Eliminating cracks in the floor. Repairing a wooden floor in an apartment and eliminating squeaks with your own hands

To lay new flooring, the floor itself must be sanded and smooth. Along with repairing or replacing floorboards, you will likely need to seal cracks and holes in plank floors, as well as remove roughness and, possibly, combat dampness of monolithic concrete floors. Any uncorrected flaws may ultimately affect the quality flooring and damage it.

Filling holes in wood floors

Holes from buried nails and screws can be easily filled with elastic putty for wooden surfaces using a spatula for this. If you plan to leave your plank floors bare and scrub them with appropriate cleaners, try matching the putty or sealant to the color of the wood the floorboards are made from; At the same time, apply a layer of putty after each floor sanding cycle.

Deeper depressions can also be eliminated with elastic putty, but if a knot has fallen out of the board, leaving behind a large round hole, insert a short wooden plug into it, having previously smeared it with glue, and then clean out this place with a plane. Match the corks to the color of the floor or paint over them after cutting them flush with the floor.

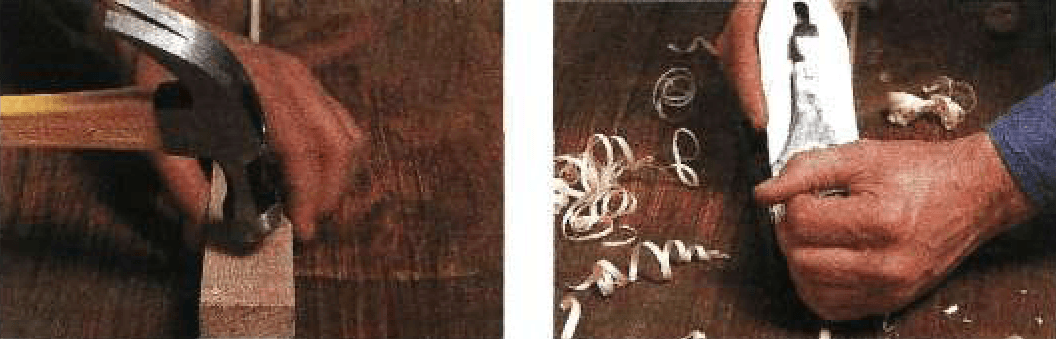

You'll find two main types of gaps in plank floors: gaps from cracked ends along the edges of the boards and gaps between the boards themselves. Such cracks can most often be eliminated by tightening them with nails: one nail must be driven into each edge of the board near the end and further into the beam at an angle to its center. As you drive in the nails, these cracks should disappear.

Eliminating gaps between boards is more difficult. If they are not wide, you can use wood putty; however, for wider gaps you will have to prepare thin slats and hammer them, after covering them with glue, into the resulting gaps. When the glue has dried, plane or sand the edges of the slats protruding above the floor; if necessary, paint over the installed wedges.

If there are many wide gaps between the floorboards, the most The best decision- lift all the boards in turn, starting from one side of the room and ending with the other. Special clamps will help you put the boards back in place by holding them together while you nail or screw them in place.

Sealing cracks in the floor. To seal wide gaps, hammer glued strips between the boards. When the glue has dried, use a plane to plane the edges of the slats that protrude above the floor.

To fill holes left when nail heads or screws are driven in, use flexible wood putty. When sealing a crack at the end of a board, first fill it with glue, then tighten it by hammering nails near the end.

Leveling a wooden floor

Separate uneven areas floors can be sanded by hand - which is what you did after using putty - however, where the floorboards have formed depressions or thick layer old paint, fat and mastic, the most the best way out- borrow an industrial grinding machine and re-scrape the floor. Start sanding the floor with a coarse sanding belt, then gradually move to a finer abrasive, aiming the machine across the boards. Finish sanding by going along the floorboards with a fine-grit sandpaper.

For hard-to-reach surfaces, also rent a special sander (if you don't have a belt sander), since the sander won't reach areas of the floor directly next to the baseboards.

