DIY smokehouse: theory, various designs (cold and hot), drawings, principles of smoking. DIY cold smoked smokehouse

If you sometimes like to taste smoked meats, you can visit the store to purchase similar dishes there. However, you can cook them yourself, using a smokehouse. Before you start building this structure, you need to understand the types of smoking, of which there can be two, namely hot and cold.

The first variety is quite quick way, which is most often used at home. The smoking period can last from 12 to 48 hours, while the smoke temperature ranges from 35 to 50 degrees. In this case, the products do not lose moisture and are well saturated with fat. Such products can be stored for quite a short time. Sometimes you don’t have to choose the size of the smokehouse, since these designs, as a rule, are based on cylinders or refrigerators that have failed. However, if you want to make such equipment for commercial purposes, then you can use metal sheets or a barrel, the volume of which can be quite impressive.

Represents a longer processing time. The products do not heat up much, since the smoke has a temperature of 18 to 25 degrees. The smoking period can last from 2 to 3 days. This type of processing involves removing moisture from products whose surfaces are drying out. Such products can be stored for quite a long time, especially when compared with hot smoking. In support of the above, it can be argued that the cold process is more labor-intensive and time-consuming compared to hot smoking. Let's get to know him in more detail.

What is a cold process smoker?

In the process of making a cold smoked smokehouse, you will need to create a device in which cold smoke will be directed away from the product. The smoke should be continuous and even throughout the entire treatment period. Its temperature is no more than 25 degrees. In order to ensure such conditions, the smokehouse must be divided into two separate parts. One of them will be the firebox, while the other will be the container. The first part should be 2 meters away from the other, and a chimney should be located between them.

Operating principle and design of a smokehouse for cold processing

If you are interested in the design of a cold smoked smokehouse, you should know that it consists of several elements, including a chimney, a smoke generator and a smoking chamber. The design works according to the following principle. The chips are placed in the smoke generator, the fuel begins to smolder and produces smoke. In the process, a draft arises, thanks to which it enters the chimney, cools in it, penetrating into the smoking chamber, where the products that are intended for processing are located. The main function in this type of processing is performed by a smoke generator, which ensures a continuous flow of smoke inside. This element is automated; the owner will only need to monitor the volume of sawdust.

Fuel preparation

Cold smoked smokers must operate on a specific type of sawdust. Under no circumstances should you use shavings of coniferous wood, namely pine, spruce, etc. This rule is due to the fact that this fuel contains resin. As best solution sawdust appears for smoking fruit trees. The best option there will be cherry, apple and pear trees. If sawdust of this type is not available, you can replace it with shavings of alder, willow or oak. In order for the smoked meat to look very attractive after completion of the process, at the last stage of processing you need to put a juniper branch in the smokehouse. To process products using the cold smoking method, you can use cassettes and briquettes, which are sold in stores.

Do-it-yourself smokehouse manufacturing technology

If you decide to start making a cold smoked smokehouse, then you do not need to have certain skills. Before starting work, you should prepare a certain set of tools and some materials. Sheets of iron should be placed at the bottom of the firebox, thanks to which the coals will smolder evenly. Now the master digs a chimney, the depth of which should be equal to the bayonet of the shovel, while the width should be equivalent to the width of the shovel. After this, you need to use slate or a sheet of iron to close the chimney, covering it with earth. This is done to prevent smoke from escaping.

Before starting work, you need to familiarize yourself with what types of smokehouse designs there are. This knowledge can help you in the process of manipulation. Next, you need to prepare an ordinary barrel, in the lower part of which the grate is strengthened. This is necessary to install a filter that will protect products from soot and resin. Burlap can act as a filter. Fixed at the top steel pipe, products for smoking will be attached to it. Stainless steel is a very good material for such a pipe. When choosing a hook, you need to be guided by the dimensions, which should not be less than 10 millimeters. The top of the smokehouse should be covered with a sheet of iron.

Making from a box

If you are making a home cold smoked smokehouse, you can use a barrel or box. Once this element can be found, a smoke generator should be attached to it. At this point, we can assume that the product is ready, it will be quite convenient to use, and, if necessary, it can be moved to another place. When using a smokehouse, the smoke must flow evenly, so you need to take special care to make the chimney correctly.

Work methodology

It is imperative to choose the most suitable place for the smokehouse; there should be no flammable objects nearby. The master should take into account the distance from neighbors who may not like the smoke. In the process of arranging the chimney, you need to use cords and pegs. Initially, it will be necessary to carry out markings along which the trench is dug. You need to install bricks along the walls of the latter, placing them on the edge. During the work, you should use a solution that is prepared from sand and clay.

When cold smoking a home smokehouse, it may be necessary to cool the smoke. This issue can be resolved in one of several ways; one of them is extending the hose through which smoke is supplied into the structure. The length of this element should be such that the smoke gradually cools as it passes through it. Some experts advise using running water. To do this, you will need to assemble the simplest water-based cooler, which is made from copper and brass tubes. If firewood is used in the smoking process, a bend in the pipe can be used to cool the smoke.

If you purchased an industrial smokehouse or designed it yourself, you should always ensure that the temperature inside is within the limits permissible norm. It's best to start this process since morning. IN bad weather smoking should be avoided. You should not look into the chamber often, and you must install a tray inside the device to collect fat.

