam were directed directly to the mechanism with blades, and when smoke poured out, the blades rotated. The Italian engineer Giovanni Branca proposed something similar in 1629. The main disadvantage of all these inventions was too much steam consumption, which in turn required huge amounts of energy and was not practical. Developments were suspended because the scientific and technical knowledge of mankind at that time was not enough. In addition, there was no need for such inventions at all.

Developments

Until the 17th century, the creation of a steam engine was impossible. But as soon as the level of human development soared, the first copies and inventions immediately appeared. Although no one took them seriously at that time. For example, in 1663, an English scientist published in the press a draft of his invention, which he installed in Raglan Castle. Its device served to lift water onto the walls of the towers. However, like everything new and unknown, this project was accepted with doubt, and there were no sponsors for its further development.

The history of the creation of a steam engine begins with the invention of the steam-atmospheric engine. In 1681, a French scientist invented a device that pumped water out of mines. As driving force At first, gunpowder was used, and then it was replaced by water steam. This is how the steam-atmospheric machine appeared. Scientists from England Thomas Newcomen and Thomas Severen made a huge contribution to its improvement. The Russian self-taught inventor Ivan Polzunov also provided invaluable assistance.

The history of the creation of a steam engine begins with the invention of the steam-atmospheric engine. In 1681, a French scientist invented a device that pumped water out of mines. As driving force At first, gunpowder was used, and then it was replaced by water steam. This is how the steam-atmospheric machine appeared. Scientists from England Thomas Newcomen and Thomas Severen made a huge contribution to its improvement. The Russian self-taught inventor Ivan Polzunov also provided invaluable assistance.

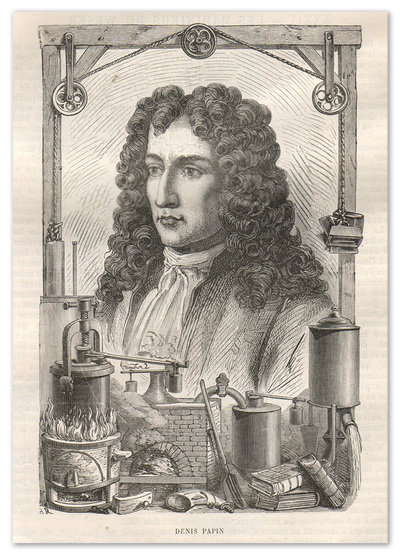

Papen's failed attempt

The steam-atmospheric machine, far from perfect at that time, attracted Special attention in the shipbuilding field. D. Papen spent his last savings on the purchase of a small vessel, on which he began installing a water-lifting steam-atmospheric machine of his own production. The mechanism of action was that, falling from a height, water began to rotate the wheels.

The inventor conducted his tests in 1707 on the Fulda River. Many people gathered to look at the miracle: a ship moving along the river without sails or oars. However, during the tests, a disaster occurred: the engine exploded and several people were killed. The authorities were angry with the unsuccessful inventor and banned him from any work and projects. The ship was confiscated and destroyed, and a few years later Papen himself died.

Error

The Papen steamship had the following operating principle. It was necessary to pour a small amount of water into the bottom of the cylinder. Under the cylinder itself there was a brazier, which served to heat the liquid. When the water began to boil, the resulting steam expanded and lifted the piston. Air was pushed out from the space above the piston through a specially equipped valve. After the water boiled and steam began to pour out, it was necessary to remove the fryer, close the valve to remove air, and use cool water to cool the cylinder walls. Thanks to such actions, the steam in the cylinder condensed, a vacuum formed under the piston, and thanks to the force of atmospheric pressure, the piston returned to its original place. During its downward movement useful work was done. However, the efficiency of Papen's steam engine was negative. The ship's engine was extremely uneconomical. And most importantly, it was too complex and inconvenient to use. Therefore, Papin's invention had no future from the very beginning.

Followers

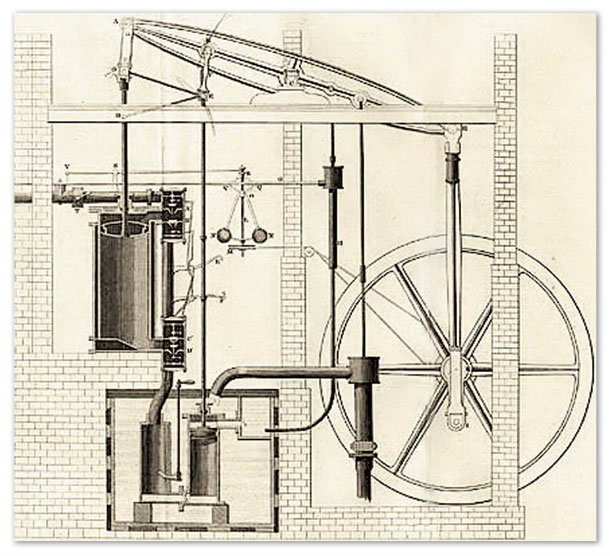

However, the story of the creation of the steam engine did not end there. The next, much more successful than Papen, was the English scientist Thomas Newcomen. He studied the works of his predecessors for a long time, focusing on weak spots. And taking the best of their work, he created his own apparatus in 1712. The new steam engine (photo presented) was designed as follows: a cylinder was used, which was in a vertical position, as well as a piston. Newcomen took this from Papin's work. However, steam was already formed in another boiler. Solid skin was fixed around the piston, which significantly increased the tightness inside steam cylinder. This machine was also steam-atmospheric (water rose from the mine using atmospheric pressure). The main disadvantages of the invention were its bulkiness and inefficiency: the machine “ate” great amount coal However, it brought much more benefits than Papen’s invention. Therefore, it was used for almost fifty years in dungeons and mines. It was used for pumping groundwater, as well as for drying ships. Thomas Newcomen tried to transform his car so that it could be used for traffic. However, all his attempts were unsuccessful.

The next scientist to announce himself was D. Hull from England. In 1736, he presented to the world his invention: a steam-atmospheric machine, which had paddle wheels as propulsion. His development was more successful than Papin's. Several such ships were immediately released. They were mainly used to tow barges, ships and other vessels. However, the reliability of the steam-atmospheric engine did not inspire confidence, and the ships were equipped with sails as the main propulsion device.

And although Hull was luckier than Papin, his inventions gradually lost relevance and were abandoned. Still, steam-atmospheric machines of that time had many specific shortcomings.

The history of the creation of the steam engine in Russia

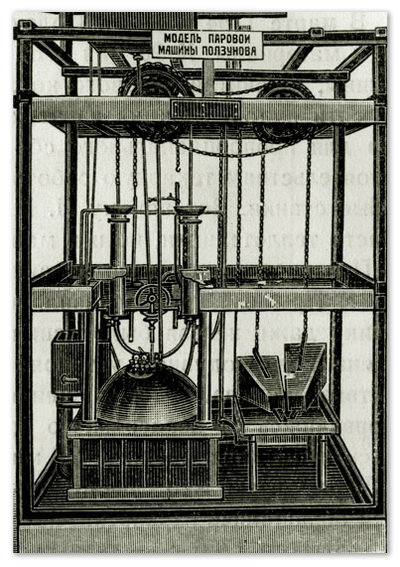

The next breakthrough came in Russian Empire. In 1766, the first steam engine was created at the metallurgical plant in Barnaul, which supplied air to the smelting furnaces using special blowers. Its creator was Ivan Ivanovich Polzunov, who was even given an officer rank for his services to his homeland. The inventor presented his superiors with drawings and plans for a “fire engine” capable of powering blower bellows.

However, fate played a cruel joke on Polzunov: seven years after his project was accepted and the car was assembled, he fell ill and died of consumption - just a week before testing of his engine began. However, his instructions were enough to start the engine.

So, on August 7, 1766, Polzunov’s steam engine was launched and put under load. However, already in November of the same year it broke down. The reason turned out to be too thin walls of the boiler, which was not intended for the load. Moreover, the inventor wrote in his instructions that this boiler can only be used during testing. The production of a new boiler would easily pay for itself, because the efficiency of Polzunov’s steam engine was positive. In 1023 hours of work, more than 14 pounds of silver were smelted with its help!

But despite this, no one began to repair the mechanism. Polzunov's steam engine gathered dust for more than 15 years in a warehouse, until the world of industry stood still and developed. And then it was completely dismantled for parts. Apparently, at that moment Russia had not yet matured enough to use steam engines.

Demands of the time

Meanwhile, life did not stand still. And humanity has constantly thought about creating a mechanism that would allow us not to depend on capricious nature, but to control our own destiny. Everyone wanted to abandon the sail as quickly as possible. Therefore, the question of creating a steam mechanism was constantly hanging in the air. In 1753, a competition was launched in Paris among craftsmen, scientists and inventors. The Academy of Sciences has announced a reward for anyone who can create a mechanism that can replace the power of the wind. But despite the fact that such minds as L. Euler, D. Bernoulli, Canton de Lacroix and others took part in the competition, no one came up with a viable proposal.

The years passed. And covered more and more more countries. Primacy and leadership among other powers invariably went to England. By the end of the eighteenth century, it was Great Britain that became the creator of large-scale industry, thanks to which it won the title of global monopoly in this industry. The issue of a mechanical engine became more and more pressing every day. And such an engine was created.

The first steam engine in the world

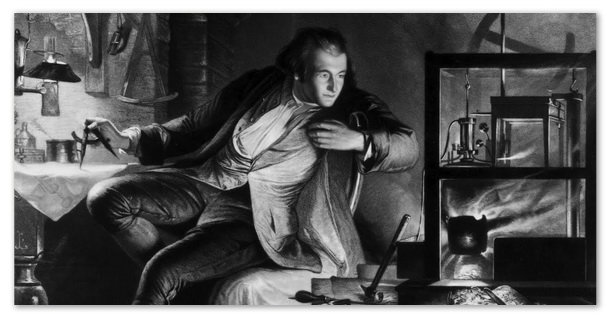

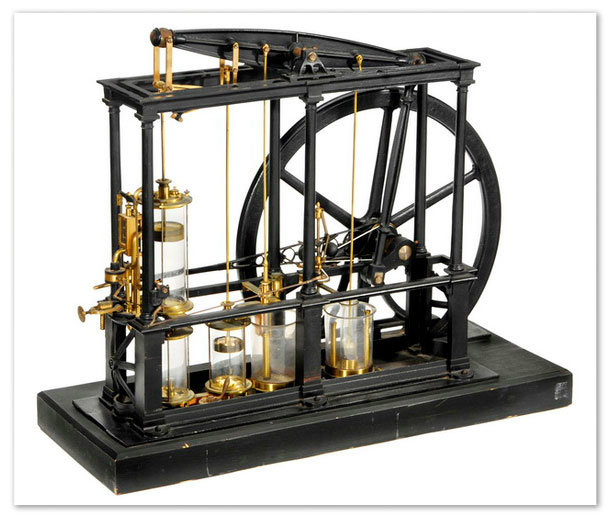

The year 1784 was a turning point for England and the world in the Industrial Revolution. And the man responsible for this was the English mechanic James Watt. The steam engine he created became the most famous discovery of the century.

For several years I studied the drawings, structure and operating principles of steam-atmospheric machines. And based on all this, he concluded that for the engine to operate efficiently, it is necessary to equalize the temperatures of the water in the cylinder and the steam that enters the mechanism. The main disadvantage of steam-atmospheric machines was the constant need to cool the cylinder with water. It was expensive and inconvenient.

The new steam engine was designed differently. So, the cylinder was enclosed in a special steam jacket. Thus Watt achieved his constant heated state. The inventor created a special vessel immersed in cold water(capacitor). A cylinder was connected to it by a pipe. When the steam was exhausted in the cylinder, it passed through the pipe into the condenser and there it turned back into water. While working on improving his machine, Watt created a vacuum in the condenser. Thus, all the steam coming from the cylinder was condensed in it. Thanks to this innovation, the process of steam expansion greatly increased, which in turn made it possible to extract much more energy from the same amount of steam. It was a crowning achievement.

The creator of the steam engine also changed the principle of air supply. Now the steam first fell under the piston, thereby raising it, and then collected above the piston, lowering it. Thus, both piston strokes in the mechanism became operational, which was not even possible before. And the coal consumption per horsepower was four times less than, respectively, that of steam-atmospheric engines, which is what James Watt sought. The steam engine very quickly conquered first Great Britain, and then the whole world.

The creator of the steam engine also changed the principle of air supply. Now the steam first fell under the piston, thereby raising it, and then collected above the piston, lowering it. Thus, both piston strokes in the mechanism became operational, which was not even possible before. And the coal consumption per horsepower was four times less than, respectively, that of steam-atmospheric engines, which is what James Watt sought. The steam engine very quickly conquered first Great Britain, and then the whole world.

"Charlotte Dundas"

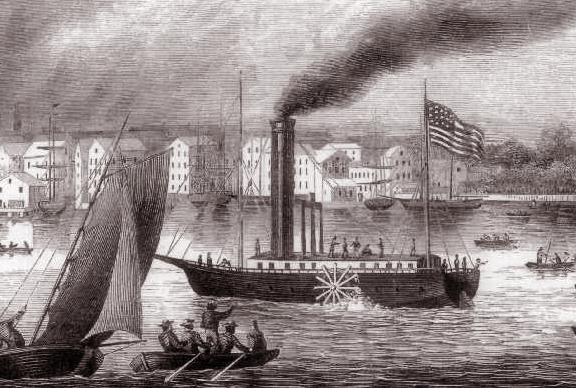

After the whole world was amazed by the invention of James Watt, the widespread use of steam engines began. So, in 1802, the first steam-powered ship appeared in England - the Charlotte Dundas. William Symington is considered its creator. The boat was used to tow barges along the canal. The role of propulsion on the ship was played by a paddle wheel mounted on the stern. The boat successfully passed tests the first time: it towed two huge barges 18 miles in six hours. At the same time, he was greatly hampered by the headwind. But he managed it.

And yet it was laid up because they were afraid that due to the strong waves that were created under the paddle wheel, the banks of the canal would be washed away. By the way, the man whom the whole world today considers the creator of the first steamship was present at the tests of the Charlotte.