Sealing cracks and holes in monolithic concrete floors

In the event that the monolithic floor as a whole is in good condition and dry, you can repair cracks and holes using a quick-setting repair mortar. Before this, it is necessary to remove all unbound particles from the cracks, and, if necessary, clean the edges of the cracks to provide the solution with a surface for setting. The edges of cracks and holes must be treated with a PVA solution (white) in a combination of one part glue to five parts water to reduce the absorbent properties of concrete and help the solution absorb into the floor.

For cooking cement mortar use PVA glue and water in the same ratio as a base; then cover the cracks with the resulting solution, and apply two or more layers to areas with large depressions. Level the surface with a spatula.

To help the freshly prepared mixture “adhere” to the edges of the crack, brush them with a solution of PVA (white). Apply a layer of quick-setting repair mortar for cracks in monolithic concrete floor. Rub the solution onto the damaged surface and leave it to harden. If the floor surface is excessively porous, apply an insulating layer of PVA adhesive solution with a brush.

Leveling monolithic concrete floors

It doesn't take much skill to create a smooth, flat surface because the self-leveling floor compound will do the job for you. There are two types of such a mixture: these are dry powders that must be diluted either in water or in a special latex (synthetic substance used for the production of adhesives, paints, foam rubber) emulsion.

Before you start pouring, clean the room and remove doors and baseboards. Attach slats (shingles) with nails along the entire length of the thresholds to prevent unwanted spreading of the mixture. Treat all cracks and holes with a depth of more than 6 mm with a solution of PVA and water, as described earlier. Dilute the self-leveling mixture in a bucket of water and pour it onto the floor, then level the resulting layer with a spatula or plaster trowel. Give time for the mixture to settle. As soon as it dries - after at least 24 hours - you can install skirting boards and doors; However, make sure that the door does not touch the floor when opening: you may have to trim the bottom slightly.

Dilute the self-leveling floor mixture according to the manufacturer's instructions. Start filling the floor with the mixture from the corner farthest from the door. Using a plaster trowel, level the layer of mixture to a thickness of 3 mm.

Sealing cracks in wooden floor is required in cases where the boards have dried out over the course of their long use and some floorboards have begun to creak. Since wooden floors have been used for centuries, during this time many ways to repair them have been invented, and with the advent of new materials, the possibilities for eliminating defects have expanded even further.

Therefore, if the need arises to seal cracks, you can always choose the method that is most accessible in execution. To be aware of ways to solve these problems, you need to consider some of them.

Repair wooden covering can be divided into three types:

- Complete dismantling of the floor and reassembly of floorboards. To carry out this procedure, you will need a hammer with a nail puller and a small crowbar. Such large-scale events are carried out if there is a suspicion of damage to the sheathing joists on which the floor boards are laid.

The boards are carefully sorted and healthy and strong specimens are selected. If necessary, they are planed a little to even out the unevenly shrunken edges.

It is possible that some of the floorboards will have to be completely replaced, so this should be planned in advance by purchasing replacement material. If necessary, some elements of the sheathing are also changed.

After all repair and preparatory actions, the floors are laid again. In this case, the boards must fit tightly and be secured to the joists.

This type of repair is necessary if sealing the cracks, due to their size, is simply ineffective.

- Partial dismantling of the boardwalk is carried out in cases where defects on the boards have formed in certain areas, where wide cracks have appeared and the boards have begun to make creaks. The flooring in these places is carefully removed and a new one is laid in its place. Most likely, the second type of repair will have to be carried out in conjunction with the third, most widespread.

- In most cases, you only have to carry out repair work to seal the cracks. This can be done different ways. Choosing a specific technique Firstly, depends on the size of the cracks and the scale of their distribution over the floor surface.

Methods for sealing cracks

Gaps in the floorboards may appear in various areas of the floor, so you need to consider not only the operating technology, but also the options for sealing materials, as well as places where flaws may occur.