Making a smokehouse from a gas cylinder

A smokehouse at home can be made using a gas cylinder. To carry out the work you will need Sander, drill, welding machine, two door canopies, a metal rod with a diameter of 10 millimeters, as well as pipes that will form the basis of the legs. Among other things, prepare metal corner, forged handle in the amount of 1 piece, electrodes for welding, open-end wrenches, electric drill and, of course, an old gas cylinder. If you are making a smokehouse from a gas cylinder, then it is important to think about whether the size of the future structure is suitable. To carry out this work, you can prepare the product required dimensions, taking care of this in advance.

At the first stage, the technician must inspect the cylinder from all sides; if it is rusty, then it will not be possible to use it for work. If there is a certain amount of gas inside, this indicates that the product is in working condition and is suitable for making a smokehouse. A smokehouse at home from a gas cylinder can only be made after careful preparation of the product.

To do this, you need to get rid of the remaining gas by turning the product over and unscrewing the valve. This will prevent a possible gas fire. Even after this procedure, propane residues will remain in the form of condensate. It is worth considering the fact that they are also dangerous. It will be quite difficult to get rid of the oily liquid that has settled on the walls. Water is most often used for this.

After you can get rid of the remaining gas, you will need to draw a line on the body with chalk along which the cut will be made. The cylinder must be divided into two parts, which are then connected by hinges. On next stage you will need to install the handles, weld the legs and install the grille inside. At this point we can assume that the design is ready. Using this principle, a smokehouse can be assembled from a gas cylinder, which, if necessary, can be easily moved from one place to another.

If you decide to make stationary equipment, then you need to start work by retreating a certain distance from the edge. Then a line is drawn three centimeters below the weld. This will result in two circles. Straight lines should divide the balloon in the middle. After this, the container is filled with water, which does not need to be drained when making the first cut. The water that flows out will be able to extinguish the sparks, preventing a fire from starting. Once you have made the holes, you can drain the water and continue cutting. After one semicircle has been obtained, the same work can be done on the other side. The semicircles should connect to each other. This will allow you to get the finished lid in a closed form, which will help provide cover for the flame from the wind.

Final works

If you will be cold smoking at home, you can make a structure for this using any of the technologies described above. After completing the above manipulations, you need to check the stability of the product. If it has long legs, then it will be quite difficult to achieve reliability. Therefore, you need to install additional corners that will be located at the bottom of the legs. After completing the legs, you can drill several holes in the wall. The coals will wake up through them, air will penetrate inside, which will contribute to better combustion. Once the basic steps have been completed, you can begin painting the structure. However, quite often home craftsmen exclude this stage.

Features of making a smokehouse from an old refrigerator

At home, you can make a smokehouse from the refrigerator. To do this, you need to remove all the elements that are located inside household appliance, leaving only a steel box with a door. After the inner chamber with thermal insulation is removed, the old seams will need to be removed with a special sealant, which can take quite a lot of time. On the rear side, where the heat exchanger is located, sufficient big hole. You can close it with a metal plate, which should be cut from the previously removed parts. If you have a potbelly stove, which is usually made from pieces water pipe, then it can be used by installing it inside. It is important to ensure that the pipe exits, which may cause some difficulties for the technician.

When making a smokehouse from a refrigerator, you will need to draw a circle with a compass, the diameter of which is slightly smaller than the diameter of the pipe. Then you should drill holes around the perimeter of the circle using a five-point drill. Bring to the right size This element can be used with a semicircular file. Stepping back 20 centimeters from the top of the box, you should install two corners that will act as holders for the mesh. On this shelf there will be products for smoking. Having retreated 10 centimeters below, you need to fix two more corners, which are necessary for installing the pallet. Fat will accumulate in it. The shelf can be used from the same refrigerator, and the tray can be borrowed from the stove.

Supplying the smokehouse with additional elements

If you purchase an industrial smokehouse, you will not have to worry about its design features, since this device already has everything. Whereas if you decide to make such equipment yourself, you can equip it additional elements. One of them is a thermometer, which is equipped in the form of a spiral. It needs to be removed from the same old slab. You can decide for yourself where to install this thermometer, but experts advise placing it in close proximity to the product that is supposed to be smoked. Such a smokehouse, reviews of which are often only positive, should have small holes on the side wall for attaching a thermometer. The indicator must be located outside. After dismantling, only the handle and nameplate will remain on the refrigerator door. You can save yourself the hassle of fixing the door; it can remain in the closed position thanks to an ordinary hook.

Such smokehouses for home smoking must undergo testing after completion of work; for this, the chamber must be calcined to eliminate foreign odors. The stove can be heated for several hours, adding firewood from time to time. It is not necessary to close the door completely. The appearance of the refrigerator body after such use may be slightly changed: the paint will come off or turn yellow. If you are not afraid of these metamorphoses, then the smokehouse does not need to be decorated with anything.

Of course, the price of which is about 20,000 rubles, can be purchased in a specialized department. However, many home craftsmen prefer to make such structures themselves. During operation, you will receive great pleasure from using the product, and you will spend minimal amount funds. Some specialists do without visiting a store at all.

Conclusion

The smokehouse, admittedly, is a fairly simple design. Even an inexperienced craftsman can make it using available materials and tools. If there is a need for welding work, then you can always contact a specialist whose volume of work will not be too large. Therefore, you will not have to overpay, which indicates the possibility of savings. But you can cook as much meat and fish as your heart desires. Some masters even use such structures not only for their own needs, but also for preparing meat that will be sold. You can ensure that the design is sized to suit your needs. This needs to be thought about when designing the device.

The technology for hot smoking products is quite simple, the process is less labor-intensive and takes little time. It is these reasons that have contributed to the widespread use of hot-smoked smokehouses of the most different designs, and smoking itself has become a favorite way of preparing food for a picnic at the dacha.

