Which is the best solid fuel boiler to buy for heating? Which wood boiler is the most efficient?

1.

2.

3.

4.

5.

If we talk about modern heating devices and the principles of their operation, it is impossible not to note such equipment as solid fuel boilers. As their name suggests, they operate by using energy. solid fuel. These innovative devices not only effectively heat the living space, but also fit perfectly into the interior and create comfort in any home.

However, not everyone can clearly say which solid fuel boiler is better. Therefore, it is necessary to determine how to choose a solid fuel boiler that best suits a particular room in terms of its performance and efficiency indicators and is reliable and for a long time services. This is exactly what will be discussed further.

Types of fuel for boilers

One of the main criteria when choosing such equipment is, of course, the type of fuel used. IN modern models It is customary to use different energy sources, such as peat, pellets, briquettes, as well as the familiar coal and firewood.Yes, thanks innovative technologies production, heat can be obtained from almost any source, which creates a unique opportunity to save significant part financial resources and save yourself from the need to regularly purchase expensive fuel.

- samples operating on coal. Without knowing how to choose a solid fuel boiler for a house located far from a large populated area, special attention should be paid to just such a mechanism. These boilers are perfect if it is not possible to provide firewood proper storage. At the same time, the performance of such equipment will be very high, and its design will not become too expensive. The main advantages of a coal-fired boiler are versatility of use, low cost consumables, as well as the ability to work autonomously;

- pellet boilers and wood boilers. Principle of operation solid fuel boiler This type is based on the use of firewood and pellets (special fuel granules) as the main source of heat. The power of these mechanisms is quite high and can reach up to 200 kW, while they are economical and can be installed in any room.

The availability of wood explains the wide popularity of these devices among the population. In addition, the efficiency of a solid fuel boiler operating on wood is high and reaches 90%. Wood and pellets burn for a long time, without leaving behind any harmful products; - pyrolysis combustion boilers. The operation of these boilers is aimed at burning bio-based solid fuel, which can be wood pulp. These substances, when burned, release a special flammable gas, due to which heat transfer is so effective (the efficiency of pyrolysis boilers ranges from 85 to 92%).

Criteria for choosing solid fuel boilers

Before deciding which solid fuel boiler to choose, it is necessary to take into account certain factors that significantly influence the choice of a particular sample.The main criteria in this case are the following:

- Area of a specific building. This parameter largely determines what power boiler should be purchased, and also affects the choice of fuel for it.

- Height of ceilings in residential premises.

- Heat loss rate. This parameter is influenced, first of all, by the thickness of the walls and ceilings in the building, as well as the material from which the house is made. It would also be useful to take into account the area of door and window openings.

- Climatic features specific region. As a rule, the main emphasis is placed on temperature indicators during the cold season, since it is these data that make it possible to calculate the optimal heating power of the boiler.

To do this, you should first take into account the square footage of the house. For example, to provide full heating to a room of 100 m², you will need to use equipment with a power of 10 kW. In this case, you should always remember about a certain power reserve, which should be approximately 1 - 2 kW.

Difference between manual and automatic loading of boilers

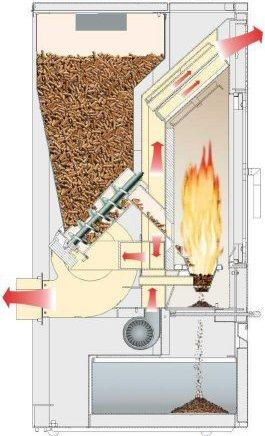

When comparing solid fuel boilers, one should also not miss such a parameter as their loading mechanism, which can be of two types: automatic and manual.The design of boilers with automatic fuel supply is based on the main part and a special bunker, into which the fuel is placed directly. If it is coal, then the size of its particles should not exceed 25 mm. However, there is also the possibility of using pellets, which definitely do not exceed this parameter.

For continuous and high-quality operation, one load of fuel is enough for approximately three to five days, which makes working with the boiler very convenient and easy.

At the same time, the size of the boiler bunker can be very different, it all depends solely on the preferences of the owners, since you can load a lot of consumables into this chamber, thereby forgetting for a long time about the need to replenish the coolant supply in the boiler.

Fuel is supplied through one of two options - either using a screw or using a piston. Regardless of this, we can say with confidence that the most economical solid fuel boiler will definitely have an automatic fuel supply mechanism, which will not only prevent excessive material consumption, but will also be able to guarantee stable operating power of the equipment.

These devices are not economical; in addition, it is not recommended to install them in residential premises, since their dimensions are very large, which will be extremely inconvenient. It would be much more correct to install such equipment at the enterprise industrial type, since it is not always possible in standard construction to provide separate room for installation of a solid fuel boiler.

What does a boiler heat exchanger consist of?

The most popular materials for the manufacture of such an obviously important functional part of a solid fuel boiler as a heat exchanger are two - cast iron and steel.It is these devices that should be discussed in more detail:

- Cast iron units are characterized by high performance if they run on coal fuel, since the use of firewood can negatively affect the power of the equipment.

The main advantages of products made of cast iron are their affordable price, the versatility of the fuel used for operation, as well as the ability to repair them quickly and without problems for the entire system. However, this technique also has disadvantages, the main of which are a small efficiency coefficient (about 65 - 75%), the need for regular maintenance, as well as high inertia rates. - In steel mechanisms, the main fuel is firewood or briquettes created by processing wood waste(read also: " ").

- thickness of the metal used in the structure;

- method of constructing a heat exchanger;

- productivity factor;

- maximum operating time on one fuel load.

Technical characteristics of solid fuel boilers

As a rule, in order to choose the best solid fuel boiler, you initially need to become familiar with the basic properties of this equipment.The main technical parameters of such boilers are the following:

- type of fuel used for work, which, as mentioned above, can be coal, firewood, peat briquettes, as well as recycled waste. Thanks to such a wide range of consumables, it becomes possible to significantly reduce the energy consumption required for heating;

- combustion chamber capacity, which mainly affects the performance of the device and the number of fuel loads;

- work automation. Many mechanisms are equipped with a similar function that helps relieve oneself from constant control over the operation of the boiler system;

- product safety indicators. When choosing a particular unit, it is imperative to take into account how safe its use will be. So, the main elements that any boiler should be equipped with are the function automatic shutdown, as well as the presence of an alarm system;

- energy consumption parameters. Some models require access to the power supply, otherwise they will not be able to function. However, most solid fuel boilers are self-contained;

- price of products. When choosing such equipment, you should not focus only on low cost, since specifications Cheap equipment is usually far from ideal.

Considering all these tips and recommendations, setting up a solid fuel boiler in your own home will not be difficult, and if necessary, you can always turn to qualified specialists, capable of providing photos of boiler samples and detailed videos, displaying the entire installation process.

27.03.2017 1313

Every year more and more products appear on the market different models solid fuel boilers. For the right choice You should focus on the power of the unit and the size of the area to be heated. It is also necessary to take into account the efficiency indicator and the type of control. Based on these criteria, everyone can choose the best option for themselves.

The most popular solid fuel boilers

- Protherm Beaver – classic version of solid fuel boilers. It has a simple installation that even an inexperienced user can handle. This series includes boilers with different power ratings, but even the Beaver 20 DLO model with a power of 19 kW can heat an area of up to 190 m2. Beaver 50 DLO copes perfectly with big house, the model has a power of 39 kW. The units are characterized by a high level of efficiency (up to 90%). The boilers are single-circuit with a combustion chamber open type. Coal and wood are suitable fuels; according to the manufacturer's recommendations, water should be kept within 3-4 bar.

Advantages of solid fuel boilers of this series:

- durable cast iron heat exchanger;

- the boiler is equipped with a thermometer and pressure gauge;

- energy independence;

- simple mechanical control;

- high thermal power levels.

- Buderus Logano – A German brand, it occupies a leading position among wood-burning boilers. It is very popular. It has a high level of efficiency and good thermal insulation, which provides excellent heating of a room up to 200 m2. For better quality work, you can use circulation pump. Heats up quite quickly. Easy to maintain and easy to clean.

Important advantages are:

- reliability;

- suitable for different systems heating;

- energy efficiency;

- big sizes fireboxes

- Stropuva S – single chamber boiler long burning Russian production. The equipment is characterized by high performance; just one load of firewood or wood briquettes is enough to heat the house for several days. The efficiency level is 91%, and in the S 40 model it reaches 95%; the combustion process itself is very slow. Such a unit can become the basis of an autonomous heating system. Wood, coal, pellets, and coke are used as fuel.

Important advantages:

- energy independence;

- compactness;

- ease of maintenance;

- unusual design.

- – single-circuit boiler with an open combustion chamber. The heat exchanger is made of cast iron, has a sufficient level of efficiency (up to 80%), and is suitable for heating an area of up to 200 m2. Firewood must be used as fuel.

Among the advantages are the following:

- economical fuel consumption up to 7 kg per hour;

- quiet operation;

- retains heat for a long period;

- high quality heat exchanger.

- Bosh Solid 2000 – single-circuit boiler made in Germany, has excellent characteristics. The heat exchanger is made of high quality steel, while the grates are made of cast iron. The power is enough to heat 160 m2. Can be used in combination with a gas boiler.

Main advantages:

- automatic power control system;

- Possibility of loading through the top cover;

- reliability;

- stylish design.

- ZOTA Mix - boilers domestic manufacturer include a large range of reliable units. The MIX series is very popular; it includes devices with an efficiency of up to 80%. These are solid fuel boilers combined type, work well on coal, wood, all types of gas, electricity and liquid fuel. The boilers of this series use modern Constructive decisions, which provide the units with important advantages:

- the heat exchanger has X-shape what increases the efficiency of heating the coolant;

- the presence of an ejector on the doors ensures complete combustion of fuel;

- easily adaptable to different types fuel;

- designed for installation of heating elements with a power of up to 9 kW;

- presence of an electronic control panel.

- ZOTA Topol M not inferior to foreign analogues. The boiler is suitable for operation in autonomous systems heating. The equipment has high power; coal and wood are used as fuel. Additional devices can be equipped heating elements, then they can work using electrical energy or can be modified to work with gas.

Advantages:

- one stack of firewood allows you to heat the room for 12 hours;

- mechanical air supply control system;

- modern thermal insulation provides protection against overheating and promotes heat retention;

- the presence of three heat exchangers contributes to faster heating of the room;

- low cost.

- ZOTA Carbon quite a popular series. The boilers are highly economical and efficient. An important advantage is the ability to regulate the air supplied to the firebox, which allows you to increase the duration of the combustion process. The boiler can be easily installed in existing system heating. The boiler can withstand water pressure levels up to 3 bar and is energy independent.

- ZOTA Pellet– an excellent series of reliable and high-quality boilers. Single-circuit boiler is ideal for heating big houses. The unit is equipped with an automatic fuel supply mode and also has automatic system management. The equipment has an outdoor temperature control sensor, which allows you to control temperature regime premises. It is recommended to use pellets, firewood, and briquettes as fuel.

The important advantages of the series are:

- availability of a bunker for automatic feeding fuel;

- overheat protection function;

- the presence of numerous sensors ensures control of equipment operation;

- Possibility of connecting underfloor heating.

- Roda Brenner – German boilers are equipped with a cast iron heat exchanger. The series is represented by models with different power levels. Among the advantages are:

- high work resource;

- high level efficiency;

- excellent thermal insulation of the firebox;

- possibility of connecting an external burner;

- increased dimensions of the loading hatch.

When choosing solid fuel boilers, you should not focus on price; first of all, decide on the preferred type of fuel, the area of the house, pay attention to technical specifications devices. Unreasonable savings in this matter can lead to significant waste in the future.

Many villages do not have a gas pipeline, and paying electricity bills can cost a pretty penny. Of course, this is annoying, but there will be no problems with heating even in this case. Using a solid fuel boiler will allow you to forget about the inconveniences associated with the cold, even if it is severely frosty outside.

Firewood - outdated?

Of course, in the age of widespread automation, nanotechnology and stunning technology, it is difficult to believe that using solid fuel for heating is advisable.

But just imagine, such a boiler is not just a “potbelly stove” into which you need to constantly add firewood. This is the real center of the heating system, efficient, economical, inexpensive and durable.

Principle of operation such equipment is extremely simple. For different fuel models, you can use shavings, briquettes, granules, even corn cobs and seed husks.

The design features of the firebox are such that not all firewood begins to burn intensely immediately, but only upper layer fuel. At the same time, its consumption is reduced significantly, which implies significant savings.

The water that circulates in the heating system enters a heat exchanger, which is heated by the energy of burning wood. When all the coolant has warmed up to the required temperature, the boiler turns off.

After connecting the unit to the water supply system and loading fuel, it can quite long time work without user attention. This time depends on both the quality of the fuel and its quantity. For example, briquettes, husks or spruce shavings burn out quite quickly, which means that it is necessary to frequently remove the ash and load a new portion of fuel in order for the boiler to continue to heat. Coal and anthracite burn longer, and often the energy they release during combustion is higher. This means that when running on this type of fuel, the boiler will heat stronger and longer.

Fundamental differences

To make choosing a boiler not difficult, we have answered several popular questions that buyers have.

Are there any differences in the operating principle and the fuel used?

Traditional devices only operate on wood, coal or peat briquettes. They are completely independent of electricity, which makes them very popular among summer residents and owners country houses. The only thing worth thinking about is the constant availability of fuel, that is, firewood, coke or coal. Such boilers provide excellent support set temperature, And long years do not cause any malfunctions.

Traditional devices only operate on wood, coal or peat briquettes. They are completely independent of electricity, which makes them very popular among summer residents and owners country houses. The only thing worth thinking about is the constant availability of fuel, that is, firewood, coke or coal. Such boilers provide excellent support set temperature, And long years do not cause any malfunctions.

Pyrolysis boilers can “boast” of very high efficiency. Their main difference from traditional ones is the use of not only the heat from fuel combustion, but also the energy released by wood gas. Special fans heat the air in the combustion chamber to very high high temperatures, the firewood begins to release gas, this process is called pyrolysis.

It is worth noting another advantage of such devices - during operation, practically no soot and soot or ash are formed.

It is worth noting another advantage of such devices - during operation, practically no soot and soot or ash are formed.

In addition, there are also ones that use special pellets - compressed wood - as fuel. The advantage of such units is that they independently add granules to the firebox using an auger.

Purchase long burning boilers , This perfect solution for heating large premises, for example, private houses or roadside hotels. They can be universal (burning coal and wood), or wood-based. These units are very sensitive to the quality of materials that the user sends into the combustion chamber. Therefore, we advise you to avoid damp firewood.

Manual or automatic fuel loading?

You will have to throw wood chips, coal or peat into the fireboxes of traditional, pyrolysis boilers or long-burning devices yourself. At the same time, do not forget to periodically check the presence of fuel in the combustion chamber.

Automatic boilers , only calibrated charcoal is used as fuel, which is fed into the firebox, as in pellet boilers - using augers. This design will make it easier to maintain the boiler, but it’s still worth “visiting” it from time to time.

Does the material from which the heat exchanger is made matter?

Getting more and more popular boilers made of steel

. If your choice fell on similar model, You can be sure that this equipment will last a very long time. Steel conducts heat well; in case of a leak, it is easy to solder, and virtually no carbon deposits form on it. But this material is not resistant to condensation, which means corrosion is possible.

Getting more and more popular boilers made of steel

. If your choice fell on similar model, You can be sure that this equipment will last a very long time. Steel conducts heat well; in case of a leak, it is easy to solder, and virtually no carbon deposits form on it. But this material is not resistant to condensation, which means corrosion is possible.

Cast iron boilers - classics, but now they are gradually becoming a thing of the past. Despite the fact that the material from which the heat exchanger is made conducts heat well and is almost 100% protected from rust, it has a number of disadvantages. Experts warn about the difficulty of implementation repair work- it is almost impossible to replace a cracked section due to the deposits that have formed.

Which chimney design is better?

In fact, on how they will pass ventilation pipes removal of combustion products is influenced by several factors.

Firstly, traction. In this case, this is an indicator of the speed at which smoke will be removed. If you notice that smoke is accumulating in the room where the boiler is operating, you need to open the damper and thereby increase the air flow.

Firstly, traction. In this case, this is an indicator of the speed at which smoke will be removed. If you notice that smoke is accumulating in the room where the boiler is operating, you need to open the damper and thereby increase the air flow.

Secondly, chimney section. This parameter always depends on design features each boiler model. But it is worth noting that a chimney that is too narrow may not cope with the entire volume of combustion products, especially if the unit is powerful. And if it is too wide, the air will “walk” without taking with it unpleasant odors and smoke.

Speaking about design, it is worth saying right away that only specialists can do this, because it is important to know the aerodynamic features of the heating system, the boiler itself and the chimney. It can be square or round. But keep in mind that the design should not be very large quantity bends, bumps and turns. By the way, draft is always better in round chimneys (since there are practically no barriers to air flow).

A solid fuel boiler is an ideal solution for heating a private home, especially if it is not possible to use gas or electricity. This equipment is capable of heating a large volume of water in heating system, so it will be warm even in a large room. Check how convenient it is to use economical, inexpensive fuel, and feel the result of the boiler’s operation within a few minutes after turning it on.

You can order a solid fuel boiler in our online store. We guarantee you low prices and fast delivery.