Gaps between the wall and the boards gender

Small distances are always left between these building elements for ventilation and in case of expansion of the material due to changes in temperature and humidity. But if over time they have grown excessively, then they will need to be repaired. This can be done using construction foam, sometimes even adding small pieces of foam to it. The work is carried out in stages:

First you need to carefully dismantle the baseboards;

Then clean the cracks from dust and accumulated dirt;

After the foam has dried, the excess is cut off exactly along the catchers;

It would be best to seal the seams on top with putty so that the pores frozen foam no dust collected;

Sealing cracks with glue + sawdust

Floor repairs can be carried out in any area adhesive composition, which can be made in one of two ways:

First option

- First, small sawdust is prepared. They are placed in a convenient container and filled with boiling water. The mass is mixed until homogeneity is achieved.

- The sawdust is left to swell and cool for one to two hours, then the mass is mixed again.

- Next, glue (carpentry or PVA) is added to the prepared sawdust and the mass is kneaded well until a viscous consistency with high adhesion appears.

- Then you can proceed to preparing the floor - all cracks are cleaned of dust and dirty deposits. Sometimes, if necessary, their upper part widens slightly.

- Prepared glue mixture using a narrow spatula, apply it to the cracks and carefully compact it inwards as far as possible, but without much effort.

- The mixture is leveled on top and excess is removed.

- After complete drying, after two to three days, the cracks are sanded sandpaper or are looped using a special machine/

Video: homemade putty from sawdust and PVA

Second option

You can repair flooring in another way, using a repair composition of sawdust and glue, but with the addition of cement.

- To do this, take two parts of PVA or wood glue, add 15 parts of very warm water, everything is mixed well until completely homogeneous. Next, 5 parts of cement and the same amount of sawdust are added to the resulting adhesive solution. The mass is mixed and left for 7 ÷ 10 minutes. If the mixture needs to be given a certain color to the wood, then you can add a special coloring pigment or thick oil-based paint.

- Next, the cracks in the floor are cleaned and lubricated with glue, which was used to make the repair composition described above.

- The mass itself needs to be warmed up a little, and then quickly seal the cracks with a narrow spatula, trying to level the surface.

- It will take about two weeks for this composition to dry completely. Then the cracks must be treated with abrasive materials until they are perfectly even.

This method is often used not only to seal widened cracks, but also to level the floor surface to a smooth state.

Repair using putty

If you don't want to bother with making complex compositions of numerous ingredients, you can, of course, do it easier: buy a special wood putty at a hardware store and seal the cracks with it. This option is suitable if the gaps not big at all. But you need to know that such fall putty is often quite short-lived - it can crack and crumble over time. Therefore, it is better to use it when you plan to then cover the old boards with plywood flooring.

The finished putty is also applied narrow or rubber spatula, pressing it into the cracks. After it has dried, you need to level the sealed surfaces using available abrasive wood processing products.

Sealing cracks with paste and paper

This method is easy to implement and not at all expensive. To perform such a process, you will need paste, paper and a little copper sulfate or, as it is also called, “blue stone”. This ingredient of the composition is necessary so that nests of various small insects do not appear in the adhesive mass over time.

- The paper is torn into small pieces or cut, then it is filled with water. The paper needs to be given time to soak.

- While the paper pulp is being prepared, you need to prepare the paste. It is cooked from flour or starch and water. The water is brought to a boil and one of the selected ingredients is gradually poured into it, stirring constantly, so that there are as few lumps as possible. The composition should cool to a warm state.

- Then add to the paste copper sulfate 1:10.

- Next, the paper pulp needs to be squeezed out, crushed with your fingers, added to the paste and mixed thoroughly. You should get a fairly thick and homogeneous consistency, similar to putty.

- Preparing cracks for sealing occurs in the same way as in other cases. The main thing is to achieve their absolute purity.

- Next, the mass is applied to the cracks and compacted into them. It needs to be thoroughly leveled on top, and after drying, smoothed with sandpaper.

- After this, the floor can be safely painted.

Sealing cracks with cord

A method has long been known for sealing cracks, not only between floorboards, but also in walls, using a cord selected according to the width of the holes. The use of this popular technology will not only help get rid of cracks in the floor, but will also relieve residents from unpleasant creaking boards

For the repair process in this way, you must have twine, rope or cord made of any material, sawdust, wood glue or PVA and putty.

- The cord must be passed through the glue so that it is completely lubricated with it.

- Next, a mixture of putty, sawdust and glue is made.

- The rope is laid on one of the cracks and deepened inward to such a state that there is 2 ÷ 4 mm from it to the floor surface - this is a necessary condition.

- The distance from the cord carefully compacted into the crack to the floor surface must be filled with the prepared mixture with a small margin on top, since when drying, the adhesive putty composition will certainly shrink.

Sealing cracks using slats or wedges

It has long been used and more the hard way sealing cracks - using thin slats, hewn at an angle in the form of wedges. These parts must be carefully adjusted and should not push the floorboards too much, but, at the same time, completely cover the cracks. The work is carried out in several stages.

- As with others repair work To repair floor defects, the cracks must be cleaned and their upper part must be slightly expanded.

- Next, a strip is made according to the size of the gap, narrowed to its lower part so that, like a wedge, it fits into the prepared and cleaned groove.

- The gap and the lath are thickly treated with PVA or wood glue.

- Next, the lath is glued into the gap; it can be slightly knocked down with a rubber hammer or mallet, or you can place a board on top and hammer the lath through it with a regular hammer.

- If the lath does not fit completely into the gap, and a small part of it protrudes above the floor surface, then it is removed with a plane after the glue has completely dried.

- When using this method of sealing cracks in floors, the color of the wedge slats driven in will be significantly different from the main coating, so they can be evened out using stain or well-chosen paint.

- If there is a thick layer of paint on the floors, and it is cracked and peeling around the cracks, it can be removed using construction hair dryer or clean it using special attachments on a drill with a soft iron brush. You can also resort to sandpaper mounted on a sander.

Other repair methods

In addition to the methods mentioned above, there are many other known techniques. In addition, hardware stores can offer numerous modern materials for these purposes.

- Tow - familiar to everyone construction material from flax fibers, which has long established itself for its positive qualities. Therefore, even with the advent of numerous new compositions for sealing cracks and cracks, they are in no hurry to abandon it.

This material is treated with wood glue and compacted into the cracks using available tools. After the glue has dried, the cracks are tinted to match the overall floor.

- A composition of epoxy glue and cement, which is prepared based on equal proportions of the material, is perfect for repairing floors with small cracks. This product is carefully poured into the openings with the top in the expectation that the mass will sag. Since the epoxy mixture sets quickly enough when mixed with cement, it will not have time to seep into the subfloor.

Then, after the glue has dried, the cracks are sanded and covered with paint.

- Composition made from thick oil paint, sawdust or small shavings and wood varnish in proportions 1:4:1, mixed into a single mass of uniform consistency, also great for sealing cracks different sizes. The process can be carried out in one stage, When the cracks are filled immediately, or maybe several times stages,

Sometimes it's much easier to simply cover the old floor with plywood.

This option is used in cases where such a quantity has formed between the floorboards various sizes cracks that sealing them is unproductive. Therefore, it will be easier, following all the technologies for working with plywood, to secure it to the floor surface with self-tapping screws and close all the defects that appear at once.

- The well-known sealant, which has a convenient packaging and a syringe attachment, is also well suited for sealing seams. Thereby special device, you can carefully fill both a wide gap and a very narrow one by cutting the tip to the desired thickness.

The sealant perfectly closes the cracks and eliminates the resulting creaking. Spreading under the pressure created in the syringe, it covers the entire internal surface without compaction or other effort. This is a durable and fairly reliable material that will eliminate problems for many years.

Sealants made on acrylic and silicone bases that are designed to work with wood are well suited for closing cracks. They are very easy to apply and dry quickly. Therefore, if you have no experience in making special compounds or do not want to tinker with them, but you have the opportunity to purchase a ready-made product for such repairs, you can opt for sealant.

This question should be asked at the stage of purchasing the material, because the gaps in wooden house can manifest themselves not only in the inter-crown space, but also on the surface of the raw material. How to choose the right material With least losses and carry out a high-quality process of caulking and sealing gaps, details below. It is worth noting that neglecting this action entails not only the impossibility of comfortable living, but also damage to the material.

