Single-pipe forced circulation heating systems. Options for single-pipe heating of a private house. Nuances of calculating the installation of a heating system with forced circulation

When organizing his life, people have long sought to create a cozy environment in their home. One of the criteria for good health is a comfortable room temperature. For these purposes people use various options heating Water heating is still one of the most popular systems. It has been used successfully for a long time in many countries. The most popular of them is a heating system with forced circulation allows you to create comfort and coziness in houses of various sizes and number of floors.

In heating systems with natural circulation, the heated coolant rises up through the pipeline. It passes through the heating elements, cooling down, and returns to a heating element. The ineffectiveness of such a system forces the use of a pump to improve fluid movement. That is why this type of heating is called a forced circulation system.

The pump, receiving coolant from one side, sends it to the heating element and further through the system without increasing the pressure. Therefore, the principle of natural fluid movement does not apply here different temperatures. With the help of a pump, the coolant moves in the desired direction without loss of heat. By adjusting the speed of the pump you can control the amount of heat produced.

Advantages and disadvantages of such a system

Thanks to the use of a pump, a forced circulation system has a number of advantages:

- the operation of a heating system with forced circulation does not depend on the diameter of the pipes used;

- the use of inexpensive pipes of smaller diameter when installing the system allows you to save on materials;

- due to the absence of temperature differences, the service life increases structural elements systems;

- possibility of independent temperature control in each room;

This system has its disadvantages:

- the pump produces little noise during operation;

- Due to the use of an electrically powered pump, the operation of the system is dependent on the power supply.

Heating schemes with forced circulation

Depending on the number of pipes and the method of their installation, the heating scheme with forced circulation can be: single-pipe and two-pipe, with upper and lower wiring. Let's look at it in more detail below.

Single-pipe heating systems

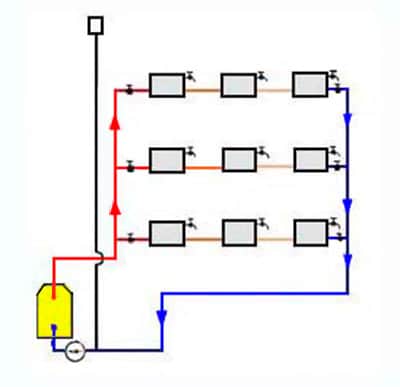

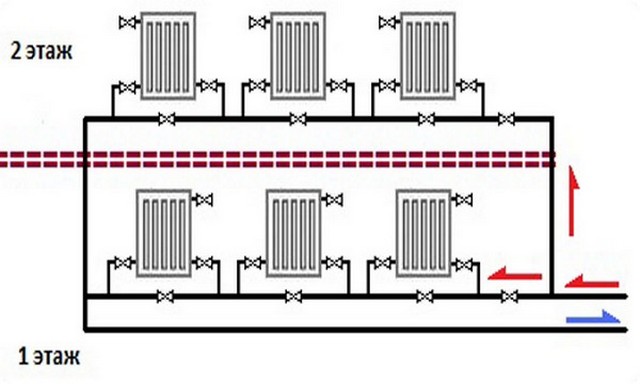

Horizontal. Single-pipe horizontal heating systems are mainly used for short houses or industrial buildings. The coolant, entering the main riser, is distributed between horizontal risers and passes sequentially through all radiators. It cools and returns through the return line.

Each radiator has a valve for removing air. The temperature of the heating elements is regulated by shut-off valves, which are installed at the beginning of the system on each floor.

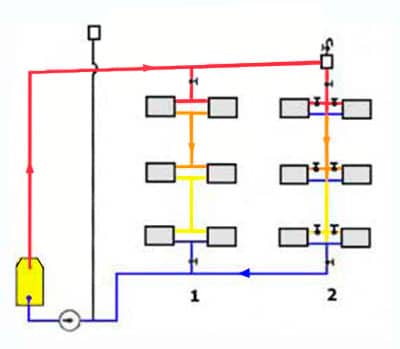

Vertical. In vertical single-pipe systems, the coolant flows directly to the top floor. Then it flows along the risers to the radiators of the upper floor. After which the liquid flows through the supply risers into the heating elements of the floor below. And so on until the very bottom. The disadvantage of this scheme is the uneven heating of radiators on the lower and upper floors.

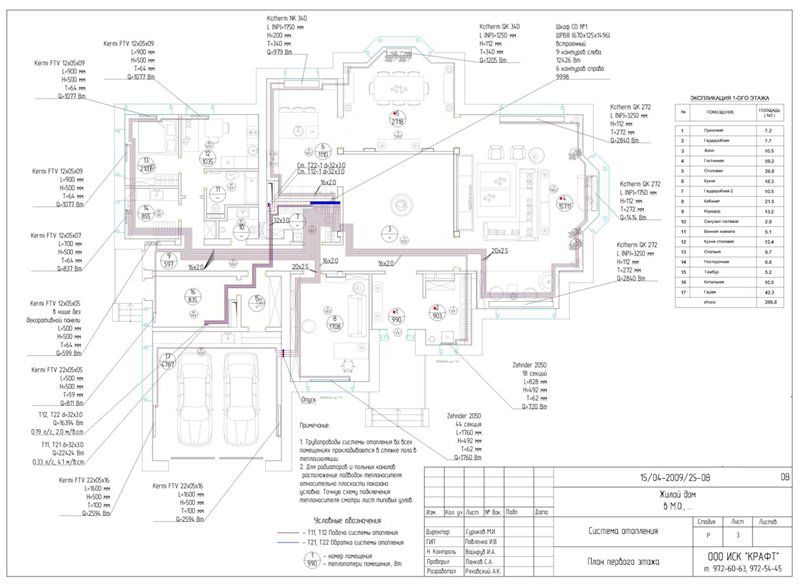

Single-pipe vertical system heating: 1- flow, 2- with closing sections

An example of a single-pipe heating system in a private house:

