Gas and electric boilers Mora-Top: optimal price-quality ratio. Full review of Mora Top gas boilers

__________________________________________________________________________

Errors and malfunctions of Mora Top gas boilers

Gas boiler malfunctions Mora Top with display indication

Error E0- The boiler does not work

Gas does not pass through the gas fittings, the burner has gone out, the pump does not work.

Malfunction of the internal element of the control and regulation unit - Replacement of the control and regulation unit.

Error E1- Wall-mounted boiler Mora Top does not work

The switch does not close. The gas fittings do not open the gas passage, the burner does not ignite, the pump does not work.

1. Lack of water in heating system, the heating water filter is clogged - Clean the filter.

2. Lack of water in the heating system, defective pump - Replace the pump.

3. Lack of water in the heating system, the pump is set to stage 1 - Set the pump to the recommended stage 2 or 3.

4. Lack of water in the heating system, there is air in the system - Add water to the recommended pressure. De-air the heating system by switching between heating and domestic water heating modes. Turn the boiler off and on again using the ON/OFF button.

5. Insufficiently movable or completely stationary axis of the heating water flow switch, transmitting movement to the switch - Remove the switch box from the flow sensor body (pull out the stopper). By turning the boiler on and off again (turning the pump on and off), you can release the fixed axis. If the axis remains motionless, you can move it with your finger.

6. Big gap between the axle, the drive arm and the switch - Correct the position of the plastic drive arm.

7. Defective switch - Replace the switch.

8. The electrical connection circuit between the switch and the control and regulation unit is broken - Check the contact of the connector in the control and regulation unit. Check the wires to the switch.

Error E2- Mora Top wall mounted boiler does not work

The burner goes out as a result of a disruption in the gas supply through the gas fittings. When the flame goes out, the next ignition attempt occurs. The pump runs until the next ignition attempt, then stops.

1. Loss of burner flame as a result of a gas supply failure - Press the RESET button.

2. Loss of flame due to burner clogging (for example, only partially burns) - Clean the burner - outlet openings.

3. Electrode malfunction - the electrical connection line is broken - Replace the electrode.

4. Faulty ignition transformer or broken electrical connection line - Check and replace the ignition transformer.

5. Incomplete or broken contact in the electrical connection circuit of the ignition transformer and the control and regulation unit - Monitoring the contact of the connector in the control and regulation unit.

6. Don't correct connection phases when connecting the boiler to the electrical network - Make the correct phase connection.

7. Disabling the reverse draft fuse when the temperature is exceeded as a result of leakage of combustion products (partial or complete obstruction of the chimney) - Control of the patency of the combustion paths - exhaust pipes or chimney. To resume the boiler function, press the RESET button.

8. Defective reverse thrust fuse - Replace the fuse.

9. The electrical connection circuit of the reverse thrust fuse is broken - Check the electrical connection line.

10. The contact in the connection between the reverse thrust fuse and the control unit is broken - Check the contact of the connector in the control and regulation unit.

11. Disabling the emergency thermostat as a result of exceeding maximum temperature heating water. Gas supply to the burner is interrupted - Find out the reason for the water overheating.

12. Defective emergency thermostat - Monitor the emergency thermostat (must be closed at temperatures below 95°C), replace if necessary.

13. Violation of the electrical connection circuit of the emergency thermostat - Monitoring the electrical connection line.

14. The contact in the connection between the emergency thermostat and the control and regulation unit is broken - Check the contact of the connector in the control and regulation unit.

15. Incorrect position of the ignition electrode - Check the position of the electrode. The distance between the end of the electrode and the burner plate should be 3-4 mm.

16. Loss of flame due to failure to open the main gas valve - Check the contact of the main gas valve connector in the control unit. Replace the defective valve.

Error E3- Heating water temperature sensor is open. The Mora Top gas boiler does not work either in heating mode or in domestic water heating mode.

The burner flame goes out as a result of a disruption in the gas supply through the gas fittings; the pump does not work.

1. Malfunction of the heating water temperature sensor - Replace the temperature sensor.

4. The contact in the connection between the temperature sensor and the control and regulation unit is broken - Check the contact of the connector in the control and regulation unit.

Error E4- The domestic water temperature sensor is open - The Mora Top gas boiler continues to operate in heating mode and in domestic water heating mode.

The temperature control function is taken over by the heating water temperature sensor - problems with maintaining the temperature of the service water.

1. Malfunction of the domestic water temperature sensor - Replace the temperature sensor.

2. The connection contact of the temperature sensor is broken - Check the connection contact.

3. Temperature sensor electrical connection circuit failure - Monitoring the electrical connection line.

4. The contact in the connection between the temperature sensor and the control and regulation unit is broken - Check the contact of the connector in the control unit.

Error E5- Malfunction on the safety module - Mora Top boiler does not work.

The burner flame goes out as a result of a disruption in the gas supply through the gas fittings; the pump runs continuously.

1. Disabling the emergency thermostat as a result of exceeding the temperature of the heating water. Stopping the gas supply to the burner - Find out the cause of overheating.

2. Defective emergency thermostat - Monitor the emergency thermostat (must be closed at temperatures below 95°C), replace if necessary.

3. Violation of the electrical connection circuit of the emergency thermostat - Monitoring the electrical connection line.

4. The contact in the connection between the emergency thermostat and the control and regulation unit is broken - Check the contact of the connector in the control unit.

5. Non-connection of the pressure switch - obstruction of the combustion products outlet or air supply - Eliminate the cause of the obstruction of the combustion paths.

6. Defective pressure switch - when the fan is turned on, it does not connect - Replace the pressure switch.

7. Violation of the electrical connection circuit of the pressure switch - Monitoring the electrical connection line.

8. Contact is broken in the connection between the pressure switch and the control and regulation unit - Check the contact of the connector in the control unit.

9. Fallout or damage to the tube connecting the pressure switch and the fan - Check, if necessary, replace the tubes.

10. Fan does not accelerate, burnt out motor, hardened impeller bearing, mechanically blocked valve - Check the fan functions, replace if necessary.

11. Violation of the fan electrical connection circuit - the fan does not accelerate - Check the electrical connection line.

12. The contact between the fan and the control and regulation unit is broken - Check the contact of the connector in the control unit.

Malfunctions of Mora Top gas boilers without indication on the display

The boiler has insufficient power - the temperature of the heating or service water does not reach the set value

The Mora Top boiler operates constantly at minimum power.

1. Violation of the electrical connection circuit of the modulation coil - Monitoring the supply cable of the modulation coil. Monitoring the connector contact in the control and regulation unit.

2. Defective modulation coil - Replacement of the gas valve.

3. The maximum and minimum boiler power are incorrectly adjusted - Adjust the maximum and minimum boiler power.

The Mora Top wall-mounted boiler does not heat domestic water - the burner does not light

A. A small flow of domestic water.

1. The domestic water filter is clogged - Clean the domestic water filter.

2. The differential valve is stuck - Clean the differential valve.

3. Low water pressure - Increase water pressure.

B. The flow of domestic water is sufficient, but 3 directional valve not rearranged.

1. The tubes between the differential valve and the 3-way valve are clogged - Clean the connecting tubes.

2. Hardened three-way controlled valve - Swing the valve by turning the service water on and off. Replace the 3-way valve.

3. The membrane in the hydraulic part of the three-way valve is cracked - Replace the membrane.

B. The flow of domestic water is sufficient, three-way valve rearranged.

1. Large gap between the axis of the rearranged three-way controlled valve, the movement transfer arm and the switch - Adjust the movement transfer arm.

2. Defective domestic water switch - Replace the switch.

3. Violation of the electrical connection circuit between the switch and the control and regulation unit - Check the contact of the connector in the control and regulation unit.

The wall-mounted boiler Mora Top does not heat the domestic water insufficiently or does not heat the domestic water at all - the burner is on

There is sufficient water flow low temperature domestic water.

The secondary heat exchanger is stuck in the hydraulic unit - Clean the heat exchanger.

Heating water flows out through the safety valve

A. After heating the heating water, the pressure in the heating system will increase by 2.5 bar - the water flows out through the safety valve; When the heating water cools, the pressure will decrease - less than the filling pressure.

1. Gas leak from the expansion vessel - Check the valve on the expansion vessel, replace it if necessary; increasing the pressure to the recommended value.

2. The membrane in the expansion vessel is cracked - Replace the expansion vessel.

B. The pressure in the heating system is increased by 2.5 bar due to the domestic water pressure.

The valve on the hydraulic unit for adding water to the heating system is not closed - close the valve.

The boiler does not ventilate well

The cap on the purge valve is tightened - Check the cap on the purge valve. He must be released.

__________________________________________________________________________

__________________________________________________________________________

_______________________________________________________________________________

__________________________________________________________________________

Wall-mounted gas boiler Mora

Mora's gas, instantaneous, heat-conducting boilers, operating on natural gas (or propane), are designed for heating rooms with heat losses of up to 10, 18, 23, 32 or 35 kW, and combination boilers are also designed for heating domestic water.

These boilers are wall-mounted. For some types of units, combustion products are removed to the outside through a chimney, and for some - through the wall using a fan.

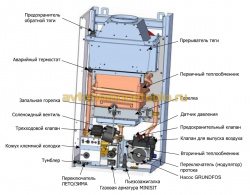

Fig.2. Top part

Fig.3. Open boiler with combustion products discharged into the chimney

Fig.4. Bottom part

Installation and connection wall-mounted boiler Mora

Fig.1. Dimensions gas boiler Mora 5118

A - heating water - outlet - G3/4”

B - domestic water - outlet - G1/2”

C - gas - G3/4”

D - domestic water - supply - G1/2’

E - heating water - supply - G3/4”

When installing a boiler, for its further safe and economical operation, it is necessary to have a professionally completed project for the entire heating system.

The Mora gas boiler can only be installed by an authorized service organization.

To operate the unit, only the type of gas indicated on the type plate of the product can be used.

The installed and assembled unit must not be moved to a new location.

The Mohr boiler must be installed so that the socket for its electrical connection is located on accessible place. The phase wire must be connected to the left sleeve, the neutral wire to the right, and the ground pin to the top pin.

Non-compliance this condition will cause the burner flame to go out after ignition.

The emergency thermostat, reverse draft fuse, fan and pressure switch are energized at 230 V. If it is necessary to interfere with the operation of these elements, be sure to remove the plug from the electrical outlet.

The gas boiler is installed in accordance with the projects for the heating system and for the gas supply of a residential building, public utility facilities, industrial buildings etc.

If the heating system meets all requirements for operation, safety and functionality, then the boiler can be put into operation after submitting the following documents to the appropriate gas supply organization: a project for the gas supply of the facility, a certificate of readiness of the gas supply system, certificates of suitability of smoke and ventilation ducts.

Installing a Mora gas boiler on a wall

The device is designed for mounting on a wall made of non-combustible material.

The installation of the Mora 5118 boiler can only be carried out by an authorized service organization that has permission (license) to carry out this work.

The boiler can be installed in bathrooms, washbasins and showers, but we recommend installing it above the bathtub at a distance of approximately 200 mm from the walls of the bathtub. It is not permissible to install the boiler outdoors.

To follow the rules fire safety it is necessary to maintain a safe distance between the device and flammable materials: 100 mm - from the front wall of the boiler, 50 mm - in other directions.

In order to have an accessible approach to the functional parts of the boiler during maintenance, repair or maintenance, we recommend observing the following dimensions: 500 mm - from the front wall, 500 mm - from above (a minimum size of 200 mm must be kept to allow removal of the casing), 300 mm - from below.

There are no special requirements for flooring or coverings.

The boiler is attached to the wall with two screws or hung on brackets with two holes located on the frame of the boiler body at a distance of 280 mm from each other.

An important consideration when placing is the height of the room.

It is necessary to pay attention to the fact that the vertical dimension from the end of the upper damper of the draft rectifier to the middle of the chimney in the wall is at least 500 mm.

Connection of boilers with combustion products exhaust pipe

Mora boilers of the “turbo” design have a closed combustion chamber, sucking in air to burn fuel from the outside. During installation there are no restrictions regarding room ventilation.

The boiler can be installed using a set of connecting elements. The tubes included in the set of these connecting elements are made of of stainless steel and they can be installed on the connection panel during installation.