The first steamship in the world

Since his youth, the English shipbuilder dreamed of a ship with a steam engine. And now his dream became realizable. After all, the invention of steam engines was a new impetus in shipbuilding. Together with the American envoy R. Livingston, who took over the material side of the issue, Fulton took up the project of a ship with a steam engine. It was a complex invention based on the idea of an oar propeller. Along the sides of the ship there were tiles in a row, imitating many oars. At the same time, the tiles kept interfering with each other and breaking. Today we can easily say that the same effect could have been achieved with just three or four panels. But from the standpoint of science and technology of that time, it was unrealistic to see this. Therefore, shipbuilders had a much more difficult time.

In 1803, Fulton's invention was presented to the whole world. The steamer moved slowly and evenly along the Seine, striking the minds and imagination of many scientists and figures in Paris. However, Napoleon's government rejected the project, and the disgruntled shipbuilders were forced to seek their fortune in America.

And so in August 1807, the world's first steamship called the Claremont, which was powered by a powerful steam engine (photo presented), sailed along Hudson Bay. Many then simply did not believe in success.

The Claremont set off on its maiden voyage without cargo and without passengers. No one wanted to travel on board a fire-breathing ship. But already on the way back, the first passenger appeared - a local farmer who paid six dollars for the ticket. He became the first passenger in the history of the shipping company. Fulton was so moved that he gave the daredevil a lifetime free ride on all his inventions.

People were able to put steam to the service of humanity only in the most late XVII century. But even at the beginning of our era, the ancient Greek mathematician and mechanic Heron of Alexandria clearly showed that one can and should be friends with steam. A clear confirmation of this was the Geronovsky aeolipile, in fact, the first steam turbine - a ball that rotated with the power of jets of water vapor. Unfortunately, many amazing inventions of the ancient Greeks were firmly forgotten for many centuries. Only in the 17th century is there a description of something similar to a steam engine. The Frenchman Salomon de Caus, who was at one time a builder and engineer for Frederick V of the Palatinate, in his essay dated 1615, described a hollow iron ball with two tubes: one receiving and one releasing liquid. If you fill the ball with water and heat it up, then through the second tube the water will begin to rise to the top, obeying the influence of vapors. In 1663, the Englishman Edward Somerset, Marquess of Worchester, wrote a brochure in which he spoke about a machine that could lift water upward. At the same time, Somerset received a patent (“privilege”) for the described machine. As we see, all the thoughts of the inventors of the New Age revolved around pumping water from mines and mines, which, it should be noted, stemmed from an urgent task. It is therefore not surprising that the next three inventors, discussed below, were also primarily concerned with creating a steam engine for pumping water. Towards the very end of the 17th century, two people in Europe worked more effectively on taming steam - Denis Papin and Thomas Savery.

Savery's "fire" car.

On July 2, 1698, the Englishman Savery received a patent for a machine for pumping water from mines. The patent stated: “Privilege is claimed to Thomas Savery for having alone tested a new invention for raising water, turning all kinds of mills by the forces of fire, which will be very important for draining mines, supplying cities with water and turning all kinds of mills.” Prototype Under the name "Fire engine" in 1699 it was exhibited at the Royal Scientific Society in London. Savery's machine operated in this way: a sealed tank was filled with steam, and then the outer surface of the tank was cooled cold water, causing the steam to condense, creating a partial vacuum in the tank. Then water from the bottom of the shaft was sucked into the tank through the intake pipe and, after a new portion of steam was introduced, it was pushed out through the outlet pipe. It is worth noting that Savery's invention was similar to Somerset's machine, and many believe that Savery was directly inspired by the latter. Unfortunately, Savery's "fiery" machine had its shortcomings. The most important of them is the inability to raise water from a depth of more than 15 meters, although at that time there were already mines whose depth exceeded 100 meters. In addition, the car consumed a lot of fuel, which was not justified even by proximity large quantity coal at the mine. The Frenchman Denis Papin, a physician by training, moved to London in 1675. Papen made several discoveries that forever inscribed his name in history. To begin with, Papen invents a pressure cooker - “Papen's Cauldron”. The former physician was able to establish the relationship between pressure and boiling point of water. A sealed boiler with a safety valve, due to the increased pressure inside, brought the water to a boil much later, so the processing temperature of the products increased and the latter were cooked many times faster. In 1674, Papin created a gunpowder engine: gunpowder was ignited in a cylinder, causing the piston inside the cylinder to move. One “batch” of gases was released from the cylinder through a special valve, and the other was cooled. A vacuum (albeit weak) was formed in the cylinder, and atmospheric pressure pushed the piston down. In 1698, Papin invented a steam engine using water that was heated inside a vertical cylinder - the resulting steam moved the piston upward. The cylinder was then cooled with water, the steam condensed and a vacuum was created. The same atmospheric pressure forced the piston down. Despite the progressiveness of his machine (the presence of a piston), Papin was unable to extract any significant dividends from it, since Savery patented a steam pump, and there were no other applications for steam engines at that time (although Savery’s patent indicated the possibility of “rotation mills"). In 1714, in the capital of the British Empire, Papen died in poverty and loneliness. Another Englishman, Thomas Newcomen, born in 1663, turned out to be much more successful. Newcomen carefully read the work of both Savery and Papin, which is why he was able to understand the weak points of the previous machines, while at