Purity of wood is the key to quality

It is possible to buy absolutely smooth raw materials. But the absence of cracks and crevices is more likely a sign of the freshness of the timber or log. This means that the wood carries a large percentage of moisture, which is not good, since when installed in a log house, shrinkage can deform the elements and cracks will inevitably appear.

It is best to purchase dry raw materials with a minimum web of defects, then there is a chance that the aging and drying technology has been followed. How to correct these shortcomings and how to cover up the cracks log house or cracks in profiled timber? Using many means known since the times of our ancestors. Namely:

- Wood glue + wood waste. Exactly this accessible remedy for independent high-quality work.

- Synthetic derivatives – sealants, mastics, resins, polyurethane foams.

- Caulk using jute, flax, tow and moss.

- Decorative sealing.

More information about processes accessible to non-professionals:

- Using carpenter's glue to seal cracks in a wooden house can be done both at the finishing stage and during subsequent regular inspections of the object for damage. The product is accessible, cheap, and brings a lot of benefits. But the disadvantage is only the use in small areas; for extensive lesions, it is worth using something else.

So: the cracks should be cleaned with fine sandpaper so that sawdust and wood dust are collected. Next, a paste is prepared from them - glue is poured into the mixture.

The substance is then placed into the cracks and left to set easily. After grinder places are being processed.

- Using sealant to seal cracks wooden house, you need to learn one rule - acrylic options are not suitable for outdoor work. You also need to be wary of silicone ones - they can delaminate in the cold, so the bottle should be labeled strictly as frost-resistant. Worth picking up suitable color to the general background of wood.

Before applying the product, the cracks must be treated for biological damage. It would be a good idea to go through all sorts of defenses in general. Next, the sealant is placed into the gaps as deeply as possible and compared with the surface.

Sealing cracks in a wooden house with foam for installation purposes is recommended only under the condition of further cladding. It looks unpresentable and even after cutting off the protruding parts, its attractiveness does not increase. In addition, foam is a kind of foam rubber that has cells.

Consequently, moisture that gets there can be retained and have a detrimental effect on the wood. Resins and mastics can play the role of putty, but when sub-zero temperatures they are destroyed.

- Caulking is the most The best way sealing the inter-crown gaps of the finished log house after shrinkage. It is periodic and takes place in three stages. The first - immediately after assembly of the object, the second after shrinkage and the third after 3-5 years of operation.

This process - sealing cracks in a wooden house - is subject to buildings made from all types of raw materials - timber, logs. Sellers expensive materials– glued or profiled kits do not have the right to say that their wood does not need it. There is practically no such type that can do without the occurrence of gaps and cracks.

The caulking process is as follows:

- First, the surface of the walls is cleaned of wood chips, protruding fasteners, and other things. You can use a grinding machine or vacuum cleaner.

- Then the surface, especially those places where cracks need to be sealed, in a wooden house is impregnated with chemical or natural protections against fire, mildew, moisture and mold. Each layer must be completely dry before applying the next.

- Next, sealing the cracks in a wooden house with the chosen caulk will not be difficult. There are two ways to do this - dialing and stretching. The first is for thread-like materials - tow, rope.

The second one is for tape materials: jute, linen. Should be used in the process special tools- additionally, flat caulking and a mallet for neat driving in.

The sufficiency is checked with an awl - if it enters the sealed gap with difficulty, the material has been laid with high quality. But you can’t overdo it either - you can disturb the position of the crowns.

- The work is carried out strictly in a circle, from both sides. Regular preventive maintenance and ridding the house of old material is the key to a windproof house.

Decorative caulk is as follows:

- Decorative cord is used as a material and such raw materials are used to seal cracks in log house looked beautiful with expensive and elite material - laminated veneer lumber, rounded logs.

- Before laying the twisted cord, the usual manipulations for caulking are performed - cleaning, impregnation. Next, the gaps in the wood are filled with sealant, mastic or resin. This is done just in case the cord suddenly falls out.