Two-pipe heating systems

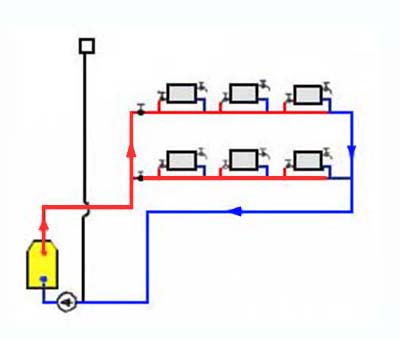

Horizontal. Horizontal systems with forced circulation are used in private housing construction. They are:

- dead-end;

- associated;

- collector

Firstly, each subsequent heating element in the direction of fluid movement is located at a further distance from the heating element. This leads to an increase in their circulation circuit and makes it difficult to control the operation of the system. In associated systems, equality of circulation circuits makes it easier to regulate the process, but increases the length of the pipeline. And this, in turn, leads to additional waste during equipment installation.

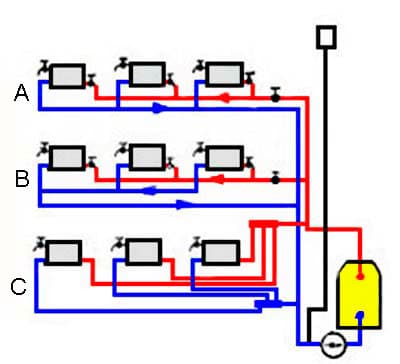

Two-pipe horizontal system: A - dead end,

B - associated, C - collector

The design of collector systems involves individual connection of each heating element. This ensures uniform heating of the radiators. But such a system is associated with large waste during installation, due to the high consumption of pipes.

Vertical, with bottom wiring. In two-pipe systems with forced circulation, the liquid is supplied to the heating element (boiler) using a pump. Then the coolant enters the supply pipeline and is distributed throughout the system, and then into heating elements. Having given off heat, the cooled liquid flows through the return pipeline through expansion tank and the pump returns to the boiler.

Vertical, with top wiring. The main pipelines of two-pipe systems with overhead wiring are located above the heating elements under the ceiling of the upper floor or in the attic. Water circulates upward using a pump from the heating boiler and flows through risers to the heating elements. Having given off heat, the liquid enters the return line located above the floor of the lower floor or in the basement.

Rules for equipment of a heating system with forced circulation

In order for the system to work for a long time and uninterruptedly, it is necessary to perform the installation correctly.

- Due to the lack of evaporation of liquid in the system, it is necessary to install an expansion tank. It compensates for thermal expansion. It is connected to the return line.

- The circulation pump is also connected to the return pipeline. This is where the least heating of the liquid occurs. Therefore, hot liquid does not come into contact with the pump, and this extends the life of the unit.

- The use of smaller diameter pipes in the distribution reduces the volume of circulating fluid. This not only reduces installation costs, but also increases the efficiency and service life of the expansion tank.

- Modern boilers with automatic temperature control will help you use fuel more economically and adjust the temperature depending on the time of day.

A forced circulation heating system is much more efficient than a natural circulation system. They make it possible to heat rooms faster and with less loss. Installed systems with natural circulation it is quite possible to remake it by installing it in the return line circulation pump and expansion tank. This will help maintain a comfortable temperature in the room without loss even in winter.

Many modern solutions water heating of houses requires the use of a circulation pump. The design and installation of a heating system with forced circulation must be carried out taking into account technical issues that arise due to the rapid movement of the coolant. The high pressure in the heating circuit allows for the implementation of many wiring schemes.

The forced scheme differs from the natural one by the addition of one or more circulation pumps.

Due to the increase in pressure and speed of movement of the coolant, the rules for the formation of nodes and the location of circuit elements change. This fact must be taken into account in order to ensure high-quality heating with forced circulation.

General requirements for the pump group

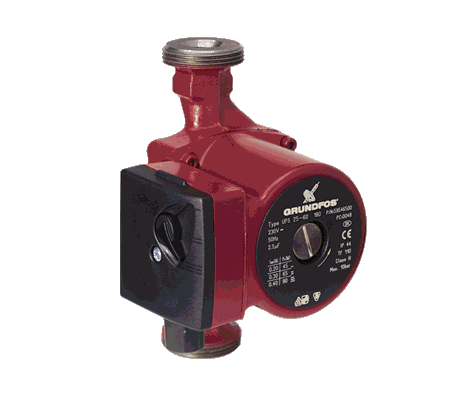

Circulation pumps are selected based on the requirements for the volume of water distilled (cubic meter per hour) and pressure (meter). The calculation of both parameters depends on the cubic capacity of the heated housing and the heating method, as well as the length of the water circuit and the diameter of its pipes. The pump should be selected so that its parameters do not match the requirements of the system. This will allow you to add elements to the circuit, if necessary, without replacing the pump.

