What kind of coal is best to fire a solid fuel boiler? Coal

As a rule, those who install autonomous boiler equipment in their home for the first time encounter problems with its operation. Not everyone, for example, knows how to properly heat a boiler with coal, what type solid fuel choose for designated purposes. Experts point out that any stove must be handled with extreme caution, carefully observing all standards fire safety. It is also useful to familiarize yourself with the operating features of the selected equipment in advance.

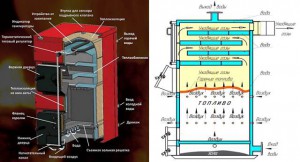

How does a coal boiler work?

What is a coal boiler? This easy installation, which consists of two sections. Coal is placed in the upper firebox. After it burns out, ash and slag remain, which fall into the lower compartment and are removed from there as necessary. Between the chambers there is a regular grate made of durable cast iron.

Such furnaces can be additionally equipped with sophisticated automation, which allows the unit to switch to offline mode and control the draft. If there is no automation, coal stoves operate using natural circulation. The first type of device has several operational advantages, but costs a furnace long burning much more simple devices.

Automation works extremely simply. Thanks to it and the operation of the fan, it is easy to control the flow of oxygen into the firebox. The more of it, the stronger the coal burns, and the faster the fuel burns, giving off maximum amount heat. Restriction of oxygen access leads to reverse effect. The fuel burns more slowly, the amount of heat released decreases, but the burning time of the coal increases.

The heating temperature is regulated by a special temperature sensor. The boiler operating modes can be programmed. If achieved set temperature, the sensor is triggered and turns off the fan. At the same time, the oxygen supply decreases and the furnace burns out more slowly. When the temperature drops, the fan turns on and begins to intensively pump oxygen into the firebox. The coal is actively burning again. If consider similar features work solid fuel boiler, it becomes clear when and how to put coal in the oven.

What coal to choose for the fire?

What is coal? This is a product of plant origin, which contains carbons and non-flammable impurities. It is they who form ash and slag-like substances after burning. The ratio of the two components is different everywhere. It is this, as well as the “age” of natural fuel, that determines the grade of coal. Experts distinguish several varieties.

The “youngest” type of coal is lingite. It has a rather loose structure. If you pick up a lump of lingite, it will quickly crumble and lose its shape. This type of coal is most often used in thermal power plants, but lingite is not suitable for heating a home.

In addition to lingite, brown coal, hard coal, and anthracite are also mined - the most ancient carbon deposits. All varieties have different humidity levels. In brown coal, for example, humidity is 50%; in anthracite its threshold does not exceed 7%. Therefore, anthracite has the highest specific heat. Its indicators are 9 thousand kcal/kg. Coal has a lower figure - 5.5 kcal/kg. In the brown variety specific heat is only 3 kcal/kg. Considering all this, it is easy to understand what type of fuel to purchase for heating the house.

How to use solid fuel units correctly?

Coal boiler operation

The operating principle of a solid fuel boiler is known, and the issue of choosing the type of coal has been resolved. All that remains is to learn how to properly light the stove. There are several simple rules, which everyone who chooses the described installations for organizing heating of a country house must learn.

Remember! First, the stove must be prepared for lighting, then fuel must be correctly loaded into it. During its combustion, the installation must be closely monitored, removing combustion products in a timely manner.

Let's look at all these points in more detail.

Preparing the stove for lighting

If the oven is in country house used occasionally, before starting its operation, for safety reasons, it is necessary to exclude the presence of cracks inside the masonry.

Why are they dangerous? Through them, combustion products and carbon monoxide can enter the room, which must be removed outside using drafts. If such a defect is discovered, it must be eliminated before kindling by covering the cracks with a mixture of clay and sand. Otherwise, when heated, the cracks may increase in size even more. And this will lead to dangerous situations.

When inspecting the stove from the outside, we remove flammable objects away from it and clean it inside. We remove the ash and slag with a shovel, freeing the internal compartment. It is advisable to wipe the inner walls of the firebox with a dry cloth. If this is not done, then during kindling the dust will begin to burn, filling the room with an unpleasant odor.

The coal stove needs to be lit several times a day. The duration of one fire should not exceed two hours. For loading, it is better to use well-dried medium-fraction coal.