The device is equipped with a fan. The design of the exhaust of combustion products and the air supply can be double (coaxial) or two-pipe (separate air supply and exhaust of combustion products).

Heating

The Mora 5118 boiler will start working when it receives a signal from the room thermostat to reduce the temperature in the heated rooms.

The pump will accelerate and the gas fittings will open the flow of gas to the main burner. Heating water flows from the pump to the heat exchanger, where it is heated and then enters the heating system.

The heating water temperature is recorded by the heating water temperature sensor. Heating of heating water continues until the boiler is turned off when the desired temperature in the heated rooms is reached.

Thus, the process is repeated as long as the boiler is connected to the electrical network. The heating water temperature is set to the maximum value.

Water heating

The process of heating domestic water takes priority over the process of heating water for the heating system.

The flow of water through the domestic water flow fuse will introduce the boiler into the process of heating domestic water when the 3-way valve changes the direction of movement of the heating water, and it passes through the secondary heat exchanger, and from there back to the pump.

From the heated heating water in the secondary heat exchanger, in accordance with the temperature set by the User, the utility water is heated.

By changing the burner power, the electronics system maintains the temperature of the domestic water at the selected level.

After the end of the selection of warm domestic water, the boiler will automatically switch to the heating process.

In the process of heating domestic water, the gas pressure supplied to the main burner changes so that the temperature of the domestic water corresponds to the set one, regardless of fluctuations in water flow under the influence of fluctuations in inlet pressure, i.e., increased water flow will cause an increase in gas pressure, and vice versa.

Work safety

Safe work Mora gas boiler provides the following elements:

Electronic control and regulation unit - An electronic unit that provides and controls the activity of individual boiler elements (pump, thermostats, 3-way controlled valve, flow sensor, etc.).

Heating and service water flow sensors will not allow the main burner to ignite if there is insufficient water flow.

Emergency thermostat - will close the gas supply to the boiler if the maximum is exceeded permissible temperature water in the heat exchanger.

Backdraft preventer - If clogged chimneys(even partial), which will contribute to the entry (leakage) of combustion products into the room, then the backdraft fuse will register an increase in the temperature of the surrounding space and cause the gas supply to the main burner to close.

The boiler can be put back into operation only after the fuse has cooled down, i.e. after approximately 10 minutes, by pressing the RESET button.

Pressure switch - If the combustion product exhaust pipes become clogged (even partially), or fuel combustion deteriorates (it will be lower established norm) under the influence of a decrease in fan speed (voltage drop in the electrical network), or the fan will not work, then thanks to the pressure switch the boiler will not turn on so that combustion products do not accumulate in closed chamber combustion.

The backdraft safety device or pressure switch must be functional during boiler operation and their functions must not be affected by anything (for example, a change in position).

If the backdraft safety device or pressure switch fails repeatedly, contact an authorized service organization to troubleshoot the problem and perform an operational test.

Preparation for use

When preparing a Mora wall-mounted boiler for operation, you must do the following:

Check the water pressure in the heating system,

- open the inlets and outlets of heating water (or utility water) - (valves under the boiler),

- open the gas supply to the boiler.

When putting the boiler into operation, a specialist from a service organization must:

Check the pump mode - it should be set to stage 3.

Start the boiler.

Carry out ignition control:

Turn on the boiler using the button on the control panel,

- after 5 seconds, the burner will ignite from a series of sparks - ignition lasts 5 seconds,

- repeat ignition 5 times.

Check the functions of the ionization electrode - blow off the flame from the ionization electrode - after 3 seconds the burner should go out.

The electronic control of the boiler will automatically switch to ignition mode (another attempt to ignite the burner will follow).

If the burner does not ignite, fault code E2 will appear on the display - loss of flame. To ignite, you must press the RESET button on the control panel.

Perform burner control:

Check the main burner, the flame should only be near the outlet openings,

- check the stability of the flame along the entire length of the burner plates.

Adjust heating and starting power.

Malfunctions during the operation of Mora boilers

Error E0 - Temporary malfunction, possibly a malfunction of the control and regulation unit - Call a service technician.

Error E1 - Lack of water (no water in the heating system or insufficient water flow) - De-air the heating system, radiators. Try turning the boiler on and off several times or running household water (in combined boilers).

Error E2 - Boiler shutdown (for example, loss of flame control, disconnection of the backdraft fuse) - In boilers with combustion products discharged into the chimney, check the patency of the combustion paths. Press the RESET button.

Error E3 - Heating water temperature sensor is open - Call a service technician.

Error E4 - The domestic water temperature sensor is open - Call a service technician.

Error E5 - Malfunction on the safety module (automatic ignition, exceeding the maximum water temperature) - In boilers with combustion products exhaust through the wall, check the patency of the combustion products exhaust pipes or air supply.

Monitoring the functions of the Mora boiler

When carrying out an annual inspection of the boiler, it is recommended to carry out periodic checks to ensure the functionality of its functions.

Gas part - check:

High-voltage electric ignition functions with ionization fuse.

Ignition of the main burner.

Gas pressure at the nozzles during heating of heating water and domestic water, as well as at initial, minimum and maximum power.

The burner flame goes out when the boiler is turned off by the working or room thermostat, or by manual shutdown, for example, when the service water flow is closed.

Tightness of connections.

Backdraft fuse.

Heating water heating - check:

Pressure in the heating system.

Pressure in the expansion vessel (nitrogen).

Function of a 3-way controlled valve.

Pump - setting the pressure, controlling noise and tightness.

Filter at the inlet to the boiler.

Heating water flow fuse - tightness of the “0” ring.

Tightness of connections (water).

Visual inspection of primary and secondary heat exchangers, cleaning of external and internal surfaces.

Functions of the purge valve (on the pump).

Domestic water heating - check:

Functions of a fuse for the flow of domestic water.

Quantitative flow of domestic water at which the fuse trips.

Tightness of the “0” ring.

Tightness of connections.

__________________________________________________________________________

__________________________________________________________________________

_______________________________________________________________________________

2015-06-28 11 354

The device and internal design that the Czech ones have gas boilers Mora Top, allowed to create heating equipment new generation, optimally meeting European and domestic standards.

The Mora manufacturer's line includes wall-mounted and floor-mounted units, differing in different technical characteristics, operating principle and performance.

Description and characteristics of attachments

Single-circuit and double-circuit wall-mounted Czech gas boilers Mora Top have three basic modifications:

The single-circuit and double-circuit gas wall-mounted heating boiler Mora Top has a built-in programmer, a unit with which you can set work program a few days in advance.

Review of Mora floor standing boilers

Floor-standing gas heating boilers Mora Top is presented in more than ten modifications, the main difference of which is the type of burner and combustion chamber used.

To increase performance and heat transfer, it is recommended to use antifreeze. Heat exchanger and internal organization designed taking into account the use of this liquid as a coolant.

As practice shows, the Czech water-heating energy-independent floor-mounted instantaneous gas heating boiler Mora Top is optimal solution for heating country houses. The absence of complex automation, electricity-dependent components, high productivity - all this distinguishes the equipment of this series.

Carrying out installation work

Mora gas appliances are designed in such a way that installation and maintenance of boilers are as simple and easy as possible. All volatile models have a self-diagnosis function. Information about all violations is displayed on the LCD display. The boilers are equipped with Mora equipment. As a result, automation, burner and other components ensure stable and long-term operation.Commissioning and adjustment of the boiler is carried out as follows:

- Volatile boilers are connected to the network. The self-diagnosis function starts automatically. The controller checks the presence of pressure in the heating system and gas pipeline. When deviations are found, a signal is issued in the form digital value. After troubleshooting, the boiler starts up.

- Non-volatile units do not have self-diagnosis functions, automatic flame ignition, etc. Therefore, before starting up and putting the equipment into operation, the company representative must ensure that all installation recommendations are followed. It is mandatory to install a water treatment system and a security group; you may need to connect expansion tank and a circulation pump.

Czech Mora gas boilers generally start up without any difficulties, but there are exceptions, mainly related to transportation or installation problems.

One of the common faults double-circuit boiler is failure of the thermocouple. After replacement, the functionality of the equipment is fully restored.

Why you should buy a Mora boiler

Mora's boilers have something that other manufacturers often miss - an understanding of the complexities and peculiarities of working in domestic conditions. A potential buyer is also attracted by the possibility of choosing a suitable model.Presented by a huge the lineup: from 15 to 750 kW. You can choose a fully automatic installation and a classic boiler without complex automation. Simple rules operation also ensures the popularity of Czech Mora models.

Calculation of power and temperature of a warm water floor

Technical characteristics of wall-mounted gas boilers mora 5107.1002

Power: 5-18 kW

Version: wall

Type: single circuit

Heating area: with heat loss 35 kW

Fuel: natural gas

Thermal power range: 6-18 kW

Gas consumption at rated power: 2.2 m/h

Nominal input pressure: 1.3-2 kPa

Boiler weight: 31 kg.

Sound power: 52 dB.

Fuse Rating: 3.15A

Rated electrical voltage: 230 V.

Method of removing combustion products: chimney

Purpose of wall-mounted gas boilers mora 5107.1002

They are also used for heating the premises and heating domestic water.

Efficiency of gas boilers mora 5107.1002

In MORA-TOP boilers, heating and domestic water sensors accurately measure the temperature of heating and domestic water at the outlet of the boiler and monitor its maintenance at a given level. Thanks to electronic regulation of gas flow, MORA-TOP boilers use only the minimum amount of gas required to heat water to the desired temperature.

Safety of gas boilers mora 5107.1002

The safe operation of MORA-TOP boilers is ensured by a number of independent elements, the operation of which is duplicated twice (for some, four times).

The burner flame will not ignite without water flow (for example, if there is no water in the heating system, clogged filters, boiler pump failure, etc.)

Electronic control systems and a temperature limiter on the heat exchanger will turn off the boiler if necessary, preventing overheating of the water and heat exchanger in the event of any problem.

The burner operation is controlled by an ionization fuse.

Thanks to the backdraft fuse, combustion products will not enter the room: the main burner will not light if the fan malfunctions or the chimney is clogged.

Shipping and payment

Our couriers deliver to homes, offices, apartments and transport companies in Moscow and the Moscow region.

Delivery in Moscow: The standard cost of delivery by courier within the city within the Moscow Ring Road is 390 rubles.Orders are delivered from 10:00 to 18:00 on weekdays. Evening orders are discussed individually.

Delivery outside the Moscow Ring Road: The cost of delivery by courier is 20 rubles - 1 kilometer, plus delivery 390 rubles in Moscow.

Orders are delivered from 10:00 to 18:00 on weekdays.

Pickup: You can independently pick up the product you like at our office at the address: Moscow, st. Baikalskaya 1.

Before arriving at the company’s office, it is mandatory to confirm the availability of goods in the warehouse!

Delivery across Russia Delivery is carried out by transport companies by road, air or rail from Moscow to any region of Russia. Delivery times and costs may vary depending on the delivery method you choose. The cost of delivery by region also depends on the weight and volume of the equipment you order. We recommend that all our regional customers do the following:

- Having selected the product you are interested in, place an order for it on our website.

- In the "Comment" column, indicate your wishes regarding the order, if any.

- After placing your order, our manager will contact you and discuss the details of payment and delivery.

- After confirmation of payment by our bank (24-48 hours), in case of payment by electronic money, the funds immediately arrive in our account, your order will be sent by a transport company.

- Bring with you a passport for individuals or a power of attorney (stamp) from the recipient company if the order was placed for an organization.

- Check the quantitative correspondence of the actually issued cargo and that indicated in the waybill.

- Check the integrity of the packaging, the presence and integrity of the adhesive tape with the markings of the carrier company, and the absence of mechanical damage to the cargo packaging.

- If the above damage is detected, it is necessary to draw up a report or claim to the transport company and notify the online store manager about it.

Bank transfer Payment by Sberbank card. The most popular payment method outside the Moscow region. You can pay at any branch of Sberbank of the Russian Federation or other banks providing such services, as well as at Russian Post branches.

Cashless payments Available to all legal and individuals. To receive the goods legal entities a power of attorney or a seal from the payer will be required, and when delivering by a transport company, these documents must be provided to the transport company that will deliver to you. Individuals only need to present their passport to receive the goods.

Electronic money Yandex Money account: 41001819674953