The choice in favor of a pump model in relation to a specific heating system is made by determining the operating point and its compliance with the required coolant flow rates

Basically, pumps are designed for a voltage of 220 Volts, but there are also those with support for 12 Volts. In case of voltage surges, it is necessary to install a stabilizer to prevent the device from failure. In case of frequent power outages, you need to ensure there is a source uninterruptible power supply. There is no need to take a powerful UPS - devices with a consumption of more than 150 Watts per hour are rarely used to heat private houses.

Conventionally, circulation pumps can be divided into two types according to the position of the engine. Devices with a dry rotor have a higher efficiency, but have an increased noise level and a reduced service life than those with a wet rotor.

If the system wiring provides the opportunity for natural movement of the coolant along the circuit, then the pump must be installed through a bypass. In this case, if it breaks down or there is a power outage, it is possible to switch the heating to the gravitational circulation mode. Water can also move through a non-working pump, but it will create strong resistance to its movement.

![]()

By installing the pump in the circuit via a bypass, you can achieve not only normal operating conditions according to the principle natural circulation, but also the possibility of removing the pump without draining the water

The problem of stopping the pump is especially pressing when using stove or fireplace heating. In this case, the oven will continue to heat the heat exchanger and the water in it may boil and the entire system may fail for a long time.

It is better to install the pump on the return pipe, because more low temperature water will extend its service life. If it is not possible to install the pump in a place other than on the pipe leaving the boiler, then a pump with ceramic seals should be used. Although they can withstand temperatures up to 110 degrees Celsius, if the system boils, they may have problems with functioning.

Subtleties of choosing boilers and furnaces

Use as a heat generator for electric and gas boilers and furnaces long burning attractive from the standpoint of ease of control of heat flow through the heat exchanger. Application solid fuel stoves, especially homemade designs, is fraught with insufficient or excessive heat generation. However, their use is often justified from the point of view of the cheapness and availability of fuel.

There are now many models of electric and gas boilers available with an integrated pump. On the one hand, the built-in circulation system is matched to the boiler power and allows you to avoid purchasing and installing a separate pump. On the other hand, if the built-in pump breaks down, it will not be as easy to repair or replace as a separate one.

An electric boiler with an integrated pump is a ready-made and compact solution for inclusion in a forced circulation circuit

The requirements for the boiler when using forced circulation are the same as when using natural circulation:

- The boiler power must satisfy the heating needs of the house in the most severe local conditions. It is advisable to have a small power reserve (10-20%) due to possible force majeure circumstances that may arise in the heating system.

- It is necessary to ensure the passage of coolant without boiling in the heat exchanger. This requirement is easier to fulfill when using a “furnace-pump” combination than when using a gravitational model of fluid movement.

To prevent water from boiling in the boiler heat exchanger, it is enough to adjust the power depending on the temperature of the outlet liquid. This method works for any type of circulation.

For stoves with natural circulation, there is no way to prevent boiling of the coolant in the event of an excessive amount of loaded fuel. The only option in the presence of a pump is to increase the volume of liquid driven through the heat exchanger. Moreover, such an emergency system can be made automatic using a thermostat and a pump speed control unit.

Operating mode control unit solid fuel boiler turns on the function of starting the pump when reaching critical temperatures at the outlet of the heat exchanger

Installation and testing of the water circuit

With a heating scheme using forced circulation, there will be higher water speeds than in the gravity model. Therefore, it is possible to use a smaller pipe diameter with the same building heating parameters. This reduces the cost of water heating in terms of costs for pipes, fittings and fittings. In addition, smaller diameter contour elements are easier to hide in technological niches or fit into the interior of the premises.

Compared to natural circulation, increased hydrodynamic pressure of the flow will be added to the hydrostatic pressure of the liquid column. Therefore, in order to avoid the formation of leaks or, especially, a breakthrough of the system, it is necessary to adhere to certain rules.

In the event of a transition from gravitational circulation to forced circulation, it is necessary to eliminate all, even minor, leaks in the circuit. As the pressure increases, the flow rate will increase, which, in addition to the problem in the room, will cause a decrease in the amount of coolant and its excessive aeration (air saturation).

Before the onset of the heating period, it is necessary to carry out hydraulic tests of the strength of the circuit with the maximum used or even a little more high pressure. This will allow you to identify problems and eliminate them before the onset of cold weather, when a long shutdown of heating for repairs is undesirable.

Heating radiator leaks can occur in the most unexpected places and fixing the problem will take a lot of time, so it is better to check the integrity of the system in advance

Since the speed of movement of the coolant will be greater than 0.25 meters per second, according to SNiP 41-01-2003 there is no need to maintain a constant slope of the pipes to remove air from the circuit. Therefore, with forced circulation, the installation of pipes and radiators is a little simpler than with a gravity circuit.

Heating options with forced circulation

The use of forced circulation allows us to move away from the principle of designing the wiring with the obligatory consideration of the hydrostatic pressure difference, which is necessary for functioning in a gravitational circuit. This adds variability when modeling the geometry of the water circuit and provides the opportunity to use solutions such as collector heating or heated floor large area.

