How to make an economical electric boiler with your own hands. Making an electric boiler with your own hands

The heating system of a small country cottage is not an easy task. There are many options, but you have to choose the best one. The most economical and cheapest is a gas boiler with pipework and radiators. But not all country villages hold gas pipe.

There remain other options, where a separate article is highlighted electrical appliance, embedded in the water heating system. Ready-made units are expensive, so some cottage owners try to make an electric boiler with their own hands. In terms of reliability and operational characteristics It will not be inferior to the factory ones, but the price is several times cheaper.

Rice. 1Design features of electrical appliances

A homemade boiler is a container in which a heating element is built. With the help of this tubular electric heating device, the coolant is heated, which is poured into the heating system of the house. The container can be made from metal sheets 4-5 mm thick. Or you can use any metal tank of certain sizes.

The best option– a pipe with a wall thickness of at least 6 mm. You need to pay attention to its size. It is believed that the smaller the volume of the heated coolant, the lower the cost of electricity consumption. Therefore, a pipe with a diameter of 219 mm and a length of 0.5 m is suitable for organizing heating in a house with two or three rooms.

Attention! Assembling a homemade boiler with your own hands is not easy. This requires skills in working with a welding machine that are not at the amateur level. Durability and reliability welding seams– this is a guarantee of the safety of the electrical appliance itself and the heating system as a whole.

Types of electric boilers

There are several types of homemade boilers, which differ in the connection method.

- Electric mini boiler. This is a pipe that cuts into the heating system piping into the supply circuit. Its diameter larger diameter pipes installed in the circuit by 4-5 times. A heating element connected to the network crashes into this pipe with your own hands alternating current. The electric mini-boiler is fastened using flanges and gaskets. This is done in case you do it yourself repair work. Making such an electrical device yourself is not a problem, much less installing it correctly.

- Freestanding homemade electric boiler. This complex design, made of pipe and connected to the heating system. Safety devices must be installed in its device: pressure gauges, thermometers, shut-off valves.

The first option can be used to organize heating in small dacha. The second one will pull and that’s enough big house. Everything will depend on the power of the heating element that will be installed in the electric boiler. It is believed that 5 kW is the power that can provide heat for a cottage with several rooms. Therefore, it is necessary to accurately calculate this indicator for each house separately.

Rice. 2

Rice. 2Electric boiler assembly

To make a cauldron with your own hands, you need to prepare for the process.

For this you will need:

- Pipe with a diameter of 219 mm.

- Metal sheet 4-5 mm thick.

- Pipe with a diameter of 25 mm and 50 mm.

- Fittings for thermometer and pressure gauge.

- Welding machine, grinder, tape measure, pencil (chalk), electrodes.

A section 500 mm long is cut from a pipe with a diameter of 219 mm. Holes are made in it at both ends for a 25 mm pipe. The holes can be located on one side (along the same line) or on two opposite sides. The second option is better, because these holes are the connection points of the pipes for two circuits of the heating system: supply and return. When they are located diagonally, the coolant is heated more efficiently.

IN homemade device another hole is cut from the bottom side. This is the place to install the heating element. It is necessary to weld a pipe with a diameter of 50 mm with internal thread. If it is impossible to cut the thread (thin wall), then you will have to weld an adapter. Five sections of 5-10 cm each are cut out of a 25 mm pipe. Three of them will be used for the legs of the electric boiler, two for the heating system pipes.

From metal sheet you cut out two pancakes with a diameter of 231 mm with your own hands (this is 219 mm plus two pipe wall thicknesses of 6 mm each). One of the pancakes is welded on one edge of the future electric boiler. The second one must be prepared in advance. This will be the top cover of the device, so holes are made in it for the fittings of the thermometer and pressure gauge. After which the lid can be welded to the electric heating boiler.

Rice. 3

Rice. 3Assembly sequence and installation

- First of all, two metal pancakes are welded.

- Legs for an electric boiler.

- Connections for heating circuits and heating elements.