- All that remains is to lay the rope. Using tools, it is carefully driven between the logs, without waiting for the substance laid before caulking to completely dry.

The sealant for the cracks of a wooden house will set together with the cord, and strength will be ensured. When caulking with rope, you should start with the corner joints and then work on the remaining areas.

Wooden flooring is an environmentally friendly atmosphere at home, a natural design that leaves pleasant impression, warmth and home comfort. And, although wood is a fairly strong and durable material, like any other, over time it tends to lose its attractive appearance, dry out, become cracked and creak underfoot. The most unpleasant thing is, of course, the cracks. Before thinking about how to seal cracks in a wooden floor, it is worth thinking about the reasons for their appearance, and there are many of them, and this is not only the duration of operation.

How cracks and crevices appear

- The indoor air is too dry. In the future, to solve this problem, you can purchase special devices and sprayers to increase the humidity in an apartment or house; in addition, too dry air is harmful for the inhabitants of the room.

- The drying of a floorboard is a natural and natural process - such drying occurs with any wood and lasts from 3 to 6 years. In this regard, it is better to immediately choose boards made using advanced vacuum drying technology - liquid has been removed from them at the cellular level.

- The reason for the appearance of cracks may be errors and shortcomings of craftsmen during installation work. During installation, the floor must be completely immobilized - to do this, use ordinary nails and nail the floorboards to the joists.

- “Underground” ventilation is of great importance in the appearance of cracks. Best advice will close the vents and conduct ventilation through the room. In cases where there is no ventilation under the floor, it would be appropriate to make holes for air intake in the corners of the room. This way you can protect the floor from dampness and rotting.

- Another reason for cracks in the floor in private country house may become mice and, before dealing with the floorboard, you should deal with rodents.

Materials for sealing cracks

For these purposes you can use different materials and ways. First, let's look at how to seal cracks in a wooden floor. It is possible to seal them with wedges or slats - this is the most effective method.

Sequence of work

- The slats should be narrowed at the bottom and match the size of the gap.

- We smooth out the cracks and treat them (and the slats) with PVA glue.

- The slats are glued into the gap and tapped with a rubber hammer.

- If, after the glue has dried, a lump of protruding wedges remains on the floor surface, it can be carefully removed with a plane.

- Next comes the sanding procedure, using sandpaper and an angle grinder.

On final stage stain or paint with varnish is applied.

Materials for filling cracks

Sometimes it is not worth engaging in such a labor-intensive process as reassembling the entire floor, especially when the sheathing on which it is located is not damaged. batten. In cases of local damage and not very large gaps between the floorboards, you can cosmetic repairs by using modern means. The question is how to seal the cracks in a wooden floor.

Today, special sealants have been created to fill cracks.

- Silicone and acrylic sealant.

- Polyurethane foam (construction).

- Putty materials.

If the aesthetic appearance of the floors is not so important, improvised means are used.

- Glue solution with sawdust.

- Oil paint solution with sawdust.

- Epoxy glue with cement.

- Construction foam with polystyrene foam.

How to use putty products

It should be noted that sealants are the most convenient to use, since there is no need to prepare a solution, but you can immediately begin to act.

The sealant has a syringe attachment, which makes the process of filling cracks much easier. The sealant is usually accompanied by instructions for preparing floors.

The putty is easy to use, easy to prepare and quickly levels the floor, but is not durable.

Construction foam is used as follows:

- skirting boards must be removed and dirt removed from the floorboards;

- if desired, fill the gaps with polystyrene foam and then with foam;

- After drying, the excess foam is cut off, and the floor must then be puttied.

The glue mixture with sawdust is prepared as follows:

- First you need to steam the sawdust with boiling water, wait until it swells, and stir. After this, mix with the adhesive base (use PVA or wood glue).

- The thick suspension is applied with a spatula, leveled, and excess is removed. After 3 days of drying, it is worth sanding the floorboards or sanding them.

- Oil paint is diluted to a thick, viscous state and pre-soaked and swollen sawdust is added to it. Mix the mixture well and use it in the same way as the adhesive solution.

Whatever floor optimization method you choose, do not forget about the causes of wood “disease” and preventive measures when using wooden floors.

How to seal cracks in a wooden floor

Warm, comfortable, harmonious life in a wooden cottage. In such a building a unique microclimate is created, as well as natural ventilation. But for care and use wooden building a special approach is required. In this article we will talk about how to make a wooden floor.

- Reasons for appearance

- Description of the work process

- Application of wooden slats

- Puttying

Tree - natural material with good thermal insulation properties. Over time, cracks may appear in it.

As a result, the strength of the flooring will decrease, drafts will arise, debris and dirt will begin to accumulate in the resulting holes, and dirt will begin to flow from the underground into the room. bad smell dampness, rot. But you can seal the cracks, and do it yourself.

It is necessary to seal the cracks in the wooden floor in a timely manner: defects reduce strength and it becomes dangerous to move on the flooring.

Reasons for appearance

- Seasonal changes in humidity. Usually associated with turning on the heating. Wood begins to dry out due to low humidity: the air in the room becomes drier. When the heating is turned off, the humidity returns to normal, but the structures and floors do not restore their previous shape. To protect the wood from drying out, you need to constantly maintain the microclimate in the room with air humidifiers.

- Violation of flooring technology. The cement-sand base may not be sufficiently dried. The wood will begin to warp over time. Similar defects can also be observed when installed incorrectly. vapor barrier film between wood and cement.

- Incorrectly selected material. High-quality floors are made from coniferous, oak boards, tropical trees. Linden, maple and some other species are not suitable.

- Using poorly dried boards. When purchasing material, you should check its moisture content. The optimal value is about 6–10%. It is not recommended to purchase material from an open warehouse.

- In old rooms there may be rodents that damage the floors. In this case, you need to seal the hole and fill all the passages with concrete mixed with glass or aluminum chips. It is not recommended to pour rat poison into holes: rodents can spread it throughout the rooms. The poison emits an unpleasant odor, which is then difficult to remove.

What will it take to fix the holes?

Required:

- wooden wedges, lath, cord (nylon or nylon);

- paste, sawdust, epoxy resin, tow;

- special silicone, putty, PVA glue;

- hammer, stiff bristle brushes, spatulas, woodworking tools, mastic.

Description of the work process

Furniture is removed from the damaged area. The floors in the room are washed. If the area is small, it is marked with chalk. Use a stiff brush or sharp spatula to remove adhered dirt. Can be removed paintwork, if it interferes with or contributes to the expansion of the holes.

The repair technology depends on the location and nature of the damage.

Application of wooden slats

This is the most effective method, but it takes a lot of time. It is used more often if the gap is quite wide and deep.

They begin work by milling holes and slots with a saw: they need to be widened. Then the dowels are driven in. Clean the ends of the boards with sandpaper. If there is a gap between the board and the wall, then the walls are also cleaned. The slats are made from boards of the same type as the main floor, 0.5 cm smaller than the size of the holes. The slats are cleaned.

The boards are treated with glue and glued together. Make a mixture of glue and sawdust. Fill cracks and other minor defects. In some cases, damage between the wall and the floor is filled with sealant.

After filling the cracks, the surface is treated with varnish and paint to match the main shade.

Puttying

If a hole or gap small size, it can be puttied. Several options are used:

- Mix paste (or PVA) with sawdust. Before this, the sawdust is poured with boiling water and left for 2-3 hours to swell. Then add glue to the mixture and mix thoroughly. The finished solution should stretch.

- To cover the gap between the boards, you can mix sawdust and gypsum dust in a 1:1 ratio. The mixture is poured with boiling water. The consistency of the finished solution should be thick and viscous. Can add citric acid(100 g per 1 l).

- A mixture of paper (cardboard) and paste is less reliable. Pre-shredded pieces of cardboard and paper are poured with water to swell them. Mix with paste.

The mixture is applied to the damaged area with a spatula. After drying, cover with varnish and paint to match the color of the floor.