Keber gas boiler repair. Gas boiler Keber - a reliable Russian heater

Keber boiler installed. What to do if the main burner takes in gas when turned on, but there is not enough for the igniter? How can I regulate this? Automation Eurosit-630.

Check the gas pressure before the automation. Static and dynamic. When the main burner is turned on, it should differ by no more than 50mm. Causes: Blockage in the pipeline. Gas meter jams. The tap in front of the device is clogged. Problems with EHR automation. Low pressure in the network.

Tell me, please, I have a Keber 12.5, the burner burns for a very long time for 4 -12 minutes, and when switching to the fuse, it lasts 10 minutes.

The burner burns until it reaches the set temperature, and if there is heat loss, it may not turn off.

The boiler is Keber KSG-10K-06. It started turning off spontaneously. Year of manufacture 2012, installed in the fall of 2016.

Check the igniter, all contacts and the draft sensor.

Gas boiler KSG-8. When you set it to 1, 2 or 3, even up to 6, the temperature is always 80. Can you tell me what the problem is?

In the temperature sensor or bypass valve.

Boiler KS-G, automatic comfort 36, turn on the burner, it works for 3 minutes and goes out. Blown it out, clean it, doesn't help. I don’t understand what the adjusting screw is, what to do with it or not to touch it, what’s the reason?

Perhaps the draft sensor is triggered or the thermocouple is not warming up well. It's better not to touch the screw; it doesn't affect it.

Tell me how to solve the problem with the KSG-12.5 boiler with Eurosit 630 automation? I light the igniter and turn on the main burner, the burner lights up and after a while (from several seconds to several minutes) the flame seems to fade out smoothly, and the igniter also goes out. Moreover, if the main burner is not started, the igniter works constantly.

There is not enough gas. Clogged tap, faulty meter, filter, etc.

I can’t start my gas boiler KGS-10. When you press the button, the gas goes out, after which I light it with a match, according to the instructions you need to wait a few seconds, then release it and turn it to the desired division, and so when you release the button, the gas goes out.

There are many reasons: The pilot light is weak. The thermocouple is faulty. The traction sensor is broken.

The gas boiler KS-G-25-06 with automatic Eurosit 630, manufactured in 2011-2012, is in operation. The door with the factory sticker is missing. Is there any other way to identify its number or at least the year of manufacture?

The number and year of manufacture are in the passport, and the year of manufacture can also be seen on the burner.

The boiler has a power of 10 kW and the burner has a power of 24 kW, do they not fit together?

Yes. Your unit requires a 12 kW burner.

I decided to change the entire automatic burner. Because I can’t solve the problem with the device any other way. They recommend the Hubert 24 burner. Will it fit the Keber boiler and will this solve my problem with the main burners not going out?

Hubert is not particularly familiar with the burner, but he looked at it and it looks the same as everything we sell. The only thing that caught my eye was that there was no sign on it. gas valve sit, but Chinese, which is cheaper. The burner is selected according to the power of the unit, look at what you have, and install it at that power. And there may also be a problem with installing the temperature sensor.

The Keber floor-standing boiler is in operation, flames are burning from the jets, what is the problem, tell me?

The bypass valve needs to be replaced.

Tell me, my Keber 12.5 boiler with Arbat automatics is constantly going out. What is the reason?

The wires go up from the thermocouple and where the contacts are fixed at the top, move them, they tend to oxidize on the contacts.

Malfunction of the KS-G boiler. I set it to "6", the temperature rises to 60 degrees and turns off. It cools down to 40-50 degrees and turns on again. What is the reason or is this how it should be?

Most likely there is a blockage in the system. It is also possible that the thermostat is not adjusted.

Malfunction of the Keber KS-G boiler 12.5. During operation, some kind of puffing was noticed in the igniter window. This phenomenon is alarming, there is also another problem, it is as follows: when the regulator is set to 3 or more, the main burner stops turning off, the device works without stopping. When I return the regulator to 2, the device starts working as expected, it worked - it turned off, according to the prescribed cycle. Tell me, what could be the problem?

If the temperature corresponds to the figure, then most likely the gas pressure is low.

The thermocouple on the floor-standing boiler Keber 12.5 (automatic Arbat) broke, I went to the store, there was a thermocouple without a union nut, but on the device it is a union nut, I did not unscrew it, but it seems to be a union nut.

The thermocouple is a regular one, unscrew it and replace it with a new one.

In operation, the Keber KS-G-10 gas boiler with Eurosit 630 automatic system works normally up to position 3, i.e. reaches a certain temperature and switches to the wick, holds the temperature, from position 4 begins to raise the temperature, i.e. The burners burn constantly and do not switch to the wick. At 3 it dials up to 60 and switches to the igniter, at 4 the burners burn constantly and the temperature rises to 100, after which the burners dim slightly. Two days ago it worked fine, at 6 it kept 80-90 degrees, i.e. dialed 90 degrees and switched to the igniter until the temperature dropped.

If at 3 it reaches 60 degrees and switches to the igniter, but at 4 it does not gain temperature, then either the gas pressure is weak, or low power boiler or large heat losses. The temperature sensor is responsible for the temperature, if it is not working, then it will boil at any number, perhaps not all the kerosene has leaked out and it is still covering the gas passage, check for another 3+, if it does not go out, change the temperature sensor.

In operation, the Keber gas boiler does not raise the temperature above 50 degrees, what could be the reason?

The reason may be low gas pressure.

Keber boiler malfunction. Small, with a water heater, installed in December 2012. Worked well. Two days ago it seemed like the gas pressure in the network was reduced ( gas stove works), and it went out, because all winter the knobs with numbers were at the minimum, even the gas valve to the unit had to be reduced (in cold weather they increased the pressure, and mine was at a minimum before that). I solved it this way: Opened gas tap, the wick lit on the 5th click of the piezo, after a minute of holding the igniter button the burners lit, burned for 2 hours, went out. The time is night. 2nd attempt: the wick lit with the 12th click of the piezo, the burners lit after 5 minutes of holding the igniter button, burned for 2 hours, went out. It's midnight. 4 more attempts to set it on fire were unsuccessful. Second night without heat. The wick lights up quickly, 1-3 clicks of the piezo, it burns as long as I hold the button (last night I suffered for about half an hour), I release the button - the wick goes out, the burners do not light. I tried it in the morning, during the day, at night, again in the morning. Tell me, is there a problem with the boiler, or should I wait for the gas pressure in the network to increase? It was a thermocouple that burned out. It has now been replaced and works fine.

With the new thermocouple, the device turned on immediately, worked, warmed up, reduced to 80°C (it worked flawlessly, the flame was strong, I could only reduce it with a tap). Now it has gone out, and now the burners also do not light up. The wick lights up, the thermocouple is in its place, it is installed with a screw, it will not move somewhere to the side, it is in the flame. I release the igniter button after holding it for 5 minutes, the wick goes out, the fire remains very small (maybe the remaining gas in the tube is burning out), it does not reach the thermocouple, the burners do not light up. Automation Orion, boiler KS-G-10-04. What can be wrong? We checked the thermocouple, it works, it is heated, it produces current. What else could be the cause of the problem? Maybe in the traction sensor, or what is the name of the hollow tube (on a wire in a winding) that is inserted into the hole in the upper part of the tank of the device, on our left? And on the right, a wire from a thermometer is inserted into the hole.

The tube in the winding is a temperature sensor. The traction sensor is located higher, with either wires or a tube going to it. Take out the thermometer. You do not have a draft sensor, since the thermocouple is not original. Now what needs to be done is that where the thermocouple is screwed in, there is a square nut; the thermocouple should not be unscrewed much, tighten the nut, and then tighten the thermocouple only with a little force so as not to crush it. If you need the draft sensor to work, then put a gap between the thermocouple, nut and wires with connectors, connect the sensor and the gap. Now about the temperature sensor, if it is damaged, the unit will not respond to temperature.

We replaced the thermocouple and the igniter tube with new ones, the boiler lights up, runs smoothly, does not smoke, but another problem has appeared. There is a small flame between the white button and the temperature control knob from the fuse. You can detect it using a lighter when checking for gas poisoning; when you light the device, there is no flame on the fuse on the igniter. Only when you turn on the burners. Tell me, what could it be?

This is not a fuse, but a screw for adjusting the low flame of the burner. There is a rubber ring on it, and it poisons through it. Ideally, replace the ring, and if the bypass valve is adjusted and there is no leakage, put out the boiler and drop some thick paint into the hole where the screw is. Wait until it dries and turn on the device.

A KS-G gas boiler of 250 sq.m. was installed and connected. m. When ignited, it does not turn off, the temperature rises, if I am not mistaken, automatic Arbat 1. The flame is not regulated - it is too large. What to do?

Adjust or replace the temperature sensor.

In operation, the floor-standing boiler Keber KS-G-16 K worked properly for almost 6 years. IN Lately It started clicking when it warmed up and cooled down. System without pump ( metal pipes). Tell me, what can I do on my own? Will it last through the winter?

Doesn't affect speed. It is some metal inside that heats up and cools down. It will last more than one winter. The back part, where the exit from the unit hot water, should be slightly higher for air to escape.

Gas installed. boiler KS-G-10, automatic Eurosit 630. Installed and started. A small problem has arisen; when ignited, it only lights up. left-hand side pilot burner. I release the control handle - it goes out, turn on the ignition again and then set fire to the right side, and then everything goes according to plan. The unit works perfectly in all modes. The problem is in the ignition of the pilot burner. What do you recommend doing?

Remove the igniter and slightly straighten the center and right sides with a thin screwdriver.

Malfunction of the Keber-12.5 boiler, automatic Arbat, 2005. At the point of contact between the thermocouple and the automation, gas poisons and ignites when the flame passes from the burners to the wick. Yesterday I started it, and this morning I discovered a light, the automation got hot from it. I looked because the batteries were no longer hot, that is, after it ignited, the burners no longer lit. How to neutralize the leak and shouldn’t the automation completely turn off the gas supply in this case?

If there was a fire there, the magnetic plug could melt and the rubber ring could become rough. Eliminated by replacing the plug and ring.

What happens if the pump doesn't work? There is no electricity, but the boiler is on fire. Will anything burn out, for example, a fuse or something else?

If the automation is working properly, then everything will be fine. The device will heat up and turn off, leaving only one igniter, which will turn on again when it cools down.

Malfunction of the Keber 12.5 boiler. The click is heard, the regulator moves like clockwork, the bellows at the end is warped, or rather metal cladding, like a sleeve, where it connects with the spring, I don’t know how dangerous it is and how to explain it more correctly. The flame increases and decreases independently as needed. I didn’t see if it was switching to the wick, I watched for half an hour, I didn’t have time to look anymore. The only thing that’s not for me, that is, not like before, is that the flame is stronger. That’s why I suspect that the bypass screw was still turned. Traction sensor I'm on put the place, the hole for it was simply tightened with a screw, all leaks were eliminated, a gas filter was installed in front of the device. What should I do to still turn off the wick?

The bypass screw is responsible for the low flame, and you shouldn’t turn it back and forth. The fact that the flame is adjustable is good, but if the thermal valve was turned, this is very bad. You won’t be able to set it up yourself, and, as I understand it, you don’t have specialists. And also - the flame is stronger when turned on. The thermal valve is responsible for switching to the igniter if everything else is normal.

Keber 10 has been installed for a couple of months, I set it to 3, it reaches 50 degrees and turns off, but the radiators are not hot. I bled the air from the radiators, but to no avail. I called a specialist, he said that the pump was overheating, replace the pump. I installed a new one that is more powerful, but it also gets hot and nothing has changed. What could be the reason?

If a gas boiler reaches the set temperature and turns off, then the problem is not in the unit. Check to see if the system is completely full.

Malfunction of the Keber 12.5 boiler, automatic Arbat. They installed new automation, domestic, not Chinese. When you turn it on at 1, 2, 3, 4, 5, it burns for a minute, a minute and a half, and then only the wick and the burner does not light up again, the fire jumps out onto the nozzles. On 6, it doesn’t burn for long at first, then the flame is low and the fire jumps out onto the nozzles, when you put it out, then after 15-20 minutes the burner lights up again and burns the same, constantly, without decreasing. How to adjust?

Fastening screws for an asterisk or a regular screwdriver. The bypass valve also needs to be adjusted for temperature.

We connected the gas and installed the KS-G 10 boiler, the temperature does not rise above 60 degrees, what is the reason?

There are many reasons - from gas pressure to heat loss at home.

A Keber boiler with Orion-21 automation is in operation. What happens is this: I press the ignition valve, gas flows to the igniter, it lights up. The valve held for even 3 minutes, I release the valve and the burner does not light up (no gas flows). The pilot light goes out (in normal mode the main burners should light up). I checked the draft sensor, it is closed (normal), 18 mV comes out from the thermocouple when the igniter is burning normally (seems to be normal too?), the thermocouple is washed by the flame well, the “Stop” button is closed (normal), maybe solenoid valve(I call him, shows briefly). Should there be a resistance of 18mV? There are no specifications written on the valve.

Where the thermocouple goes, there is a branching to the draft sensor, right? Then check the contacts, better solder them. Tighten the connections well. There may be a problem with contact oxidation. If that doesn't work, connect the thermocouple directly to the gas valve. Check what exactly is not working for you. You cannot leave it without a traction sensor.

__________________

____________________________________________________________________________

_____________________________________________________________

_____________________________________________________________

Heating system control. Installation. Connection. Transfer to another type of gas. Adjustment devices and protection devices.

Peculiarities. Installation and assembly. Automation components.

Technical specifications. Installation. Adjustment and checking. Maintenance.

Adjustment and protection. Installation and assembly. Pressure setting. Maintenance.

After starting, a malfunction appeared. It doesn’t want to turn on, it worked for two years, now the whole display lights up, just like when the boiler is turned on, when the self-diagnosis mode is in progress, then it clicks, turns off for miles and seconds and turns on the whole display again. It turned on once, but it gives error E10 water pressure, although the pressure in the system is 1.5 atm. Tell me, what could it be?

We installed and connected the Baxi Fourtech 24 F boiler. What is the pressure? cold water allowed at the entrance to the DHW device?

Bosch Bosch 6000 24 kW, single-circuit with built-in three way valve. The boiler sensor does not see it and gives an error. Tell me how to do it so that it doesn’t give an error and works normally for both the heating and the boiler?

If you turn off the DHW flow sensor, maybe it will be possible to reprogram it into a single-circuit device through menu L3?

We installed an Arderia esr 2.13 ffcd boiler. If my coolant pressure drops slightly by a couple of notches over 2-3 days, could the reason be a faulty three-way valve (there are no leaks from the radiators)?

The gas boiler Arderia 2.35 is in operation. Tell me about reducing power. I heard something about modulation, fan speed, etc. Is it really possible to reduce power?

We installed and connected the Buderus Logano G234-WS-44 kW boiler, automatic Logomatic 4211. Heating is based on cylinders without hot water, and the jets for reduced gas were also replaced. We survived the winter, the cylinders were replaced, all without problems. Then in the spring, when the outside temperature was +16+18, the boiler began to turn off for a long time and when turned on, it began to display a burner error on the screen and the red button light on the front wall came on. We pressed the button, turned the power back on and everything worked. This happened several times, then the boiler was turned off completely for the summer, what could be the problem?

In the single-circuit Buderus 072, is the BKN coil circuit heated by the same heat exchanger as for heating or the same as on the 2-circuit one that is used for DHW?

Tell me, for Vaillant wall-mounted gas boilers, are there real/actual differences in better side in the new generation turboTEC plus VU/5-5 compared to /3-5?

There is a malfunction in the boiler, the green LED (power) is flashing, the instructions say that the thermal protection has tripped, the green indicator is flashing, even if nothing is connected to the board. How to fix? I checked all SMD resistors and transistors, everything is fine.

In operation there is a double-circuit gas boiler Daewoo Gasboiler with an electronic panel. When the DHW is turned on, the heating heats up, the operating mode is summer. I removed the three-way valve, there is no dirt or wear. It seems that the board does not control the three-way valve. How to check?

The Electrolux Basic Xi wall-mounted boiler has been installed and connected. A problem began that the boiler stopped seeing the flame and turned off the gas supply after 7-8 seconds. And after 3 attempts it gave error E1. How can I fix it?

Koreastar boiler malfunction. Heating works great, hot the water is flowing intermittently, when you turn on the hot water tap, cold water comes out first, then boiling water. After a few seconds it’s cool, then boiling water again. What could be the problem?

The Ferroli Domiproject 24 boiler is malfunctioning - I set it to 60-70 degrees, it switches to minimum combustion, does not turn on, does not turn off. Restart is unstable. No pattern emerges. What to do?

In operation, a Junkers euroline gas boiler, when hot water is turned on, gas ignites, then goes out, and so on several times. If you turn it on while the heating is running, the water heating starts immediately. Please tell me what could be the problem?

Tell me about the adjustments gas boiler Navien Ace 16 turbo remote control v1.3. It is not possible to adjust the fan run-on. I set it to 30 seconds, but still 2 minutes. spins.

Malfunction of the Oasis ZRT18 boiler. The unit starts, the gas lights up, then goes out. It lights up again and then goes out (this happens three times). Then it lights up and works fine. It doesn't give any error. What is the reason?

Malfunction of the Senor Duval gas boiler - the water pressure sensor shows 0.0, the indicator flashes red, the hot water does not heat up, but the water pressure in the apartment is good. How to fix the problem?

In which place coaxial chimney should a steam trap be installed? Boiler wh1d c closed camera combustion, located at a distance of 1 m from the wall.

GAS EQUIPMENT

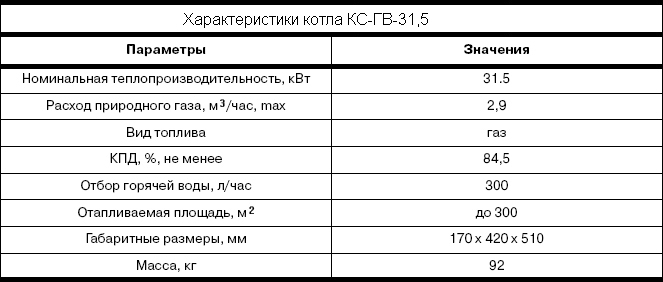

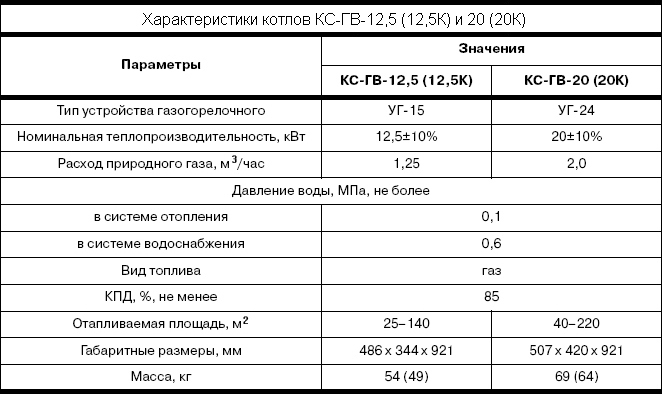

STEEL GAS BOILERS "KEBER"

Steel gas boilers are intended for heat supply individual houses, buildings for public utility purposes and hot water supply for domestic needs, equipped autonomous systems water heating continuous action, both with natural and forced water circulation. The fuel for boilers is natural gas. New design gas burner device ensures stable combustion, high efficiency and complete combustion of gas. The design of the firebox and heat exchangers ensures the efficiency and durability of the boiler. "Keber" boilers are manufactured with a gas burner device "Comfort".

Steel gas boiler "Keber-31.5"

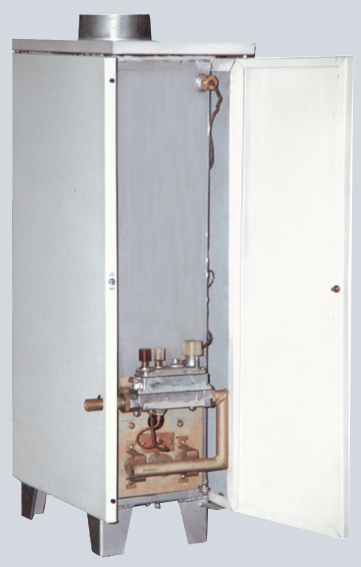

Steel gas boiler "Keber-12.5K"

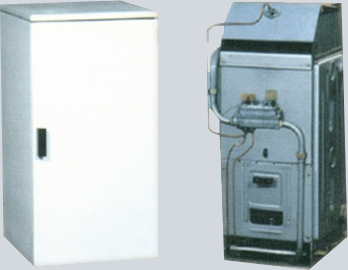

GAS HEATING EQUIPMENTS

Heating devices

Gas heating devices are intended for local water heating of premises, with an approximate area of 100 - 270 m2 for operation in areas with temperate climate. The circulation in the system is natural. The devices can operate on natural gas and propane-butane mixtures. Heating devices AOGV-17.5-3-U and AOGV-23.2-1 have good environmental characteristics and high coefficient useful action.

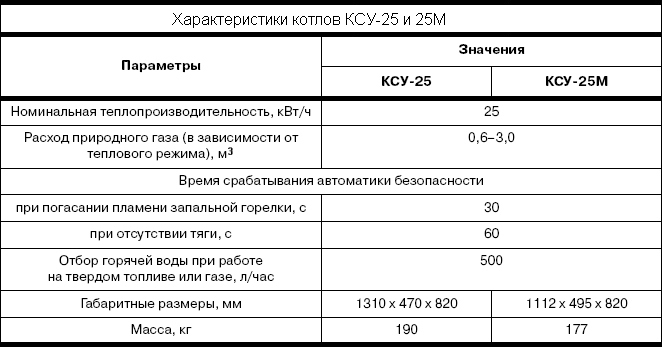

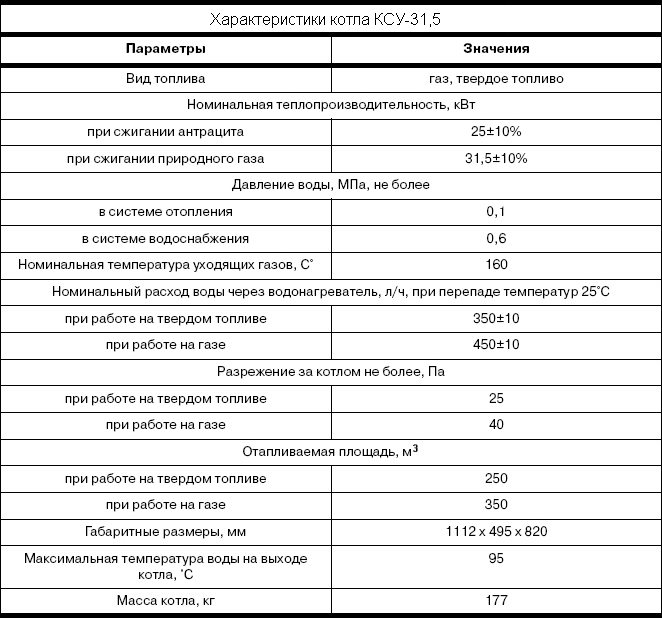

WATER HEATING BOILERS KSU ("FARMER")

Universal water heating boilers KSU-25, KSU-25M and KSU-31.5 (“Farmer-25”, “Farmer-25M” and “Farmer-31.5”) are designed for heating premises with an area of 250-300 m2 and hot water supply for residential and auxiliary premises, cottages, farms and other buildings equipped with a water heating system. The boiler has good environmental characteristics in terms of the quality of the exhaust gases and the radiation of the boiler's thermal insulation, and a high efficiency. The boiler can operate on natural gas and solid fuel. The boiler is equipped with backup electric water heating with a power of 4 kW.

Boilers KSU-25M and KSU-25

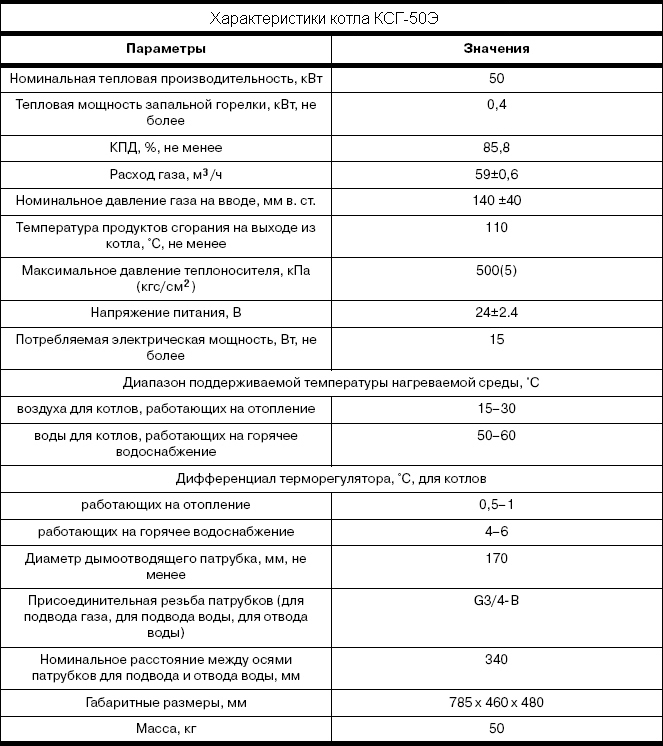

STEEL GAS BOILER KSG-50E

Steel, gas boilers are designed for heating water systems autonomous heat supply and working under compulsory forced circulation water, as a rule, in automatic mode without the constant presence of an operator. Boilers can be used either individually or as a group installation. The connection of boilers in a group can be parallel or serial, or parallel-series. The boilers are designed to operate on natural gas in accordance with GOST 5542-87 with a nominal pressure of 1274 Pa and a calorific value of 35570 ± 1780 kJ/m 2.

Steel boiler KSG-50E

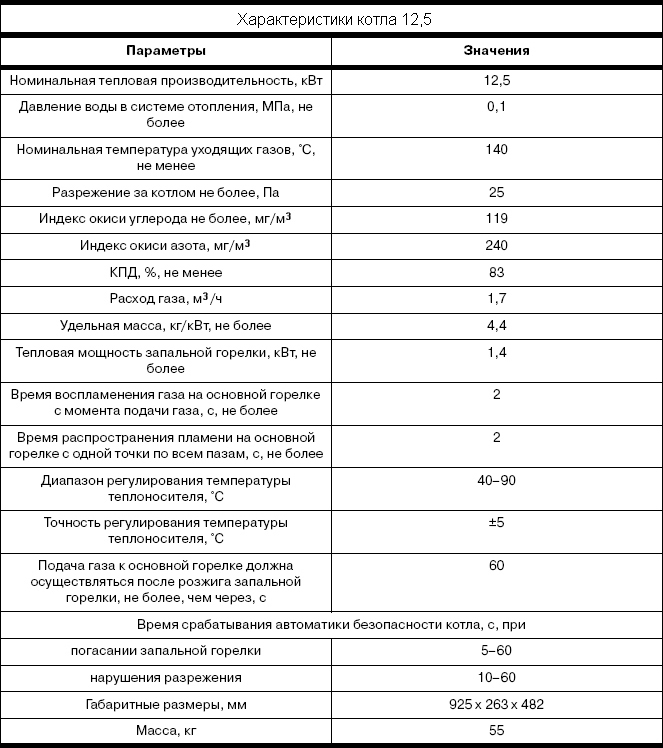

STEEL GAS BOILER KSG-12.5

Designed for heat supply of individual residential buildings and public utility buildings equipped with continuous water heating systems with natural circulation water in automatic heating mode, carried out by automatic control and safety "ARBAT-11". The fuel for the boilers is natural gas in accordance with GOST 5542-87 with a nominal pressure of 1274 Pa. The established trouble-free operating time is 22,000 hours. Average term The service life of a steel boiler is 15 years.

Boiler KSG-12.5

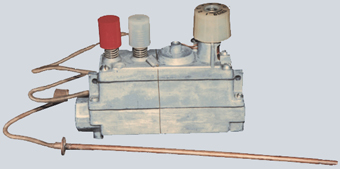

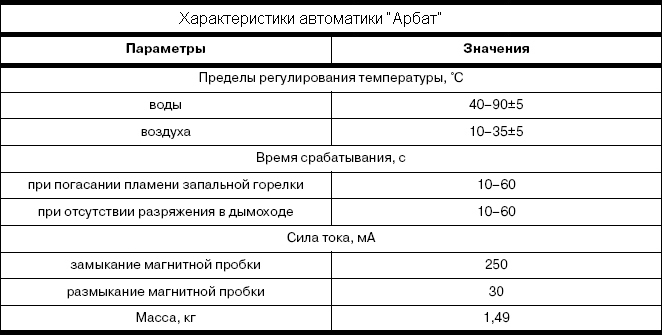

AUTOMATIC CONTROL AND SAFETY "ARBAT"

Used for installation as part of gas burner devices on domestic gas heating boilers and devices with a power of up to 50 kW, operating on natural or liquefied gas and is used to automatically regulate gas flow, the thermal process in a heated room and turn off the gas burner device in the absence of draft in the chimney or the pilot burner flame goes out. Automatic Regulation and Safety type "ARBAT" provides 5 degrees of protection:

Automation is distinguished by its versatility, rational layout, relatively simple design with large quantities completed operations. The operation of the block does not depend on its orientation in space.

Automation "Arbat"

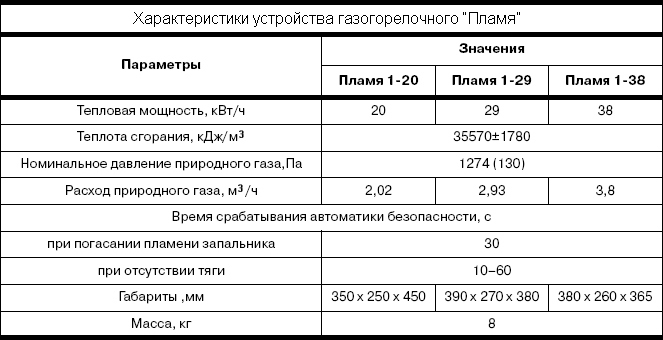

GAS BURNER "FLAME" DEVICE

Gas burner device "Flame"

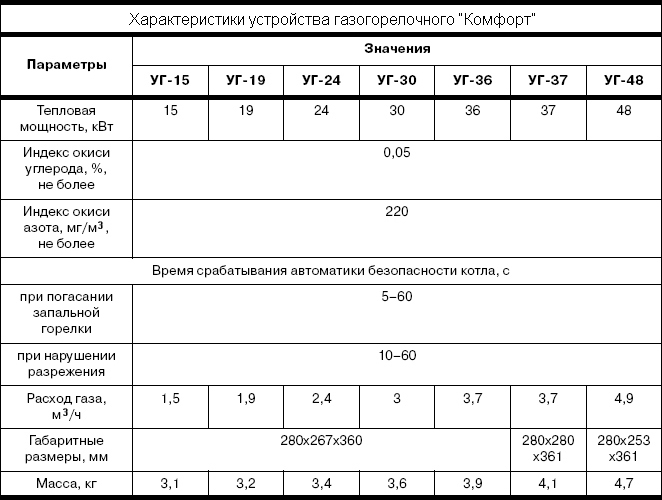

GAS BURNER DEVICE "COMFORT"

Gas burners are designed for burning gas in household heating boilers, hot water and household furnaces. Can be used for gasification of residential buildings and conversion of previously installed heating equipment from solid fuel for natural gas. The presence of automatic regulation "Arbat" ensures that the room temperature is maintained within specified limits by automatically regulating the gas flow to the main burner depending on the temperature of the water in the heating system or the temperature of the furnace masonry. Automation allows you to automatically turn off the gas supply when the pilot burner flame goes out or the draft in the chimney is disrupted, ensuring safe operation of the device.

