The diagonal of the roof did not agree on the solution options. Sequence of work on a roof with layered rafters

It is impossible to equip a roofing system without sheathing, which is laid on top of the rafters. It serves as a direct attachment point for the finishing roof sheathing.

What is the roof made of?

Thanks to the roof, the building not only receives a decorated appearance: it also has a protective function to prevent rain, snow, heat and cold from entering the ceilings. In addition, thanks to the roof, the impact of wastewater on walls and basement surfaces is noticeably reduced, which significantly increases their service life. Most often, there are 2 or 4 slopes on the roof of a building: the second design involves several arrangement options.

In the composition of the usual gable roof includes:

- Rafters. To connect these vertical or horizontal supports, they usually use gusset equipped with bolts and brackets.

- Mauerlat. This beam is located in a horizontal position. It rests on individual elements of the rafters.

- Overhangs. This is what the lower sections of the rafters are called.

- Horse. It is located on top of the structure, in the area where the rafters meet.

- Lathing, counter-lattice. Basic parts that ensure the installation of roofing materials and insulation.

- Waterproofing and insulating materials. With their help, warm attics are equipped.

- Roof decking. Can be hard or soft.

In general, roofing is divided into cold and warm subspecies. The first option involves laying thermal insulation in the attic space: the roof in this scheme is not insulated. The second method involves laying insulation and waterproofing. This approach is mainly used for the design of attic residential floors.

Purpose of sheathing in a roofing system

Thanks to the lathing, the following tasks are achieved:

- Happening reliable fastening roofing materials.

- In this case, the space between the roof and the insulation is well ventilated: this is especially important for adjacent areas of warm and cold roofing layers.

- It is convenient to attach a layer of insulation and waterproofing to the roof sheathing.

- The rafter system receives protection from excessive load in cases of heavy snowfall.

What tools and materials will be needed

Before lathing the roof, you should prepare the following tools and materials:

- First grade wooden beam, 6 m long, without knots or other defects. The cross section is selected depending on what finishing material will be used. For metal tiles you will need products with a cross section of 50x50 mm, metal roofing equipped with timber 60x40 mm. Ceramic tiles laid on timber with square section 75x75.

- Edged board 25x100 mm, 6 m long. Small flaws in the form of rare knots are allowed here. In some cases, it is necessary to replace the boards with OSB boards, plywood or chipboard panels.

- Hacksaw, chainsaw.

- Polyurethane foam.

- Hammer, perforator.

- Large bolts and nuts. Fastening is also carried out with staples and nails.

- Construction level, tape measure.

Types of roofing sheathing

When studying the question of how to properly frame a roof, it is important to know about the most popular system designs. Choice suitable option lathing directly depends on the roofing material used.

There are two main types of lathing:

- Solid. When laying the beams, a gap of 10 mm is assumed. A continuous sheathing is usually constructed under soft tiles, roll laying, flat slate or metal tiles. To give the roof additional reliability, the structure is fixed on top of the eaves overhangs, as well as in areas where the slopes adjoin. When choosing this sheathing, you need to prepare for a significant consumption of material.

- Sparse. The gap between the timber in this case can reach several centimeters, which is very convenient for installation natural tiles, metal sheets and wave slate.

We install the roof sheathing with our own hands

After rafter system fully equipped, careful measurements of the roof are carried out. This is done using a rope, which simplifies the measurement of diagonals. When comparing two indicators, it is desirable that they do not differ from each other by more than 20 mm. If this tolerance is exceeded, subsequent work may encounter certain difficulties. Next, vapor barrier and insulation is installed, in the form of mineral wool or other suitable material.

The roof sheathing is assembled with your own hands on top of the previously laid waterproofing film, when laying it there is an overlap of 15 cm. It is most convenient to install the sheets from the top and down, taking the rafters as the directions. Suitable for attaching film construction stapler. The slats are stuffed on top of the rafters to create a counter-lattice.

It is important not to forget about the ventilation gaps separating the film and the roofing material being laid. Simply put, when laying down film, it is important to leave some slack. The same method is used to separate the film and insulation. To simplify the task of how to properly make a roof sheathing, a sheathing template is used, which is designed to strictly adhere to design parameters.

If a soft roof is being laid, then the installation of the sheathing elements is carried out using the method of leveling and joining. To avoid subsequent deformation, solid structure need to be fastened with special care, using at least two nails on each beam.

How to attach under rolled material

To lay rolled sheets, you will need a continuous roofing sheathing made from beams and boards with a thickness of at least 25 mm. In this case, the flooring must be laid tightly, without cracks. The sheathing pitch is chosen to be no less than 15 cm, otherwise the roofing material will begin to deform. It is important to achieve an ideal smoothness of the sheathing surface, with the obligatory recessing of the nail heads and screws deep into the wood.

How to make a soft roof

Installation of soft type roof sheathing is most common due to the high popularity of this roof. This material is inexpensive, and it is very easy to install. Here you will also need to equip a continuous type of sheathing, which is equipped with a special calibrated board. This installation has a two-layer structure, ensuring maximum evenness of the joints.

In these conditions, tongue-and-groove boards and roofing plywood, which have undergone preliminary testing, have proven themselves well. antiseptic impregnation. To avoid damage soft roof in corner areas, the ends of the boards must be rounded.

Under the tiles

According to experts, it is tiled roofs that have the most optimal performance characteristics in terms of quality and durability. Usually these are single-layer structures, the sheathing for which is made of bars with a cross-section of at least 6 cm.

The laying step is based on the dimensions of the tiles used. Some situations require the creation of double sheathing from the same material. To achieve uniform fit of the tiles, it is necessary to build the most even plane of the structure. This implies using timber of the same size.

What is the difference between lathing for slate and metal tiles?

To arrange the sheathing, we can use one or two layers of laying. The first option involves the use of timber with a square cross-section of 50 mm. The optimal step in this case is 50 cm, with the elements laid in a parallel direction to the ridge. If a unified profile is used instead of the usual corrugated slate, the pitch can be increased to 80 cm, with the section of the beam increasing to 75 mm. The main thing is that there are at least three crossbars under each slate span.

The cornice is loaded the most in this design, so its thickness should be increased. Ridges and overhangs are decorated with continuous decking. To achieve uniform load distribution and density of sheet laying, even beams are made 30 mm thicker than odd ones. In order for the structure to last as long as possible, before attaching the sheathing to the roof, all its wooden parts must be treated with special fire-fighting and antiseptic compounds (for more details: “How and with what to treat the rafters and sheathing - choose an antiseptic”). To apply them you will need paint brush: impregnation is carried out in two layers.

To test the quality of a fire-fighting substance, it is enough to chop off a small piece of treated wood and try to set it on fire. A well-protected material ignites only when it is exposed to an open flame: once it is removed, the substance immediately dies out.

Proper design and arrangement of the roof will be the key to both the aesthetic beauty of the house and its protection from all external influences. It is important to achieve good quality of each individual part. roofing structure. The lathing, despite its inconspicuousness, plays a very important role, so when arranging it it is important to comply with all necessary requirements and standards on how to make roof sheathing. Special attention At the same time, attention is paid to the selection of suitable building materials of appropriate quality.

Roof sheathing: how to fasten it, installation on the roof, how to make a proper roof sheathing with your own hands

Roof sheathing: how to fasten it, installation on the roof, how to make a proper roof sheathing with your own hands

Roof sheathing: we create it ourselves

Building a beautiful, cozy home for a family is a city dweller’s dream. Having studied all the intricacies of the art of construction, you will be able to bring your idea to life. But, during the work, one of the main questions will be - how to make a roof sheathing? Approach it correctly, because the protective and aesthetic properties of the roof depend on the quality of workmanship.

The need to create a frame

Before moving on to listing the types of roof sheathing, understand what sheathing is and what it is used for. The lathing used for the roof of private buildings is a structure made of wooden beams and boards. The roofing system installation process is necessary to:

- evenly distribute the load of a person walking on the surface during its maintenance;

- securely fix the materials - use a frame welded from metal or made of wood for the sheathing;

- correctly create a ventilation space between the ceiling and the waterproofing, which protects the building from condensation;

- promptly prevent the accumulation of moisture at the boundary between warm and cold roofing layers;

- fully ensure the protection of rafters from the effects of weather precipitation (snow and ice).

The number of layers that the sheathing has will depend on the slope of the roof. For a pitched roof, a horizontal single-layer covering is sufficient. The two-layer method involves working with lower load-bearing beams, fixed in increments of 50-100 cm. A layer of plywood or wooden planks is attached on top of it. This technique will allow you to save material and even out the errors in the rafter system using roof sheathing.

Types of roof frames

The roofing needs a reliable and durable surface on which it will be laid. An incorrect construction algorithm will lead to deformations, lack of protective functions homes during bad weather.

Depending on the number and frequency of mounted planks, the type of material used, and the angle of inclination, the frame is divided into the following types:

- Double layer. Used when maximum structural strengthening is required. The first layer is laid with a large step, and the second - with a normal or without gap.

- Solid. It is carried out at intervals of about 1 cm and prevents the appearance of deformations when the wood shrinks or swells.

- Normal, in increments of 20-40 cm. Mainly used to reinforce the coating of metal profile sheets.

- Sparse. The gaps between the boards reach 75 cm. Used for lightweight floors.

To choose the right required material, purchase tools, you need to draw up a drawing of the sheathing and carry out preparatory manipulations.

Materials and tools used

Choosing a floor material to cover a building is difficult. Slate, corrugated sheeting, tiles - which of these positions is suitable for covering? It all depends on your desires and financial capabilities.

Cost calculation

To find out how to make the lathing correctly, you need to carry out calculations. The basic rule of construction is accurate planning of costs and quantities of raw materials. For calculations you will need the following data:

- roof size;

- material type;

- roofing structure.

If independent design seems like a daunting task, use an online program. Enter the size of the coating, all known parameters of the materials used - the program will automatically perform the calculation.

Purchasing building materials for wooden sheathing

Use seasoned wood with no visible defects. The presence of knots and cracks can lead to a violation of the integrity of the structure and subsequent destruction. Used for work following materials and tools:

- timber wooden section 50×50, 60×60, 75×75 mm;

- edged boards for the sheathing with a section of 150×20, 150×50 mm;

- fastening elements (screws, nails) with a length twice the size of the timber;

- level, pencil, tape measure for marking;

- circular saw used for cutting roofing material;

- a hammer for nails or a screwdriver if self-tapping screws are used.

The lumber must be marked and cut according to the drawing. If electrical equipment is not available, you can buy or rent it.

Execution technology installation work

Having completed preliminary calculations and made a purchase necessary materials and tools, you can begin installation. For different types of flooring there are separate technological nuances. But general order production looks like this:

- Carefully measure the roof after the rafter frame is installed. To do this, you need to check the diagonals along all slopes with a nylon cord. Deviations should not exceed 20 mm, because the run-up will cause difficulties during further fastening of the roof.

- Process all wooden elements antiseptic solutions to avoid rotting and insect damage.

- Place waterproofing materials on the rafters.

- Install the bottom strips. Use large cross-section timber for these purposes.

- Continue work, laying boards at the selected spacing. For each type of flooring it is selected individually. An incorrectly performed step can lead to weakening of the entire structure.

- If it is necessary to carry out insulation, place on the first layer mineral wool, and, after this, a second layer of sheathing can be made.

- Lay the end boards next to each other to use them for later decoration of the ridge.

- Fasten on both sides, and if the overhang is large, perform additional fixation.

These rules should be followed when installing a frame under any type of roofing material. But there are minor features.

Features of moisture protection of sheathing

To create a waterproofing layer, vapor barrier or hydrobarrier materials are used. When working with them, an overlap of 10-15 cm should be maintained. The waterproofing is installed in the direction from the eaves to the ridges, with slight tension. Ventilation holes are formed due to the sagging of the film material, which is secured with a construction stapler.

How to make sheathing for corrugated sheets?

The roof sheathing under corrugated sheets differs in some nuances. The profile sheet has a large load - a person can walk on it without fear of falling through. When working with a profiled sheet, consider several important nuances:

- For a roof made of corrugated sheets, it is necessary to strictly maintain the spacing between the boards. Its distance can be varied from 50 to 150 cm, focusing on the wave of the material and its marking (sheets with the H index will be optimal for roofing systems);

- When using sheets with a height of less than 35 millimeters for work, the step should be kept to a minimum. This will increase the strength and rigidity of the coating;

- standard parameters wooden planks less than the size of the slope, so it is necessary to splice them;

- in the horizontal planes, the joints must be shifted to prevent weakening of the structure;

- For corrugated sheets, special fasteners are used - galvanized self-tapping screws with rubber washers that prevent the sheets from being crushed during fastening. The connection is made using rivets.

If it was built from a profile sheet pitched roof with a slight slope, you need to make a solid frame from boards 60-70 mm wide. The nail heads are recessed as much as possible. The sheathing board is laid strictly at an angle of 45 degrees. Only well-dried wood is used so that warping does not occur when it is placed tightly.

Lathing for slate roofing - specifics

For sheathing under slate, it is advisable to purchase beams with a larger cross-section. Three beams must be placed under each sheet to evenly distribute the load. Fastening is done with special slate nails in places where the wave touches the wood. Use lumber without bending to ensure a tight, gap-free fit of the slate sheet.

Making a frame for metal tiles

In addition to profile sheets, there is another type of durable and durable coating- metal tiles. When building a house, it is placed in a single-layer manner. The lathing can be made by stuffing bars with a cross-section larger than 1 mm onto the rafters. The pitch of the structure depends on the parameters of the tile. To ensure a uniform fit of the roof, the frame is made as even as possible. The position of the boards is checked by a level.

Benefits of self-building

Roofing installed in accordance with the requirements technological process, will last long years, will save your home from destruction. After studying the recommendations on the issue, you can perform labor-intensive tasks yourself. Having carried out a set of measurements with the required accuracy and followed the installation recommendations, you will receive good and durable protection from all sorts of adversities, ensure peace and comfort of living in a country house.

Roof sheathing: how to make and install it yourself?

Roof sheathing: creating a frame, types of roofing frames, materials and tools used, sheathing for various types roofs

Good afternoon

Please tell me what to do correctly.

Flooded strip foundation on the 16th reinforcement, 62-64 centimeters wide to a depth of 2 meters 10 centimeters. Dimensions along the outer perimeter are 11 meters by 12 meters 60 centimeters. With a middle tape under a load-bearing partition 62 centimeters wide for laying floor slabs PP-63 and PP-54. It is planned to build a house on three floors from aerated concrete blocks with a width of (400*600*250 mm) or (450*600*250 mm), with insulation of the external wall - 50 mm basalt insulation, air gap-20 mm, finishing brick -120 mm.

During the installation of the foundation of the protruding element of the octagonal “bay window” sector (protrusion beyond the dimensions of the foundation 11 * 12.6 meters along the wide half of the PP-63 foundation) for the halls. The diagonal of the foundation was increased by 18 centimeters while controlling the dimensions of the diagonal perimeter of 11*12.6 meters.

The support of the floor slab on the walls is planned to be 200 mm.

I kindly ask you to give professional advice:

1. Is it worth trying to level the diagonals by installing an overhanging masonry made of solid ordinary brick with a hardness of 200 with mesh reinforcement and a maximum of how many centimeters?

There is a fear that under the weight of the facing brick, the overhanging part of the widening above the foundation will deform and the cladding of 3 floors will crack

2. Limit yourself to a large overhang of 3-5 cm to compensate for the diagonals with the subsequent construction of the structure.

3. What deviations of diagonals are allowed for such building sizes in construction?

4. What consequences can there be if diagonal compensation is not applied when installing floor slabs, will it change load bearing capacity building??? How to lead external finishing when facing facing bricks. Nikolay

Hello, Nikolay!

- Aligning the diagonals makes sense since the loss right angle can lead to difficulties in performing a number of works - from facade masonry to roofing and finishing.

Most reliable way align the diagonals - make a monolithic belt at the level of the basement of the building. The outer contour of the belt should clearly form the desired geometry of the facade. Task internal contour– to ensure the possibility of erecting main walls from aerated concrete blocks at right angles.

The height of such a belt should be taken within the range of 200-300 mm. Longitudinal reinforcement – at least 6 reinforcing bars with a diameter of 12 mm of class A-III (A400). Since such a belt will have side overhangs (due to which the geometry will be adjusted), transverse reinforcement in such places should be performed with closed-section clamps made of reinforcement with a diameter of 8 mm A-I (A240) with a pitch of 100 mm in places of overhangs and 400 mm at other areas.

An example of reinforcement of a belt with 6 longitudinal rods and transverse clamps of a closed section

The belt should be supported on the walls of the underground, made, for example, with masonry made of red (clay) bricks or FBS blocks. The width of the belt must be sufficient to install a wall structure on it (not less than the sum of: 120 mm of cladding + 20 mm of gap + 50 mm of insulation + 400 or 450 mm of masonry from aerated concrete blocks).

To avoid deformation of the cladding, the façade masonry must be securely anchored into the main wall.

An example of anchoring facade masonry (in your case, a different insulation and a smaller ventilation gap, but the essence is the same) with a flexible connection “Galen” BPA L-6-2P with a pitch of 500x500 mm

- With small overhangs, you can limit yourself to reinforced masonry with solid bricks of a sufficiently high strength grade (M200 is suitable). But in this case, it will be possible to only partially correct the geometry, which will complicate further work. In addition, this grade of strength is typical for white (silicate) bricks, which are not intended for laying underground parts of walls. Red (clay) brick, often used for these purposes, is less durable.

- Deviations in geometric dimensions during the construction of walls made of brickwork are regulated by the requirements of SP 70.13330.2012 “Load-bearing and enclosing structures,” in particular Table 9.8.

Dimensional tolerances for masonry structures

As can be seen from the table, the deviation of the walls from the alignment axes (that is, in plan) should not exceed 10 mm. There is no standard prohibiting making a building in a diamond-shaped or trapezoidal shape (that is, figures with different diagonals).

- If you do not compensate for the differences in diagonals, the main consequences will be as follows: difficulties with the construction facing masonry(in the corners), wedge-shaped cuts of the flooring material (if the geometric pattern is correct, it will be noticeable), possible problems when joining the roofing material (depending on the roof configuration), etc. Measures to correct geometry will pay off handsomely.

If the depth of support of the floor slabs along the entire length of the supporting part is not less than the required one (90 mm for reinforced concrete and 120 mm for brickwork), there will be no reduction in the reliability of the building in terms of load-bearing structures. Do not forget to anchor the floor slabs to each other and to the masonry.

Stingrays gable roofs should have the shape of a regular rectangle, the slopes of hip roofs should have the shape of isosceles triangles or trapezoids. This requirement is due to the fact that almost all piece elements roofing coverings have a rectangular shape. When laying them on a non-rectangular slope, for example, having a rhombic or trapezoidal outline with different heights of the ridge or incorrect dimensions of the perimeter of the walls, an unclosed wedge will inevitably result. It can be closed only by adjusting piece roofing materials, which creates additional difficulties, increases the consumption of materials, reduces the speed of construction and, finally, simply spoils the appearance of the building, but most importantly, it greatly increases the possibility of roof leakage.

Isosceles slopes of hip roofs make it possible to cut roofing materials according to one or two templates, and use the halves of some roofing materials on opposite sides of the slope. For example, a sheet of ondulin, cut diagonally, can be used on both sides of the slope. If, by design or as a result of negligence, the roof slopes have different angles tilting, cutting of piece elements is carried out individually. As a result, the speed of work is significantly reduced, and there is no talk of any savings in building materials.

To obtain the correct shapes of the slopes, you need to measure the length, width, diagonals and heights of the rebuilt building frame. A lot of unexpected surprises can open up here. Differences in height on opposite walls can reach several centimeters, and the perimeter of the walls can have angles other than right angles. The check begins with measuring the diagonals along the top edge of the walls on each of the rectangular sections of the building. If the lengths of the diagonals do not match, this means that the walls either have different elevations, or the building does not have right angles and has a rhomboid or trapezoidal shape. In buildings with gables made of wall material, use a long stick to check the height of the opposite gables.

After taking measurements, identified wall defects are eliminated. Align the walls to the horizon and, if possible, make the corners rectangular. On buildings with gables, due to improper laying out of the foundation and then the construction of walls, differences in elevations along the top of the gables can sometimes reach 20 cm. Such a defect can only be corrected by re-placing the gable, or you need to come to terms with the idea that the ridge will not be horizontal, but therefore, the slopes of the gables will be different. In principle, such a height difference is not very noticeable on the roof, but each rafter and each element of roofing material will need to be adjusted individually.

Height differences along the perimeter of the walls, carrying the roof, are eliminated with a cement-sand screed. The walls around the entire perimeter are checked with a water level and a leveling screed is applied on top of them. A solution of a grade not lower than M150 is used. Big changes are eliminated by masonry with a pin, or the walls are not leveled, and wooden pads are inserted under the mauerlat beams, which is much worse, as often as possible. Walls for laying or installing racks of a sub-rafter structure are leveled to the horizon, but they do not have to be coordinated with the elevations of the external walls. The internal walls for laying the beds can be higher or lower than the external ones, but must be horizontal. When laying the plank on brick columns, the top of the columns is leveled off to the horizon.

All wooden structures Before installation, they must be treated with antiseptics and maintained for a period of time specified by the manufacturer of the chemical composition.

After the leveling screed has set external walls roll out waterproofing material, roofing felt or other rolled material waterproofing material and fold it in half along the longitudinal axis. The resulting width of the waterproofing should ensure that it bends to lateral surface Mauerlat, because in brick houses Bricks are still being laid there for the construction of the cornice. In general, waterproofing should protect the wooden wall plate from all possible contacts with the wall material. If the Mauerlat is attached to the wall with anchors, then the waterproofing is pinned onto pins. If it is fastened with staples, then the waterproofing is simply laid dry. Sometimes the waterproofing is glued to the leveling screed with a bitumen primer; this is not prohibited, but there is no particular need for it.

There are many ways to mark rafters and rafter beams, including such exotic ones as using Swenson and Stanley rafter angles. We will describe how this most often happens in construction practice, when the roof is made by ordinary carpenters who have a very vague understanding of geometry as a science. However, they rarely make mistakes and their roofs turn out excellent.

By laying the Mauerlat they try to correct the non-rectangularity of the perimeter of the walls. The beams are laid out on the wall and the diagonals of the building are checked, measuring at the corners of the mauerlat frame (Fig. 52). By moving the beams along the wall, the diagonals are equal, and its final position is marked with a pencil. The Mauerlat beams are sawn to make the locks, assembled on the wall and finally fixed to it.

Rice. 52. Marking the installation site of the Mauerlat and the bed

There is one subtle point when installing the Mauerlat frame. The height of the Mauerlat must be selected in advance, that is, at least a preliminary design must be drawn. Otherwise, the fillets nailed to the rafter leg may not fit over the edge of the wall and the wall will have to be cut down. Therefore, when determining the height of the ridge, walls and rafters, it is better to draw a section of the roof on a scale in advance and select the height of the mauerlat and its installation location. You often see a picture when, when building roofs without a design, craftsmen move the mauerlat to the very edge of the wall along the outer surface, otherwise they will not be able to release the filly. In general, there is nothing wrong with the fact that the mauerlat is installed along the outer edge of the wall, but only if it is a non-thrust rafter system and it is the edge of the wall, and often it is a brick cornice in which the brick has already been released beyond the wall. It would be smarter to increase the height of the Mauerlat beam and leave it in the center of the wall or closer to the inner surface of the wall. If it is not possible to increase the height of the mauerlat, then you just need to raise the parapet higher from the inside or dismantle part of the wall from outside parapet. That's all. Then the Mauerlat will remain where it should be and the filly will not rest against the wall.

Next, mark the position of the prone position. Measuring from the Mauerlat, we place it strictly in the middle, then we will get a roof with equal slopes. To install hip roofs, we move the bench the same distance, from its end to the mauerlat, deep into the house, then the angle of inclination of the hip will be equal to angle inclination of the main slopes. However, if you plan to change the angle of the hip relative to the slopes, then we move the bench to the distance that is needed. We lay the bed on two layers of waterproofing and fasten it with staples or wire twists with internal wall. The twists either had to be laid in advance in the wall during its construction, or they are attached to self-jamming anchors (ruffs) installed in the wall. If the bench is laid on newly laid brick pillars, then we attach it to the wall, and not to the pillars. In buildings with reinforced concrete floors twists can be tied to the mounting loops of the floor slabs. In buildings with gas silicate, foam concrete and other light walls you need to first make a monolithic belt and release the anchors. The bed is secured with anchors. In general, we attach the bench to the wall in one of the following ways in the designed position; the top of the bench should be aligned with the horizon. If the roof will be made without supports, then the installation locations of the racks are marked in a similar way, and the bottom of the racks is subsequently secured to each other with contractions.

After laying and securing the beds, they begin to construct the scaffolding. The most unpleasant part of the job is wasting time and lumber on unproductive work. However, the scaffolding must be made reliably; you will not only have to walk on it, but also work on it with the load of lifted rafters and purlins. The scaffolding must be supported by struts and secured with cross braces, otherwise they will lose stability and fall.

Next, the racks for the rafter structure are cut out. Since the bench was installed horizontally, all racks are made of the same design length. In buildings with gables made with defects (of different heights), a cord is stretched between the top of the gables and each post is cut to the length required taking into account the height of the purlin and rafters. When installing racks on a bench, they are checked for verticality in two planes (along two edges): transverse and longitudinal. Verticality is checked with a plumb line or level, placing it against the side surface of the racks. After which the racks are fixed in the design position. The easiest way is to fasten them with boards to the scaffolding.

What to do first: install scaffolding or racks? Whichever is more convenient for you. You can first install the racks and temporarily secure them with struts, and then attach scaffolding to them; you can, on the contrary, first securely place the scaffolding and attach the racks to them. Sometimes they try to work from stepladders. The racks are positioned and secured, and to lay the purlins and rafters, the ladder is supported on the racks. Is it dangerous. Firstly, under the weight of a person and the load he is holding, for example, when laying a purlin, the steps of the stairs can break. Secondly, a poorly secured rack may lose stability and fall along with the ladder leaning against it. And finally, thirdly. Try to work normally when you have a 60-centimeter stair tread under your feet, and you have to move a heavy purlin or rafter to install it correctly.

The purlin is laid on the racks. If everything is done correctly, the top of the beam is horizontal, the posts are the same height and are installed vertically in two planes, then the purlin will simply fall into place. In buildings with gables of different heights, the top of the purlin should be parallel to the tensioned cord. For hip roofs, do not forget to extend the purlin beyond the racks, forming consoles for supporting the slanted rafters.

Once again we check the truss structure for verticality and the girder for horizontality, correct it if necessary and fasten all the nodes to the design position: we nail wooden plates, install brackets or metal plates, but leave the entire truss frame temporarily attached to the scaffolding or to the struts.

Next, install the test board rafter leg. There are several ways to cut and fit rafters. We will focus on the simplest and most often used, which do not require any equipment other than the head and hands.

1. The rafters are marked for the slider and for the assembly with the support beam.

At the bottom there is a slider or a hinged, fixed support with a support beam; the top of the rafter is simply laid on the purlin and stitched to the other rafter leg with an overlap or rests against the other rafter leg.

The board is laid with the upper end on the upper edge of the purlin, the lower end on the inner upper edge of the Mauerlat (Fig. 53.1). One or two pieces of rafters are placed on the Mauerlat and a line parallel to the Mauerlat is drawn. When cutting onto a slider, the rafter does not change the slope; it simply falls lower and rests against the mauerlat; if necessary, it can be supplemented with a support bar. If the rafter is marked and cut into teeth, then after cutting the cut becomes incorrect.

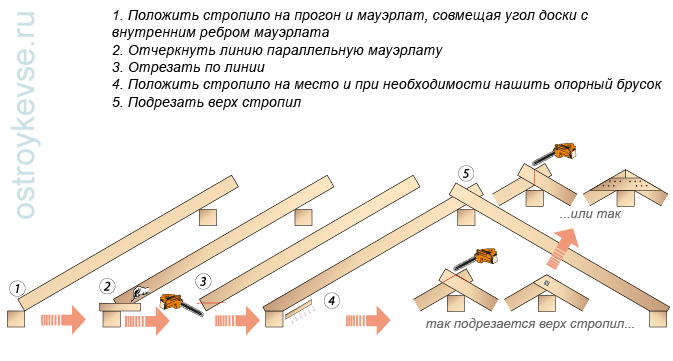

rice. 53.1. Marking and cutting rafters.

rice. 53.1. Marking and cutting rafters. Bottom with Support on the Mauerlat, top - with Support in each other or next to each other

After cutting and installing the first rafter leg, the opposite rafter is also installed and trimmed. The top of the rafter legs is left as is until complete installation all the rafters. Then they are either cut along the edge of another rafter and bolted together or sewn together with nails, or a vertical is marked on them and the excess is sawed off, joining the rafters into each other. It is not recommended to saw two rafter tops at the same time, since the thickness of the saw teeth will leave big gap and the rafters do not fit together tightly. It is better to move the rafters apart and saw off the tops of them separately, one to the left of the line, the other to the right. At good quality works, the rafters fit together without a gap.

2. At the bottom and at the top there are articulated, fixed supports.

At the bottom of the rafter leg, a notch is made to engage the Mauerlat with a tooth, and at the top, a notch is made with a triangle. If the upper notch is made exactly along the profile of the purlin, then the assembly will work as a hingedly fixed support; if the vertical cheek of the notch is made with a bevel, then the assembly will turn into a hingedly movable one.

The rafter board is laid edgewise on the purlin and mauerlat (Fig. 53.2). The lower part of the board rests at an angle against the Mauerlat at any point on its surface. A template is placed on the side of the mauerlat; for example, it can be a rafter cut with well-trimmed edges (the ends are sawn off at right angles). The pattern moves to inner corner Mauerlat and is combined with its vertical surface. The bottom of the rafter leg begins to move along the mauerlat, ensuring that a notch with a tooth is formed on the rafter. It’s quite simple: laying down a template board and moving the rafter, you can visually see how the cut will turn out. Having achieved the right size cuts outline the lines along which the rafters will be cut. The template is transferred to the upper notch, or more often, another person stands at the top on the scaffolding and he has his own template (cut from the same board, so they are the same), at the command of the first, he installs the template on the run, aligning its end with the vertical plane of the run, and outlines the second notch. Without removing the rafter from the purlin and the mauerlat, they turn it over and cut out notches. Then install it in the design position.

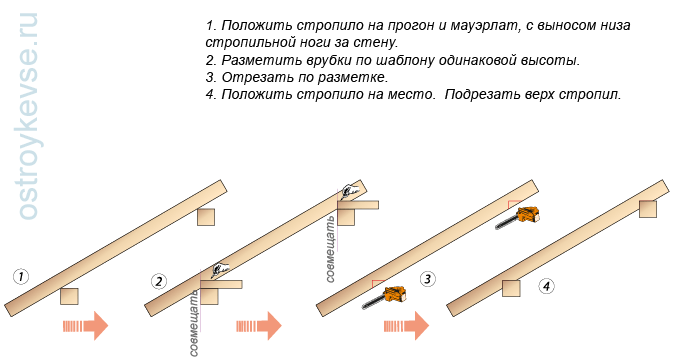

rice. 53.2. Marking and cutting rafters.

rice. 53.2. Marking and cutting rafters. The bottom is with an emphasis on the mauerlat, the top is a horizontal notch with an emphasis on the purlin

Why is a trimmed piece of board used as a template, because you can also use a level and a tape measure? It is possible, but cutting the board gives a visual idea of the future profile of the cut, and in this case it is better not to use a level at all. Wooden beams, due to drying, are far from the correct rectangular geometry; most often, despite seeming evenness, they are actually humpbacked and twisted. Therefore, it is better to place another board on their plane and outline the cuts along it. Carpenters use a hacksaw for this purpose, for example, when outlining a notch for landing on a purlin, they apply the hacksaw with a toothless edge to the vertical edge of the purlin and draw a line on the rafter with a pencil. No matter how the purlin beam twists, the line will repeat its profile, but the level showing the vertical would give an error. So it's better to use the age-old wisdom: cut the board, trim it and use it as a template. The thickness of the board is selected depending on the depth of the cuts and is different for each project; most often, the template is made from the same board as the rafters.

3. At the bottom there is a pivotally movable support (slider), at the top there is a pivotally fixed one.

At the bottom of the rafter leg, support is placed on a slider, which, if necessary, by installing support bars, can be turned into a pivotally fixed support. At the top, a notch is made into a triangle, which, in turn, by cutting the side cheek can transform the assembly from a hingedly fixed one to a hingedly movable one (Fig. 53.3).

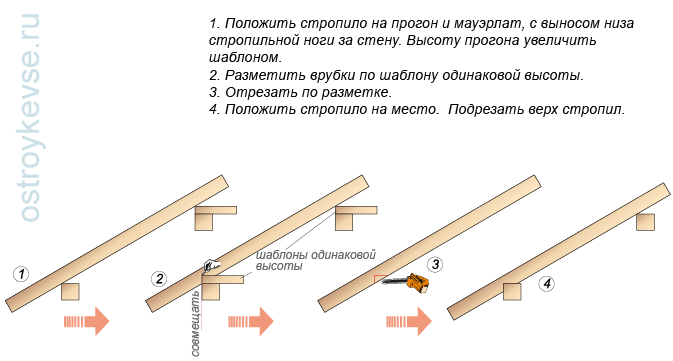

rice. 53.3. Marking and cutting rafters.

rice. 53.3. Marking and cutting rafters. Bottom with support on the mauerlat, top - horizontal notch with emphasis on the purlin

Everything is done the same as in the second option described above, with the only difference: when the lower end of the rafter leg is moved along the rafter, they ensure that the rafter is cut in the same plane, that is, without gearing.

4. At the bottom and top of the rafter leg there are hinged, fixed supports.

At the bottom of the rafter leg, a notch is made on the tooth; at the top, the end of the rafter leg rests against a purlin or a slanted (diagonal) rafter.

The rafter board is laid edgewise on the purlin and mauerlat. The lower corner of the board is aligned with the outer edge of the Mauerlat. At the top, a template or hacksaw is applied to the vertical surface of the purlin and a cutting line is drawn on the rafter. To connect to the slanted rafter legs, two lines are drawn on both sides of the board being processed. The length of the cutting line (x) is measured: pencil marks are made with a tape measure or on a template. The template is transferred to the lower support unit, it is placed against the inner vertical plane Mauerlat and from its edge put the size (x) on the rafter board. Then, in any way, most often by applying a board, draw a line parallel to the upper plane of the Mauerlat (Fig. 53.4).

rice. 53.4. Marking and cutting rafters.

rice. 53.4. Marking and cutting rafters. Bottom with emphasis on the mauerlat, top - with emphasis on the purlin

By moving the bottom of the rafter leg along the mauerlat, one can increase or decrease the depth of the tooth cut. On roofs with steep slopes, the tooth may not work out at all, no problem, installing a support block will help. By changing the size (x) when moving it to the lower node, you can change the nature of the support in the upper node, that is, align the rafter along the upper or lower edge of the purlin. If you decrease (x), the rafter at the top will rise, if you increase it, it will go down.

The board is turned over, sawn along the marks and installed in the design position. In the rafters, supported by the cranial bars of the slanted rafter leg, a notch is marked, the board is turned over again, a notch is made and put in place. The notch for landing on the cranial block is done in the same way, you just need to raise the bottom of the rafter to the height of the cranial block: place a piece of the cranial block under it or simply support the end of the board in weight while an assistant marks the notch.

5.Marking the rafter leg extended beyond the wall, that is, the rafter is installed without fillies.

At the top there is a hinged fixed support, at the bottom there is a slider (Fig. 53.5).

rice. 53.5. Marking and cutting rafters.

rice. 53.5. Marking and cutting rafters. Bottom with support on the mauerlat and extension of the rafters beyond the wall, top - horizontal notch with emphasis on the purlin

The rafter board is laid edgewise on the purlin and mauerlat. The bottom of the board is carried outside the wall and held in weight. Templates are installed on the Mauerlat and purlin with the ends aligned with the outer vertical surface of the beams. The cutting line is outlined, the board is turned over and notches are cut out. The rafter is installed in the design position.

6. Marking only the lower support unit, below and above there are articulated movable supports - sliders. The stability of the structure is ensured by a ridge knot when tying the top of the rafter legs.

The same thing is done as in the previous case, but a template is placed on the run, which maintains the angle of inclination of the slope. After the bottom notch is cut and the template is removed from the purlin, the rafter is moved into the design position (Fig. 53.6).

Fig.53.6. Marking and cutting rafters.