Attention! The return pipe is installed with your own hands above the edge of the homemade boiler by 5-7 cm. On the opposite side is the heating element (can be on the side). The heating supply pipe is located 5-7 cm below the top cover.

The electric heating boiler is made with your own hands; it can be connected to the heating of the house. If the heating piping consists of metal pipes, then the connections of the pipes and circuits are made using gas welding. If the heating pipes are plastic, then adapters from metal to plastic must be installed on the pipes. It's easy to do it yourself.

The final stage is to install the heating element yourself. It simply screws into the thread, pressing tightly against the edges of the adapter. The tightness of the joint is ensured by a gasket made of heat-resistant rubber or plastic. Install a thermometer and pressure gauge yourself.

Now you need to connect the heating element to the power supply. It is recommended to do this through a separate machine installed in the distribution panel. You will first have to take care of running the power cable from the switchboard to the homemade heating boiler. Doing it yourself is also easy. The installation is tested to detect malfunctions and incorrect operation: the heating is filled with water and the heating element is turned on.

If all the assembly parts were assembled correctly, welding was carried out reliably, and the heating element was accurately selected, then the homemade electric heating boiler should work correctly.

1.

2.

3.

Insulation and heat supply are the main problems that concern property owners every year with the arrival of autumn cold. The issue of heating and creating comfortable conditions accommodation for owners of private households.

If the family has limited financial resources, self-installation An electric boiler with heating radiators will provide your own home with heat.

To make an electric heating boiler with your own hands, you must have certain knowledge and skills, as well as a responsible approach to working with it. Otherwise, the cost of an error may be too high - as a result of a breakdown homemade device 220 volt power may cause a fire.

Making a homemade electric heating boiler

The design and subsequent assembly of a boiler requires a clear understanding of how it works, how it works and why each part is needed. First of all, you will need a drawing. Next, to make an electric heating boiler with your own hands, you should know that it is a regular heater.You also need to purchase all the materials, including:

- one steel pipe having a diameter of 10 - 12 centimeters;

- two pieces of pipe with a diameter of 4-5 and a length of 5-15 centimeters;

- stainless steel sheet with a thickness of at least 2 millimeters;

- one heating element (tubular electric heater) with three electrophases and a recommended power of 9 kilowatts (read also: " ").

First of all, a heating element is purchased, since this is a fundamental part when assembling a homemade electric boiler for heating. Depending on the size of this tubular, other elements are purchased. For example, the heating element must match the diameter of the steel tube so that it can fit in it.

Steel pipe cut depending on performance heating device, and then pre-prepared stainless steel sheets are welded to its ends, and bends with a diameter of 4-5 centimeters are attached to the sides, top and bottom so that the electric boiler can be inserted into the heating system. To one of the end holes in the big pipe screw on the nut, with which the heating element is then secured (read also: " ").

Advantages and disadvantages of homemade electric boilers

The advantages of electric boilers made independently include:- low cost;

- ease of creation and operation;

- the ability to select the necessary individual operating parameters depending on the premises that need to be heated.

- low energy efficiency;

- significant fire hazard;

- To assemble a high-quality boiler, the skills of an electrician and turner are required.

Ensuring safe operation of an electric boiler

In order to ensure safety during operation of an electric boiler, such as the photo, a number of important points must be observed:- grounding – a bolt should be welded to the body of the future device and grounding should be connected to it;

- it is necessary to make a casing to protect it from external factors and impacts from which occupants may suffer;

- you need to carefully consider the place where it is best to locate the equipment, since there should be no flammable or combustible objects and materials near it. Children should not have access to a homemade heating boiler. Contact of a child with a very hot surface, which is also under high voltage, will certainly lead to tragic consequences.

- if it is decided to connect the boiler to a water structure, then the location of the electric heating element does not have special significance;

- when a heating element is needed to heat the air, it is advisable to place it from top to bottom to ensure uniform heating.

For creating effective system heating requires a modern heating boiler. This can be a device that runs on electricity, solid fuel, or gas. Today there is also a large number of combined models. However, having a sufficient level of knowledge, necessary materials and a diagram, you can easily create a homemade electric boiler for heating.

In essence, the boiler is a metal reservoir in which a thermal electric heating element (TEH) is located. The most common are models with a power of 6 kW - this is quite enough to heat a small, well-insulated house or apartment. However, it is most rational to use such a boiler as an auxiliary one in the presence of a main boiler operating on solid or liquid fuel. If the system does not provide for a boiler of a different type, you can use two or more electric boilers - this will increase the heated area.

A modern home-made electric heating boiler, even one created with your own hands, can perfectly maintain the set temperature level in the room automatically.

To do this, you need to equip it with several sensors and a simple automatic unit. Using automation - great way reduce energy costs, since the boiler will be able to maintain the temperature in the room at a programmatic level - thus, the coolant will not be heated excessively.

Air heating control in manual and automatic modes

Manual operating mode. Toggle switch T must be turned off. Next, click Start. The system checks the room temperature. If it is below the adjustable value (closed TP contacts), the magnetic switch is automatically triggered. It blocks (temporarily) the Start button and starts the heating element. The coolant gradually heats up, resulting in an increase in the temperature in the room. As soon as the sensor shows that the temperature is within the established limits, the contacts of the TP and the magnetic switch of the heating element are opened. The heating element is switched off and the Start button is unlocked.

Auto mode.Toggle switch T should be turned on. This will allow you to maintain indoors constant temperature, limited by the activation zone of the TP contacts. If the air temperature drops below specified limit, – the boiler switches on automatically. Thus, the coolant heats up, which increases the temperature in the room. Upon reaching set temperature the circuit breaks, the electric heating boiler with its own hands becomes inactive. If necessary, the activation is repeated.

Features of connecting homemade electric boilers

Even if the electric boiler for heating with your own hands is auxiliary, it must still be located next to the main boiler. In this case, the combination of boilers is carried out using bends.

The electrical control board must be installed on a special panel insulated from the coolant. At the same time, by creating the boiler yourself, you also determine the components selected for the board yourself.

To comply with all installation rules, which, in turn, ensures the continued safety of the equipment in use, it is advisable to invite an electrician.

It is especially important to do this, given that even individual “kulibins” cannot always properly ground an electrical appliance. In addition, it is important to regularly check the security of the system - invite a specialist who can carry out necessary measurements and issue an appropriate report on the condition of the operating heating element.

It should be taken into account that individual sensors, in particular the room air temperature sensor (TR-OMb-OZ), must be installed in a heated room. If there are several such rooms, then the sensor is installed in the one that, in your opinion, has an average level of heating. It should be noted that the proposed heating boiler circuit is designed specifically for the sensor of this type– and if you replace it, some of the elements of the electronic control system must also be replaced.

Homemade electric boilers heating of this type will easily serve you for more than 10 years. However, it is important to understand that in order to achieve such a service life, it is necessary to follow certain installation rules, and, of course, operating rules. Here are the most important ones.

2017-07-11 Sergey Dyachenko

Making an electric heating boiler

Inductive

Let's figure out how to make an electric boiler correctly and, based on this, choose suitable principle work and compose for ourselves step by step instructions assemblies. Today you can find schemes for the production of a boiler of almost any complexity.

To make a simple inductive machine, we need to purchase a welding device. Its power is selected depending on the load on the future boiler. We will also need steel wire, a plastic pipe and a set of tools.

The body will be a half-meter piece plastic pipe. To make heating elements, use wire cutters to cut the steel wire into pieces 5 cm long. We put a mesh on one side of the tube and pour the cut wire inside. On the other hand, it also covers the tube with a mesh so that the wire does not spill out. Nozzles are cut into both sides for subsequent connection to heating system.

We carefully wind the wire onto the pipe so that we get at least 90 turns. Its ends are connected to welding machine. The coils are insulated at the top. Such a device paired with a radiator is quite enough to heat one room or a garage.

To make a more powerful induction boiler yourself from a welder, you need to take as a basis metal pipe, insulate its surface and wind turns of wire on top. The heating element here will be a rod or tube of smaller diameter. Such a device can only be connected to the network if there is water inside, as it heats up very quickly.

heating elementnew

By the way! Did you know that a heating boiler from any manufacturer can explode at any minute - "".

Let's consider the main advantages of an electric boiler for a summer residence:

Operating principle and main components

You can find out the whole truth about the conspiracy associated with the selection, operation and maintenance of heating boilers of all manufacturers and models.

Any water heating electric boiler works on the same principle. In fact, its main task is to convert electricity into heat and transfer it to water.

In all considered stand-alone devices the same elements are present:

Also, a well-thought-out heating system is necessary for operation. Before assembly begins, detailed drawings with dimensions are made. The system includes the following elements: circulation pump, expansion tank, thermostat, pressure gauge and safety group.

If you want a dual-circuit system, the easiest way is to buy it separately or make your own boiler indirect heating. This way you can provide FGP and heating with one device.

Since all designs are based on high voltage, it is important to observe safety precautions during assembly and testing. All wires are well insulated. The outlet to which the device will be connected must be equipped with grounding.

If you want to receive full information on this problem, as well as find out other important nuances about the heating boiler from your manufacturer.

But we also have information on this problem and more, which you will not find anywhere, first of all, because it is asked by specific people who could not get more support and advice anywhere (which they themselves tell us). And secondly, their problems are so complex that sometimes our expert Alexander Kholodov takes 10 days or more to deal with people.

And now EVERY question from the user and the answer to it, in order to avoid financial costs as a result of improper operation or repair of the boiler. And here it doesn’t matter which manufacturer’s device is involved in the issue. The only thing that matters is the unique situation as a result of which this issue arose, because as one good saying goes: “forewarned is forearmed.”

In order for the heating system to work as efficiently as possible, it is necessary to use a modern heating boiler. There are many types of these units operating at the most various types fuel - gas, solid fuel, electricity - everything that can give is used thermal energy. The modern consumer on the market has a wide selection of boiler models, but if you have a diagram, materials, and sufficient knowledge, anyone can make an electric boiler with their own hands.

What is an electric boiler?

By and large, an electric boiler is an ordinary metal tank equipped with a heating element (thermal electric heating element). In our country, the most popular models are electric boilers with a power of 6 kW. Usually for heating small apartment or at home this power is enough “for the eyes”.

It is most rational to use a home-made electric boiler as an auxiliary device if the house has an installed main unit that runs on another type of fuel - liquid or solid. If your home does not have this type of equipment, then you can use several heating boilers. It’s easy to master this simple science on your own, although not as quickly as you would like.

A do-it-yourself electric boiler, made competently and according to all the rules, is modern device, which does an excellent job of automatically maintaining a given temperature in the room.

Mandatory structural elements

In order for the device to fully cope with the responsibilities assigned to it, you need automation for the electric boiler and several sensors. It is very important to use an automatic unit - with a correctly set program heating level, the heating boiler will not heat the liquid in the system too much, while at the same time maintaining the required temperature regime. This is a great opportunity to save money.

You should only make an electric boiler yourself if you are completely confident in your knowledge and skills. If this is not the case, then you shouldn’t take it. Mistakes made mean not only a non-working device, but also a high risk of a fire in the house from burnt wiring.

Another extremely important point, which applies to all devices, no matter whether you use a store-bought or home-made electric boiler for heating - it should be grounded. You definitely need to remember this, otherwise at some point (most often unexpected) you may be hit with an electric shock of such power that it will not seem like much at all.

How to do grounding correctly

Ideally, when the diversion is done during the construction stage of the house, but if this is not possible, the following method will do.

3 steel rods with a diameter of 3-4 mm are driven into the ground to a shallow depth (at the bayonet of a shovel), and at a distance of 200-220 cm from each other. You will get a triangular outline. Next, dig a small ditch, where you lay steel wire Ø8-10 mm and use it to connect the rods for welding. You bury the groove, and bring the ends of the wire to the outlet and also weld it.

Some homeowners use grounding on metal fences, well pipes, etc. This is not the most good idea, since the electric shock, if it does not kill, will be very noticeable.

Types of electric heating unit

A homemade electric heating boiler can be created in two variations to choose from. It can be electrode or heating element. Is there some more induction boilers which heat water using magnetic field, but making such a device yourself is an unrealistic task.

Homemade heating element boiler

In order to make a heating element type device, you first need to find a suitable tank, the shape of which does not play a special role. Heating of water in such a boiler is carried out by installed heating elements, which will need to be purchased at the store in the quantity required for your specific scheme. Usually for a standard electric boiler designed to heat not very much large area, two or three heating elements are enough. The purchased heating elements immediately have a threaded head, so it will be convenient to screw them in.

Let's look at how to make an electric boiler. What will you need for this:

- Conventional ball valve.

- Nuts and heating elements.

- Several pipes. Three will be enough. Please note - their diameter should not be smaller than the diameter heating pipes in system.

- A pair of plates with a diameter of 15 centimeters.

- Steel pipe with a diameter of 15 centimeters.

To make a homemade electric boiler, it is important to choose its dimensions correctly. The future boiler body should be significantly longer than the TNnov. It is necessary to weld plugs onto the ends of the future boiler. It is necessary to solder two pipes on the side - for supply and return.

Now another decision - how to position the heating elements. And so it is clear that the location of the heaters will be vertical, the question is different - to install them from below or from above.

The difference is this: if you install heating elements at the bottom in an electric boiler for heating with your own hands, then if they burn out, in order to replace them, you will first have to drain the liquid from the boiler and then fill it back, which takes time. On the other hand, this arrangement ensures maximum contact between the coolant and heating elements, and also reduces the risk of burnout of the spiral, which is not completely lowered into the water.

If you do the opposite, replacing heating elements will be easier; you won’t have to add water to the system. But on the other hand, air will often accumulate in the upper part of the unit. But this problem can be solved quite simply - by installing an automatic gas vent.

Both the first and second options have their advantages, and the choice is yours. Next, everything is simple - we screw nuts of the appropriate diameter onto the threads of the heating elements and weld them. A pipe is installed in the aggregator located below for convenient drainage of liquid. Afterwards, threads should be cut on all pipes for convenient connection to the heating system.

That's all - the device can be installed on heating circuit and connect to the network.

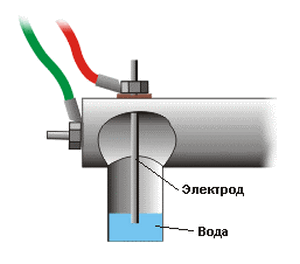

An electrode-type boiler heats the coolant a little differently. It has two electrodes, one of which is negatively charged and the other positively, and the movement of ions between them heats the liquid.

Blueprints electrode boiler doing it yourself is not that difficult, and the device itself will cost you little. Even if you buy all the parts, it will still be inexpensive.

So what you will need:

- Rubber for seals, several bolts and nuts.

- Dielectric of your choice. This is a material that does not conduct electricity. You can take textolite.

- Flange. Flat is best.

- Several couplings with threads from the inside.

- A metal rod, 2 centimeters thick.

- Pipe. It is best to take a diameter of 5 cm.

Using welding, we install the coupling in one of the ends, and place the second one on the side, closer to the end located on the other side, onto which the flange must be welded. Next, we take a metal rod, drill it and cut the thread inside. This hole is necessary for the bolt with which we will attach the electrode to the dielectric. Be sure to insulate the electrode from contact with the body, otherwise it will short out.

To make the homemade electric boiler neat, we cut out a circle from the dielectric to the size of the flange. We drill the necessary holes in the circle in the middle and for fastening. Before assembling the unit, screw the rod. To make the joint more reliable, you can put a rubber gasket between the flange and the dielectric, and then tighten all the bolts. That's it, the device is ready for use.

Naturally, here is a “minimum program”, and you can add to the device a control unit with a temperature sensor and other devices that simplify control. But you must admit, everything turned out to be not as difficult as it might seem at first glance, and you were able to get a high-quality and inexpensive heating device.

How to assemble an electric boiler with your own hands: