Error chimney boiler Ariston. Error codes for gas boilers Ariston: meaning, malfunctions, troubleshooting methods

__________________________________________________________________________

Boilers Ariston - Questions for experts

Question: Boiler ARISTON EGIS. Can you please help me to solve this problem? When heated in heating mode to 70 degrees or more, the boiler begins to gurgle inside. Why? What to do?

Answer: Heat exchanger in scale. Try to wash it off with acid.

Question: Please tell me if anyone knows which relay on the Ariston EGIS 24FF boiler board refers to the fan? I want to change it, otherwise the fan is spinning all the time and does not allow the pneumatic relay to work. And how to avoid such breakdowns in the future? Someone advises a stabilizer (which one?), someone a surge protector (which one?), someone an uninterruptible power supply (which one?). Now it's worth nothing.

Answer: Neither a surge protector nor a stabilizer will help against relay breakdown - it all depends on the quality of the relay itself. The relay on the board is RL01 (you can see it along the tracks) - the name is F3AA024E (single-pin, 24V power supply).

Question: On the ARISTON EGIS 24FF boiler, the water temperature after the hot water supply is not regulated (the water is overheated). Switching the boiler to winter / summer mode, changing the water flow (more / less) through the DHW does not give results. In heating mode, the water outlet temperature of the boiler is regulated normally.

Answer: Perhaps the minimum gas pressure has not been adjusted, the NTC - DHW temperature sensor has deteriorated, the temperature regulator-setter does not work, etc.

Question: Boiler ARISTON EGIS 24 - a problem with the DHW turbine. Cleaned, washed and all without results. It starts only with a small pressure of water and then not always.

Answer: If the impeller does not spin from a strong breath and cleaning does not give results, then you need to change it.

Question: Tell me, please, what could be the matter? Boiler double-circuit Ariston Egis 24FF: opened hot and cold water, took a shower, closed the taps after 10 minutes, and after 15 minutes noticed that the fan in the boiler was still working. Only the green light is on to indicate that the boiler is on. I pressed the button of the two-pole switch, the indicator went out, but the fan continues to work and turned off only when the boiler was disconnected from the mains.

A minute later I connected the boiler to the network - the fan immediately started working. I pressed the button of the two-pole switch - the green indicator lit up. I turned the heating regulator - the boiler buzzed (probably the pump turned on), but the burner did not light up, but the orange chimney malfunction indicator began to flash. The fan is running all the time. I set the heating regulator to zero - the orange indicator stopped flashing.

Opened faucet hot water- the 40 degree indicator blinked twice (as always it blinks when hot water is opened) and the orange smoke exhaust malfunction indicator blinked again. The gas never ignited. The fan is running all the time. Pressure in the heating system

normal is slightly less than 1.

Answer: You need to check the turbine relay.

Question: Hot water does not work when the heating is turned off. When the heating is on hot water is coming If you turn off the heating, hot water disappears. What can be?

Answer: The DHW flow sensor does not work - the turbine is dirty.

Question: Boiler ARISTON EGIS 24FF. Something clicked in the boiler, and all the LEDs went out. Replaced the fuse. The boiler came to life, but both in heating mode and in hot water mode, the red indicator "burner ignition failure" lights up. Same thing after reset. The burner is trying - clicks of discharges are heard for a few seconds, then the relay clicks and the "burner ignition failure" LED lights up. What can be done?

Answer: Check the gas valve coils and the voltage coming to it during spark ignition.

EV1 resistance (between pins 3 and 4) = 878 Ohm

EV2 resistance (between pins 1 and 3) = 6860 Ohm

Question: Water began to actively drip from the air vent and the pressure in the system began to drop. What could it be?

Answer: It is necessary to change the air vent and the pressure will stop dropping. As a temporary measure, you can close the air vent.

Question: The Ariston 24 double-circuit boiler lights up normally and heats up the heating, but if you turn on hot water, the burner goes out. If the heating is turned off and you turn on the hot water, the burner does not ignite. What can be done?

Answer: Check the NTC sensor that is on the DHW.

Question: The problem is this - today I wanted to turn on the heating, the circuit lit up, began to boil, the pressure rose sharply and it turned off. Such an assumption that the circulation pump did not start. What can be done? How to check?

Answer: Unscrew the pump plug and use a thin screwdriver to turn the pump shaft. If it rotates easily, but does not start, check the pump capacitor.

Question: Tell me please, I have ariston egis 24, the heating works, but there is no hot water. How to setup?

Answer: check the impeller of the DHW flow sensor.

Q: The red LED is on today. When you press Reset, the red LED goes out, the boiler starts up, the burner lights up, the spark continues to click weakly, as if in the glow floor and the boiler is blocked. What could be? Chimney boiler.

Answer: The boiler does not see the flame - check the electrode.

Question: Boiler ARISTON UNO. Help troubleshoot. When the boiler is operating in the DHW mode, the coolant circulates simultaneously through the heating circuit (through the batteries). As far as I understood from the instructions - this is not normal. For winter period it's not critical, but for the summer. It may be enough to close the fittings for the supply of coolant from the boiler to the heating system, will this not lead to even worse consequences?

Answer: You can make out 3 way valve and clean, check the servo - does it switch normally - if anything, change the drive and the inside of the 3-way valve. But you can also close the heating tap for the summer - there should be no consequences.

Question: Ariston Uno turbo boiler. The drive of the three-way valve is in the DHW mode and does not switch to heating, I tried to put another one, I checked the DHW flow sensor. The result is 0. Tell me, what else can it be?

Answer: If the boiler is converted to summer mode, but do not turn on the DHW, the drive will be in DHW mode, but the gas will not light up. If the temperature is set higher in winter mode, the drive should switch and the gas will ignite.

It is necessary to remove the drive - check the switching (press with a match - check the movement of the stem) when turning on - turning off the DHW in winter mode, if it does not move, but the gas lights up, check whether voltage is supplied from the relay to the drive. Check the stem of the 3-way valve itself, whether it moves 1 cm in depth.

Question: When the Ariston Uno boiler is operating in heating mode, only one battery in the apartment is heated, the boiler caught up maximum temperature and cycles on and off. There is no air in the system. What to do?

Answer: Check the filter on the return of the heating system, check the valves that cut off the system from the boiler, check the gaskets on the union nuts, if any, check the pipes - especially the supply - for the presence of a flow. Check the operation of the 3-way valve - whether the DHW heat exchanger is heating in heating mode.

Question: There is a problem with the Ariston Uno boiler, in heating mode, only those batteries that are next to the boiler heat up. Feeling like poor circulation, pump sound was louder before. There is no air, the return filter is clean. Operating mode: burner on for 30s, standby for 2min.

Previously, the operating mode seemed to be different, the burner burned longer and the standby mode was longer. You put on a maximum warm up normally all batteries. The last few days it turns itself off 1 time like this: all indicators are on and do not blink, made a reset - it started. 2 times: nothing is on, the boiler is on, it does not respond to reset.

Turned off the power for a few minutes - it started. 3 times: the green indicator flashes and that's it, the boiler simply does not start, does not respond to reset, also turned off the power. Maybe it's a coincidence, different breakdowns. What can be done?

Answer: Breakdowns seem to be different. How does DHW work? Fine? 1 and 2 times - board failure. 3 times - NTC sensors do not work well. When only nearby radiators are warming up, you need to check the return and supply temperatures on the boiler, as well as the temperature that is set.

Perhaps the minimum flame on the boiler is not set, perhaps sensors, or scale in the heat exchanger, or maybe the 3-way valve does not switch over, or maybe debris in the supply pipe.

Question: Please tell me the ariston uno turbocharged boiler, the pressure constantly rises in 8 hours, it reaches 4 and if it is not reset, then an emergency drain occurs and 2 buckets of water are poured. Pressure in expansion tank they checked it was 0.5 pumped up to 1.5, the air was bled from the system, the cap on the tank was changed to a more reliable one.

Answer: The whole problem is in the proportion of the amount of water in the heating system / the volume of the expansion tank. The pressure in the tank is checked when there is no water in the boiler and the pressure gauge = 0 bar.

The pressure of nitrogen or air in the tank must be within 0.8 bar. If your heating system contains a large number of water - more than 100 liters - you need an additional expansion tank.

__________________________________________________________________________

__________________________________________________________________________

_______________________________________________________________________________

OPERATION AND REPAIR OF BOILERSThe trademark Ariston, which has the full name Hotpoint/Ariston, belongs to Italian company Indesit, issuing household appliances different direction. Including heating boilers. All equipment is equipped with electronic control; in case of malfunctions, the Ariston boiler displays error codes on the built-in indicator.

Features of Ariston gas boilers

The popularity of Hotpoint / Ariston branded equipment is associated not only with the low price of all products. Functionality of this technique are often close in their characteristics to the flagship models of well-known manufacturers.

So, for gas appliances of this developer, the presence of such functions is considered the norm:

- Automatic maintenance of the leaving water temperature regardless of any changes in environment, as well as fluctuations in the temperature of the water itself and a change in its pressure. The intensity of the flame is regulated without user intervention;

- Automatic evacuation of air from the heating system, which creates safe conditions for the operation of the device;

- In the event of emergency situations, the operation of the circulation pumps is blocked.

All protective systems, as well as the flame maintenance and regulation unit, work through an electronic board. This allows you to organize not only a convenient panel with control buttons, but also an indication of the current operating mode, and, if necessary, error codes indicating the alleged cause of the problem.

The decoding of these codes is usually presented in the instruction manual. The owner of the equipment can independently understand the situation and, as far as the skills are available, also eliminate the cause. But in most cases, such information is only useful in order to determine whether it will be enough to simply restart the boiler or whether it is time to call the master to the house.

Typical errors in the operation of Ariston boilers

All arising malfunctions in the operation of gas boilers can be divided into categories, which allows them to be attributed to individual components of the device, or to a different level of complexity according to the degree of need to call the wizard. Of course, there are problems that occur in almost all gas boilers, for example, flame separation.

Deciphering boiler error codes

Numeric combinations are displayed on the screen instead of a clock, which is why not an alphabetic designation was chosen, but a digital one.

So, the list of codes usually looks like this:

- 101 - boiler overheating.

- 102 - the pressure sensor does not work.

- 103 - lack of water or its low pressure (rate of change in carrier temperature over 7ºC per second).

- 104 - lack of water or its low pressure (rate of change in carrier temperature over 20ºC per second). With error 104, the Ariston boiler must be reset to its original state using the Reset button.

- 105 - lack of water or its low pressure (supply water temperature is higher than at the inlet by more than 55ºC).

- 106 - lack of water or its low pressure (supply water temperature is lower than at the inlet by 10ºC or more).

- 107 - lack of water or its low pressure (supply water temperature is lower than at the inlet by 30ºC or more).

- 108 - no water in the primary circuit. With error 108, the Ariston boiler cannot be reset using the Reset button, repairs are needed.

- 109 - excessive pressure in the primary circuit. With error 109, there is also no point in resetting the Ariston boiler, it is necessary to check the water supply line.

- 110 - the contact in the NTC1 sensor has disappeared.

- 111 - short circuit in the NTC1 sensor.

- 112 - the contact in the NTC2 sensor has disappeared.

- 113 - short circuit in the NTC2 sensor.

- 114 - outside temperature sensor not detected.

- 115 - the external temperature sensor has shorted out.

- 1p1 - poor or no water circulation, defined as: carrier temperature rise faster than 7ºC per second.

- 1p2 - poor circulation of water or its absence, determined by the sign: when the temperature difference between the outlet and inlet is more than 55ºC.

- 1p3 - poor water circulation or its absence, determined by the sign: when the return water temperature is 10ºC higher than the supply.

This list of codes applies exclusively to the heating circuit, other units also have their own set of codes. Depending on the model, additional signals may appear, their description can be found in the operating instructions.

Rice. 2

Rice. 2

Error codes of other boiler units

List of all possible errors, their digital designation, decoding can take a long time. In order to more fully understand the significance of various codes, it is worth giving a description of the most important, most frequently occurring problems with gas boilers.

- 501 - Ariston boiler error 501 indicates problems with ignition, the boiler must be reset with the RESET button. If there is no flame, the gas supply must also be checked.

- 6p1 - if an error 6p1 occurs, the Ariston boiler must be checked exhaust system, it means that the contacts of the relay responsible for the operation of the fan did not close normally. Sometimes resetting with the Reset button helps.

- 5p3 - with an error 5p3 in the Ariston boiler, a flame separation from the burner was detected.

- 117 - if error 117 occurs, the Ariston boiler must be reset using the Reset button, and it should work.

- sp3 - no burner ignition. It is found in models with the EGIS Plus index and the like. Sometimes it is interpreted as a flame detachment, which makes it possible to attribute the sp3 code to the most critical errors.

Particular attention should be paid to problems such as flame separation. It occurs due to too powerful gas flow and can lead to gas contamination inside the boiler. The same error of the Ariston 501 or 6p1 boiler does not cause any special problems, except for the inability to turn on the water heating. Error - flame separation in the Ariston boiler may indicate serious problems in the supply system, you cannot solve them yourself, you just need to call the master, having previously turned off the gas supply.

When the flame breaks off, a fire hazardous situation arises, so if it occurs frequently or at least systematically, it is necessary to be puzzled by checking the gas supply line. In the boiler, the accumulated gas can flare up and cause mechanical damage to it or even endanger the health of people living in the apartment.

In addition, the heating efficiency is significantly reduced, the gas consumption for the same volume of water increases. The power of the flame must be regulated smoothly, without pops inside the boiler and other abnormal phenomena and sound effects. Only then can you expect economical operation from the heater.

Rice. 3

Rice. 3

Features of some models on the example of Ariston EGIS Plus 24

The gas boiler of the EGIS Plus 24 brand is equipped with a double-circuit heating system, closed camera combustion and wall-mounted corps. They can heat an area up to 250 sq. m. In addition to automatic protection against major misfortunes (overheating, freezing or jamming of the pump), there are two important features. This is the ability to easily endure all power surges and stable operation under conditions of reduced gas pressure.

But, despite such a well-thought-out design, this model also has weaknesses. So, the sp3 error in it appears much more often than others. In different situations, the flame does not burn, even when externally favorable conditions up to the fact that the masters shrug. And they adjust the valves, check the access and removal of air / exhaust gases, clean the scale and still the mistake can happen again at the most unexpected moment.

The alleged causes of the sp3 error according to the reviews of the owners look different. It seems that the connection to the water supply through the hose interferes, then an error is generated after switching to the heating system after use hot water. In general, EGIS Plus is considered a reliable model, but the appearance of defects, such as the floating error described, reduces its popularity.

2017-04-19 Julia Chizhikova

Features of boilers Ariston

Ariston gas boilers are the most in demand on the market, thanks to their time-tested reputation. They are compact in size, convenient system connection and maintenance, reliable operation, a variety of models. The company produces single-circuit and double-circuit units, wall-mounted and floor-standing, with an open (chimney required) and a closed combustion chamber (removal of combustion products through a coaxial pipe).

Ariston devices are equipped with an improved heat exchanger design that reduces gas consumption, protective automation, which increases the service life, and precise settings. In case of interruptions in the supply of water or gas, an automatic blocking occurs, which eliminates the failure of the device.

Most Common Error Codes and Troubleshooting

To know full information on the selection, operation and maintenance of gas boilers of all manufacturers, you can if you go.

The most popular among Ariston boilers are wall models at 24 kW. During operation, the gas boiler Ariston may experience failures and malfunctions, like any other equipment. The list of error codes is given in the instructions in the form of a table. Some of them are a malfunction of the automation (cause a protective shutdown of the device) and are eliminated by pressing "Reset", and some signal malfunctions and interference in the operation of the boiler and require intervention (block the operation of the system).

All codes are divided into six groups according to the number of boiler nodes. The first value indicates the node in which the failure occurred, the rest - the error code. But it should be noted that if the protective error is repeated often, this indicates a malfunction.

The most frequent of them:

101

Error 101 indicates overheating, the sensor has tripped, after cooling the boiler starts up. The reason may be the accumulation of scale in the heat exchanger, as a result of which the flow decreases and the temperature rises, or interruptions in the operation of the circulation pump. Flush the heat exchanger, adjust or change the pump. Sometimes the reason may lie in the increased gas supply, screw the valve, if it does not help, you need to adjust the gas valve.

103,104,105,107

Error 103, error 104, error 105, error 107 occur when there is a violation of the circulation of water in the circuit, its absence or low pressure. This happens when air has accumulated in the system, to remove it in the Ariston Egis Plus 24 (Ariston Egis Plus 24) boilers, press and hold the mode button for 10 seconds. On Ariston Mathis and Ariston UNO boilers, hold the rezet button for no more than 6 seconds. The pump will operate for 5 minutes without ignition, removing air from the system. then check the pressure, the norm is 1-1.2 bar, increase if necessary.

Boiler Ariston Egis Plus 24

Boiler Ariston Egis Plus 24

108

By the way! Did you know that a heating boiler from any manufacturer can explode at any moment - "".

Error 108 appears when there is insufficient water pressure in heating circuit. Why the pressure drops - the cause may be a leak from the heating radiators, you should check the joints in the pipes. AT heating season it will not be easy to notice a small leak, since on hot batteries a small leak will evaporate. It is necessary to turn off the heating and add pressure up to 2.5 bar to determine the location of the leak.

The next reason may be the leakage of the heat exchanger pipes. To eliminate it, you can solder the heat exchanger, if soldering is not possible, it needs to be replaced. The expansion tank may be depressurized or the membrane has become unusable in expansion tank- seal the tank or change the membrane.

The tank itself may also leak - you can determine this by pressing the spool at the top of the tank. If this causes water to escape, change the tank. How to raise the pressure - you can use a home-made original device, consisting of a plastic bottle, a tap and a spool. On the plastic bottle, cut a thread on the cover with a tap so that the tap can be fixed on it.

FROM reverse side drill a hole to fix the spool on it. We put the spool into the inside of the bottle and fix it. We fill the bottle with water, close the tap and connect the heating system to it through the hose, connect the pump to the spool and, pumping it, pour water into the heating system. The procedure for pumping water into the system is repeated until the pressure normalizes, up to 1.5 atm.

109

But it often happens that if you do not follow our advice and other recommendations, other often more expensive breakdowns may appear, which in some cases can lead to really dangerous emergencies. Therefore, to prevent them, we recommend that you arm yourself with additional information.

Error 109 appears at an overpressure above 3 bar and is considered one of the infrequent occurrences. To eliminate it, you need to relieve the pressure, as prescribed in the instructions for the device, using the Mayevsky crane. if this does not help, most likely the reason lies in the secondary heat exchanger.

When a partition is destroyed inside the heat exchanger, it may be a fistula in it, mixing with liquids begins. Water from the tap, which has more than high pressure, begins to flow into the heating system, resulting in an increase in pressure. What to do if this happens - eliminating the fistula or replacing the heat exchanger will help solve this problem.

117

Error 117, according to the instructions for the Ariston BS 24 FF unit, means insufficient circulation. To eliminate, press the reset button, in this case the system will check and adjust the temperature difference at the inlet and outlet of 3.5 degrees in 8 seconds.

Reset button on the boiler Ariston - "reset"

Reset button on the boiler Ariston - "reset"

201

If the circuit is broken or the sensor is short-circuited at the supply to the hot water circuit, error 201 appears. You should check the contacts, they may have oxidized, or the wire has come off, or the sensor itself is faulty and will have to be changed.

302

Error 302 appears on the display when there is no circuit between the control board and the display. The reason may be a violation of the contacts or their oxidation, in which case the contacts should be connected or cleaned. The control board may also fail - replacement is required.

303

In addition, our expert Alexander recommends that you study this problem that occurs with boilers of other companies, models and manufacturers, because when people use them, as a rule, there are various non-standard situations that may coincide with yours. You can do this on our, another site -.

Error 303 means a malfunction of the main control board, the only solution to the problem is to replace it.

304

Error 304 also appears in the event of a malfunction of the control board and appears if more than 15 resets are performed within 15 minutes.

Boiler board Ariston

Boiler board Ariston

307,308

Error 307, error 308 also appears in the event of a malfunction of the control board, pressing the reset button will help correct the situation.

501

Code 501 is described above in the most common errors section.

601

On models Ariston Egis Plus 24 (Ariston Egis Plus 24) CF, class 24 FF and others, with open cam combustion, error 601 means no thrust. The sensor blocks the operation of the column in case of interference in the smoke exhaust system.

This blocking is temporary, after 12 minutes the system will switch to operating mode if the cause is eliminated, otherwise it will repeat again. To eliminate, clean the chimney, if the chimney is free, check the operation of the draft sensor.

604

Error 604 occurs when the fan speed is low or the Hall sensor is faulty. The fan and sensor should be checked, if a breakdown is found, replacement is required.

Hall Sensor

Hall Sensor

607

The description of the cause of occurrence and the method of elimination are described above, in the most frequently repeated errors.

a01

Error a01 blocks the operation of the boiler due to a failure of automatic ignition. May occur when the mains voltage is low, install a stabilizer. The polarity can also affect, in some cases the problem can be fixed by changing the polarity in the outlet, reverse the plug, changing the phase to zero.

In addition, there may be problems with the flame ionization sensor. Check if it is clogged, not bent, the wire connecting the sensor to the board may have broken or oxidized. Solder or strip the wire.

e34

Error e34 means a malfunction of the pneumatic relay when the fan is running. What to do - check the relay and replace it if necessary.

e108

Error e108 means a pressure drop in the heating circuit. The cause and solution of the problem is described above in the description of code 108.

sp2

Error sp2 (5p2) means that the second ignition attempt is unsuccessful. If the boiler does not start, there may be several reasons - there may be a problem in the ionization sensor, low gas pressure, insufficient air flow, removal of combustion products. Check if the sensor is working, possibly closed or not open enough gas cock, open the window and the door, check if the chimney is clogged.

Ionization electrode

Ionization electrode

sp3 (5p3)

This DTC is described in Frequently Recurring Errors.

1p1,1p2 (ip2)

Error 1p1, 1p2 (ip2) appears in case of poor or no water circulation. The causes and solution of the problem are similar to code 108 and are described above.

6p1

Error 6p1 appears when there are problems with the air supply and smoke removal, the relay is delayed. to eliminate the problem, check whether there is enough air in the room where the boiler is installed, whether the chimney is clogged, whether the relay contacts are stuck.

6p2

Error 6p2 also occurs when there are problems with smoke removal and air intake, and the contacts of the combustion product pressure switch open during normal operation of the fan. The solution to the problem is the same as when the code 6p1 appeared.

Boiler pressure switch Ariston

Boiler pressure switch Ariston

Other breakdowns

You can find out the whole truth about the conspiracy related to the selection, operation and maintenance of heating boilers of all manufacturers and models.

In addition to those described above, the following codes may appear:

- 608 - the system generates such an error when the fan has started working, but the pressure switch has not worked.

- H45 - the last two digits may vary. The reason lies in the NTSc sensor, there is no hot water at the outlet, the safety valve is leaking. If there is no hot water, but the heating system is working, the water flow sensor is most likely faulty, clogged with debris.

Another reason may be that the turbine blades have worn out a lot, stuck to the body, this can interfere with rotation, replace the blades or the turbine itself.

The second reason in this situation may be the NTC sensor, to check its performance, measure the resistance on its contacts with a multimeter, if it is unstable, replace the sensor with a new one. If the safety valve is leaking, the gaskets may have worn out, replace them.

NTC sensor

NTC sensor

How to determine the error code if there is no display on the device or without a dial, such as on the Ariston BS II 24FF model? Such a device is equipped with indicator lights, thanks to which you can determine the breakdown. So, for example, if indicator 90 and a crossed-out water drop icon are on, this means that overheating has occurred and the boiler is blocked. To eliminate it, it is necessary to check the pressure switch and its connection to the board.

If you want to get complete information on this problem, as well as find out other important nuances about the heating boiler from your manufacturer,.

But, we also have on this problem and not only that, first of all, you will not find it anywhere, because it is asked by specific people who could not get more support and advice anywhere (which they themselves inform us about). And secondly, their problems are so complex that sometimes our expert Alexander Kholodov deals with people for 10 or more days.

And now EVERY question of the user and the answer to it, in order to avoid monetary costs as a result of improper operation or repair of the boiler. And here it doesn’t matter which manufacturer’s device is involved in the issue. What matters is the unique situation that gave rise to this question, because as one good saying goes: "forewarned is forearmed".

In case of violation normal operation gas boiler, the indicator gives an error message. Knowing the meaning of the displayed error code, the specialist determines in which direction to look for the malfunction.

Good day or night, dear readers. I am sure that if your gas boiler is "sick" then you will not leave it alone at night. They swam…. we know! So, to help you, a thermometer, looking at the values \u200b\u200bof which you can determine "where it hurts"

This thermometer is an indicator on the boiler control panel, and if you know the meaning of the error code that the boiler electronics gives you, then this can greatly facilitate the task of troubleshooting.

It will also not be superfluous to know where and which sensor is located.

Because before you start with error codes, you should know that the “Brains of the Boiler” are guided by the readings of various sensors and sometimes a malfunction of not the boiler, but the sensor itself can lead to an error.

Purpose of sensors and where they are located

We look at the pictures, read the inscriptions - here I collected all the sensors used in the boiler and reporting any error. With the exception of the pressure sensor with a pressure gauge, well, I think everything is clear there. By the way, in some modifications of the boilers, the submersible temperature sensor in the DHW circuit - NTCs may not be installed.

Meaning of Ariston boiler error codes with explanations

In this section, I will try not only to announce the entire list, but also to give Additional information on some points known to me, with links to articles on repairing the Ariston Clas boiler.

In the event that something in the operation of the boiler is disturbed: Either you can reset the error with the Reset button and restart it, or this will not work until the malfunction is eliminated.

Error codes are divided into six groups according to the functional units of the device. The first digit of the code just tells which group the corresponding violation of work belongs to:

1. Primary circuit;

2. DHW circuit;

3. ECU - (electronic control unit)

4. Data exchange with peripheral devices; (external sensors, thermostats, etc.)

5. Ignition and flame detection.

6. Air supply and removal of combustion products.

Primary circuit

1 01 — Overheating (Overheating sensor triggered 102 ± 4 °C.) After cooling down, the error is reset.

Due to scale in the primary heat exchanger, insufficient flow of the coolant, the filter of the heating circuit may be clogged, or problems with circulation pump.

There is also a very large flame on the burner, gas valve adjustment is required, (done by a specialist) You can close the gas valve, sometimes it helps.

1 02 — Pressure sensor in the CH circuit. — Faulty sensor or insufficient pressure in the circuit. You can’t reset, we eliminate the causes.

1 03 — 104 — 105 — 106 -107 - Insufficient circulation, or insufficient amount of coolant.

Possible reasons for what can be done.

- Air in the system, it is necessary to remove air, for this we press the ESC button for more than 5 seconds. The boiler will run the pump for 6 minutes without igniting the flame to remove air. We check the pressure, at least 1 - 1.2 bar, if necessary, add.

- Problems with the circulation pump, often the reason for this is the pump control relay

- And of course, the slagging of the heat exchanger or filter in the heating circuit, this can also greatly hinder good circulation.

1 08 — There is no water in the primary circuit.

Possible reasons for what can be done. Make sure there is water - check the pressure, if necessary, add. We observe - if the pressure drops again for some time (several days or a week), find out the cause of the leaks. Remember about possible malfunction the sensors themselves. And we read

I have not encountered the following error codes, but in a smart book for servicemen they are described as follows:

1 09

— Overpressure in the primary circuit (P>3 bar)

1 10

- Temperature sensor at the supply to the CO circuit (NTC1) - no contact

1 11 —

CO supply temperature sensor (NTC1) - short circuit

1 12 —

Temperature sensor at the inlet from the CO circuit (NTC2) - no contact

1 13 —

Temperature sensor at the inlet from the CO circuit (NTC2) - short circuit

1 14 —

Outdoor temperature sensor - no contact

1 15 —

Outdoor temperature sensor - short circuit

DHW circuit

These codes also did not occur, especially since it was not necessary to see a boiler working in tandem with a solar plant ( solar collector) and a boiler. So the most likely errors are associated with a malfunction of the sensors in the DHW or CO circuits.

2 01 —

flow sensor in DHW circuit(NTCs) - no contact

2 02 —

DHW supply sensor (NTCs) - short circuit

2 03-

Tank temperature sensor - no contact

2 04 —

Tank temperature sensor - short circuit

2 05 —

Sensor at the inlet to the DHW circuit (from the solar system) - no contact

2 06 —

Sensor at the inlet to the DHW circuit (from the solar system) - short circuit

2 07 —

Solar collector pipe overheating

2 08 —

Low temperature in solar collector pipe

2 09 —

Overheating in the tank (Boiler) Alert

ECU - Electronic control unit “It’s better not to climb here without the necessary knowledge. The maximum that a layman can do is reset with the RESET button. Check the reliability of the contacts of the connected loops and wires. And also such an easy way how to turn off the boiler from the network and turn it on after a few minutes. Sometimes it can help. (See error 304) For the rest, entrust it to specialists. After all, you won’t be flashing the EEPROM (memory chip, in case it flies)

However, there is another option, manually set the necessary parameters through the menu if a failure occurs. I once did this, after the owner of the boiler flooded the water control board, the firmware fell off, the boiler was not controlled and behaved incomprehensibly, for example, when the temperature setting knobs were rotated, the display showed all sorts of rubbish. The only thing you need for this is to know how to enter the service menu and what parameters you need to set. I wrote off the necessary parameters from my own, the same working boiler, also going into the service menu and rewriting all the parameters with a pen on a piece of paper. Which then he put up in the affected boiler. But by the way, this is a topic for another article - maybe someday.

For now, just ECU error codes.

3 01

Display failure, ROM problems

3 02

GP Exchange Error - GIU

3 03

ECU internal error

3 04 More than five resets within 15 minutes - This means more than 5 presses of the RESET button, to reset error 304, simply turn the boiler off and on again.

3 05

ECU internal error

3 06

ECU internal error

3 07

ECU internal error

Communication with external devices

Well, this is in case your boiler is connected to GSM or the Internet. (generally skip it)

4 01

Communication error between modem and bus

4 02

GPRS/GSM modem error

4 03

Modem Sim Card Error

4 04

Communication error between modem and computer

4 05

Modem error

4 06

Modem error

4 07

Room temperature sensor - no contact

4 08

Room temperature sensor - short circuit

Ignition and detection

(And this is what you can really encounter) By the way, some of these and not only errors can occur when the mains voltage is low or the ground is poor. Use a stabilizer. Sometimes the operation of the boiler is affected by the “polarity” in the outlet, try turning the power plug over to change the phase and zero on the wire.

5 01

- No flame when ignited.

The gas ran out, this time 🙂 (they forgot to open the tap after a long departure) If there is still gas, and the boiler even ignites, and then goes out with error 501, then check the ionization electrode (Flame sensor) Make sure that it is clean, not bent, (see illustration at the beginning of the post) the wire from it is not interrupted and reaches the board with which it successfully connects.

5 02 — Flame detected with closed gas valve

Possible reasons for what can be done

If there is no flame in reality, but the boiler gives this error, saying “I haven’t discovered the gas yet, but everything is already burning there,” then the reason is that the ionization electrode is probably wet and sees something that is not there. The second thing could be a gas valve malfunction. Work for specialists.

The next four errors are general description: Possible problem in the ionization electrode, gas pressure, or air inflow, outflow of combustion products. It happens that in frosts the condensate on the chimney freezes and prevents the movement of air into and out of the boiler. That's why correct installation chimney with a slight downward slope to drain condensate.

5 P1 First ignition attempt failed

5 P2 Second ignition attempt failed

5 P3 Flame break during operation

5 P4 Three flame breaks in one working cycle

6 01

The gas duct overheating sensor has tripped (only in devices with an open combustion chamber, it is located in the chimney area)

6 04

The fan speed is too low or the Hall sensor is faulty.

6 08 — The pressure switch did not work, but the fan turned on (we check the pressure switch and all its connections)

6 P1 or 6P2 - Air pressure switch contact closing delay.

You can also meet such problems with hot water supply due to sensors.

Error H45 - Moreover, the value of 45 may differ depending on the temperature of the water. - cause, NTSc sensor.

Unstable operation of hot water supply, the boiler either lights up or not, everything is fine for heating. - the reason is the flow meter (water passage sensor) Details about all this, as well as a malfunction of the reset valve

Well, perhaps that's all, except that it remains to give a link to an article where the reason is described when And suddenly come in handy!

Dear visitors!!! If suddenly you decide to repair a gas boiler with your own hands, without having the proper qualifications, then you must understand that you are going to interfere in the design of gas equipment. The information in this blog is provided for informational purposes only, as to what I encountered and how I fixed it in my case.

You must understand that you perform all the work at your own peril and risk, and therefore, before you undertake, consider whether it is better to turn to specialists.

The first malfunction that happened to my boiler and laid the foundation for the study of this unit was as follows, the boiler does not light up on the display error - 607. And it's winter outside, brrr cold. Let me remind you that we are talking about the Ariston Clas 24 FF boiler.

So, having a specialty of radio engineering and a little time to keep from freezing, I perform an autopsy and start looking. What I managed to find out and how to solve this as it turns out to be a typical problem.

The boiler does not light up on the display error - 607

If the boiler behaves in this way, we pay attention to one more detail, the exhaust fan of the combustion products is constantly working in the boiler. Even if you turn off the boiler with the button on the control panel, it will still spin.

It will stop only when it is completely de-energized by pulling the boiler out of the socket. And as soon as you plug it back into the network, the fan immediately starts spinning. This symptom is a 100% guarantee of the malfunction described below.

Cause fan control relay stuck - treatment, relay replacement. In general, many boiler malfunctions are connected precisely with the relay, and since all this refers to malfunctions of the electronic control unit of the computer, the service masters sometimes recommend replacing the entire computer, and this is very decent money.

DIY electronic control unit repair

In this topic, I don’t just want to point out the reason - they say the relay is stuck - in this topic you will learn why the boiler reacts so much to a relay malfunction, which relay on the board is responsible for the fan, how to replace it and where to get it.

Well, in the following notes I will talk about other malfunctions associated with the ECU and not only. To begin with, we look at the block board and the location of the relay.

RL01 - Fan control relay. RL02 - Management three-way valve. RL03- Pump speed control. RL04 - Pump control. RL05 \ RL06 - Supply power to the ignition unit and gas valve.

The serial numbers of the relays are indicated as they are indicated on the board. The fault we are talking about now is caused by a relay malfunction. RL 01 relay type JZC-43F (3A 30VDC)

It is this relay that controls the fan.

The problem is that it was not possible to get such relays at that moment, and as I already mentioned it was winter, there was just barely enough time for repairs. Therefore, for critics of this method, I will immediately say that I did what was possible in those circumstances. Installed a relay bigger size and with a 24 volt coil supply.

As you must have noticed, native relays are powered by 30 volts. Therefore, to make life easier for the 24 volt relay, I used the L7824CV stabilizer. This is a simple stabilizer with an input voltage of up to 35 volts, the output of which is 24 volts. Conclusion 1- This is an input, 2- This is a common, negative wire, 3- A voltage output of 24 V.

1 and 2 pins of the stabilizer, observing the polarity, soldered to the board, right where the relay coil pins should be soldered, and the coil contacts of the new relay, neatly wired, soldered to the stabilizer, pin 2 (you can go straight to the heat sink where the hole for the bolt is also a mass ) and 3. This was how the relay coil was powered at a level of 24 volts. Also, carefully, by wiring, we connect a group of contacts on the relay (you need a freely open one) with the board, those two points that will have to be closed by the contacts of the new relay.

Everything was done carefully with the subsequent isolation of the joints heat shrink tube. But as subsequent experience showed, all these troubles with an additional stabilizer turned out to be superfluous.

Later, when another relay failed, I installed the relay at 24 volts and didn’t bother with the stabilizer anymore, it also works, for a long time, but the truth is that it heats up noticeably stronger than the first option.

Relay for boiler Ariston

Then, much later, analogues of the necessary relays were found on Aliexpress. This is an OMRON relay G5NB-1A-E, or Panasonic ALD124 24 B. They are also 24 volts, but as it turned out, this is not a problem. The relays are made and look great, probably the original. So now I have some stock.

Addition: If you order these relays on Aliexpress, then pay attention to the fact that there are exactly the same relays with power supply to the voltage winding and 5 and 12 volts. You need to find those that are 24 volts.

I already had to repair the boiler with friends and use one of the Omron relays that I received: It got up like a native, it works fine. By the way, sellers mainly offer these relays in batches of 10 or 50 pieces. So I ordered a batch. Later I found a seller from whom you can order them individually at a good price, the reviews are good. Link to this seller By the way, there is an opportunity to use Cashback.

P.S I want to add about cashback, for a few small purchases I received $ 2.32. So it really works. Sign up and get a refund on every purchase. About

For those who are interested in why the gas boiler does not light up when the fan is running, read on.

Why does the gas boiler go out, or rather, the boiler does not ignite

The gas wall-mounted boiler has several degrees of protection, for your own safety, and to protect the boiler from more serious damage. One of the elements of the safety group is a pressure switch or, as it is called in the manual for the boiler, “air pressure switch” (Instructions for operating and repairing the boiler)

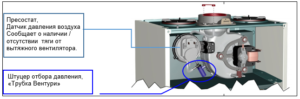

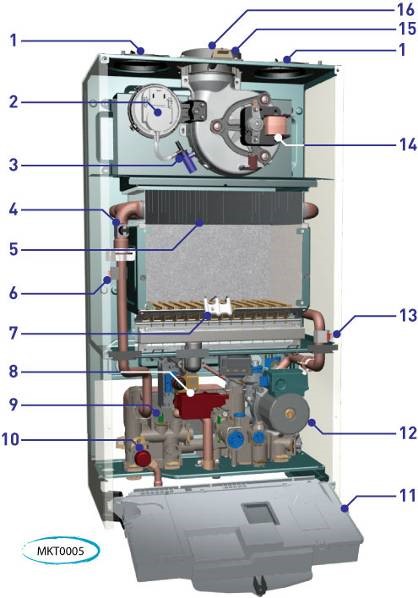

In the above drawing, the air pressure switch (Pressostat) is under No. 2,

No. 14 Fan motor for exhaust gases (combustion products)

No. 3 Air pressure tap with steam trap.

By the way, in my boiler, this node No. 3 was performed differently. I had the so-called venturi tube, which also has a certain protection function, but more on that in the next post.

Back to our problem: So, as it should be. In short, after the start command is received from the control unit, the fan control relay is turned on.

In the chamber with the turbine (Snail), a thrust is created that, through the venturi tube, transmits a vacuum to the pressure switch in which the membrane is retracted with the contacts closed, which in turn informs the control unit that everything is in order - there is thrust, you can work, give a spark!

Thus, in a working boiler, the order is as follows:

START COMMAND —> FAN —> PRESSOSTAT —> GAS VALVE and SPARK.

But what happens when the fan control relay sticks? The fan receives power as soon as the boiler is plugged into the socket. It starts to rotate, creates a vacuum and the contacts of the pressure switch are closed even before the command to start was received. The control unit does not leave this unnoticed and cancels the ignition command, displays error 607 on the display - which means: The air pressure switch worked before the start of ignition.

So with a stuck relay, the following is obtained:

FAN —> PRESSOSTAT —> START COMMAND —> ERROR 607

Here are the pies! That's all.