Fig.53.6. Marking and cutting rafters. Bottom with support on the mauerlat and extension of the rafters beyond the wall, top - with support on the purlin

All of the listed options for trimming rafters work on the same principle: the rafter board is installed in the required position, from which, after making the notches, it slides into seats from above or from the side, without changing the angle of inclination.

If the mauerlat frame can be positioned horizontally and the diagonals are aligned, and the purlin is installed horizontally, then it is enough to make one rafter leg, and make all the others according to it, using the first one as a template. If the walls of the house are so crooked that the diagonals on the mauerlat frame could not be aligned, or on houses with pediments the pediments are of different heights, then install a pair of rafter legs at both ends of the building. Cords are stretched between them and all other rafters are made individually, since each of them will be different from the previous one. During installation, the flatness of the slopes is constantly checked. This is done either by pulling the cords between the outer rafters, or by placing a long, even board on top of the rafters, which is moved along the edges of the rafter legs and checked for clearance.

The rafters are installed at a certain distance from each other, this distance is called a pitch. When designing a roof, the installation pitch of the rafters is set along the longitudinal axes of the rafter legs; this is not very convenient during installation. Therefore, to measure the pitch, 2–3 slats are made with a length equal to the pitch of the rafters minus the thickness of the rafters, that is, the length of the slats will be equal to the distance between the edges of the rafters - the distance in the clearance. Having installed one rafter leg, the location of the other is determined by placing it against the first rafter.

After all the rafters have been installed, the distance between them is checked again and the support units are secured in the design position: they are secured with staples, special metal plates, wooden bosses, nails, and bolts.

Then they begin to install the fillies. The filly (Fig. 11) is the extension of the rafters beyond the wall, providing an overhang of the roof. They are usually made from boards half the height and thickness of the cross-section of the rafter leg. The fillies are attached to the rafters using nails. The length of the fastening part is about 60–80 cm, and the free overhang above the wall is 40–50 cm. If the fillets are in contact with the wall material, and more often than not, they are in contact, then in these places they need to be wrapped with rolled waterproofing material.

The overhang of the cornice is selected, no matter how strange it may sound, depending on the length of the arms. The eaves overhang is often subsequently hemmed with molded materials, so you need to somehow reach, for example, with a clapboard board, to the end of the overhang, hold the board in the design position and nail it. If the overhang is short, then the wall of the building may get wet from slanting rain, if it is long, there will not be enough hands to install the hem and you need to install scaffolding, and at heights of up to 10 m, this is very problematic for an amateur builder. In brick houses, walls are laid with brick release and a cornice made from the wall material, thereby increasing the overhang. In houses made of lightweight concrete materials, the overhang is either 40–50 cm, or we come up with scaffolding. If the cornice is not hemmed with anything, then the overhang can be made longer, but not more than 60 cm. Longer overhangs should be supported by consoles released (or secured in another way) from the wall, which can also serve a decorative function.

To do it right calculate and set the diagonal of the foundation or formwork foundation - it’s very good to hire specialists. But if you have already seen the program several times “ square meter”, heard a conversation several times about how to build, and also a bunch of jokes about construction? - another thing. This gives us “every right” to assume that we ourselves can cope with this simple matter, like the corners and diagonals of the foundation formwork. This is exactly the high opinion of himself that everyone who plans to build a bathhouse with their own hands (Ha-ha!)

I wrote about the beginning of marking and designing the foundation and formwork in the article. At the time of driving in the stakes and installing the outer formwork boards, I already checked the length of the diagonal. Everything converged down to the millimeter. This is the most important condition for obtaining right angles for a bathhouse log. But after the first marking, there were manipulations with installing the bottom of the grillage, installing internal formwork panels, and finishing the formwork of the columns from ground level to the bottom of the future foundation. Of course, I tried very hard not to move anything, and drove the stakes deep.

But as with any construction project, something went wrong. It's not as scary as if I didn't notice it or I didn't know about it. Therefore, before laying the reinforcement, I decided to check the diagonals again. The difference was 2 cm. It’s good that it was discovered before the concrete was poured.

How to display the diagonal of the formwork?

To simplify construction correct formwork I made the length of the walls absolutely equal. Therefore, the distortion can only turn out to be in the form of a diamond. In the figure, the degree of skew of the formwork is deliberately increased for clarity.

To correct the situation, we did this:

This combined movement of one side of the formwork (north side in the picture) was not too difficult since the stakes and the original arrangement of the formwork were in the correct position. Therefore, the diagonal displacement was minimal and efforts to “adjust” the position of the shields did not cause mechanical stress and effort.

The method of setting angles along equal diagonals can only be used if the sides are equal. Diagonal Equalities will be sufficient!

The method of setting angles along equal diagonals can only be used if the sides are equal. Diagonal Equalities will be sufficient!

For formwork sides with large size It is possible to apply the golden triangle rule. If such a triangle, according to the Pythagorean theorem, has sides 3, 4, then the hypotenuse is equal to 5 units. Thus, it is enough to measure on the sides of the formwork parts that are multiples of 3 and 4 at the top of the right angle and then the distance between the control points will be 5 parts! This will guarantee right angles and equality of diagonals!

For formwork sides with large size It is possible to apply the golden triangle rule. If such a triangle, according to the Pythagorean theorem, has sides 3, 4, then the hypotenuse is equal to 5 units. Thus, it is enough to measure on the sides of the formwork parts that are multiples of 3 and 4 at the top of the right angle and then the distance between the control points will be 5 parts! This will guarantee right angles and equality of diagonals!

For proper planning formwork installation I highly recommend using the stripping method, which allows you to check corners, remove and reinstall foundation perimeter cords at any time during installation work.

Before pouring the foundation, do not be too lazy to check the diagonals again. It won't be superfluous! Concrete cannot be fixed easily or quickly. Errors are very expensive and time-consuming to correct. The foundation for a log house has more quality requirements than the foundation for a stone house. Nothing can be leveled with mortar!

Before pouring the foundation, do not be too lazy to check the diagonals again. It won't be superfluous! Concrete cannot be fixed easily or quickly. Errors are very expensive and time-consuming to correct. The foundation for a log house has more quality requirements than the foundation for a stone house. Nothing can be leveled with mortar!

Don't forget to remove it before pouring for easy removal!

General rules for any foundation

Select a starting point. The first side of our foundation needs to be tied to some object on our site.

Example. Let's make sure that our foundation (house) is parallel to one of the sides of the fence. Therefore, we stretch the first string equidistant from this side of the fence to the distance we need.

Construction of a right angle (90⁰). As an example, we will consider a rectangular foundation in which all angles are as close as possible to 90⁰.

There are several ways to do this. We will look at 2 main ones. © www.site

Method 1. Golden triangle rule

To construct a right angle we will use the Pythagorean theorem.

![]()

In order not to go deep into geometry, let's try to describe it more simply. So that between two segments a And b To make an angle of 90⁰, you need to add the lengths of these segments and derive the root of this sum. The resulting number will be the length of our diagonal connecting our segments. It is very easy to do the calculation using a calculator.

Usually, when marking the foundation, the dimensions of the sides are taken so that when taken from the root, a whole number is obtained. Example: 3x4x5; 6x8x10.

![]()

![]()

If you have a tape measure, then in general there will be no problems if you take segments that are different from those in common use. For example: 3x3x4.24; 2x2x2.83; 4x6x7.21

![]()

![]()

![]()

If we made measurements in meters, then the values turn out to be very clear: 4m24cm; 2m83cm; 7m21cm.

Calculator

It is also worth noting that measurements can be made in any length measurement system; the main thing is to use the aspect ratio we know: 3x4x5 meters, 3x4x5 centimeters, etc. That is, even if you don’t have a tool for measuring length, you can take, for example, a staff (the length of the staff does not matter) and measure it with it (3 staff x 4 staff x 5 staff).

Now let's see how to put this into practice.

Instructions for marking a rectangular foundation

Method 1. Rules of the golden triangle (i.e. Pythagoras)

Let's look at the example of building a rectangular foundation with dimensions 6x8m using the golden triangle (so-called Pythagoras).

1. Mark the first side of the foundation. This is the easiest part in constructing our rectangle. The main thing to remember. If we want our foundation (house) to be parallel to one of the sides of the fence or other object on the site or beyond, then we make the first line of our foundation equidistant from the object we have chosen. We described this procedure above. To place the first string, you can use pegs firmly fixed in the ground, but in ideal For this purpose, use cast-offs. We will use it. We will make the distance between the cast-offs for this side 14 m: between the cast-offs and future corners, 3 m and 8 m under the foundation.

2. Pull the second string as perpendicular to the first as possible. In practice, it is difficult to pull it perfectly perpendicular, so in the figure we also showed it slightly deflected.

3. We fasten both strings at the intersection point. You can fasten it with a staple or tape. The main thing is to be reliable.

4. We begin to form a right angle using the Pythagorean theorem. We will build right triangle with legs 3 by 4 meters and a hypotenuse of 5 meters. To begin with, we measure 4 meters from the intersection of the strings on the first string, and 3 meters on the second. Place marks on the lace using tape (clothespin, etc.).

5. Connect both marks with a tape measure. We fix one end of the tape measure at the 4 meter mark and lead it towards the 3 meter mark on the other string.

6. If we have a right triangle, then both marks should converge at a distance of 5 meters. In our case, the marks did not match. Therefore, in our case, we move the string to the right until the 3 m mark coincides with the 5 m division of the tape measure.

7. As a result, we got a right triangle with an angle of 90⁰ between the two strings.

8. We don’t need any more marks and they can be removed.

9. Let's start building a rectangle. We measure on both strings the lengths of the sides of our foundation to be 6 and 8 meters, respectively. We put marks on the strings.

10. Pull the third string as perpendicular to the first string as possible. We fasten both strings at the 8 m mark.

11. Pull the fourth string as perpendicular to the second string as possible. We fasten both strings at 6 meter marks.

12. We make marks on the third string 6 meters and on the fourth 8 meters.

13. To get a quadrilateral with right angles in our case, it is necessary that both marks on the third and fourth strings coincide. To do this, move both strings until the marks connect.

14. As a result, if everything was measured correctly, then we should get a regular rectangle. Let's check if it turned out by measuring the diagonals.

15. We measure the lengths of the diagonals. If they are the same, as in our case, we have a regular rectangle. The diagonals have the same length in an isosceles trapezoid. But we know one angle of 90⁰, and in an isosceles trapezoid there are no such angles.

16. Ready markup rectangular foundation using the Pythagorean theorem. © www.site

Method 2. Web

A very simple way to make markings in the form of a rectangle with corners of 90⁰. The most important thing we need is twine that does not stretch, and the accuracy of your measurements using a tape measure.

1. Cut the pieces of twine that we will need to form the markings. In this example, we are building a foundation with sides of 6 by 8 meters. Also, to correctly construct a rectangle, we will need equal diagonals, which for a rectangle 6 by 8 meters will be equal to 10 meters (i.e. Pythagoras is described above). You also need to take a reserve length of string for fastening.

2. We connect our “web” as in the picture. We fasten the sides with diagonals in 4 places in the corners. The diagonals themselves do not need to be fastened at the intersection point.

3. Pull the first string (points 1,2). We will secure it with pegs. The main thing is that the pegs hold firmly in the ground and do not move away when our structure is pulled. This important point need to be taken into account.

4. We tighten corner 3. The main condition is that string 1-3 and diagonal 2-3 do not sag and are as tight as possible. After fixing with a peg at point 3, we have an angle at point 1 of 90⁰.

5. Pull corner 4 and install the peg. We make sure that the twine at points 2-4, 3-4 and diagonal 1-4 do not sag and are as tight as possible.

6. If all conditions are met, then the result should be a rectangle with angles as close as possible to 90⁰.

Marking for the foundation of the house

We make a two-tier cast-off. The lower tier is the level of the pillars.

The upper tier of cast-off is the level of the grillage.

Create a rectangle for the outer contour using the so-called Pythagoras. Then we retreat by an amount equal to the width of the tape and make an internal contour.

The easiest way to mark. We build a rectangle according to the dimensions of the foundation using the Pythagorean theorem to find the right angle. © www.site

From the author

In this article, we looked at how to make markings for the foundation with your own hands by constructing a rectangle with angles of 90⁰. In general, there is nothing complicated about the markup. The cost of the issue is the cost of twine, boards for casting (an economical option - pegs) and the ability to use a tape measure.