What are the features of preparing products using the hot smoking method?

To achieve the readiness of a smoked product using the hot processing method, it will only take a couple of hours. The processing temperature should reach from +75 to +150 C, the processing time will be determined depending on the size of the semi-finished products and the degree of their pre-treatment.

If the smoking regime is followed, then smoked fish, meat or lard will remain juicy and will acquire pleasant aroma and golden hue, pathogenic microbes that may be in the raw semi-finished product die under the influence of temperature. At the same time, the texture of the processed product becomes softer, and there is a tendency to stratify; this is especially evident when hot smoking fish.

Hot smoked smokehouse and its varieties

Today you can meet a large number of a wide variety of devices for hot smoking, both industrially manufactured and homemade. To make homemade ones, you can use a wide variety of metal containers:

- buckets,

- pots,

- kegs,

- containers for sterilizing medical instruments.

Such a container must provide for the possibility of its hermetically sealed closure. If you have a choice, it is better to give preference to a vessel with thicker walls - the heat will be stored in it longer.

Inside the container you will need to secure grates and a drip tray for draining fat. One grate is placed in the upper part of the structure, since semi-finished products will be laid out on it, it is advisable to use stainless steel for manufacturing.

It’s easy to make a hot smoked smokehouse with your own hands, just study the drawing of the smokehouse and prepare suitable materials. The principles of arranging a smokehouse for fish and meat are practically no different.

Do-it-yourself hot smoked smokehouse - we construct it from metal sheets

Before starting work, we will prepare the following materials and tools:

- sheets of 2 mm metal of the appropriate size,

- thin fittings,

- grinder,

- welding machine,

- corner, tape measure.

The order of work will be as follows:

- Using a grinder, you will need to cut the metal sheets into 4 equal parts.

- Using a square to measure the accuracy of the angles, weld the cut metal pieces at an angle of 90 degrees. Cut the bottom from the remaining sheet and weld it to the resulting structure. Then you need to boil each inseam- this will ensure the tightness of the structure.

- After creating the box, you can proceed to the lid; to make it you will need to cut 4 strips of metal, larger in length than the size of the box. Assemble by welding deep cover, which would fit freely onto the body.

- Next, you will need to cut pieces of fittings of the appropriate length and weld them in two levels inside the smokehouse - at the top for placing food, at the bottom for placing a tray for draining fat. For convenience, it is advisable to weld handles on both sides on the outside of the box.

In principle, the smokehouse can be considered ready. An electric stove or a gas stove can serve as a heat generator for it; they are more convenient, because... make it possible to regulate the temperature inside the smoking compartment. If a higher temperature is required, you will have to build a fire.

Smoking chambers can have the most different sizes and shape - the main condition for their successful functioning is ensuring the tightness of the smokehouse. To determine required amount materials, before making a smokehouse you should draw detailed diagram its designs.

Hot smoked smokehouse at home - operating principle

Now you can start smoking meat or fish. They will require pre-processing - salting in accordance with the selected recipe. Before storing, the semi-finished products are removed from the brine and their surface is dried with a paper towel.

A small amount of sawdust is poured into the bottom of the smokehouse. Then semi-finished products are placed on the upper grill, preferably so that there are some leftovers between the pieces. small gaps. Now you can light a fire or turn on the stove.

The processing time of products is counted starting from the time the required temperature is reached and smoke appears. During the smoking process, you will need to control the temperature; this is not difficult to do on a stove; you just need to turn the regulator or reduce the gas supply. If we get heat from a fire, then we will have to rake out the coals from it or remove the smoking chamber for a while. Please note that heating the smokehouse to very high high temperatures may cause food to burn. But at the same time, the temperature in the chamber must be high and allow efficient processing semi-finished products, the smoking chamber must not be allowed to cool.

How and for how long can you store hot-smoked products?

While cold smoked products can be stored for months, hot smoked products should be consumed within 10-12 hours. perfect option- use immediately after preparation. Another option, which involves storage for a long period, is freezing in vacuum packaging at temperatures below -5 C. Naturally, during storage taste qualities and the aroma of the product will change slightly.

Preparation of semi-finished products for smoking

You can smoke a wide variety of meat and fish semi-finished products. Preparing meat and fish for smoking involves pre-salting or marinating them with all kinds of spices. To determine the readiness of the semi-finished product, simply pierce it with a knife if the juice released has become light shade without admixture of blood, then the product is fully ripe and can be transferred to the smokehouse.

Experienced smokers recommend that when preparing a chicken carcass, first remove the blocks, scorch it over a fire, rinse it, and cut it lengthwise into two halves. Then you will need to place the carcass pieces between two cutting boards and using gentle blows with the butt of an ax, flatten the joints and bones. Next, the carcass is rubbed with salt mixed with spices, hung in the cold, and if possible, a draft is created. After such preparation and smoking, the meat will be very soft.

Fish for smoking can be salted or fresh. If the fish is large, it is cleaned, gutted, cut along the spine or into layers. Small fish can be smoked whole; if the fish is very small, then it doesn’t even need to be gutted. Pre-salted and dried fish has higher taste qualities.

Preparation of fish carcasses is as follows:

- they are rubbed with coarse salt,

- very fatty fish are wrapped in parchment paper,

- put the fish in a container and press it down with a weight, which can be used as a brick,

- stand for 3-5 hours, then hang and allow the brine to drain completely,

- wash the fish to remove salt residue cold water, wipe dry,

- Just before smoking, the carcass is rubbed with spices.

What sawdust and wood chips can be used for smoking?

The main condition for quality smoking is the presence sufficient quantity smoke, so the choice of sawdust should be taken responsibly. You will need the ability to achieve smoldering of flammable material; the appearance of fire will ruin the whole process. In a hot smoked smokehouse, it is practiced to use moistened wood; it is not prone to combustion, and the moisture evaporated from it will give the product greater juiciness. Thin branches can also be used as fuel; they tend to smolder for a long time.

It should be remembered that the taste of a smoked product is influenced not only by salt or pepper, but also by the quality of the smoke. Delicious smoke can be obtained from sawdust or branches of fruit trees, especially cherry, apple, pear, and wood waste from other hardwoods. Juniper and alder wood chips produce very aromatic smoke. You can also use waste wood from oak, beech, hazel, ash, maple or a mixture of wood of different species.

Before you start splitting wood, you should remove the bark from it, especially if you use birch firewood. You can use either sawdust or wood chips for smoking; the pieces should be about 3 cm long. Dried wood should be used to make wood chips, but it is recommended to moisten it a little before placing it in the smokehouse. The fuel is laid out on the bottom of the smoking chamber in an even layer.

Hot smoked smokehouse at home - different options for home and camp smokehouses

hiking option

It was mentioned above that the designs of hot smoked smokehouses can be quite diverse. For example, in hiking conditions A bucket can be used very successfully as a smoking compartment.

You will need to pour about 20 cm of sawdust or shavings at the bottom; a metal grate is installed at a height of approximately 15 cm from the top edge of the container, and food is placed on it. The bucket is tightly closed with a lid, and a small fire is lit under it. It is not recommended to open the lid during the smoking process.

The moment of smoking begins is determined by the appearance of smoke leaking from the bucket. The temperature of the smoking compartment should be about +90 C, it should be maintained at this level for approximately 1/4 of the entire time required to bring the product to full readiness. The rest of the time, it is advisable to maintain the temperature in the smoking chamber at +120 C.

To determine whether the temperature meets the desired parameters, a very simple method is used: water is dripped onto the lid. It should not hiss or boil; the temperature at which the water simply evaporates is considered normal; at this temperature the food is smoked and not cooked.

You can adjust the temperature by adding wood to the fire or removing coals from it. Typically, 30-50 minutes of processing of products is sufficient for smoking. When you try smoking for the first time, to determine the degree of readiness, you will have to remove the smokehouse from the fire, open the lid and try the semi-finished products. When preparing similar products again, you will be able to rely on previously obtained results.

After the smoking process is completed, the bucket is removed away from the fire and cooled. The removed products are dried.

how to smoke in a hot smoked smokehouse - setting up a smokehouse in an apartment

The best option for a smokehouse for an apartment would be a small stainless steel box. sheet metal, of course with a lid. You will need to make a hole in the lid, weld a tube into it, and use a hose attached to the tube to remove the smoke through the window. To eliminate the possibility of smoke entering the apartment, the sides of the box are made L-shaped. The lid will be inserted into them. After installing the lid, the sides are filled with water.

The bottom of the smokehouse is lined with a layer of sawdust. A tray for collecting fat is installed on the welded bottom layer of the mesh (at a height of 8-12 cm), and semi-finished products are placed on the one located higher (at a height of 25-30 cm). The smoking process begins after installing the smokehouse on gas stove or electric stove. Hot smoking at home in a smokehouse is quite easy to regulate; it will be enough to increase the gas supply or reduce it; you can also control the smoking temperature using drops of water.

smokehouse in the country from an old refrigerator

The work of creating a smokehouse from a refrigerator begins by removing all of it internal parts- only the metal body and the door should remain. The hole formed on the rear wall should be sealed with a metal plate; it can be cut from dismantled parts of the internal parts. To close and secure the door, you will need to attach a very ordinary hook to it.

Then the corners are welded on the walls of the body:

- at a distance of about 20 cm from the top of the wall - for installing a grate with food,

- at a distance of 30-40 cm from the top of the wall - for a frying pan into which drops of fat will flow.

Sawdust intended for smoke generation is poured directly onto the surface of the stove; after adding firewood to the stove, the refrigerator doors are tightly closed.

Tasty and aromatic smoked fish on the table, and even cooked with your own hands, is the pinnacle of celebration. Unfortunately, not everyone knows how to smoke fish and what equipment is needed for this. At the same time, not everyone realizes that this is not at all difficult. The main thing is to understand the type of smoking and smoking technology. And then be patient and prepare everything you need.

The structure of the smokehouse is so simple that anyone can make it. Here's what you need for this:

- The smoking chamber is installed on bricks or wooden blocks built into the ground. Since condensation may occur, the soil may move to the side.

- Wood chips or sawdust can be used as fuel material. You need very little firewood (20%). The firewood is placed in the center, and everything else is piled around it. This will allow the fire not to burn, but to smoke, as a result of which the food will acquire a pleasant aroma.

- It is necessary to ensure normal draft from the fire to the chamber. Naturally, this is not easy, especially since it is difficult to guess with temperature. To do this, install a long chimney so that the smoke has time to cool to the desired temperature. To ensure excellent draft, you can install fans, and for cooling - distributors.

Unfortunately, this is no longer simple design, but will be more similar to an industrial design.

Design

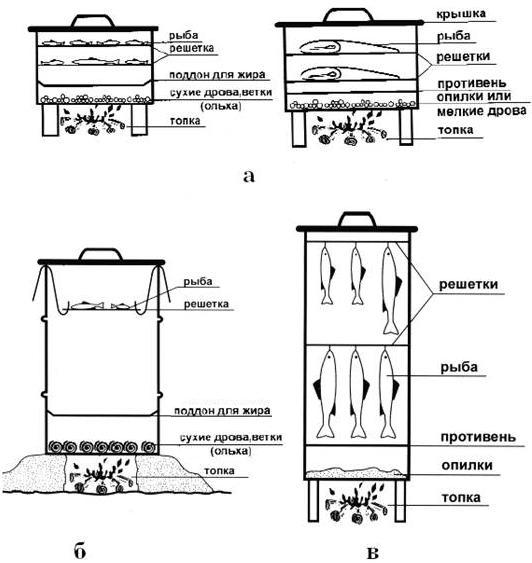

For such a device, metal or wooden barrel. As a rule, a home does not require a large amount of smoked fish, and such a smokehouse design can easily provide a family with smoked fish. A chimney is mounted between the firebox and the barrel. Its role is played by a trench dug in the ground, up to 2 meters long. The trench is reinforced with iron or slate, after which it is covered with earth. The container (barrel) is installed on a sheet of iron in which holes are made. This is necessary so that the smoke from the trench penetrates into the barrel.

Another option is possible: a barrel is installed on the stove. A fire is lit in the stove, and fish is smoked in a barrel. The main thing here is to ensure the required smoking temperature (40°C), and what kind of design it will be does not matter. The smoking process under such conditions can last up to several days.

In any case, such a homemade smokehouse will cost much less than one bought in a store. Ready product can cost from 3 thousand to 7 thousand rubles. Made independently, from unnecessary scrap metal, such a product will not be worth anything at all.

Smokehouse for hot smoked fish

The device is practically no different from a cold smoking device. The only difference is that the smokehouse chamber has the appropriate temperature (from 60 to 100°C). As can be seen from the condition, there is no need for a cooling channel, but otherwise everything is exactly the same. There are many simple and elementary designs, for example:

- Take an enamel bucket or pan.

- Wooden chips are placed at the bottom of the vessel.

- The container is divided into half (in height) and a grill is installed.

It's so easy that the smoker can be ready in minutes. Despite its simplicity, the result is the same as if it were complex design. Naturally, the device is not so productive, but for a family it is quite enough.

In such a smokehouse, the fish is cooked for about an hour. First, the temperature is set somewhere around 60-70°C, and then rises to 100°C.

If you buy something similar in performance, it will cost from 6 thousand to 10 thousand rubles. There are smokehouses using new technologies.

- To begin with, you need to decide suitable place. Since all the technology is related to fire, the smokehouse will have to be installed away from residential buildings.

- In this case, you need to take into account the distance to neighboring buildings.

- First of all, they are engaged in marking the chimney, after which it is laid out of brick.

- It is better to use clay and sand for the solution.

Bucket smokehouse

To make a simple smoker you will need an old bucket. Here you can cook both fish and meat, but very little, although quite enough for a family.

Products are cooked in such a smokehouse for about an hour.

Smokehouse from a barrel

This is a good solution, because at one time you can cook as much food as in a bucket smokehouse several times.

Smokehouse from a gas cylinder

Such a device, if you buy it, is not cheap. A gas cylinder with a capacity of about 50 liters is suitable for this purpose. But before using the gas cylinder, you should do the following:

- Release all gas, if any, from the cylinder. Be sure to check by processing the hole soap solution. After this, the cylinder is washed with water to remove any remaining gas.

- After this, it is cut off top part balloon.

- At the next stage, the legs are welded to the cylinder. It is very important that the structure is stable, because the cylinder weighs a lot.

- Finally, the firebox and chimney are installed.

- The firebox and chimney are made of metal.

This is what the smokehouse should look like:

Preferably! The gas cylinder should not be too old (rusty), and before use it should be calcined so that the remaining gas burns out.

The fact is that no matter how thoroughly the container is washed, it will emit an unpleasant aroma for a long time. This means that products cooked in an unprepared container will emit the same smell.

Brick smokehouse

- First, a trench is laid in the ground, which will serve as a chimney. All work should be done only with red brick.

- At the end of the trench there is a smoking chamber, no more than 150 cm high.

All masonry is done on edge using clay mortar.

At the beginning of the trench there is a firebox.

5 advantages of home smoking

- Usually, home cooking– these are only fresh products.

- There is a possibility independent decision about additional ingredients.

- The cost of homemade products is several times less than store-bought ones.

- Guaranteed quality finished products.

- Smoking is prepared only from natural ingredients, without the use of “chemistry”.

Smoking has long been one of the most favorite ways of preparing meat and fish products. But since there are several types of smoking, amateurs are often faced with a choice: which smoking to prefer - hot or cold? Experts with experience in this industry largely prefer hot smoking, which can be subjected to various varieties meat and fish, and in support of their choice they list a large number of advantages of a hot smoked smokehouse, which we, of course, will consider in this material. The modern variety of products presented in the relevant field allows you to purchase a hot smoked smokehouse in a specialized store, and those who like to make purchases in a relaxed atmosphere will be able to do this in the appropriate online stores. And the operation of factory smokehouses is not difficult - just place the firewood in a special compartment, place the food inside, close the door tightly, light the fuel and, after the allotted time, enjoy the aromatic, golden smoked meats. But what to do if you are only going to indulge in smoked meats from time to time? Why do you need unnecessary waste money if you can make a homemade hot smoked smokehouse that is in no way inferior to industrial models. And the answer to the question: “How to make a hot smoked smokehouse?” look in the article prepared by our specialists.

Features of various types of smoking: studying the smoking process

Smoking is one of the most common types of heat treatment of products, which has a preservative effect on them. During the smoking process, products acquire a specific aroma, are also saturated with smoke substances released during the combustion process, and are subject to partial dehydration, which helps extend the shelf life of products. There are hot, semi-hot and cold smoking. Each of these types is characterized by its own advantages and disadvantages.

Hot called smoking, carried out at a temperature of at least 50-60 degrees for small fish. It is a priority when smoking low-fat products. The process of hot smoking occurs quite quickly and is smoking carried out in hot smoke. In the lower section of the smokehouse, small chips smolder, and above them hang meat, fish, vegetables or cheese, which are quickly brought to readiness at a smoke temperature of 80 to 140 degrees, depending on the type of product. Since the process of hot smoking involves melting of fat, only low-fat products are suitable for it, which after such heat treatment can be stored for no more than two days.

Cold smoking, unlike hot, the process is more labor-intensive, which can last up to several days and actually represents a somewhat accelerated withering of products. In order to achieve cooling of the smoke, a pipe is pulled from the place where the firewood is smoldering, the length of which reaches 1-2 meters, and in order to control the temperature of the smoke, a thermometer is installed in the smoking chamber. As for meat, it is smoked at a temperature of 15-20 degrees, and fish - from 20 to 40. Products treated with cold smoke can be stored for quite a long time.

Semi-hot smoking is an intermediate option between hot and cold smoking.

General structure of the simplest hot smoked smokehouse. The essence of the smoking process

A home hot smoked smokehouse is essentially a container, the volume of which depends only on your preferences and needs. But no matter how much food you want to smoke at one time, the smokehouse must be of such a volume that it can accommodate a grate for storing food, and a tray necessary to ensure that fat dripping from smoked meat or fish does not fall on coals, which can reduce the taste characteristics of the finished product. The grate can be made from metal rods connected by welding. However, the main element of the smokehouse, which it cannot do without, is the area for placing firewood, which is located at the very bottom of the tank. As wood material Various types of wood can be used, the choice of which will be discussed a little later.

To make a hot smoked smokehouse, it is recommended to use stainless steel, which combines such characteristics as resistance to heat, high strength and lack of tendency to corrosion under the influence of aggressive environmental factors. In order to make it easier to insert and remove products, the smokehouse design should include a lid or door. And in order for the design of the smokehouse to be completely complete, equip it in such a way that the smokehouse container is at a slightly elevated distance from the ground, which can be achieved by making metal legs. This is necessary in order to locate the fire source. Since it is not the fire that is important for the process, but the heating temperature, you can choose the source of fire at your discretion.

The essence of the smoking process:

Once the food has been placed on the metal grate and wood, such as juniper sprigs, in the lower part, close the smoker tightly and begin heating the lower part. As the fire begins to flare up, the wood smolders and releases aromatic hot smoke, which rises up and passes through the products laid on the grill, causing smoking. The duration of smoking depends on the number of products, the size of the smokehouse, the temperature of the smoke and your preferences, however, after 40 minutes it is recommended to test the results obtained, since if the smokehouse overheats, the process technology may be disrupted.

Advantages of a hot smoked smokehouse:

- The simplicity of the design of a hot smoked smokehouse makes it easy to manufacture at home;

- The following advantage follows from the previous advantage, the essence of which is that there is no need for large financial investments to manufacture a smokehouse;

- Using a smokehouse anywhere: at home, in the country or outdoors;

- When using a hot smoked smokehouse, the smoking process is characterized by speed and simplicity;

- No need for additional processing of smoked products.

Hot smoked smokehouse photo

Hot smoked smokehouse: step-by-step instructions

Let's consider one of the options for installing a hot smoked smokehouse with your own hands using metal sheets. Before you begin installing the smokehouse, study the most common drawings of a hot smoked smokehouse, which are presented in our material. It is worth noting that the dimensions of the smokehouse for hot smoking are quite variable and depend only on your taste preferences and the amount of material you have:

To work you will need the following materials and tools:

- Two metal sheets with dimensions 150x60 cm, the thickness of which does not exceed 2 mm;

- Thin fittings;

- Welding machine and grinder;

- Construction corner.

Step-by-step manufacturing instructions:

- Using a grinder, cut one of the metal sheets into 4 equal parts. Dividing exactly into equal parts is necessary so that the finished smokehouse acquires a square cross-section;

- Use drip welding to join the two sheets. In the process of connecting them, use the construction angle to achieve the ideal ratio of the two planes, equal to 90 degrees;

- To achieve the tightness of the metal box, carefully weld the internal seams;

- Divide the second sheet into two parts and cut out the bottom of the future smokehouse from one half of the metal sheet and weld it to the finished box;

- From the remaining part of the metal, cut 4 identical strips, the dimensions of which are slightly larger than the outer dimensions of the smokehouse, and weld them to metal sheet, with dimensions similar to the dimensions of the bottom or walls of the smokehouse (since the smokehouse is square-shaped, their dimensions are the same). The result should be a lid of moderate depth that fits easily onto the body homemade smokehouse hot smoked.

- So, our smokehouse can be considered almost ready. To complete the process, it is necessary to weld metal rods located in two levels in the upper and lower parts of the smokehouse, as well as comfortable handles. The lower level of rods is necessary for installing a tray into which fat from smoking products will drain, and the upper level is for placing hooks with lard, fish or other products, depending on your preferences.

How else to make a smokehouse? Backup option for the lazy

Most in a simple way Making a hot smoked smokehouse involves assembling a smokehouse from a bucket or large pan. To make a smokehouse, experts recommend using buckets made of of stainless steel, while the use of galvanized buckets is under strict ban. This is due to the fact that during the heating process toxic zinc oxide is released, which penetrates into food and causes serious harm to the body. Also stock up on a lid for a pot or bucket in which you need to make holes for the smoke to escape. The design of a smokehouse made from a bucket involves the installation of three grates. The lower one is located one third from the bottom of the homemade smokehouse, while the upper one, on the contrary, is one third from its lid. As for the middle grille, its location is approximately 5 cm lower than the top grille.

To make gratings, use steel wire. Wrap wire around the smokehouse in the places where you plan to place the grates, then cut the wire to the required length. Make hoops from finished pieces of wire and connect them by welding the joints. After the hoops are ready, intertwine them with pre-prepared, thinner wire, ensuring that the width of the cells does not exceed 2 cm. For those who do not want to bother with making lattices, experts suggest using a mold from an old dumpling maker.

Next, start preparing shavings, sawdust and wood chips for the smokehouse. Experts recommend using oak, rowan, alder or juniper shavings. Wood shavings will also work fruit trees. As for birch shavings or coniferous wood chips, on the contrary, it is not recommended to use them, since products that are smoked will acquire a bitter taste. Pour the prepared wood chips onto the bottom of the homemade smokehouse in a layer the thickness of which reaches 1.5-2 cm, then install the lower grate, on which place the tray necessary to collect fat. Pallet dimensions are important practical significance, since it should not be excessively large so as not to create an obstacle to the passage of smoke. Having installed the tray, place the second and then the third grate with the laid product that you are going to smoke. After completing all of the above steps, close the smokehouse tightly to prevent air from entering it and subsequently igniting the fuel, and hang it over the fire. It is important to know that the flame during the smoking process should not be too large so that the smoked product does not burn.

During the smoking process, it is not recommended to open the lid in order to check the readiness of the product. You can easily do this by assessing the color and structure of the smoke. On initial stage Smoking smoke is usually thick, which indicates smoldering wood chips. Then it gradually begins to turn white and becomes less abundant. At this stage, it is important to ensure that the smoke does not become yellow, which clearly indicates wood fire. If you follow our recommendations and smoke the product over low heat, it will be ready in 45-50 minutes, when the smoke becomes dry and acquires a pleasant aroma. To determine the temperature of the smoker, splash water on the lid. The optimal temperature is indicated by its silent evaporation, but not boiling.

Various options for hot smoked smokehouses and their advantages

The design option shown in the figure is the most improved. The presence of a baking sheet (it is located to the left of the smokehouse and is a bit like its lid) allows you to smoke fattier products without fear that the fat released during the smoking process will get on the wood chips and thereby create an obstacle to its smoldering. And the use of two grids at the same time, provided by the design, allows you to prepare a larger number of products.

All considered designs are characterized by mobility, which determines their use in any conditions. For home use We suggest you pay attention to the massive stationary smokehouse shown in the figure, which can only be used at home. This device is more professional and will allow you to prepare high quality products.

To make a smokehouse, a version of which is shown in the following figure, no special professional skills are required. If you have two 50 liter barrels and a grinder at your disposal, after making cuts in the appropriate places, you can easily install these barrels as shown in the figure.

In order for the finished product to have excellent taste characteristics, it is necessary to strictly follow the rules for choosing firewood for a smokehouse, which not everyone is familiar with. In this regard, our goal is to tell them to you. In order for the finished product to please you with a pleasant taste and aroma, it is necessary to use raw wood, in the absence of which the logs are additionally moistened.

Advice! If, despite our clear recommendations regarding the choice of wood, you decide to use birch logs, remove the bark from them before starting smoking. Otherwise, the products will acquire a bitter taste.

To give your food a specific, pleasant aroma, add juniper branches or cherry leaves to the firewood.

Advice! It is also not recommended to use it as firewood for a smokehouse. conifers trees, due to their high resin content.

According to experts, the color and, accordingly, the quality of the finished product is influenced by the degree of combustion of firewood. Incomplete combustion contributes to the appearance of light smoke, which significantly improves the taste characteristics of smoked meats.

It is important to know that it is forbidden to fan the fire in the smokehouse to eliminate the risk of accidental fire. Ready-made, chopped logs are placed in the smokehouse and covered with sawdust or wood chips on top, which smolder, but, despite this, do not burn.

Concerning color characteristics finished product, they depend on the wood species you choose. In order to obtain a golden shade of products, use mahogany, while the product will acquire a dark yellow shade due to the smoldering of alder and oak sawdust.

To operate the smokehouse, use old garden trees that have outlived their usefulness, or tree branches obtained after pruning;

It is not recommended to use only large firewood, as it is only suitable for producing coal. Therefore, first put firewood in the stove and set it on fire, and then place a tray with shavings of fruit trees, which will smolder and give the smoke a pleasant aroma;

To get high-quality aromatic smoke, after receiving the coals, close the holes in the lid to ensure efficient smoldering of the sawdust;

The quality of smoking depends not only on the type of wood chosen. Also important is the constant supply of smoke until the product to be smoked is finally ready. With this in mind, to maintain constant temperature When smoking sawdust, you have to constantly add sawdust to the tray.

Hot smoked smokehouse video

A hot smoked smokehouse with your own hands is not only tasty and healthy, but also convenient. You will have the opportunity to smoke fish and meat at any time, using only fresh products. Note that you can smoke various products, for example, vegetables, fish, lard, meat, chicken, etc. Making a smokehouse for hot smoking with your own hands is not as difficult as it seems, although there are certain nuances that need to be taken into account. We will tell you what to consider, what to pay attention to, and also explain the advantages of hot smoking over cold smoking.

Sometimes it is difficult to give a preference on which smokehouse to make - cold or hot smoking. If you want to try perfectly cooked fish, ready to eat in literally a matter of minutes, you should opt for hot smoking. It will take only 35-40 minutes to cook the fish this way, while with the cold method it will be ready in a few days.

You can build a smokehouse for both cold and hot smoking from scrap materials, but the construction of the first will require much more free time and significant financial costs, and the construction of the second will require a lot of free space.

The principle of smoking is to create the optimal temperature for heating sawdust. They will smolder. This process produces a lot of smoke. Heat the bottom of the smokehouse to a temperature in the range of 300-3500C. At this temperature, sawdust will slowly smolder, but if you exceed the upper threshold even by a small number of degrees, the wood will begin to burn, releasing dangerous carcinogens.

How to make a smokehouse for hot smoking with your own hands from different materials

First, let's get acquainted with the principle of operation of the smokehouse and how it is made. She should have 2 cameras:

- for meat (fish);

- for wood.

As a rule, they are combined in one container. Before starting work, prepare all materials and tools. Most simple option is an electric smokehouse, which can be made even without special knowledge, just follow the recommendations (see smokehouse from the refrigerator).

From an old barrel

If you are going to smoke a lot of products, then we suggest making a hot smoked smokehouse from an unnecessary barrel with your own hands. This photo shows an example of a finished smokehouse.

To use an iron barrel, clean it of any remaining paint. Place the barrel in the fire for at least 1 hour, and not even a trace of paint will remain.

Wash the wooden barrel well and dry it. After it is ready, you need to make holes in its walls, with the help of which the rods with products will be attached.

The next step is making a metal cup. A pipe is suitable for this purpose suitable diameter. The glass must be inserted into the hole located at the bottom of the barrel. When using a wooden barrel, it must be protected from overheating with a special fire-resistant asbestos fabric. You can use plywood as a cover. For your convenience, we suggest watching a video that shows and tells how to make an excellent hot smoked smokehouse. To ensure that the lid fits tightly enough, a small weight is placed on it.

After hand made hot smokehouse has come to an end, you can go directly to the smoking process. Let's warm up the pipe for an hour gas burner. This time is enough for sawdust to burn. Don't forget to control the size of the flame. After the time has passed, let the smokehouse cool, after which you need to remove the food.

Before starting to work with products, run the unit 1-2 times to see it in operation.

Made of brick

You can watch the video of the process of making a stationary smokehouse in order to accurately understand the sequence of actions and how the ordering takes place.

We will briefly discuss the main processes.

The operating principle of such a device is no different from other smokehouses. It is very similar to an ordinary traditional oven, because instead of a lid it has a wooden door. For the solution, you should use fireclay clay and additionally fix it with a sheet of iron. This is necessary to prevent shedding. The foundation for a brick smokehouse needs to be strengthened.

The dimensions of the future smokehouse are determined according to the drawing:

In turn, you can change them a little at your discretion. Having decided on its dimensions, you need to lay out a brick food cabinet.

Keep in mind that the chamber should be 2 times the size of the firebox itself, and the air duct should be ¼ of the height of the smokehouse.

Protect the joint with a special collar. Brick smokehouse may have a lid made of wood or iron sheet. To begin the smoking process, remove the lid, add wood and light the fire.

Install the cover so that there is a small opening, which is necessary for the penetration of air flows. Smoke will enter the smoking cabinet through the air duct.

After the coals have formed, you need to put fruit sawdust on them. We put food in the cabinet and after it is filled with smoke, close the lid. The cooking process takes about 1 hour.

This photo shows a hot smoked smokehouse, made by hand according to the previously indicated drawing:

From a used gas cylinder

Do you have an unnecessary gas cylinder that you hate to throw away? Make a smokehouse out of it. Before starting work, release the remaining gas from it. After this, the container must be rinsed with ordinary water. The dimensions of the smokehouse, made from a cylinder, are not large, but it is quite enough for a family of four.

To put meat in it, you need a large door, so you shouldn’t cut the walls all the way and weld hinges for the door. The bottom must be cut exactly halfway. The firebox is made of thick iron, after which it is welded to the cylinder. Before using it, it is advisable to heat such a smokehouse with wood.

From an old refrigerator

To make a smokehouse from an old refrigerator, you need to remove all the plastic parts from it, as well as the freezer. An electric stove is installed at its bottom and plugged into an outlet. A tray with sawdust is placed above it. A hole must be made in the lid to allow smoke to escape.

Smokehouse with water seal

This smoker needs a metal box custom size. It is advisable to use not too thin sheets of iron for its manufacture, but thick ones will not be of much use. Inside, it is necessary to weld strips of steel that will serve as supports for the gratings. Leave a small distance between it and the lid.

The secret of such a smokehouse for hot smoked fish, made by yourself, is the water seal. This is a special ditch that runs along the entire perimeter at the top of the smokehouse.

It is necessary to weld the sides on the smokehouse lid, which will be directed downwards. As for the size of the lid, it is necessary to choose one in which the sides fit into the groove of the water seal without any problems. In addition, a chimney outlet is welded into the lid. It is made from pipe.

The bottom of this smokehouse is removable. It should have sides, like a lid, only they are folded up. The bottom is designed to collect dripping fat. It is necessary to weld small legs on the bottom so that a small cavity is formed between the bottom and the plane. The smokehouse is ready. Now you can start smoking.

How to smoke food quickly and tasty without marinating - video