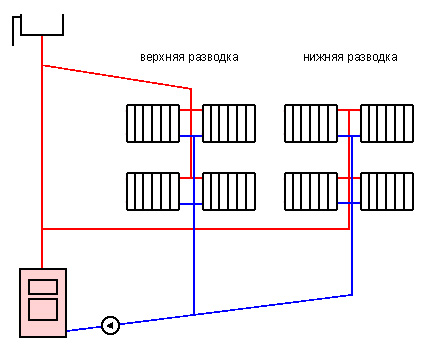

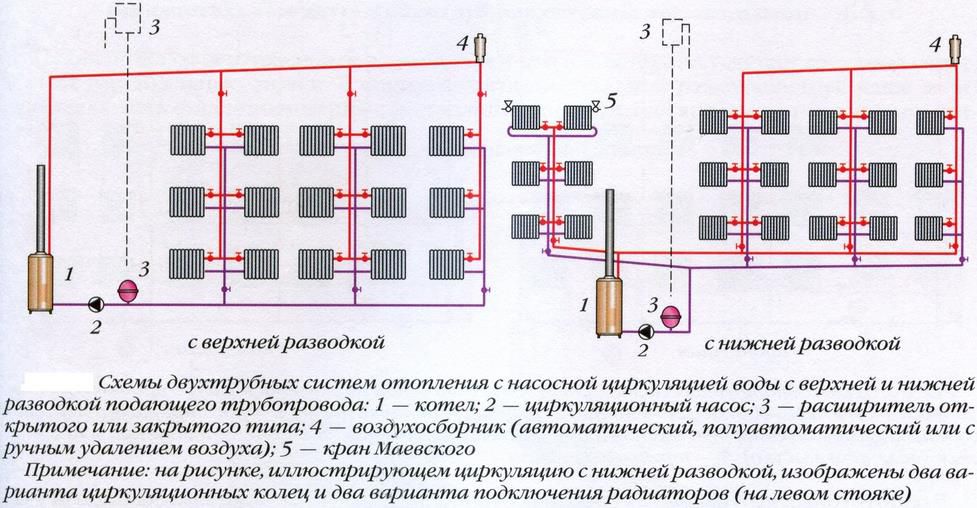

Application of upper and lower wiring

Any heating scheme can be conditionally classified as upper or bottom wiring. With overhead wiring, hot water rises above the heating appliances, and then, flowing down, heats the radiators. With the bottom - hot water is supplied from below. Each option has its positive sides.

Upper wiring also used for natural circulation. That's why heating circuits This type allows the use of both types of circulation. This, firstly, provides the opportunity to choose, and secondly, increases the reliability of the system. In the event of a power outage or pump breakdown, the movement of water along the circuit will continue, albeit at a lower speed.

Good pressure allows you to choose between upper and lower wiring, taking into account the convenience of pipes supplying coolant to the radiators

When using bottom wiring total length There are fewer pipes, which reduces the cost of creating the system. In addition, there is no need to lay risers on the upper floor, which is good from the point of view of room design. The lower hot water supply pipe is laid either in the basement or at the floor level of the first floor.

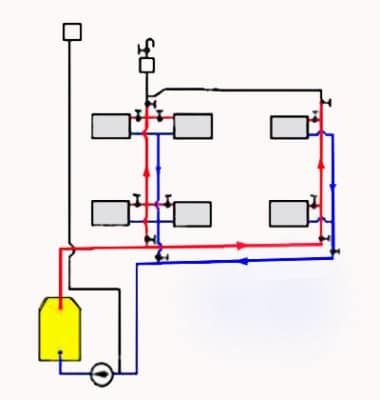

Varieties of one-pipe connection schemes

Single-pipe design uses the same pipe for supply hot water to radiators and cold outlet to the heating boiler. With this layout, the length of the pipes used is almost halved, and the number of fittings and shut-off valves is reduced. However, the radiators are heated sequentially, therefore, when calculating the number of sections, it is necessary to take into account the gradual decrease in the temperature of the supplied coolant.

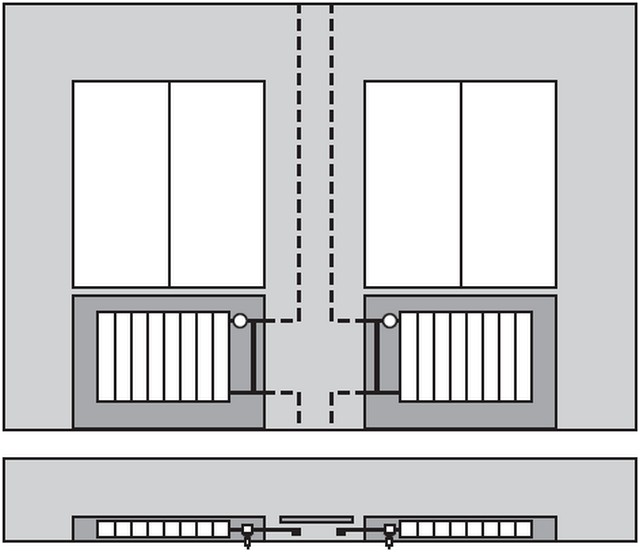

Serial connection of radiators using one pipe for supplying coolant is often used in modern houses to minimize material costs and simplify installation work

Single-pipe circuits can be implemented in horizontal and vertical versions. With forced circulation, if vertical risers are used, hot water can be supplied not only from above, but also from below. The feasibility of using one or another option depends not only on the convenience of pipe installation, but also on the maximum permissible number of radiators on one riser of a single-pipe circuit.

There are two ways to connect heating radiators:

- The coolant flows sequentially through all radiators. In this case, a minimum number of pipes is required, but if it is necessary to turn off one of the radiators, the entire branch of the system will have to be stopped.

- The coolant can flow bypassing the radiator through an installed outlet - “bypass”. Using a tap system, you can redirect the flow past the radiator, which will allow it to be repaired or dismantled without stopping the heating.

A single-pipe circuit is often used for heating, but if there are a large number of radiators, another option is used to heat them evenly.

Single-pipe schemes have many implementation options for forced circulation, so choosing the appropriate solution for a specific room geometry is quite easy

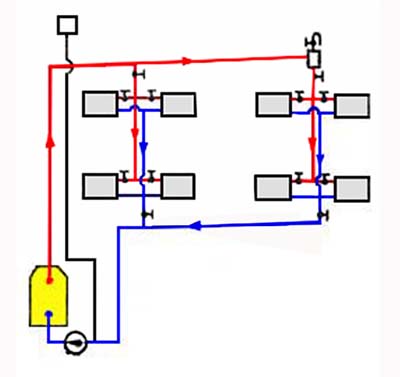

Methods of using the two-pipe version

The heating circuit diagram using a second pipe to drain cooled water to the boiler is called two-pipe. The pipe footage increases, as does the number of connections and devices. However, the main advantage of the system is that coolant of the same temperature is supplied to each radiator. This makes the two-pipe option very attractive.

For water heating with forced circulation, both horizontal and vertical wiring are used. Moreover, when vertical version It is possible to use top and bottom hot water supply.

The two-pipe water supply and drainage circuit, combined with the diagonal connection of the radiator, provides maximum heat transfer to the room

Since the temperature of the water supplied to all radiators is the same, the geometry of the circuits depends only on the following factors:

- minimizing pipe footage and number of connections;

- ease of conducting the heating circuit through walls and ceilings;

- the ability to fit heating elements into the interior of the premises.

Depending on the movement of hot and chilled water, two-pipe circuits are divided into associated and dead-end. In a parallel circuit, movement in both pipes occurs in the same direction. The coolant cycle has the same length for all radiators in this part of the system, so their heating rate is the same.

In a dead-end circuit, radiators located closer to the boiler heat up faster. However, for systems with forced circulation this is not very important due to the significant speed of water in the circuit. Therefore, when choosing between the associated and dead-end options, they are guided by the condition of convenience of installing the return pipe. IN vertical schemes with the lower wiring, a dead-end system is obtained, and with the upper wiring, a passing system is obtained.

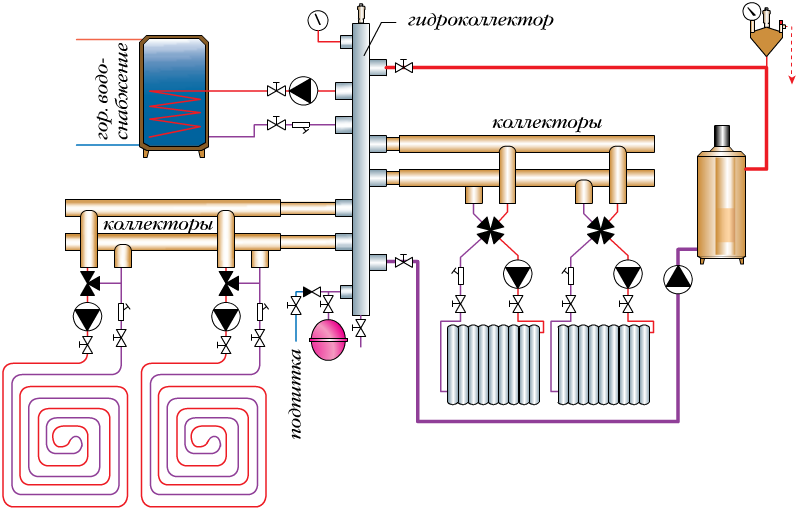

Using a heating distribution manifold

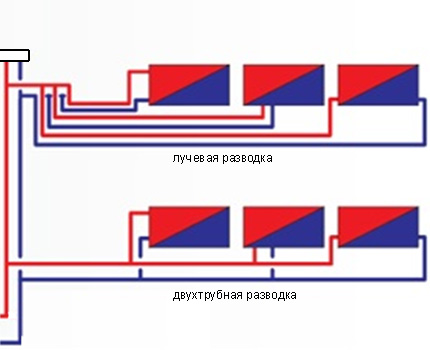

Another popular way to organize heating now is to create a collector or beam scheme. To some extent, this scheme can be called a subtype of two-pipe, although it is also used in the organization of single-pipe heating circuits.

Only the distribution of hot coolant and the collection of cooled coolant occurs not from the main riser, but from special distribution node devices - collectors. Such a system operates stably only using forced circulation.

Beam wiring, compared to two-pipe wiring, requires a larger collector total length pipes, number of fittings and shut-off valves

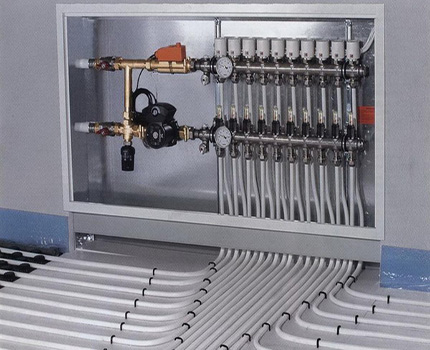

Distribution unit for two-pipe system is a complex combination of supply and return manifolds, with the help of which a coolant supply balanced in temperature and pressure is carried out. Each branch of the device powers one heating element or a small group of them. The branches are usually located under the floor, each floor of a multi-story building is served by one centrally installed collector.

Despite obvious advantages With this type of heating arrangement, the collector system has two significant disadvantages:

- the longest length of pipelines, so this option for organizing a water circuit requires considerable investment;

- pipes with this option are located, usually under the floor or in the walls, so if you add heating devices It will be very difficult to make any changes.

All collectors are usually mounted in a special cabinet, since the shut-off valves are located there and access is required. Placing the taps in one place is very convenient. If there is a need to turn radiators on or off or an emergency occurs, it is enough to have access to the cabinet and there is no need to visit all rooms.

Distribution manifolds can have a simple structure consisting of two combs and a minimum of shut-off valves. Complex components may also include automatic thermostats, electronic valves, mixers, automatic air outlets, sensors and control units, a water drain valve, and a separate circulation pump.

The distribution manifold can contain many devices with which you can easily adjust the temperature anywhere in the house on site

These systems can most accurately regulate the temperature in your home, but require a good understanding of the basics and nuances of hydronic heating.

Heating using underfloor heating

One of the most comfortable heating methods is the organization of a heated floor. It should be noted that installation of this heating option living rooms, showers, kitchens and other rooms are quite complex. Water heated floors over a large area are only possible with forced circulation, since it is necessary to create pressure in a long system of narrow pipes.

Pressure is necessary to overcome the resistance of narrow pipes with many bends. In addition, it is necessary to achieve a pressure that allows air to be removed from the underfloor heating pipes, which are located horizontally.

There are a large number of tube laying combinations. For small rooms, circuits with one inlet for hot water and an outlet for chilled water are used. For large rooms, more complex floor heating systems are organized using distribution manifold. Often, separate circulation pumps are installed for parts of the circuit with heated floors.

The use of a collector is justified for large areas of heated floors, when calculations show that one pipe may not cope with heating

Video examples of systems using a pump

A detailed description of the two-pipe and sufficient complex circuit heating a two-story house:

Open type system based on a solid fuel boiler for a summer residence:

System closed type for a three-story house based on a gas boiler:

The use of pumps for water heating of premises greatly simplifies the design of the circuit, making possible options, inaccessible for the gravity model. Correct selection equipment will solve the issue of home heating, making this process convenient and simple.

IN last years gravitational systems are giving way to more “advanced” ones. Many people ask the question: can a heating system with forced circulation be installed with their own hands?

This is exactly what they are now installing in all new buildings without exception, and this is exactly what heating systems look like inside residential buildings.

This scheme is based on forced circulation due to the difference in pressure, which is carried out by a pump, the latter in this case is called circulation.

Advantages

- Premises that need to be heated heat up much faster and, accordingly, the required air temperature in the room is achieved much faster;

- Heating devices in the network heat up evenly. With natural circulation, the temperature of heating radiators depends on the distance to the boiler;

- It becomes possible to regulate heating in the network in individual sections, as well as shut off part of the circuit. In addition, you can change the diagram and installation of the entire layout heating system building;

- Forced heating prevents airiness in the heating system pipelines;

- The use of a pump makes it possible to make the entire system closed by including a membrane in the circuit expansion tank. The consequence of this is a decrease in water evaporation in the system;

- Installation of the entire system is simplified. There is no need to carefully calculate the heights, lengths, diameters and slopes of pipes for normal circulation;

- The forced circulation heating circuit saves heat. Consequently, fuel consumption is reduced;

- The use of smaller diameter pipelines results in savings during installation. With the same length, the price for pipes of smaller diameter is lower than for pipes larger diameter;

- IN closed systems the temperature difference at the inlet and outlet of the heating boiler is much smaller. Due to this, the service life of boiler equipment increases.

Disadvantages of closed systems

Water heating with forced circulation also has disadvantages:

- A significant drawback of this design is its dependence on power supply. This problem can only be solved by providing the heating system with an independent uninterrupted source of electricity;

- The circulation pump itself, although not very expensive equipment, still has a certain cost, which makes installation of the system itself more expensive. In addition to the pump, it is necessary to purchase fittings to cut it off in the system and normal operation;

- Pump operation requires fixed costs for electricity.

Selecting a circulation pump

There are a number of factors to consider before choosing a pump:

- Type of coolant (antifreeze or water);

- Coolant temperature;

- Pipeline characteristics (material, diameter, length, etc.);

- Heating devices (radiators and radiators), as well as their specifications(heat transfer area, material, design);

- Shut-off valves and control elements;

- Availability and nature of the automatic control system.

Important!

General principle The following should guide you when choosing a circulation pump.

Its performance should ensure three times the coolant turnover in the system per hour of operation at full capacity.

Only if this condition is met will there be good circulation.

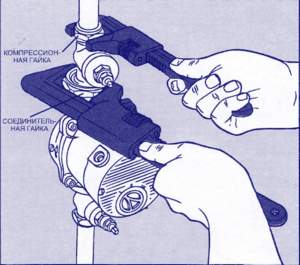

Installation of a circulation pump

What are the main points to take into account when connecting a circulation pump to a circuit?

They are listed below:

- The pump is mounted on the return main pipeline. With this connection scheme, the service life of all devices in the system is extended;

- When connecting the pump in front of it in the circuit, it is highly recommended to include a filter that will protect the impeller from damage due to foreign objects (scale, scale, solid particles, foreign objects, etc.);

- The pump must be de-aerated during connection. For this purpose, a special screw is provided in the pump design;

- The instructions that come with the pump have a calculation of power consumption depending on performance;

- The pump designation indicates the diameter of the pipeline to which it can be connected (in millimeters) and the pressure that this pump creates (in decimeters of water column).

For example, the marking GPD 25-100 means that this pump is connected to a pipe with a diameter of 25 mm and creates a pressure of 10 m.

- When choosing a pump, pay attention to energy consumption;

- The structure must be durable;

- The equipment should not require high maintenance long time;

- The pump must be durable.

Example of approximate calculation of pump power

- For, which gives a productivity of 4 m3 per hour and a pressure of up to 0.5 atmospheres;

- For a house with a total area of 500 m2, you will need a pump with a capacity of 6 m3 per hour and a pressure of up to 0.7 atmospheres;

- For a house with an area of 700 m2, the pump capacity should be 10 m3 per hour, and the pressure should be up to 0.8 atmospheres.

In addition, when choosing a circulation pump, it is necessary to take into account its ability to independently regulate the engine speed. If such a function is present, it increases the service life of the equipment and reduces energy consumption.

It is also worth considering the fact that the forced heating system does not work if there is air in the system (see). For this reason, it is necessary to consider the inclusion of automatic air vents in the circuit.

The video shows how you can install the pump yourself:

conclusions

In the heating scheme described above, the same principles of installation and calculation are used as in the gravitational scheme. Due to the inclusion of a pump in the circuit, there is no need to observe all slopes in a closed heating system.

Including the pump in the return line allows you to prolong the operation of all parts of the heating. The use of forced circulation makes it possible to operate heating systems for a long time.

Among many heating schemes, the system with forced circulation of coolant is distinguished by its versatility and wide functionality. It can be used in the heat supply of a small private cottage or apartment, as well as in a large multi-storey building. Is it difficult to do it yourself, without involving specialists? Let's find out what home heating with forced circulation is with our own hands, diagrams and the optimal configuration of a specific system.

Features of forced circulation heating

Modern water heating with forced circulation replaced the gravitational scheme. In the second, the coolant moves due to the thermal expansion of water when it is heated. This principle significantly reduced the efficiency of heat supply.

One of the determining factors in the feasibility of installing a water heating system with forced circulation is the relatively fast movement of the coolant along the main line. Thanks to this, heat is distributed evenly across all radiators in the circuit.

In addition, it is necessary to note the following features of heating with pump groups:

- Ability to install small cross-section pipes: 20, 25 mm. This reduces the total volume warm water in the system, which affects energy consumption;

- Select from several pipeline installation schemes V. The forced heating system of a private house can be one-pipe, two-pipe or collector;

- Temperature adjustment both for individual elements and throughout the system as a whole. Collector heating copes best with this task;

- Increased operating comfort.

However, along with this, it should be noted the disadvantages that a two-pipe or single pipe system heating with forced circulation. First of all, this is the installation of a pump group to increase the coolant flow rate. This entails an increase in primary costs, and also makes the operation of the entire system dependent on the supply of electricity. But these disadvantages are compensated by the above advantages.

You can upgrade what you already have. To do this, just install a pump. However, first you need to calculate the parameters of the system - not always pipes large diameter suitable for forced circulation circuits.

Types of heating schemes with forced circulation

The basic principle of operation of a forced circulation heating system is to install pumps to increase the flow rate of the coolant. The location of their installation directly depends on the selected piping layout.

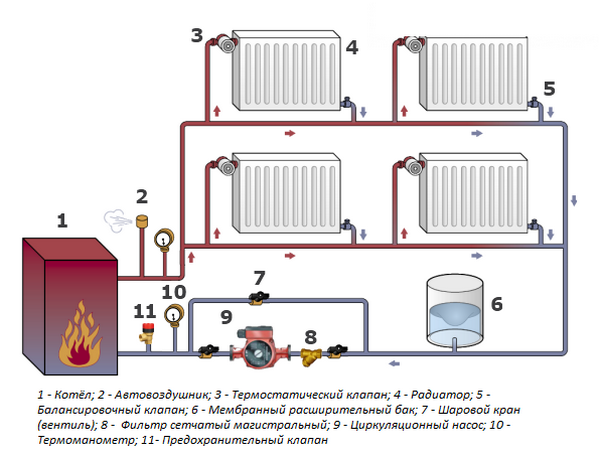

In addition, the heating system of a private house with forced circulation must include safety groups. This is necessary to timely stabilize the pressure in the pipes due to possible overheating of the coolant. Each type of heating with forced circulation has a number of features that directly affect the choice in a particular case. But regardless of this, a do-it-yourself forced circulation heating system, in addition to the pump, should include the following components:

- Security group: air vent and bleed valve. Installed immediately after the boiler;

- Expansion tank. It is best to choose a membrane-type design with the possibility of replacing an elastic valve;

- Each radiator harness must contain balancing valve , Mayevsky crane. It is advisable to install a thermostat;

- Shut-off valves. It is necessary to partially or completely block the flow of coolant in a specific section of the system.

Each of the above components must have performance characteristics, corresponding to the parameters of a specific heating system. Otherwise, they will not perform their assigned functions.