Note! Wet fuel produces steam when burned. It forms condensation, which settles inside the chimney. Mixing with soot, condensate forms coke, which gradually clogs the chimney passage, narrowing it. And this leads to problems with traction.

Do not use household waste or flammable liquids such as gasoline or kerosene to ignite coal. Do not leave the stove unattended while it is burning. This rule must be observed especially strictly if there are small children or animals in the house.

How to properly melt coal?

Laying solid fuel boilers

The stove must be lit as follows:

- First, we place sheets of newspaper or any other dry paper on the bottom of the firebox. On top of it we place a layer of small wood chips. And we stack small firewood on them, for example, birch logs. To make them flare up faster, they need to be folded in the form of a well or a small hut.

- Set fire to the paper. We close the oven door and open the ash pan. Using it, it is easy to control the intensity of fuel combustion. The stronger the air flow, the faster the stack of firewood burns out.

- After the firewood has completely burned out and only a pile of smoldering ash remains, you need to lay a 15-centimeter layer of fine coal directly on it.

Note! When opening the fuel loading door, be sure to close the vent.

- When the 15-centimeter layer of coal burns out well, we place larger coal directly on it and build a cushion 60 cm high. It is useful to stir the burnt fuel thoroughly beforehand, which will improve air circulation and prevent caking of the coal mass. Coal can be placed by opening the firebox door.

Note! Low-quality solid fuel tends to coke. Therefore, experienced stove makers advise laying a layer of coal with layers of firewood. Such a multi-layer cake will allow the unit to burn well and give off the maximum amount of heat.

- To properly light the stove, it is better to do this - open the ash pan and let the paper with wood chips burn out using natural circulation. This will allow the chimney to warm up well. As the fuel burns, the draft will increase, so you then need to close the ash pan and turn on the fan.

How to remove ash?

Heating solid fuel boilers

When the stove is heated with wood, removing the ash is very simple. The fuel burns out and falls into the ash pan chamber.

Coal has a much longer burn time, so it is quite difficult to remove slags in time. Laying with wood saves the situation - a layer of firewood, a layer of coal. You can cope with this problem by increasing the combustion temperature. Therefore, it is useful to learn how to regulate cravings.

Conclusion

Heating your home with coal has a number of advantages:

- Firstly, coal has high heat transfer, and its burning time is many times longer than the burning time of firewood. Therefore, one bookmark is enough for 12 hours. Loading is done only by hand, and you will only have to load the oven 2-3 times a day.

- Secondly, there are several types of coal on sale. The lower the moisture content of the fuel, the more expensive it is, but to operate heating installation It's much easier when using a quality product.

Heating a stove with coal is quite simple. But there are a number of nuances that must be taken into account when operating the described installation. All of them are indicated in the article.

How to fire a solid fuel boiler with coal - basic rules and useful tips

When purchasing boiler equipment, the new owner is faced with difficulties in its operation. First question of interest how to fire a solid fuel boiler with coal Right. Before you start to understand it, you need to remember that any autonomous heating equipment requires unconditional compliance with instructions and safety precautions.

Combustion process

The process of starting to fire a solid fuel boiler is divided into two main stages.

Even if you constantly use only coal as fuel, kindling should be done using dry wood. Before directly laying coal, you must first burn it to coals small portion firewood They are laid evenly on the grate and ignited.

In this case, it is necessary that the pipe valve is slightly open.

When the kindling flares up, the pipe valve is opened all the way, and the first portion of solid fuel is added. The layer should be uniform over the entire grate with a thickness of 5-8 cm. Afterwards, open the ash chamber and close the combustion door. As soon as the coal burns well, you need to throw in the rest of the coals, which should also be distributed evenly over the grate.

Subsequent portions of solid fuel should be added only after the coal has ignited well.

Tip 2: don’t forget about the doors

When adding, if you open the furnace door completely, you must close the ash chamber.

Tip 3: Don't be afraid to wet the coal

To increase the combustion time of coal and, accordingly, its heat transfer, it is necessary to moisten it with water before throwing it. The intensity of humidification depends on the brand of coal you burn with:

- Highly caking coals consisting of small fractions, grades Zh and PZh, require abundant wetting. You need to add enough water so that all the particles stick together. But you also need to make sure that there is no excess moisture;

- Fine coals of CC, T and PS grades require moderate moisture;

- Long-flame coals are only sprinkled with water to settle dust;

- Anthracite, in general, does not require wetting. If it contains a lot of small particles, then you can sprinkle it with a little water to prevent dust.