Gas burner device "Comfort"

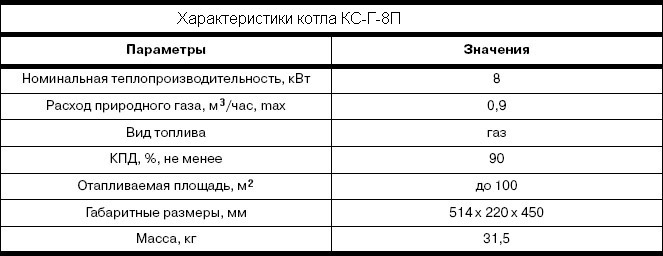

STEEL GAS HEATING HOUSEHOLD BOILER WITH WATER CIRCUIT APARTMENT KS-G-8P

The KS-G-8P residential steel gas heating boiler with a water circuit is designed for heating residential premises with an area of up to 100 m2. The fuel for the boiler is natural gas in accordance with GOST 5542-87 with a nominal pressure of 2000 Pa. The boiler takes in air and exhausts combustion products outside the room through its own smoke-air channel and does not require a vertical chimney. Thickness outer wall building, through which a gas duct passes from 250 to 490 mm. Reliable and highly efficient safety automatics from SIT (Italy) are used with a gas pressure stabilizer in front of the main burner, regardless of the gas pressure at the inlet. A slotted low-flame burner made of of stainless steel with minimal noise level and maximum combustion. Thanks to its compact design, high efficiency, low gas consumption, as well as high reliability of automatic safety and temperature control, the KSG-8-P boiler is an excellent solution for heating rooms and apartments.

Boiler KS-G-8P

LLC "Trading House "Zvezda-Strela" is engaged in the production heating equipment under the Keber brand since 2006. A responsible approach to the development of each model has made this technology very popular in the domestic market. Today, many experts emphasize the special adaptability of Keber gas boilers to the very difficult Russian conditions.

Units produced in our country have always been considered more adapted to the climatic difficulties of the far north. And in this context, the Keber gas boiler can rightfully be considered one of the leading developments of Russian engineers.

The equipment supplied to the domestic market under the Keber brand is designed for complete heat supply to premises for various purposes. Some units have a dual-circuit design, which makes it possible not only to support optimal temperature in a house or apartment, but also provide for residents hot water year-round.

Natural gas as a universal fuel – perfect solution For Russian consumer. And that is why the manufacturing company has focused its attention on this category of heating products.

Each Keber gas boiler is a tandem of reliability and durability. The minimum service life of the system is 15 years. Naturally, with proper maintenance and careful treatment of the main components of the structure, the actual service life is significantly extended. Keber equipment meets Russian quality standards, which is an additional guarantee long term its operation.

The boilers are equipped with special burners that ensure stable heating of the coolant. We are talking about a special Danko mechanism, consisting of a so-called pipe nozzle. The latter has high anti-corrosion properties. Special design"Danko" ensures the most efficient combustion of fuel, even if the flame height reaches seven centimeters. It is important to note that the Danko nozzle is a certified design, which in terms of quality is fully consistent with foreign-made analogues.

Keber gas boilers have a small combustion chamber, the size of which has been reduced thanks to the use of the same Danko design. During operation of the unit, a small amount of fuel is consumed, which indicates the efficiency of the equipment.

Keber devices are equipped with time-tested Arbat automation, which is designed to regulate the operation of the boiler and make it safe. The equipment provides five levels of unit protection. If the pressure in the water or gas supply system drops, the Keber boiler turns off automatically. The unit is also capable of coping with many other non-standard situations. What is important is that the design of the automation itself is quite simple, which increases its reliability and facilitates repairs in the event of a malfunction.

Despite the fact that the Arbat automation deserves high praise, in some aspects it is still far from ideal, which is the famous Italian development of EUROSIT. The Keber gas boiler manufacturing company, in an effort to satisfy the needs of all categories of potential buyers, optionally offers boilers equipped with the EUROSIT system. When purchasing a model with this configuration, the consumer can completely rely on automation and enjoy constant warmth in his home or apartment.

Keber boilers: possible malfunctions

Of course, there is no engineering design that is perfect in all respects. And if we are talking about domestic units, then the consumer even more needs to be prepared for a variety of “surprises”. This trend does not bypass heating equipment either. For Keber gas boilers, malfunctions are quite common. That is why it makes sense to list the main ones:

- Unstable operation of the igniter. As a rule, cleaning the nozzle solves the problem. In some cases, it is necessary to check the meter, as it may not allow gas into the system in the required amount.

- The burner goes out a few minutes after starting operation. There can be many reasons for the malfunction. The most common is the failure of the traction sensor. In this case, experts recommend contacting professional repairmen.

- No gas supply to the injectors. If the unit is equipped with domestic automatic equipment "Arbat", then most likely the rod is jammed in the middle part of the structure. You can drop a little yourself machine oil, after which it is necessary to check the automation for gas leaks. If the cause of the malfunction cannot be eliminated, it is recommended to call a specialist.

Of course, list everything possible problems problems arising during the operation of Keber boilers cannot be covered in one article. However, we were able to consider the most common ones. However, we strongly recommend not to engage in self-repair, if you are not confident in your own skills and professionalism.

1.

2.

3.

4.

When arranging a heating structure, many homeowners prefer installing double-circuit gas boilers. These heating units when installed modern models They are reliable, they are economical and allow you to provide hot water in the house, but it is important to know how to start a gas boiler correctly the first time.

In order for the device to work for a long time and without repair, you need to properly organize the first start-up of the gas boiler, during which the system is filled with water and the air trapped in them is removed from the pump and heating batteries. In order to facilitate this process used for radiators special devices– Mayevsky cranes. They should be unscrewed until water comes out of them.

To ensure that no air remains in the pump, first remove the front panel of the unit and make the necessary adjustments. Air pockets are quickly removed, and the equipment automatically starts working.

How to start a gas boiler: preparation

Exists simple instructions, explaining how to start the gas boiler shown in the photo. The initial start-up is carried out when the installation and wiring of all elements of the heating equipment is completed, and the correctness of the work has been verified by the relevant authorities.The location of the heating unit must be selected in accordance with safety standards and regulations that prevent fires. The boiler must be located at a certain distance from the wall, which depends on the manufacturer's recommendations. By the way, for some models of gas appliances this requirement is not relevant. You should also make sure that there are no flammable materials or objects nearby.

In addition, it is prohibited to place boilers near windows, as their operation will be disrupted. The even position of the device body is of no small importance - even minor distortions are unacceptable.

After installation is completed, they begin to connect the equipment to a source of cold water: remove the plugs from the pipes, and place a filter with a ball valve at the inlet. Such a device protects the heating structure from all kinds of contaminants that cause damage. Ball Valves must be placed on all pipes used for piping.

Solving the problem of how to start a gas boiler, Special attention should be given to the installation of pipes from the gas main. They do not carry out this installation work themselves, but invite specialists from the relevant services who are involved in connecting, sealing and, if necessary, installing a gas meter.

Before you turn on the gas boiler, you should lay a separate power line specifically for the heating unit. Equipment needs to be equipped electric cable with a plug, and install a socket next to the device, separating it from the others.

After this, the boiler is connected to the chimney pipe, in which the draft and its performance are checked. She must go outside. Carrying out installation work chimney installation depends on the type heating device.

When preparing for startup, the boiler is disconnected from the power supply to fill it and the heating system cold water. Then they check for leaks, turn the thermostat to the maximum value so that it lights up automatically

operating mode switch.

Rules for filling the system with water before turning on the gas boiler

Before lighting a gas boiler and turning on the heating system, it is first filled with cold coolant, which, after heating, will circulate through the pipes and radiators. During the first launch, everything is carefully checked so that further operation is uninterrupted and the equipment does not require repairs.The unit body has a special tap located near the pipe to supply coolant to the system. During the filling process, the pressure in the system is monitored thanks to the presence of sensors and pressure gauges. IN modern boilers They are already installed and there is no need to purchase them additionally. When the device is filled with water, the mark on the sensor rises. When it reaches the 1.5-2 atmosphere mark, the water supply is shut off and thus completing the filling.

These pressure parameters are subject to change as they depend on the manufacturer's operating pressure requirements. heating system. But filling with cold water does not end there, since replenishment will be required after the structure is freed from air pockets.

Removing air pockets before lighting a gas boiler

Before lighting a gas boiler, you need to fill the heating structure with liquid cold coolant. But just filling with water is not enough. It will either not work, or the degree of heating of the room will be insufficient. A full first start is impossible without releasing the air accumulated in the system. Often in modern gas boilers There is a special system that automatically releases air when filling. But often its effectiveness is insufficient: you will still need to manually reset the air locks. Only after this can you start.Delete air jams Before turning on the gas boiler, it is necessary not only from the heating unit, the circulation pump, but also from all heating radiators. The process should begin with batteries - for this, as mentioned above, they will be equipped with Mayevsky cranes. They are opened by placing a container underneath. First, a slight whistle will be heard, indicating that air is gradually leaving the system. After removing the plugs, water begins to flow. Then the taps are closed. A similar procedure should be done with each of the radiators.

When air has been removed from the batteries, the pressure gauge needle should point to a certain value. Before lighting the gas boiler, coolant should be added to the system and thus recharged.

To eliminate the plugs that have accumulated in the circulation pump, partial disassembly of the boiler will be required. This work is not difficult: you need to remove the front panel from the device, then find a cylindrical element that has a cover in the middle of the body with a slot for a screwdriver.To start the boiler, you need to supply power and set the heating regulator to the required working position. The presence of a weak hum indicates that it has started working circulation pump. Using a screwdriver, lightly unscrew the cover on the detected part. But this must be done before the water begins to flow. If liquid begins to seep out, screw the cap back into place. Such actions are performed several times and after this the air pockets will be completely removed from the system. The gurgling sounds will also disappear and the pump will run quietly.

After this, the electric ignition of the boiler will work, and the device will turn on independently. The system pressure should be adjusted by adding coolant liquid to the required level. The design, gradually warming up, enters the desired operating mode. The effective functioning of any type of heating equipment depends on the correct execution of the stages of preparation, start-up, and adjustment.

How to start a gas boiler, watch the video: