Gas consumption for heating. Gas heating: gas consumption of a gas boiler

Many buyers of equipment (boilers, burners, boiler rooms) try to independently determine the possible maximum or minimum gas flow or flow rate diesel fuel during operation of the boiler, burner, as well as the boiler room as a whole. It is not always possible to determine fuel consumption yourself with 100% accuracy. Consumption depends on the type of fuel used and the power range at which the equipment operates (boiler, burner, boiler room or process unit).

For example, you are planning to build a boiler house with a capacity of 1 MW (1000 kW), and you need to calculate the preliminary consumption of gas or liquid fuel in order to determine the possible financial costs associated with the operation of the boiler house. Many people believe that fuel consumption is determined by the power of the boiler or boiler room. In practice, such a calculation is erroneous and does not allow determining the required volume of fuel.

Example of preliminary calculation.

We take as initial data:

- boiler house power: 1000 kW (1 MW);

- number of boilers: 2, with a unit capacity of 500 kW or 0.5 MW, respectively;

- boiler efficiency = 92%;

- conventional aerodynamic resistance in the combustion chamber = 0 mbar;

- installed on boilersgas-burners: fuel is natural gas;

- the boiler room operates at constant power without switching to the second stage (operates at maximum power);

- the boilers are equipped with single-stage, two-stage, smooth-stage or modulating burners (this does not affect fuel consumption when the boiler room is operating at constant power);

- calculated calorific value of natural gas: the calorific value of gas is accepted, which is used by European companies to determine fuel consumption, and the calorific value generally accepted in Europe is 8.83 kW per m3/h.

The calculation is made as follows:

The burner power required to operate a 500 kW boiler is divided by the conventionally accepted calorific value of the gas. For the operation of the selected boiler at an efficiency of 92% and an aerodynamic resistance of 0 mbar, we obtain a combustion power of the burner equal to 543.45 kW (500/0.92 = 543.45 kW). In this case, we obtain the average consumption at the existing constant boiler power, namely: 543.45/8.83 = 61.55 m3/h of gas. The data obtained were calculated precisely under the condition that the burner operated at a constant maximum power of one boiler of 0.5 MW (500 kW). To determine gas consumption when operating a boiler room with two 500 kW boilers, it is necessary to multiply the fuel consumption by the number of boilers.

For determining minimum flow fuel (gas or diesel) requires a similar calculation, but maximum power boiler (500 kW) replace with the minimum boiler power.

By determining the minimum and maximum gas or diesel consumption, you can only obtain the range of possible gas or diesel consumption. Actual fuel consumption will depend on many indicators (real calorific value of gas, boiler efficiency, resistance in the firebox, burner power control range, type of burner power control, weather conditions). To be able to optimally regulate the power of a boiler or boiler room, you will need to install burners with a two-stage, smoothly stepped or modulating type of power control.

The method we have indicated for preliminary calculation of gas or diesel fuel consumption is not the main one and does not provide a 100% guarantee of accuracy in determining the real need for heat and fuel. To do this, “Calculation of heat and fuel requirements” is performed to design and determine the real gas consumption during operation of a boiler room or process installation (furnace, spray booth, drying unit and other heat generators).

For questions about selecting a burner for a boiler, choosing the optimal equipment and consultations on technology, price, and delivery times, please contact the sales department by phone or email.

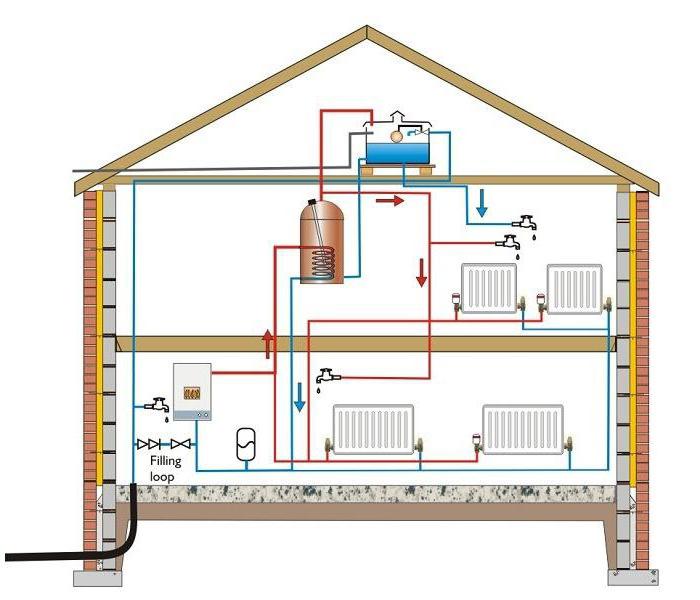

A gas boiler is the optimal equipment that allows you to ensure not only uninterrupted supply hot water both in winter and in summer period, but also to heat a private house, using relatively inexpensive fuel for this. But despite its low price and economical consumption, it is necessary to control the use of fuel. Gas consumption for the boiler is the most important part of operation that must be taken under control.

Floor-standing boilers are more economical and easy to operate; even a beginner can understand them.

Let's find out what the gas consumption for boilers depends on, how to make calculations, whether it is possible to reduce the consumption and by how much. With the help of simple tips from our specialists, you will learn how to save on gas consumption and make your heating system efficient and convenient for home use.

Gas consumption criteria

For optimal performance Gas heating systems in a private home require monitoring gas consumption.

So what does gas consumption depend on? Let's look at the main points that will help you find out:

- Any instructions for the boiler indicate the flow rate in cubic meters. But this figure shows the maximum flow rate, that is, the burner must be turned on full. This consumption is directly dependent on the power of the equipment. This means that when determining how much fuel is consumed, we take into account the power and type of equipment, the operating mode of the burner for heating water;

- Room area.

When heating a room or house using a gas boiler, fuel consumption will be directly dependent on the area of the home.

But not always the expense for small room means saving. The fact is that with a large number of windows, doorways, the amount of gas for heating increases because heat losses are significant;

- Gas consumption for heating is greatly influenced by how well the walls are insulated. If modern quality materials, then the power heating system may be smaller, that is, the amount of gas for heating the coolant will be much lower.

- Gas quality. With low calorie content, consumption increases. That is, when purchasing a gas mixture for a boiler, you need to pay attention to what quality is offered to you. In many cases, it is better to spend a little more on fuel than to double or triple your heating costs.

Calculation features

The gas tank plays in the gas heating system of a private house important role, indirectly affecting fuel consumption.

Calculating the fuel consumption of a gas boiler depends on many circumstances. This concerns not only use, but also storage, for which it is recommended to install a special gas tank.

For household use It is necessary to take into account the purpose of the device and the required area for heating. If we assume that the gas boiler will heat the room thirty days a month around the clock, then you can get the number of kilowatt hours by multiplying all the initial data (taking into account the area of the room). Now the received data must be divided in half, that is, the monthly average consumption, which must be multiplied by seven. The resulting value is the average gas consumption figure for a particular home.

Let's look at an example of how to calculate gas consumption. For example, the area of the house is 100 square meters. meters, to calculate one square, one kilowatt of thermal energy is needed. That is, the boiler power for a home should be 10 kilowatts. Next, the boiler power must be multiplied by the number of days in a month: 10*30 = 300, by the number of hours in a day 300*24 = 7200 kilowatts per hour. The resulting value must be divided in half, that is, 7200/2=3600. As a result, 3600 kilowatts per hour is the desired flow rate for the specified area.

How to save fuel consumption?

If there is a gas water heater in the house, gas stove and a medium power boiler, install a membrane gas meter.

As a rule, gas is used for cooking, heating, and hot water. But the amount of fuel can be significant, and there is often a need to reduce it. When using a gas boiler, gas consumption can be reduced, making it more economical. First of all, this is the installation of special meters that will help show fuel consumption. In this case, you can clearly see what and what volumes were used.

On sale today gas meters several types: vortex, turbine, rotary, diaphragm (that is, membrane). The choice of such a meter depends on what kind of gas is used, in what volumes and for what purposes the gas will be consumed. For example, for counter G1,6 throughput is from 1.6 to 2.5 cubic meters of gas mixture. Manufacturers usually indicate such data in the technical data sheet, which allows you to purchase exactly the meter that is needed in the given conditions.

But besides installing metering devices, there are other methods to save gas consumption for the boiler. Let's look at the main options:

- When heating water for a shower, you must remember that economical, accurate consumption will significantly reduce not only fuel consumption, but also the water itself. It is recommended to use economical nozzles in the shower, and when taking a bath you should not fill it completely, which will reduce the heating time and make consumption more economical.

- When using the boiler for heating, you should install optimal temperature, which creates comfortable conditions. “Tropics” at home only increases gas consumption, but there is no real benefit.

- The walls need to be insulated. This will reduce heat loss and reduce gas consumption.

- Installation of an automatic control system that makes the flow rate correct and optimal.

Such thermal heads for heating batteries allow you to save up to 20% of fuel.

For radiators with a gas boiler installed, it is recommended to install thermal heads, which allow you to save approximately 15-20 percent of fuel. It is advisable to install a hydraulic arrow on the boiler piping, use an adjustable pump and a chronometric thermostat. Within a month, when calculating the amount of fuel consumption, you will notice that the consumption has become much less.

For a private home, it is best to install a special automation system, which allows, using convenient, modern sensors, not only to control, but, if necessary, reduce the temperature. That is, you don’t need to heat it anyway warm room when the outside temperature is quite high. This automation allows you to regulate the flow; it turns the gas boiler on and off if necessary.

Such simple tips will help you save about 20-25 percent of fuel. Today this is very important, since the price of gas is not getting lower, but for heating a house this is the only option that is low cost and convenient.

When using a gas boiler, fuel consumption is much less than when heating with a solid fuel stove or when using electric boilers. In this case, the price of the fuel itself is much lower, the water heats up faster and only when it is necessary. But how to control consumption and minimize its consumption? It’s all very simple: you need to install meters and put automation into control. This will significantly save family expenses.

Blue fuel - gas is an excellent energy carrier and therefore it is very often used in various heating devices. The most common such device is a gas boiler.

There are several types of heating boilers operating on natural mains or liquefied gas and each of them differs in its characteristics and has its own gas consumption. One of the main characteristics is the gas consumption for operating a gas boiler. Perhaps this characteristic will be more important to you than appearance heating device. Ultimately, the cost of the gas consumed is included in the price of the heating device you purchase.

The main factors influencing gas consumption in the boiler

A heating device operating on gas can consume working material at different rates. The following factors may influence this:

- The thermal power generated by the device is

- Coefficient useful action or completeness of transformation internal energy gas to heat,

- The load with which the heating device operates at a particular point in time. So in winter, gas consumption in boilers can increase. The consumption of gas boilers for heating is also increasing running water with its active use.

- The amount of heat loss in your room has a significant impact on energy consumption in gas boilers. Badly closed doors, uninsulated windows and walls, drafts on the floor or ceiling - all this will negatively affect the gas consumption in your heating boiler, will inevitably lead to increased costs and will hit your wallet.

Calculation of gas consumption for heating for a certain period

The easiest way to understand the amount of gas consumed over a certain period is to use a simple example. Let’s say we have a task to build gas heating for a house with a heated area of one hundred square meters. Approximately for each square meter the heated room should consume about one hundred watts of thermal power of the heating device. Thus, our planned house will require about 10 kilowatts (10,000 watts) of heating power. With constant operation of heating equipment, for a full month of operation you will use 7200 kilowatts. But actually, heating equipment(unless your home is located in the far north) will not work more than half of a full day. Consequently, about 3,600 kilowatts will be spent on heating our house per month. Depending on the climatic conditions prevailing in your area, you can calculate the required amount of thermal energy that will be spent on heating your home during the cold period.

In a good gas boiler, about 0.1 cubic meters of gas will be consumed to generate one kilowatt of thermal energy. Based on these figures and the cost of a cubic meter of gas in your region, you can easily calculate the required amount of gas to heat your home.

Naturally, these calculations will be quite approximate and can change both up and down depending on many conditions.

We determine whether there is excessive gas consumption in our heating system

Let's determine the main signs that will indicate that there will be excessive gas consumption in our heating system. The presence of these signs should force the prudent owner to take measures to improve the efficiency of the heating gas boiler:

- In the room where the heater is located, overheating of the surrounding air is detected. Also, a similar sign may be overheating of the outer surface of the heating device. However, the combustion products that leave the boiler are not overheated. In order to increase the efficiency of the boiler in this case, it is necessary to install an air duct that will move heated air to the heated rooms. Please note that heated air tends to move upward. Thus, it will be better if the heated room is located above the installation site of the gas boiler. In other cases, you will have to arrange forced circulation of heated air. Please note that heated air must be taken from the upper part of the boiler room and distributed to the lower part of the heated room.

- Also a negative sign may be overheating of the combustion products of the heating boiler. In this case, it is necessary to adjust the settings of the heating device or completely replace it.

We achieve economical gas consumption

In order to use incoming energy resources more economically, you should take the following measures:

- Purchase a heating device with increased efficiency,

- Modify the heat exchanger of the heating system. The built-in circulation pump. In order to ensure uninterrupted operation pump - place a water filter in front of it,

- It is imperative that the heat exchange unit with forced circulation air must be installed in systems with universal power supply, capable of operating from any type of fuel.

- When installing radiators, make sure that there is a heat-reflecting surface behind it on the wall. Bare concrete will reduce the efficiency of a running radiator by approximately 30 percent. Good decision there will be installation of fans at the bottom of the radiators that move warm air deep into the room.

- Installation automatic systems adjustments to heating devices significantly increases their efficiency. But such automation usually requires a constant connection to a source of electricity.

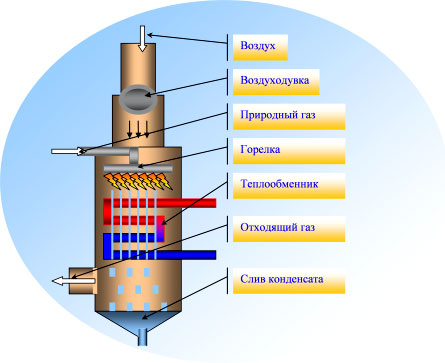

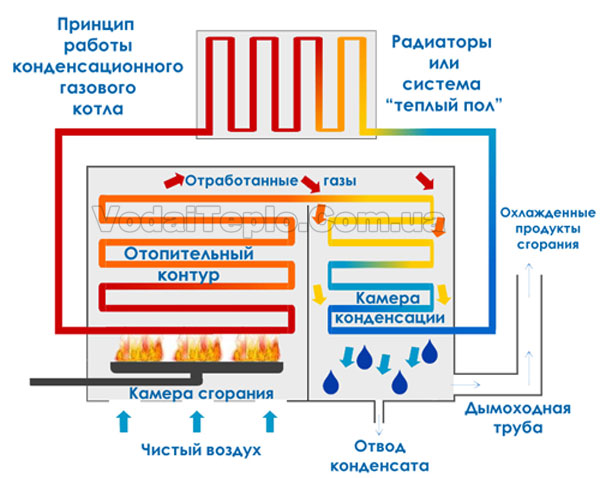

Using economical condensing gas boilers

Modern modernization of gas heating boilers has significantly increased their operating efficiency. The latest innovations in gas heating equipment are condensing boilers. They use the higher calorific value of the energy carrier and consume approximately 17 percent less gas. In some cases, gas savings when using condensing boilers can reach 33 percent.

The “higher heat” of combustion products when using modern gas boilers is achieved by summing the combustion energy of the gas itself and the energy of steam condensation in heat exchange devices.

In a conventional gas boiler, after passing through the heat exchange unit, heated water vapor rushes out, and therefore it thermal energy not fully used.

However, a condensing boiler also uses latent thermal energy, which condensing steam can release. Water vapor turns into a liquid state, releasing some of the thermal energy.

Despite the fact that the effect of releasing energy during steam condensation has been known for quite some time, it was possible to implement it in serial devices only after the industry learned to use materials that are resistant to corrosion. A gas boiler with condensation shows significantly lower gas consumption compared to conventional devices.

How to choose the right gas boiler, gas boiler gas consumption: training video

Any private home needs high-quality heating due to some peculiarities of the climate of our country. Usually in many villages this is done using a good old stove, which also acts as a stove and oven. Moreover, in the role of the latter it is even better than its electric counterpart. But some prefer to use it for good natural resource. And here the question of how much gas is needed and how to calculate gas consumption may arise. This is what our article will be devoted to.

The calculation of gas consumption is influenced by many factors, which we will consider below. In addition, let’s try, without involving specialists, to at least determine average fuel consumption. At the same time, let's look at some of the advantages of gas heating.

Advantages of gas heating

Natural gas today is an excellent fuel in terms of efficiency and convenience. And since it is an inexpensive source of energy, gas heating can compete with electric heating in terms of efficiency. In addition, the efficiency of some modern equipment already exceeds 100%. This means that gas boilers are more in demand on the market.

Some time ago, gas boilers and convectors were not cheap, but the situation has changed, and now such equipment has become affordable. Gas is easily transported, and if you follow certain rules, then it can be considered a safe fuel. In the room where the modern gas boiler is located, there are no unpleasant odors, and gas consumption is carried out in an efficient manner. You can also observe the absence of dust and debris, which eliminates the need for ash sampling.

But the most important thing lies in the operation of the equipment - some models are almost completely automated, which allows minimizing maintenance. Controls adjust temperature regime, ensuring uniform heating throughout the entire heating period. And since safety comes first, enough attention is paid to this point in the production of gas heating equipment. All that is required from the consumer is to make the necessary settings.

Why gas?

Why not?! This natural fuel is highly efficient in terms of combustion due to the low sulfur content in its composition. Thanks to this, the boiler becomes less dirty. In addition, the walls of the unit are not subject to corrosion, which helps to increase the service life of the equipment. And gas consumption during combustion is accompanied by the release into the atmosphere of a negligible amount harmful substances.

It has gained great popularity due to its improved properties. It can be delivered in cylinders to any place where there is no central gas main, which greatly simplifies living conditions for a large number of consumers.

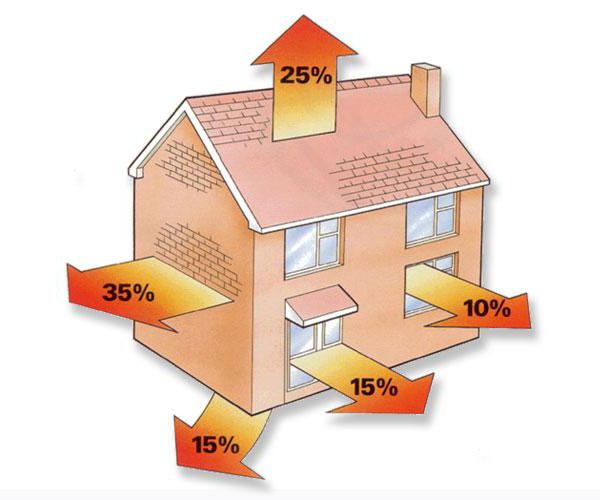

Heat loss

Before you start calculating natural gas consumption, you need to know about the so-called heat losses - those areas of the house from where heat escapes to the outside. Typically, future owners deal with this issue at the design stage. But, unfortunately, as practice shows, this point is not always given due attention. After all, if the house is lost most heat, then increased costs will cast doubt on the efficiency of gas heating. The money will simply go down the drain.

We list the most vulnerable areas through which heat loss occurs in the house:

- walls;

- joints;

- window;

- doors;

- roof;

- dimensions of the building.

Poorly insulated walls are also the reason why gas consumption increases, since warm air will escape through them. And not just in large quantities, but rather in huge quantities. And the fact is that the walls have the largest area. Therefore, insulation plays a big role. Depending on what the house is built from, the necessary thermal insulation materials With required thickness. WITH wooden buildings(logs, laminated veneer lumber) the situation is much simpler, since in this case you can do without additional thermal insulation.

If the wall joints are poorly made, then a lot of heat can also escape through them. And if the shape of the house is complex, this point should not be overlooked.

The degree of heat loss through windows depends on their size and quantity. The more there are in number and size, the correspondingly more heat will go outside. The quality of the windows themselves also matters. Gained great popularity plastic products with multi-chamber double-glazed windows (2, 3, 5 or more). When choosing windows for your home, you should be careful, as you can find many fakes on the market, the quality of which is much worse. In addition, installation is important metal-plastic windows- with poor installation, increased gas consumption by the boiler is inevitable.

As everyone knows from school, warm air is light and rises. That's why good thermal insulation It is needed not only for the walls, but also for the roof. This process is not easy, especially if the house project is quite complex, but necessary.

As for the floor, this does not imply heat loss, but rather the discomfort of a cold surface that is not insulated from the low temperature of the ground.

The size of the house is also a factor in heat loss. A tall building requires more powerful equipment, so as to provide such a house required quantity heat is not easy.

What should you consider?

Calculating how much gas is consumed is not such a difficult process. It is not necessary to involve specialists in this field, but you need to take into account some parameters that will act as initial data:

- Equipment operating intensity. If the house is poorly insulated, and a large number of heat goes outside, then the equipment will work at full capacity most of the time.

- Heating season. This refers specifically to the time factor. Those owners who come only for the summer or on weekends do not need to worry about how the gas boiler works. Gas consumption in this case will be minimal. But those owners who live in houses on a permanent basis will face large expenses.

- Building area. Everything is clear here.

- View Some modern boiler models are capable of operating in automatic mode and are able to control the temperature and degree of heating. If necessary, they can stop working for a while, in which case the savings are obvious.

You should also consider the following. Based on generally accepted standards, 1 kW/h of heat is required to warm a room of 10 m2 to a comfortable temperature.

Calculation

As an example for calculation, let’s take a house whose area is 100 m2, and for convenience, let’s denote the amount of heat in kW with the letter Q. Using the above-mentioned remark, we calculate that our house requires 10 kW/h of heat. That is, we divide the area of the house by 10 and get the result (in this example, the number is also 10). It is not difficult to calculate (average) how much of this energy is required for one month: Q m =10 x 24 x 30 = 7200 kW.

Usually it lasts 7 months, but the boiler does not always operate at full capacity 24 hours a day. Basically, the peak power occurs only in winter. In addition, it all depends on the area of residence. Therefore, we can safely divide the obtained result in half: Q av = 7200/2 = 3600 kW.

It remains to make further calculations of gas consumption for the entire heating season: Q os =3600 x 7=25200 kW. As a rule, in gas boilers, 1 m 3 of fuel is equivalent to 10 kW/h. Using this, we calculate the volume of gas that will be needed throughout the entire heating period V=Q/10=2520 m 3 .

In a similar way, you can carry out calculations for a house of any other size. And having learned these averages, you can estimate the financial costs.

One caveat

The calculation given is an average. In practice, the calculated result may appear higher or lower. This is explained by the presence of a number various factors, and the deviation of the actual flow rate from the calculated one is not uncommon. In addition, it is not so easy to comply with the numbers obtained on paper. And saving significantly is even more difficult. However, some tips may come in handy.

Economical ways to optimize consumption

These tips will help to some extent optimize gas costs for heating. First of all, you should purchase only reliable and high-quality equipment. Accordingly, it is not worth saving on this. As for power, you should choose a boiler according to your personal needs. You shouldn’t think that a large supply will be beneficial, rather the opposite. Equipment with high power, operating in medium mode, will nevertheless consume a lot of fuel.

The same applies to a low-power boiler, which will constantly work hard. Both options are not suitable, and the best option would be to choose equipment with a small performance margin (about 25-30%). Then you don’t have to worry about what gas consumption the boiler will have.

If good thermal insulation was not provided during the design of the house, it is not too late to do it later. As discussed above, a lot of heat can escape through the walls and roof.

Although purchasing automatic equipment will cost more, it will result in savings. It would also not hurt to think about installing gas sensors, with the help of which timely fuel leaks will be detected.

Autonomy as a rational solution

With the help of autonomous equipment, gas savings can be achieved, and the more technologically advanced and sensitive it is, the more significant the result will be. This is achieved thanks to numerous sensors and controllers. Receiving all the necessary information from them, the equipment adjusts the heating level optimally. Modern models have a remote control remote control or its analogue can be a smartphone or personal computer/laptop. It is convenient to use them to determine how high the gas consumption is or whether it is within the acceptable limits.

If your heating equipment is equipped with a timer, you can use gas even more economically. With its help, you can reduce the boiler operating mode to a minimum at night or at a time when everyone is usually at work and no one is at home. Comfort will not be affected. It is estimated that lowering the temperature by 1 degree saves up to 3-5% of natural fuel.

Bottom line

It takes time to create a good heating system. However, not everyone has it, and therefore good solution The solution to the situation will be to contact specialists in the relevant field. The given independent calculation will be average, but if accuracy is important, then professionals will determine a more accurate rate of gas consumption. And based on them, it will become clear how advisable it is to use gas heating.

Gas is considered one of the more economical fuels due to the high efficiency achieved during the combustion process.

In addition, this is the most environmentally friendly fuel, that is, when burned, it emits a minimal amount of harmful substances into the atmosphere. It is for these reasons that the use of gas heating is very popular.

When purchasing any equipment, you should be guided by the efficiency of its operation. Gas boilers for autonomous heating. When choosing a heating unit, perhaps the first question that interests consumers is how much gas does the heating equipment consume? First of all, gas consumption depends on the power of the boiler, the more powerful gas equipment, the more gas it consumes. But there are also additional factors, on which the consumption of “blue” fuel depends:

- area of the heated room;

- number of floors;

- insulation of the room;

- drafts from windows and doors.

When calculating the heating system, all these factors are taken into account, which directly affect fuel consumption. How to find out how much gas is consumed gas boiler and what is its power consumption?

Calculation of gas boiler consumption

![]()

Correctly calculating gas consumption for autonomous heating is not difficult; it does not require special skills, you just need to know the basic parameters. To do this, we need to know the power of the unit and the area of the heated room. The heating season per year can be up to 250 days. But as a rule, during this period we do not always turn on the gas boiler at full power. After all, winters can be both very cold and relatively warm, therefore, even with maximum load on the heating system, the boiler operates at full capacity for less than 100 days. If we assume that the boiler operates all day long for 30 days and multiplying these data, we get kilowatt-hours. However, as we said earlier, the boiler is not operated in this mode, so this figure can be safely divided by 2, and thus we get the average consumption per month. We multiply it by the number of months of the heating season (usually 7) and get gas consumption for the year. As for the boiler power, it is taken from the calculation of 1 kW per 10 m².

Let's look at how this works using a separate example. If the area of your premises is 100 m², then you need to choose a boiler with a capacity of at least 10 kW. To calculate gas consumption, we multiply the boiler power by 24 hours and by 30 days, it comes out to 7200, divide in half and get the monthly thermal energy consumption, which is equal to 3600 kW/hour. To calculate for the entire heating season, we multiply this figure by 7 (the number of heating months) and get the annual boiler power consumption or annual consumption in the amount of 25,200 kW/hour.

This figure won’t mean anything to most people, so consumption can be converted into a monetary equivalent. To do this, you need to know the exact cost of gas per 1 kW/hour. For example, it is 15 kopecks. We take our calculated data of 25200 kW/hour and multiply it by 0.15. Thus, we get annual heating costs in the monetary equivalent of 3780, that is, the price for heating a room with an area of 100 m².

To make the picture clearer, you can calculate the gas consumption for heating in m3. To generate thermal power of 1 kW, on average, the boiler consumes 0.112 m3. We have already found out that the boiler power consumption per 100 m² should be 10 kW, multiply it by 0.112 and get gas consumption per hour of 1.12 m 3. The data obtained can be multiplied by 24 to obtain gas consumption per day. The formula looks like this:

- 1.12*24=26.88 (consumption per day);

- 26.88*30=806.4 (monthly expense);

- 806.4*7=5644.8 (consumption for the heating season).

Now all that remains is to multiply the resulting figure by the tariff. It seems to you that this is not so much, but ever-growing tariffs force us to look for all sorts of ways to save money, and why pay more if it is possible to reduce the consumption of “blue” fuel. And when it comes to country house with an area of 800 m²? Let's try to figure out how to reduce the amount of natural gas consumption for heating.

Basic ways to save gas consumption by a heating boiler

There are 3 main ways to avoid high consumption of “blue” fuel by the boiler:

- Heat loss. When heating any room, heat loss occurs, there is no escape from it. In order to achieve minimal heat loss, it is necessary to take into account the characteristics of the room when calculating the heating system. On average, per 1 m² of heated room with standard height ceiling (2.5-3 m) thermal energy should be at least 100 W. Calculating possible heat losses, drafts and cracks are eliminated.

- Timer. Most modern boilers are equipped with a timer, which helps save gas consumption and regulate the room temperature. This way you can set the desired air temperature in the room during the day, at night or on weekends when there is always someone at home. Similar automatic adjustment will significantly reduce natural gas consumption.

- Condensing boilers. This type of boiler, compared to a traditional one, consumes much less “blue” fuel. This is explained by the fact that during the condensation of water vapor, thermal energy is released from the combustion of fuel, which the boiler consumes in full, that is, it additionally uses the temperature of the already exhaust gas. The cost of condensing boilers is higher than conventional ones, but in general they can save up to 20% of gas consumption, which completely pays for the additional costs.

In addition, if you are going to heat a private house, you can also use next view boiler

Gas boilers with reduced gas

Separately, it is worth mentioning the reduced gas. Reduced gas has several advantages. The main ones include: preservation of energy intensity and the absence of impurities. What is reduced gas?

The principle of obtaining reduced gas is the conversion of natural gas into a liquid state. To do this, natural gas is first purified from impurities and then cooled until it condenses. This technology allows you to reduce its volume up to 600 times. Reduced fuel is stored in cylinders that are directly connected to the boiler. This heating system is ideal for private homes, especially large area, and is the only solution for remote areas where it is difficult to install a gas pipeline. Therefore, reduced gas is considered an excellent alternative traditional types fuel.

The table below will allow you to compare the difference in gas consumption and show the boiler power in relation to how much gas is consumed:

Consumption also depends on the type of gas boiler, and they can be turbocharged or atmospheric. Atmospheric gas boilers A traditional chimney is required to remove combustion products. The fuel consumption of such boilers is significantly higher than that of turbocharged boilers, for which a coaxial chimney is used instead of a conventional chimney.

As you can see, choosing a heating unit requires a serious approach, because not only gas consumption, but also the microclimate of your home, as well as water heating, depend on it. Today, the sales market offers a wide range of heating boilers of both domestic and imported brands. They differ from each other not only in price, but also in functionality, so when paying attention first of all to the technical characteristics.

No related posts.

Most popular blog articles of the week