How to poke coal correctly

To avoid rapid combustion of coal, it must be constantly stirred. How often and intensively this needs to be done depends entirely on the type of coal:

- Brown polyash coals require frequent stirring, otherwise they will burn very quickly and turn into ash. It is best to load this type of coal in small portions;

- All other types of solid fuel need to be stirred as little as possible so that the firebox does not cool down and the coals do not fall into the grate and mix with the resulting slag.

How to finish a firebox correctly

When the fuel burns out, you need to slightly close the ash door. When the layer of the last fuel is no more than 4 cm, the chimney must be closed completely, and the pipe must be closed three-quarters with a valve. And only after all the coals have completely burned, the pipe closes completely.

If you do this earlier, you can get burned from the accumulation carbon monoxide.

More on the topic:

We make a sawdust boiler with our own hands Heating boilers combined, wood and electricity Floor-standing gas boiler Proterm Bear 30 klz Combination heating boilers, wood and electricity

A solid fuel boiler is an investment in your home. If used to replace an old style fireplace or boiler, it has the potential to reduce your home's carbon footprint by at least 14% and truly makes the majority of wood eco-neutral and renewable energy. Making the decision to replace an existing inefficient unit or install a boiler from scratch in your living space may seem daunting, but there are a large number of options from which to choose.

How to use a solid fuel boiler

- If you are lighting a boiler for the first time, only a small fire should burn.

- A fire that is too hot will cause smoke to emanate from the paint, which is not necessarily a bad thing, but it is annoying.

- The paint may also become soft during this time. Avoid all contact as the finish can be easily damaged!

- The rope door seal may stick to the body of the boiler - leave the door slightly open during first use!

- All materials must be given time to adapt to the effects of heat.

- Heat-resistant paint reaches its maximum thermal stability after several hours.

- It is recommended to open doors or windows when the boiler is lit for the first time.

- Vibrations caused by transportation can loosen nuts/bolts holding glass, door handles, etc. so please check and tighten them before use. Be careful not to overtighten the brackets that hold the glass in place, and make sure the seals are in place beforehand.

- Some models have a spring-loaded door for security purposes. It may be weakened.

- Before lighting, check that the removable baffle, which you will find inside the combustion chamber at the top, is pushed towards the rear of the boiler, thus directing the flame forward. Usually a small piece of wood holds it in place, visible from smoke passage. It may be left in place and burned during first use.

- Also check that other internal components are in their correct positions. Remove any additional tools from the ash pit, as well as any heating stones/bricks.

- Primary air passes through the bottom vent, through the grille and into the combustion chamber. It is useful for igniting fires and for burning solid fuels such as coal.

Wood burns more efficiently when the combustion air comes from above the fire bed rather than below it. Oxygen supplied from above the fire bed through the auxiliary air vent above the door ensures the combustion of gases escaping from the wood as it heats up. This heat heats the unit instead of being wasted in the chimney or condensing and creating gum deposits inside the boiler, flue pipe or on the door glass. Since the draft is determined by the height of the chimney, proper control of the secondary air will be achieved through trial and error.

Boiler ignition

- Fully open the upper and lower air controls.

- Place the folded and crumpled newspaper at the back of the cauldron. Place a small amount of tinder on the surface of the newspaper and then a few slightly larger pieces of wood on top of it all. Light the newspaper and close the door.

- Let the flame burn until all the pieces of wood are lit. Then you can add more large pieces of wood/logs.

- When you burn wood: If the fire is established, then the lower regulator can be closed so that all the air for the flame enters through the upper regulator. The burning rate can now be controlled by adjusting the top air regulator and adjusting the amount of wood added. The lower air regulator should normally remain closed when the boiler is running. If the fire has been allowed to almost go out or get too low, the lower control may be opened to allow air into the base of the flame in an attempt to revive it. If the temperature environment above 14 C, then the draft may be insufficient, and the use of the main regulator will become necessary.

- When you burn coal and other solid fuels: a primary air regulator must be used.

- Do not operate the boiler with the door open.

- Regulators and knobs become hot when the boiler is in use, so gloves should be worn.

- Never use a boiler without putting fire bricks in it - they protect the steel from oxidation.

Please note that the glass will darken at first, but it will eventually clear when running correctly with the correct fuel. Logs that have not been sufficiently dried and seasoned will always darken the glass.

The first stage of fire, immediately after ignition, is often the smokiest. During this stage, make sure that both air inlets on the boiler are fully open in order to obtain a hot flame. The extra heat "forces" the chimney to produce a strong draft and helps keep the chimney clean by releasing creosote that may remain as residue from a previous fire. The hot initial firing also removes moisture from the wood and provides an ignition source for the smoke that emerges from the timbers.

- Gradually adding small amounts of fuel will help maintain stable temperature and burning rate so that the boiler will operate efficiently and cleanly. Adding large amounts of fuel at one time will significantly reduce the temperature inside the boiler. After adding large timber, it is a good idea to enlarge the top air hole a little more until the new fuel begins to burn and the boiler returns to the required temperature.

- Gradually adjusting the air regulators will also help maintain a steady burn rate.

- Do not start the boiler if the upper air regulator is completely closed. It supplies air to the blower system. The more open the upper regulator is, the more efficiently the blowing system works.

How to fire a boiler with coal

Despite the simplicity of the design, combustion methods must be selected based on the requirements, the main of which is the duration of combustion and maintaining a high temperature after complete combustion for about 8 hours. When burning coal determine the appropriate mode. Keep the coal burning constantly.

First, melt a small amount of coal using paper and wood chips. Fill in boiler a small amount of coal and close the loading door. Adjust the air supply. The more oxygen is supplied, the faster the coal combustion process will take place, but the heat obtained as a result of rapid combustion will be short-lived. And vice versa, if you tightly close the door to the air supply channel, the coal will smolder, or maybe even go out and will not provide enough heat, since it will emit a lot of smoke. In addition, there is a danger of this smoke entering the room, which you do not want at all.

Once you have adjusted the air flow and are burning evenly, add a small amount of more coal to the firebox through the top loading door. With the volume of coal in the firebox up to one third of the chamber will provide continuous burning and stable heat for 3 hours. Control the supply of coal to boiler. based on the water temperature sensor.

As a rule, it is sufficient to maintain the temperature within 80°C. To burn for a longer time, pour in and distribute evenly to half the chamber. Do not add too much coal, otherwise it will not burn, but will be baked on the grate and it will be quite difficult to clean it.

Adjust the combustion of coal by feeding it into boiler air. Do not open the views too much, otherwise uncontrolled burning will occur large mass coal, which will cause the water in the boiler to boil, and you will receive heat for a maximum of 5 hours. Ash will accumulate in the lower chamber - the ash pan. Clean the ash pan daily. As a rule, this is done before the morning heating of the boiler. A clean ash pan will provide good outlet smoke through the chimney duct.

Features of solid fuel boiler combustion with coal

The efficiency of any boiler depends on the correct ignition and combustion of fuel in it. After all, for example, improper ignition of coal can result in the conversion of a large part of its mass into coke. Although it will burn, it will burn for a long time. This will generate insufficient heat. To heat the device correctly, you need to know what features it has different kinds fuel for solid fuel boilers and how best to light a fire in various types boilers

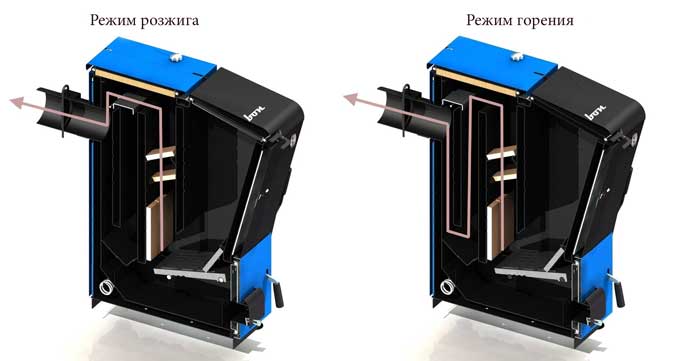

In some boilers, coal, wood or pellets can burn from bottom to top, in others, on the contrary, from top to bottom. In most long-burning boilers, pellets or other fuel burns from the bottom up. These are pyrolysis and pellet devices. Some models of pyrolysis units allow you to burn pellets, wood and coal from top to bottom. However, this combustion method is the most typical for a boiler "Stropuva" and its analogues.

Preparing to ignite fuel

This process is the same for all types of long-burning boilers. It includes several stages:

- Cleaning the grates from ash. This is done by moving the ash with a spatula over the grates. During this process, the ashes fall down easily.

- Removing ash from the ash chamber. A spatula is used for this. Work carefully so as not to raise dust into the air.

- Wiping the walls of the firebox. To do this, use a dry cloth. This get rid of accumulated dust on the walls and future unpleasant odor, which is formed when dust is burned during the combustion of pellets, firewood or other types of fuel.

- Chimney cleaning. It is done very rarely. However, before the first kindling in the new heating season The chimney needs to be checked and cleaned.

Ignition of coal in pyrolysis boilers

If the boilers are planned to be fired with coal. then you always need to pay attention to the type of grate. This is because there are special modifications for each type of fuel. Many manufacturers often include coal grates in the kit.

If the boilers are planned to be fired with coal. then you always need to pay attention to the type of grate. This is because there are special modifications for each type of fuel. Many manufacturers often include coal grates in the kit.

Ignition of coal depends on whether the long-burning boiler has been used before and whether it has automatic controls for regulating the air supply. The main element of automation is the fan.

If the boiler was heated several days ago and is equipped with automatic equipment, then the ignition method is the simplest.

It is carried out like this:

- Open screw door(is the second from the bottom) and put paper on the grate. Place thin paper or newspaper correctly.

- poured onto paper special wood chips for ignition. A little is required, so the consumption is low.

- Small firewood is placed on top.

- Crushed coal is placed on the firewood. Its consumption is greater compared to the consumption of wood chips, because the layer thickness should be 15 cm.

- I open the damper in the chimney t completely.

- They light the paper, close each door and turn on the automation, setting the required temperature level.

- After 5-10 minutes, check how the fire has flared up. To do this, turn off the automation and open the combustion door. It is better to open it slowly as the smoke output will be minimal. If the first portion of coal does not ignite, then close the door, turn on the automation and wait some more time. If the coal catches fire, the main portion of fuel is poured on top. Sprinkle correctly so that the cracks in the front part of the grate remain uncovered.

If a long-burning boiler is cold and has not been heated for a long time, then it is correct to light the coal using natural draft. This process is the same as igniting fuel in a long-burning boiler without a fan. The procedure will be described below. After kindling, all doors are closed and the automatic control unit is turned on. He himself evaluates the intensity of combustion, makes all the calculations and determines how hard to heat the boiler.

Ignition of coal in pyrolysis boilers using natural draft

It is performed as follows:

- Open the door of the fire chamber.

- Open the door of the ash chamber. She must be open at an angle of 45° in relation to the front wall of a long-burning heating boiler.

- Fully open the chimney damper. Thanks to this, traction will be maximum.

- Place the paper on the grate. and on paper - wood chips. They set the paper on fire.

- Small firewood is placed on a small fire. Their consumption will be small, because their quantity should be small. Afterwards, close the firebox door.

- When the firewood has flared up, open the firebox door, fill a third of the firebox with coal and close the door.

- After all the fuel has ignited, open the firebox and add coal. They fill the firebox with top level combustion door. If low-quality coal is used, it may coke. This can be avoided by mixing the fuel (this is very inconvenient) or by laying a layer of firewood, then a layer of coal, again firewood and coal. In the second case, coal consumption will decrease, and wood consumption will increase. But this better than the first case.

- The ash door is closed halfway. If, in this position, smoke comes out through the ashpit, then it still needs to be covered. It cannot be completely closed.

- As soon as the coolant in the system has become warm enough, the vent is covered so that there was a gap of 2-5 mm .

- Close the throttle in the chimney halfway. This position of the throttle and the blower will contribute to the most efficient operating mode of a long-burning solid fuel boiler. In this mode the device should operate until 9/10 of the loaded volume of coal is burned .

New fuel can be added almost at any time. That is, when the coal in the chamber is burning (pellets, firewood), or when it is still smoldering. As soon as it stops smoldering, the fire goes out and ash forms at the bottom of the firebox. According to technical documentation it should be cleaned every 10 days. The frequency may be higher. It depends on how quickly the top of the ash pile rises above the top of the air control door.

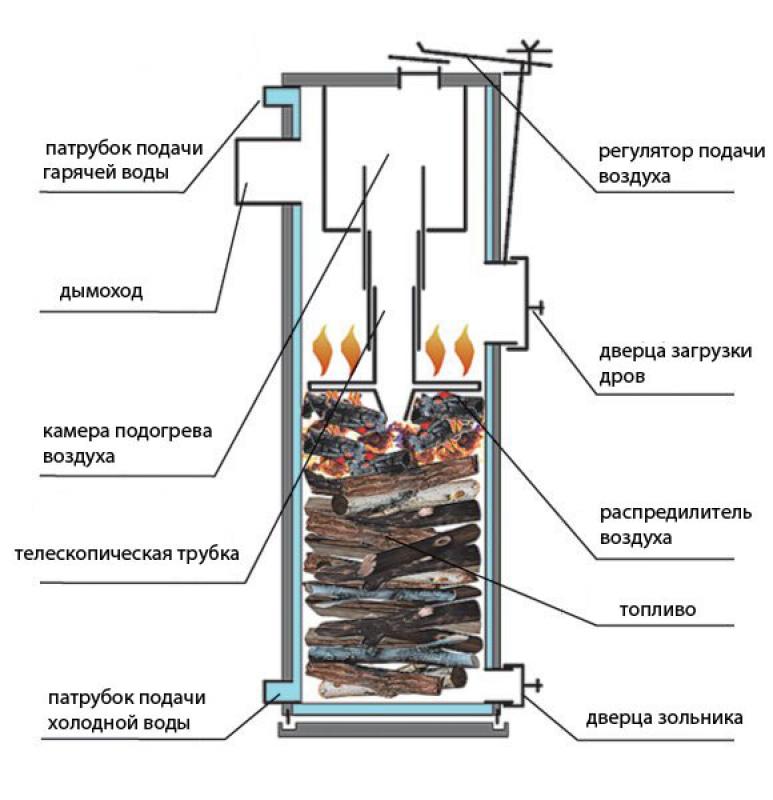

Lighting coal in the Stropuva boiler

The most common method of igniting coal in such a heating boiler involves pouring fuel into a container, pouring a flammable mixture into the duct and throwing a lit match or burning wick into it. However, this number does not work with every type of coal. So, anthracite will not catch fire.

To make it light up, it is better to do the following:

- Pour in enough coal to reach the level of the bottom edge of the loading door. The consumption in this case depends on the volume of the chamber.

- Place a layer of dry small firewood on the fuel. Its thickness should be two thirds of the height of the loading door .

- Light the wood and close the door.

- Wait until the fire burns. You can evaluate the intensity of combustion by looking through a special window made by the manufacturers. Most branded heating boilers, which are analogues of Stropuva, have such a window. Of course, it is made of heat-resistant glass.

- When the wood has burned down to burning coals, you need to open the door and add enough coal to make the top of the fuel level with the top of the fire door.

- Open the air duct completely. This is done in order to obtain maximum traction.

- Wait 30-60 minutes while watching the fire. You can look at the fire from time to time.

- If the oven begins to heat up, close the air duct back to normal.

- The boiler must be heated in this mode until the coal is completely burned.

walnut">Anthracite fist, walnut

Coal or Carbon (from the Latin Carbon) a product of the decay of ancient carbon forests, formed in a process that lasts millions of years. Dying and falling into the soil, the wood first turned into peat, which, as the soil sank, crystallized and, under the influence of temperature and moisture, gradually hardened, turning first into brown and then coal. As the ground moved in the complete absence of oxygen, the coal was pressed, occupying extended layers. The formation of one such coal seam takes from 30 to 40 million years. The high carbon content makes coal an excellent fuel, and therefore, humanity develops coal deposits and extracts coal from coal mines. Coal is the oldest energy fuel used by humans. It has not lost its relevance in modern conditions, even with the advent of modern and cheaper energy resources.

Coal.

Coal is a type of fossil fuel, an organic substance that is formed deep underground as a result of the decomposition of plant matter without access to oxygen over a long period of time. Coal, along with oil and gas, is a type of fuel that is widely used in all countries of the world and forms the basis for the development of modern economies.

Coal was the first fossil to be used by humans as fuel. A specific type of coal, such as hard coal, lignite, or anthracite coal. Depending on the work in which coal is used, it must be of a certain quality. It is used as fuel in ferrous metallurgy, in the manufacture of filters and electrodes, and other industries. Anthracite coal reserves are small compared to other types of coal - only 3 percent of all mined coal. Coal is mined in mines or quarries up to several kilometers deep. Anthracite coal is often transported by rail or barge. The Anthracite coal deposit in Ukraine is located in the Lugansk and Donetsk regions. Mining is carried out in mines up to 1500 m deep; from the mine, coal goes to coal processing plants (Mining and Processing Plants), where it is enriched and sorted by fractions (piece sizes) and then supplied to consumers.

Coal for furnaces and boilers.

Coal for stoves, coal for boilers. Which brand of coal is best for my stove or boiler?- our clients often ask this question. Our recommendations for choosing a brand of coal are as follows. First, light the stove with simple firewood, then pour DPK grade coal into the flared flame. If you use modern boilers for heating on solid fuel and these installations use forced air injection, it’s hard to think of anything better than anthracite or coal for solid fuel boilers. But again, for initial ignition, we would recommend using simple firewood or DPK coal.

Advantages of using coal for space heating:

- High calorie content during combustion. Unlike firewood, coal emits much more more heat and burns much longer.

- Does not require special storage tanks. Unlike gas and liquid fuel.

- Boilers and stoves for heating premises using solid fuel are much cheaper to manufacture and install and do not require specialized maintenance.

- Buying coal in Moscow and the region in any packaging is not difficult.

- The use of coal-fired stoves allows you to organize autonomous heating of premises anywhere.

Coal– solid fuel, mineral of plant origin. It is a dense rock of black, sometimes dark gray color with a shiny matte surface. Contains 75-97% carbon, 1.5-5.7% hydrogen, 1.5 - 15% oxygen, 0.5-4% sulfur, up to 1.5% nitrogen, 2 - 45% volatile substances, the amount of moisture varies from 4 to 14%. The highest calorific value calculated for the wet ash-free mass of hard coal is at least 238 MJ/kg. The uses of hard coal are varied. It is used as a household, energy fuel, raw material for the metallurgical and chemical industries, as well as for extracting rare and trace elements from it.

Types of coal.

The brand and size of coal pieces are indicated by letter combinations:

A- anthracite

D- long flame

DG- long-flame gas

Based on the size of the pieces obtained during mining, coal is classified into:

P- slab coal - more than 100 mm

TO- coarse coal (fist) - 50-100 mm

ABOUT- charcoal walnut - 26-50 mm

M- fine coal - 13-25 mm

WITH- coal seed - 6-13 mm

Sh- piece of coal - less than 6 mm

R- raw coal - not limited in size

Our company sells coal for stoves of the following brands: Anthracite AK And AKO, Long-flame WPC,DPKO and DGO. Coal is sold in Moscow and the Moscow region. Delivery of coal to the customer’s site is possible, and customers can also receive coal themselves at the company’s warehouse in Odintsovo, Moscow region.

Coal packaging for furnaces and boilers.

In our company, coal for heating premises of any brand (Anthracite, DPK, DPKO, DGO) is packaged in bags of 25 kg and 50 kg, as well as in MKR (Big Bags) of 1 ton. These types of coal packaging fully satisfy the needs of our customers. The advantage of coal in packaging is obvious:

- You can buy any amount of coal you need. The constant availability of packaged coal of all brands in the company's warehouse allows our customers not to create large reserves of fuel at home.

- Coal in bags of 25 kg and 50 kg is easily stored and, if necessary, transported from place to place.

- Using packaged coal, you can easily calculate your costs based on the amount of coal needed to heat your room. And also calculate the rate of its combustion in your stove or boiler.

- Ultimately on own experience you can decide which brand of coal suits you best, and all this will not cost you much.

Buying coal in large containers in MKR (Big Bags) of 1 ton is justified only if crane equipment is installed at the site that can lift this weight.

Sale of coal for furnaces and boilers.

Sale of coal for heating and other purposes in Moscow and the Moscow region - has not lost its relevance in modern conditions. A large number of enterprises offer coal various brands and in various packaging and in bulk. Our company is no exception. For several years now we have been specializing in the sale of coal in Moscow and the Moscow region. Our company sells coal for heating and other industrial purposes from a warehouse in Odintsovo

Price of coal for stoves and boilers.

Any owner sooner or later thinks about installing own home autonomous heating. Unfortunately, it is at this stage that various difficulties arise regarding operation. heating equipment. Frequently asked question home owners are wondering how to properly heat a solid fuel boiler with coal, since this fuel is a common raw material for normal operation heating.

Handling the equipment heating type must be careful in compliance with safety regulations.

Important! After purchasing solid fuel heating equipment, you should definitely familiarize yourself with the features and principle of its operation.

Each unit operating on coal fuel has individual characteristics operation. For example, some options are equipped with automatic mechanisms, others simply operate under the influence of the human factor.

The operating principle of TT equipment is quite simple. Its interior consists of two chambers: the upper one is intended for the firebox, and the lower one is for collecting slag and ash, which are cleaned as the chamber becomes dirty. In order to properly light the boiler, it is enough to purchase required material. If you do not use chemical mixtures, then you can solder the boiler using paper and dry brushwood, and after it flares up well, add coal.

If you don’t have the opportunity to regularly look into the firebox or don’t want to, you can use long-burning equipment. In such situations, the question of how to properly heat a coal boiler will disappear without a trace. However, such stoves are several times more expensive than ordinary stoves intended for home use.

There are solid fuel boilers with automation on sale, let’s look at their advantages:

- automatic mechanism helps control the combustion process;

- regulates the flow sufficient quantity oxygen into the furnace;

- the normal operating temperature of the heating system is optimized;

- The heating of water in the pipes for each room is controlled equally.

How to fire a coal boiler: preparation and kindling

Before you start using it, be sure to check that the device is working properly. To do this, it is necessary to exclude all sorts of cracks, metal tears, and also check the internal mechanism. After the inspection is completed, you can start kindling.

Regular charcoal equipment will need matches, paper and thin brushwood.

Attention! Before lighting the boiler, clean it. Rake out the ash and remaining fuel from previous work from the ash pit. If you are heating the device for the first time, we skip this stage.

When everything is carefully prepared, we proceed in the following steps:

- Place dry paper on the grill. It is advisable to crumple it a little to make it easier to set on fire;

- put brushwood on top. It is better to place it evenly: you can lay it out in the form of a well or make a hut. Avoid carelessly laying out firewood; it will take too long to burn;

- light a match and bring it to the paper with different sides. This is done to ensure that the sheets burn evenly;

- then close the firebox door and open the blower door;

- watch the combustion of the contents in the firebox. After a crust of ash remains, place a wide layer of fine coal on top up to 15 cm;

- Stir the burnt fine coal well, and then place a layer of larger coal on top. Monitor burnout regularly and add fuel.

Important! If you open the firebox door to load fuel, be sure to close the vent.

How to heat a long-burning boiler with coal?

Such installations are not used as often, but are still considered more alternative options in application. It is worth noting that the operation of this equipment is somewhat different, so you will have to heat it according to the attached instructions.

Long-burning heating boilers can operate on brown coal, but the question of what else can be used to heat such a unit has many answers. An operating mechanism created in this way will lengthen the burning time of the device, regardless of how many fuel loads were made into it.

First you need to put firewood in the upper chamber of the boiler, then paper and thin wood chips are placed. The entire contents are set on fire - you need to wait until it flares up, for better oxygen supply to the furnace, you need to pull out the damper, it can be adjusted depending on the desire to receive heat transfer from the boiler.

Attention! It is dangerous to leave the chimney damper closed - this entails the movement of carbon monoxide into the living room.

If you have lit a coal stove for the first time this season, do not worry if liquid appears on the pipes - this is condensation, which will disappear after some time. If this does not happen, your system may need repair. After the fuel in the boiler has ignited, you can turn on the control system. It's better to install high temperature, and during the heating process it can be reduced to a suitable level.