the same time taking the best from them. In 1712, together with glassmaker and plumber John Calley, he built his first steam engine. It used a vertical cylinder with a piston, like Papin's machine. However, the steam was generated in a separate steam boiler, which was similar to the operating principle of Savery's "fire" engine. The tightness inside the steam cylinder was increased by a skin that was secured around the piston. Newcomen's machine was also steam-atmospheric, i.e. The rise of water from the mine was carried out under the influence of atmospheric pressure. It was quite bulky and “ate” a lot of coal. Nevertheless, Newcomen’s machine brought incomparably more practical benefits, which is why it was used in mines for almost half a century. In England, for example, it allowed the reopening of abandoned mines that were flooded with groundwater. And another striking example of the effectiveness of Newcomen’s machine - in 1722 in Kronstadt, in a dry dock, water was pumped out of a ship within two weeks, while with an outdated pumping system using windmills it would have taken a year. Despite all this, Thomas Newcomen did not receive a patent for his steam engine because of Savery's patent. The possibility of using Newcomen's steam engine to propel a vehicle was considered by designers, in particular, to drive a paddle wheel on a ship. However, the attempts were unsuccessful. James Watt had the opportunity to invent a compact but powerful steam engine. In 1763, Watt, a mechanic at the University of Glasgow, was given the task of repairing Newcomen's steam engine. During the repair process, Watt comes up with the following idea - the cylinder of the steam engine must be kept constantly heated, which will sharply reduce fuel consumption. All that remained was to understand how to condense the steam in this case. It dawned on Watt while he was taking his evening exercise near the laundries. Seeing clouds of steam trying to escape from under the boiler covers, the inventor suddenly realized that steam is a gas, and it must move into a cylinder with reduced pressure. Watt takes up the matter decisively. He uses a water pump and metal tubes, from which the pump will pump out water and steam, creating a reduced pressure in the latter, and this, from the tubes, will begin to be transferred to the working cylinder of the steam engine. For the power stroke, Watt uses steam pressure, thereby abandoning atmospheric pressure, which was a big step forward. For this purpose, to prevent steam from passing between the cylinder and the piston, a hemp rope soaked in oil was wrapped around the piston along special grooves. This method made it possible to achieve a fairly high tightness inside the steam cylinder. In 1769, Watt received a patent for "the creation of a steam engine in which the temperature of the engine will always be equal to the temperature of the steam, although the steam will be cooled to a temperature below one hundred degrees." In 1772, James Watt met industrialist Matthew Bolton. This rich gentleman bought and returned to Watt all his patents, which the unlucky inventor was forced to pawn for debts. With Bolton's support, Watt's work accelerated. Already in 1773, Watt was testing his steam engine; it performed the same function of a steam pump, but required much less coal. Seeing the obvious advantages of Watt's machine, Bolton opened a company with the inventor to produce steam engines, and in 1774 their production began in England. The sale of steam engines was going so well that Bolton wanted to build a new rolling shop, for which he asked Watt to create a special steam engine to drive rolling machines. Watt coped with the task brilliantly, and in 1781 he patented a steam engine “for moving around an axis for the purpose of driving other machines.” Thus, the first steam engine was born not to raise water from the bottom of mines, but to set machines in motion. Watt's new machine had a number of improvements. For example, a regulator for uniform rotation of the main shaft of a steam engine, as well as a planetary mechanism for creating circular motion. Watt invents the latter because the current patent does not allow him to use the crank mechanism. But in 1784, Watt still managed to obtain permission to use a crank mechanism in a steam engine. Thus, the world's first universal steam engine, created by Watt, began to drive industrial machines, heralding the advent of the era of steam engines. Very soon, steam will begin to move steamships and trains, thanks to which human life will radically change. The enormous merits of James Watt did not go unnoticed by posterity - in 1819, by order of the English Parliament, a marble monument was erected to the great inventor in Westminster Abbey. It is believed that the first steamboat was built by the American Robert Fulton in 1807 - his ship with a paddle wheel was called the Claremont. At first Fulton tried using steam to move the oars, but then turned to more good idea wheels. Fulton made his first voyage on the Claremont alone, since the residents of the surrounding area flatly refused to board the “devilishly” smoking vessel. But on the way back to Fulton, one brave man nevertheless got hooked, for which he received from the inventor the right to lifelong free travel on the Claremont. Then Fulton's ship's voyages became commonplace - the Claremont transported people along the Hudson River from New York to Albany, reaching a speed of about 5 knots (9 km/h). The first screw steamship was built in 1838 by the Englishman Francis Smith. The use of propellers instead of paddle wheels made it possible to significantly improve the performance of steamships. Auxiliary sails are gradually disappearing on steamships (remember that in 1819 the American steamship Savannah crossed Atlantic Ocean mostly with the help of sails), and by the beginning of the twentieth century, sailing ships themselves became history. The first steam locomotive was built by Briton Richard Trevithick. It was a steam-powered carriage moving on rails at a speed of 7 km/h and carrying a train weighing 7 tons. In 1804, a small railway was built in London to test the Trevithick steam locomotive. In our time, both steamships and steam locomotives have long become a historical curiosity, which, however, can be found in the most different countries. Thus, in Norway, on Lake Mjøs, the oldest paddle steamer in the world, the Skibladner, built back in 1856, still operates. In turn, steam locomotives are actively used in third world countries, which means that steam still faithfully serves humanity."Steam Cart" by Cugno.

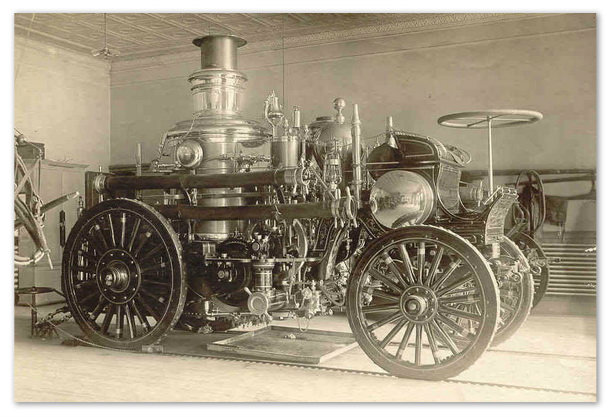

A separate milestone in the history of steam is steam cars. The first working steam car ("steam cart") was built by the Frenchman Nicolas-Joseph Cugot (Cugot) in 1769. It was a very heavy cart, weighing more than a ton, which two people could barely handle. Aesthetically, the car did not look very beautiful - the boiler, like a pot on a handle, was placed in front of the vehicle. Cugno's "cart" developed a speed of about 2-4 km/h and could carry up to 3 tons of cargo. It was difficult to operate - to maintain the steam pressure, which was rapidly falling, it was necessary to stop and light the firebox every quarter of an hour. In the end, on the next test drive, Cugnot and the fireman (by the way, fireman in French sounds like “chauffeur,” which is where the word “chauffeur” came from) suffered an accident on a sharp turn, causing the boiler to explode, causing noise throughout Paris. Cunho built a new “cart”, but it did not reach the masses. In 1794 it was handed over to the museum. Another Frenchman, Leon Serpollet, made a significant contribution to the development of steam engines. In 1875, he created a small but powerful steam car. Leon decided that it was better to heat the water not in a boiler, but in heated tubes, where it turns into steam very quickly. Serpolle's first working vehicle was a two-seater, three-wheeled carriage made of wood. At first, the police forbade the Frenchman to travel even at night, but in 1888 they finally gave in and issued an official document with permission to travel. Serpollet did not stop there. Instead of coal, he begins to use liquid fuel, which is supplied to two burners. In 1900, he opened a company together with the American Frank Gardner - Gardner-Serpollet. In 1902, Serpollet created a racing steam car and set a world land speed record with it in Nice - 120.77 km/h. It is not surprising that at that time steam cars competed quite successfully with their gasoline and electric counterparts. The first ones flourished especially in the USA, where, for example, in 1900, 1690 steam, 1585 electric and only 936 gasoline cars were produced. Steam cars were used in the USA until the 1930s. In the first half of the 19th century, steam tractors were also built, in particular with caterpillar tracks. However, the coefficient useful action steam engines accounted for only 5%. For this reason, at the beginning of the twentieth century, steam engines in cars were replaced by engines internal combustion. With their help, cars have become more economical, lighter and faster. It is impossible not to mention other, less successful uses of steam at the end of the 19th and beginning of the 20th centuries. The widespread use of steamships, steam locomotives and steam cars prompted inventors to think that steam could be used in aviation and the army. Alas, steam was not useful in these areas. Although by the middle of the 19th century there were several attempts to create airplanes with a steam engine. The Englishman William Henson built the Ariel Steam Carridge, which had a 25-30 hp steam engine that powered propellers with a diameter of 3.05 m. To reduce the weight of the machine, the conventional boiler was replaced by a conical vessel system using an air condenser. In 1844-1847, Henson tested his airplanes without success. They all ended unsuccessfully. But already in 1848, John Stringfellow finally built an airplane that took off from the ground, although not for long. The apotheosis of “ferry mania” in the aircraft industry was the airplane of Hayrem Stevens Maxim, which had a steam engine with a power of 360 hp and could be compared in size to two-story house. It is not surprising that Maxim’s airplane collapsed overnight, like all man’s dreams of conquering the air with the help of steam. Although, we note that in 1896, the American Samuel Pierpont Langley nevertheless built an airplane with a steam engine, which flew for about a kilometer without a pilot until it ran out of fuel. Langley called his creation an “airfield” (translated from ancient Greek as “running in the air”). However, by the beginning of the 20th century, it was clear to everyone that bulky steam engines were not suitable for aeronautics, especially since by this time gasoline engines had proven themselves excellent in airplanes - on December 17, 1903, the famous Wright Brothers airplane, equipped with a gasoline engine, appeared in the sky. Things were no better with steam in the army. But Leonardo da Vinci himself described a cannon that fired projectiles with the force of only fire and water. The great Florentine suggested that a long copper barrel with a core, placed in a furnace at one end, could eject a projectile if a little water was injected into the compartment behind the core when the tube became very hot. Leonardo believed that water at such a high temperature would evaporate very quickly and, becoming an analogue of gunpowder, would push the cannonball out at great speed. It is worth noting that the idea of the steam gun is attributed to Archimedes. The ancient manuscripts mention that during the siege of Syracuse in 212 BC, Roman ships were fired from cannons. But there was no gunpowder in Europe then! And Leonardo da Vinci suggested that Archimedes, whose devices defended Syracuse, had steam cannons. The Greek engineer Ionis Sakkas decided to test this idea of da Vinci. He built a wooden cannon, to the back of which was attached a boiler heated to 400°C. As suggested by Leonardo da Vinci, water was supplied to a special valve, which, evaporating instantly, burst into steam into the barrel, causing the concrete core in Sakkas’s experiments to fly away to a distance of 30-40 m. Students from MIT and participants in the television series “MythBusters,” although without the success of Sakkas. In the 19th century, steam was again used, but it was not possible to create a truly combat-ready weapon (a cannon or a machine gun). In 1826-1829, the Russian engineer-colonel of the Railway Corps A. Karelin manufactured a copper 7-line (17.5 mm) experimental steam gun. Shooting was carried out with ball bullets using water vapor, the rate of fire reached 50 rounds per minute. But the tests carried out in 1829 did not impress the “selection committee”, which considered the gun too complicated for use in the field. At the end of this article, it is impossible not to mention steampunk (English: "steampunk", from "steam" - "steam" and "punk" - "protest"). This direction of science fiction describes the era of a couple of times Victorian England(second half of the 19th century) and early capitalism (beginning of the 20th century). Cityscapes, characters, public moods, etc. are described accordingly. The term itself appeared in 1987. The steampunk genre gained popularity after the appearance of the novel “The Difference Engine” by William Gibson and Bruce Sterling (1990). The forerunners of steampunk can be called Jules Verne and Grigory Adamov. IN last years Many steampunk films have appeared, the most famous of which are “Wild Wild West” (1999), “The Time Machine” (2002), “The League of Extraordinary Gentlemen” (2003) and “Van Helsing” (2004). Dieselpunk is chronologically adjacent to steampunk - a genre that describes the technological world of the 20-50s of the 20th century, very close, it should be noted, to the technoworld of the early 20th century.Steam engine- an external combustion heat engine that converts steam energy into mechanical work the reciprocating movement of the piston, and then into the rotational movement of the shaft. In a broader sense, a steam engine is any external combustion engine that converts steam energy into mechanical work.

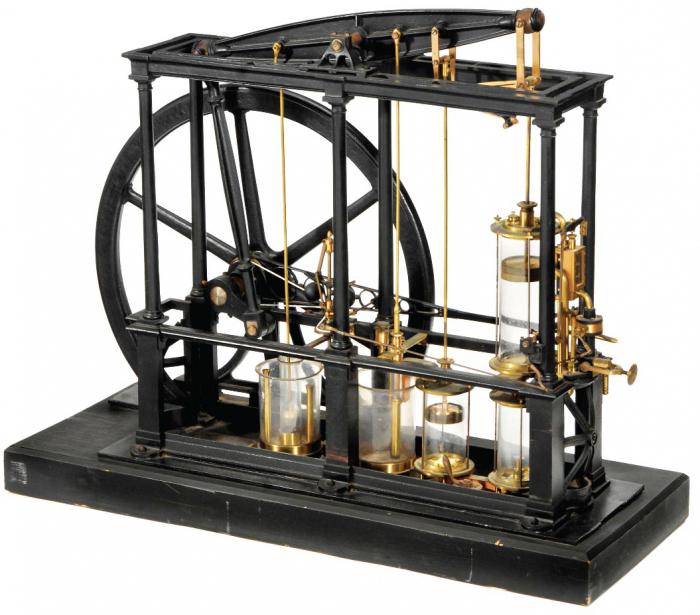

Horizontal stationary two-cylinder steam engine for driving factory transmissions. End of the 19th century Exhibit of the Museum of Industrial Culture. Nuremberg

The importance of steam engines

Steam engines were used as a driving engine in pumping stations, locomotives, on steam ships, tractors, steam cars and other vehicles. Steam engines contributed to the widespread commercial use of machines in enterprises and were the energy basis of the industrial revolution of the 18th century. Later steam engines were supplanted by internal combustion engines, steam turbines and electric motors, which were more efficient.

Steam turbines, formally a type of steam engine, are still widely used to drive electricity generators. Approximately 86% of the world's electricity is generated using steam turbines.

Operating principle

To drive a steam engine, a steam boiler is required. The expanding steam presses on the piston or on the blades of the steam turbine, the movement of which is transmitted to others mechanical parts. One of the advantages of external combustion engines is that, due to the separation of the boiler from the steam engine, almost any type of fuel can be used - from dung to uranium.

Invention and development

The first known device powered by steam was described by Heron of Alexandria in the first century. Steam escaping tangentially from the nozzles attached to the ball caused the latter to rotate. The actual steam turbine was invented much later, in medieval Egypt, by the 16th-century Arab philosopher, astronomer and engineer Taghi al-Dinome. He proposed a method of rotating a spit by means of a stream of steam directed to blades attached to the rim of a wheel. A similar machine was proposed in 1629 by the Italian engineer Giovanni Branca for rotating a cylindrical anchor device, which alternately raised and released a pair of pestles in mortars. The steam flow in these early steam turbines was not concentrated, and most of its energy was dissipated in all directions, resulting in significant energy losses.

However, further development of the steam engine required economic conditions, in which engine developers could benefit from their results. Such conditions did not exist either in ancient times, or in the Middle Ages, or in the Renaissance. It was only at the end of the 17th century that steam engines were created as one-off curiosities. The first machine was created by the Spanish inventor Jeronimo Ayans de Beaumont, whose inventions influenced T. Severi's patent (see below). The principle of operation and application of steam engines was also described in 1655 by the Englishman Edward Somerset. In 1663 he published a design and installed a steam-powered device for lifting water onto the wall of the Great Tower at Raglan Castle (the recesses in the wall where the engine was installed were still visible in the 19th century). However, no one was willing to risk money on this new revolutionary concept, and the steam engine remained undeveloped. One of the experiments of the French physicist and inventor Denis Papin was to create a vacuum in a closed cylinder. In the mid-1670s in Paris, he collaborated with the Dutch physicist Huygens on a machine that forced air out of a cylinder by exploding gunpowder in it. Seeing the incompleteness of the vacuum created by this, Papen, after arriving in England in 1680, created a version of the same cylinder, in which he obtained a more complete vacuum using boiling water, which condensed in the cylinder. Thus, he was able to lift a weight attached to the piston by a rope thrown over a pulley. The system worked as a demonstration model, but to repeat the process the entire apparatus had to be dismantled and reassembled. Papin quickly realized that to automate the cycle, the steam had to be produced separately in the boiler. Therefore, Papin is considered the inventor of the steam boiler, thus paving the way for Newcomen's steam engine. However, he did not propose the design of a functioning steam engine. Papin also designed a boat propelled by a wheel with reactive power in a combination of Taghi-al-Din and Severi's concepts; he is also credited with inventing many important devices eg a safety valve.

None of the devices described have actually been used as a means of solving useful problems. The first steam engine used in production was " fire installation", designed by the English military engineer Thomas Savery in 1698. Severi received a patent for his device in 1698. It was a piston steam pump, and obviously not very efficient, since the heat of the steam was lost each time during cooling of the container, and quite dangerous to operate, since due to high pressure steam tanks and engine pipelines sometimes exploded. Since this device could be used both to rotate the wheels of a water mill and to pump water out of mines, the inventor called it “the miner’s friend.”

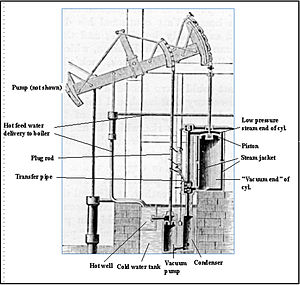

Then the English blacksmith Thomas Newcomen demonstrated his “atmospheric engine” in 1712. It was an improved Severi steam engine, in which Newcomen significantly reduced operating pressure pair. The first use of the Newcomen engine was to pump water from a deep mine. In a mine pump, the rocker arm was connected to a rod that went down into the shaft to the pump chamber. The reciprocating movements of the thrust were transmitted to the pump piston, which supplied water upward. It was Newcomen's engine that became the first steam engine to receive widespread practical use, with which the beginning of the industrial revolution in England is usually associated. Russia's first two-cylinder vacuum steam engine was designed by mechanic I. I. Polzunov in 1763 and built in 1764 to drive blowers at the Barnaul Kolyvano-Voskresensk factories. A further increase in efficiency was the use of high-pressure steam (American Oliver Evans and Englishman Richard Trevithick). R. Trevithick successfully built industrial high-pressure single-stroke engines known as "Cornish engines". They operated at a pressure of 50 pounds per square inch, or 345 kPa (3.405 atmospheres). However, with increasing pressure, there was also a greater danger of explosions in machines and boilers, which initially led to numerous accidents. From this point of view, the most important element high pressure machine was safety valve, which released excess pressure. Reliable and safe operation began only with the accumulation of experience and standardization of procedures for the construction, operation and maintenance of equipment. French inventor Nicolas-Joseph Cugnot demonstrated the first working self-propelled steam vehicle in 1769: the fardier à vapeur (steam cart). Perhaps his invention can be considered the first car. The self-propelled steam tractor turned out to be very useful as a mobile source of mechanical energy that drove other agricultural machines: threshers, presses, etc. In 1788, a steamboat built by John Fitch was already providing regular service along the Delaware River between Philadelphia (Pennsylvania) and Burlington (New York State). It carried 30 passengers and traveled at a speed of 7-8 miles per hour. On 21 February 1804, the first self-propelled railway steam locomotive, built by Richard Trevithick, was on display at the Penydarren Ironworks in Merthyr Tydfil in South Wales.

Reciprocating steam engines

Reciprocating engines use steam power to move a piston in a sealed chamber or cylinder. The reciprocating action of the piston can be mechanically converted into linear motion piston pumps or in rotational motion to drive rotating parts of machine tools or wheels of vehicles.

Vacuum machines

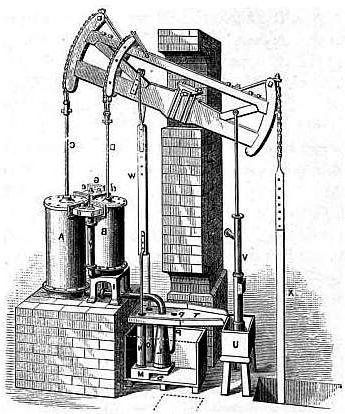

Engraving of Newcomen's engine. This image is copied from a drawing in Desagliers's A Course in Experimental Philosophy, 1744, which is a modified copy of an engraving by Henry Beaton dated 1717. This is probably Newcomen's second engine, installed around 1714 at Grief Colliery in Warkshire.

Early steam engines were first called "fire engines" and also Watt's "atmospheric" or "condensing" engines. They worked for vacuum principle and are therefore also known as "vacuum engines". Such machines worked to drive piston pumps, in any case, there is no evidence that they were used for other purposes. When a vacuum-type steam engine operates, at the beginning of the stroke, low-pressure steam is admitted into the working chamber or cylinder. The inlet valve then closes and the steam cools by condensing. In a Newcomen engine, cooling water is sprayed directly into the cylinder and the condensate drains into a condensate collector. This creates a vacuum in the cylinder. Atmospheric pressure at the top of the cylinder presses on the piston and causes it to move downward, that is, the working stroke.

The piston is connected by a chain to the end of a large rocker arm, which rotates around its middle. The pump under load is connected by a chain to the opposite end of the rocker arm, which, under the action of the pump, returns the piston to the top of the cylinder by gravity. This is how the reverse happens. The steam pressure is low and cannot counteract the movement of the piston.

Constantly cooling and reheating the working cylinder of the machine was very wasteful and inefficient, however, these steam engines made it possible to pump water from greater depths than was possible before their introduction. In 1774, a version of the steam engine appeared, created by Watt in collaboration with Matthew Boulton, the main innovation of which was the removal of the condensation process into a special separate chamber (condenser). This chamber was placed in a bath of cold water, and was connected to the cylinder by a tube closed by a valve. A special small vacuum pump(a prototype of a condensate pump), driven by a rocker arm and used to remove condensate from the condenser. The resulting hot water was supplied by a special pump (a prototype of the feed pump) back to the boiler. Another radical innovation was the closing of the upper end of the working cylinder, which now contained low pressure steam at the top. The same steam was present in the double jacket of the cylinder, supporting it constant temperature. As the piston moved upward, this steam was transferred through special tubes to the lower part of the cylinder in order to undergo condensation during the next stroke. The machine, in fact, ceased to be “atmospheric”, and its power now depended on the pressure difference between the low-pressure steam and the vacuum that could be obtained.

Watt's version of the steam engine

In Newcomen's steam engine, the piston was lubricated with a small amount of water poured on top of it; in Watt's machine, this became impossible, since there was now steam in the upper part of the cylinder; it was necessary to switch to lubrication with a mixture of grease and oil. The same lubricant was used in the cylinder rod seal.

Vacuum steam engines, despite the obvious limitations of their efficiency, were relatively safe and used low-pressure steam, which was quite consistent with the general low level of boiler technology in the 18th century. The power of the machine was limited by low steam pressure, the size of the cylinder, the rate of fuel combustion and evaporation of water in the boiler, as well as the size of the condenser. The maximum theoretical efficiency was limited by the relatively small temperature difference on both sides of the piston; it made vacuum machines designed for industrial use, too big and expensive.

Around 1811, Richard Trevithnick needed to improve Watt's machine in order to adapt it to the new Cornish boilers. The steam pressure above the piston reached 275 kPa (2.8 atmospheres), and it was this that provided the main power to complete the working stroke; In addition, the capacitor was significantly improved. Such machines were called Cornish machines, and were built until the 1890s. Many old Watt machines have been restored to this level. Some of Cornish's cars were quite large.

High pressure steam engines

In steam engines, steam flows from the boiler into the working chamber of the cylinder, where it expands, exerting pressure on the piston and making useful work. The expanded steam can then be released to the atmosphere or supplied to a condenser. An important difference between high-pressure machines and vacuum machines is that the pressure of the exhaust steam exceeds or is equal to atmospheric pressure, that is, a vacuum is not created. The exhaust steam usually had a pressure above atmospheric pressure and was often discharged into chimney, which made it possible to increase the boiler draft.

The importance of increasing steam pressure is that it becomes more high temperature. Thus, a high pressure steam engine operates at a greater temperature difference than can be achieved in vacuum machines. After high-pressure machines replaced vacuum ones, they became the basis for the further development and improvement of all reciprocating steam engines. However, the pressure that was considered high in 1800 (275-345 kPa) is now considered very low - the pressure in modern steam boilers is tens of times higher.

An additional advantage of high pressure machines is that they are much smaller for a given power level and therefore significantly less expensive. In addition, such a steam engine could be light and compact enough to be used on vehicles. The resulting steam transport (steam locomotives, steamships) revolutionized commercial and passenger transportation, military strategy, and generally affected almost every aspect of public life.

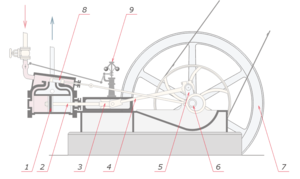

Diagram of a horizontal single-cylinder high-pressure, double-acting steam engine. Power take-off is carried out by the drive belt:

1 - Piston2 - Piston rod

3 - Slider

4 - Connecting rod

5 - Crankshaft

6 - Eccentric for valve drive

7 - Flywheel

8 - Spool

9 - Centrifugal regulator.

Double acting steam engines

Next important step In the development of high-pressure steam engines, the appearance of double-acting machines began. In single-acting machines, the piston moved in one direction by the force of expanding steam, but it returned back either under the influence of gravity or due to the moment of inertia of a rotating flywheel connected to the steam engine.

In double-acting steam engines, fresh steam is alternately supplied to both sides of the working cylinder, while the spent steam on the other side of the cylinder is released to the atmosphere or to a condenser. This required creating enough complex mechanism steam distribution. The double-acting principle increases the machine's operating speed and improves smoothness.

The piston of such a steam engine is connected to a sliding rod extending from the cylinder. A swinging connecting rod is attached to this rod, driving the flywheel crank. The steam distribution system is driven by another crank mechanism. The steam distribution mechanism may have a reverse function so that you can change the direction of rotation of the machine flywheel.

A double-acting steam engine is approximately twice as powerful as a conventional steam engine, and can also operate with a much lighter flywheel. This reduces the weight and cost of the machines.

Most reciprocating steam engines use precisely this principle of operation, which is clearly seen in the example of steam locomotives. When such a machine has two or more cylinders, the cranks are installed at a 90-degree offset to ensure that the machine can be started in any position of the pistons in the cylinders. Some wheeled steamers had a single-cylinder, double-acting steam engine, and on them it was necessary to ensure that the wheel did not stop at a dead point, that is, in a position in which starting the engine was impossible.

Interest in water vapor accessible source energy, appeared along with the first scientific knowledge ancient. People have been trying to tame this energy for three thousand years. What are the main stages of this path? Whose thoughts and projects have taught mankind to make the most of it?

Prerequisites for the emergence of steam engines

The need for mechanisms that can facilitate labor-intensive processes has always existed. Until about the middle of the 18th century, they were used for this purpose. windmills and water wheels. The possibility of using wind energy directly depends on the vagaries of the weather. And to use water wheels, factories had to be built along the banks of rivers, which is not always convenient or practical. And the effectiveness of both was extremely low. A fundamentally new engine was needed, easily manageable and devoid of these disadvantages.

History of the invention and improvement of steam engines

The creation of a steam engine is the result of much thought, success and disappointment of many scientists.

The beginning of the way

The first, isolated projects were just interesting curiosities. For example, Archimedes designed a steam gun, Heron of Alexandria used steam energy to open the doors of ancient temples. And researchers find notes on the practical use of steam energy to drive other mechanisms in the works Leonardo da Vinci.

Let's look at the most significant projects on this topic.

In the 16th century, the Arab engineer Taghi al Din developed a design for a primitive steam turbine. However practical application it did not receive due to the strong dispersion of the steam jet supplied to the turbine wheel blades.

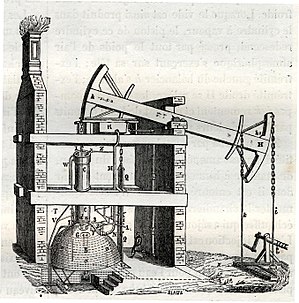

Let's go back to medieval France. Physicist and talented inventor Denis Papin, after many unsuccessful projects, settled on the following design: a vertical cylinder was filled with water, above which a piston was installed.

The cylinder was heated, the water boiled and evaporated. The expanding steam lifted the piston. It was fixed at the top point of the rise and the cylinder was waited for to cool and the steam to condense. After the steam condensed, a vacuum formed in the cylinder. The piston, freed from its fastening, rushed into the vacuum under the influence of atmospheric pressure. It was this fall of the piston that was supposed to be used as a working stroke.

So, the useful stroke of the piston was caused by the formation of a vacuum due to steam condensation and external (atmospheric) pressure.

Because Papen's steam engine like most subsequent projects, they were called steam-atmospheric machines.

This design had a very significant drawback - repeatability of the cycle was not provided. Denis comes up with the idea of producing steam not in a cylinder, but separately in a steam boiler.

Denis Papin entered the history of the creation of steam engines as a very important detail- steam boiler.

And since steam began to be produced outside the cylinder, the engine itself became an external combustion engine. But due to the lack of a distribution mechanism ensuring uninterrupted operation, these projects have found almost no practical application.

A new stage in the development of steam engines

For about 50 years, it was used to pump water in coal mines. Thomas Newcomen steam pump. It largely repeated previous designs, but contained very important new items - a pipe for removing condensed steam and a safety valve for releasing excess steam.

Its significant disadvantage was that the cylinder had to be either heated before steam injection, or cooled before it condensed. But the need for such engines was so high that, despite their obvious inefficiency, the last copies of these machines served until 1930.

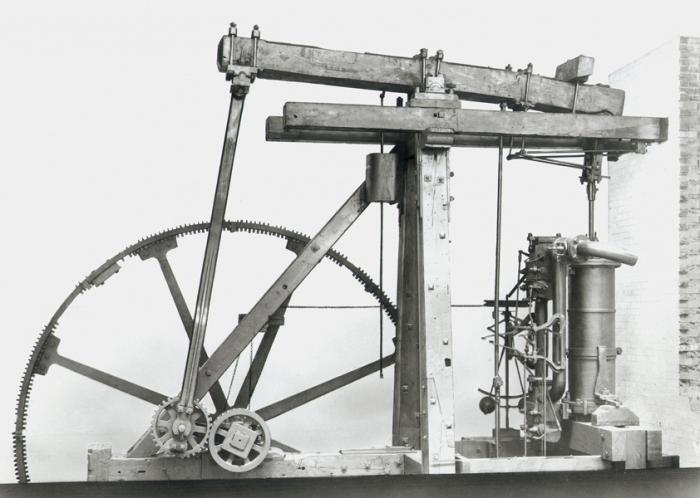

In 1765 English mechanic James Watt, having started improving Newcomen's machine, separated the condenser from the steam cylinder.

It became possible to keep the cylinder constantly heated. The efficiency of the machine immediately increased. In subsequent years, Watt would significantly improve his model, equipping it with a device for supplying steam on one side or the other.

It became possible to use this machine not only as a pump, but also to drive various machines. Watt received a patent for his invention - the steam engine continuous action. Mass production of these machines begins.

TO early XIX century, more than 320 Watt steam engines operated in England. Other European countries began to purchase them. This contributed to significant growth industrial production in many industries both in England itself and in neighboring countries.

Twenty years earlier than Watt, the Altai mechanic Ivan Ivanovich Polzunov was working on a steam engine project in Russia.

The factory management invited him to build a unit that would drive the blower of the smelting furnace.

The machine he built was two-cylinder and ensured continuous operation of the device connected to it.

After successfully operating for more than a month and a half, the boiler leaked. Polzunov himself was no longer alive by this time. The car was not repaired. And the wonderful creation of the lone Russian inventor was forgotten.

Due to the backwardness of Russia at that time the world learned about the invention of I. I. Polzunov with a great delay...

So, to operate a steam engine, it is necessary that the steam produced by the steam boiler expands and presses on the piston or turbine blades. And then their movement was transmitted to other mechanical parts.

The use of steam engines in transport

Despite the fact that the efficiency of steam engines of that time did not exceed 5%, by the end of the 18th century they began to be actively used in agriculture and on transport:

- a steam-powered car appears in France;

- in the USA, a ship begins to operate between the cities of Philadelphia and Burlington;

- a steam-powered railway locomotive was demonstrated in England;

- A Russian peasant from the Saratov province patented a 20-horsepower caterpillar tractor he built. With.;

- Attempts have been made several times to build a steam-powered aircraft, but, unfortunately, low power These units, given the large weight of the aircraft, made these attempts unsuccessful.

By the end of the 19th century, steam engines, having played their role in the technical progress of society, were giving way to electric motors.

Steam devices in the 21st century

With the advent of new energy sources in the 20th and 21st centuries, the need to use steam energy again arises. Steam turbines are becoming an integral part of nuclear power plants. The steam that powers them is obtained from nuclear fuel.

These turbines are also widely used in condensing thermal power plants.

In a number of countries, experiments are being conducted to produce steam using solar energy.

Piston steam engines have not been forgotten either. In mountainous areas as a locomotive Steam locomotives are still used.

These reliable workers are both safer and cheaper. They do not need power lines, and fuel - wood and cheap coal - are always at hand.

Modern technologies make it possible to capture up to 95% of atmospheric emissions and increase efficiency to 21%, so that people have decided not to part with them for now and are working on a new generation of steam locomotives.

If this message was useful to you, I would be glad to see you

To convert the energy of water vapor into mechanical work. The first double-acting steam engine, in which steam was supplied alternately from one side or the other of the piston, was built by J. Watt in 1784. The main part of a steam engine is a cylinder in which a piston with a rod moves under the influence of steam. Next to the cylinder there is a steam distribution box - a spool box communicating with the steam boiler, condenser and cylinder through two windows. The box contains a spool - a switch that provides alternating steam supply from one side or the other of the piston. As a result, the piston and rod perform a reciprocating movement, which is converted into rotational movement of the crankshaft using a crank mechanism. It consists of a slider connected to the rod, a connecting rod and a crank, which, in turn, is connected to the crankshaft. Switching of the spool is ensured using a feedback lever connected at one end to the spool and at the other end to the crankshaft eccentric. This creates a difference in steam pressure in the right and left parts of the cylinder, which sets the piston in motion. It is unprofitable to release waste steam into the atmosphere, since it still contains a lot of thermal energy. To increase the efficiency of the steam engine, a condenser was used - a water-cooled vessel in which the exhaust steam was condensed (turned into water). At the same time, the pressure in the condenser dropped below atmospheric pressure. This significantly increased the pressure difference acting on the piston in the cylinder. Water from the condenser was sent back to. This made it possible to create closed system"boiler - steam engine", in which chemical organic fuel was first converted into thermal energy water vapor, and then into the mechanical energy of rotation of the steam engine shaft.

The steam engine was the first and last. 19th century practically the only universal engine. She played an exceptional role in the progress of industry and transport. It was used to drive machine tools in factories, factories, electric current generators at power plants, wheels of steam locomotives, propellers of steamships, etc. The efficiency after various improvements did not exceed 20%. In the 20th century The steam engine was replaced by much more economical steam turbine And internal combustion engine.

1 – cylinder; 2 – piston; 3 – rod; 4 – slider; 5 – bed; 6 – flywheel; 7 – spool; 8 - ; 9 – connecting rod; 10 – crankshaft

Encyclopedia "Technology". - M.: Rosman. 2006 .

See what a “steam engine” is in other dictionaries:

Big Encyclopedic Dictionary

A piston engine that converts the thermal energy of steam into mechanical energy. work. Being the earliest representative of heat engines, P. m. since the time of the so-called. Watt's second machine (1784), continuously improved, found the widest application... ... Technical railway dictionary

Steam engine- - [A.S. Goldberg. English-Russian energy dictionary. 2006] Energy topics in general EN steam engine ... Technical Translator's Guide

Steam engine- STEAM ENGINE, a thermal piston engine for converting the energy of compressed hot water steam into mechanical work. Steam entering the cylinder of a steam engine moves the piston and cools. Continuous steam engine project... ... Illustrated Encyclopedic Dictionary

An external combustion heat engine that converts the energy of steam into mechanical work of the reciprocating movement of the piston, and then into the rotational movement of the shaft. In a broader sense, a steam engine is any external combustion engine ... Wikipedia

Thermal piston engine for converting the energy of water vapor into mechanical work. Steam entering the cylinder of a steam engine moves the piston. The design of a continuous steam engine was developed by I. I. Polzunov (1763). How… … Encyclopedic Dictionary - primary piston engine, in addition to potential. the energy of compressed water vapor is converted into mechanical energy. work (see figure). Up to the end. 19th century P. m. was practically unified. a common engine in industry and transport. Development of P. m.... ... Big Encyclopedic Polytechnic Dictionary