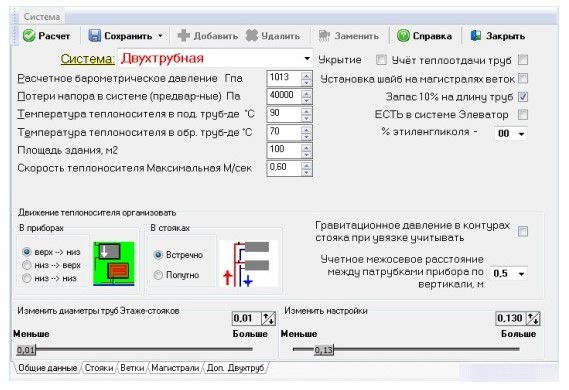

The selection of certain system components is carried out according to a pre-made heating scheme for the house with forced circulation. The calculation must be as accurate as possible - using specialized programs or performed by professionals.

Single pipe system

This is an outdated scheme that is practically not used for individual heating at home. In a single-pipe forced circulation heating system, there is only one supply line, in which radiators and radiators are connected in series.

The only advantage of this scheme is the small footage of the pipelines. However, in addition to this, the single-pipe system has several significant disadvantages:

- Uneven distribution of coolant. The further the radiator is located from the boiler, the lower the degree of heating of the hot water entering it;

- For repair work it is necessary to stop the heating boiler and wait until the coolant temperature drops to normal levels.

Pump power for single-pipe heating with forced circulation it will be much less than for a two-pipe one. This is due to the smaller volume of coolant in the system. Also for laying pipelines it is necessary less space– they can be installed under the floor, baseboards.

For a single-pipe heating system with forced circulation, it is necessary to provide for the installation of a bypass for each radiator. This will make it possible to turn off the device without completely stopping the heating supply to the house.

Two-pipe system

The design of a two-pipe heating system with forced circulation differs from a single-pipe one by the presence of another line for the cooled coolant. It runs parallel to the main one and receives cooled water from the radiators.

When designing a system, it is necessary to correctly draw up the piping layout. The forward and return lines must be installed in close proximity to each other, but no more than 15 cm; in addition, the system can be with one direction of coolant movement, with different vectors, or a dead-end one. Most often, a one-way directional scheme is chosen.

Water heating with forced circulation has several important features:

- Small pipe diameter - from 15 to 24 mm. This will be enough to create the required pressure indicators;

- Possibility of installing both horizontal and vertical piping;

- A large number of rotating elements will affect the hydrodynamic performance of the system for the worse. Therefore, they need to be done as little as possible;

- When choosing hidden installation, inspection hatches are installed at the pipe joints.

In each forced system heating a private house, it is necessary to provide a bypass channel in the circulation pump assembly. It is designed for gravitational movement of the coolant in the event of a power outage.

Job pumping equipment must ensure normal circulation in the system. To do this, you must correctly calculate its power and performance.

If a water heating system with forced circulation is equipped with polymer pipelines, they must be with reinforced layer from aluminum foil or polyester.

Collector system

If the area of the house exceeds 150 m² or it has 2 or more floors, it is recommended to collector system heating with forced circulation with your own hands. It is one of the modifications of the two-pipe scheme and is designed to increase the efficiency of heat supply.

The main element of the manifold heating circuit is the distributor. It is a pipe with a round or rectangular cross-section, on which several pipes are installed. They are necessary for distributing the coolant throughout the individual heating circuits of the house.

A distinctive principle of operation of a heating system with forced circulation of a collector type is the arrangement of pipelines independent from each other. This makes it possible to regulate the heat transfer of each of them, and also stabilizes the pressure in the system.

A circulation pump is installed on each collector pipe to ensure the proper flow rate of the coolant. Such a heating system for a private house with forced circulation has a number of important features:

- Increase in the number of pipes and fittings. Each circuit is a separate heating system connected via a manifold into a single network;

- To adjust the volume of coolant, special elements are required - thermostats and servos with temperature sensors;

- For the most efficient work system, it is recommended to install a mixing unit. It connects the forward and return pipes and mixes the water flows to achieve optimal temperature coolant.

A manifold heating circuit for a house with forced circulation can consist of several distribution nodes. It all depends on the total area of the house, as well as the location of the premises in it.

The sum of the diameters of the pipes on the collector should not exceed its cross-section. Otherwise, pressure destabilization in the system will occur.

Design of heating with forced circulation

The first priority when self-installation water heating with a circulation pump is to draw up the correct diagram. To do this, you need a house plan, which shows the location of pipes, radiators, shut-off valves and safety groups.

System calculation

At the stage of drawing up diagrams, it is necessary to correctly calculate the parameters of the pump for the forced heating system of a private house. To do this, you can use special programs or do the calculations yourself. There are a number simple formulas which will help you make the calculation:

Pn=(p*Q*H)/367*efficiency

Where Rn– rated pump power, kW, R– coolant density, for water this figure is 0.998 g/cm³, Q– level of coolant flow, l, N– required pressure, m.

To calculate the pressure indicator in a forced heating system at home, you need to know the total resistance of the pipeline and heat supply as a whole. Alas, it is almost impossible to do this on your own. To do this, you should use special software systems.

By calculating the resistance of the pipeline in a water heating system with circulation, you can calculate the required pressure using the following formula:

Н=R*L*ZF/10000

Where N– calculated pressure, m, R– pipeline resistance, L– length of the largest straight section of the highway, m, ZF– coefficient, which is usually equal to 2.2.

Based on the results obtained, it is selected optimal model circulation pump.

If the estimated pump power of a self-installed forced circulation heating system is high, it is recommended to purchase paired models.

Installation of heating with circulation

An example of hidden installation of collector heating

Today there is a return of interest from the engineering community to such a heat supply tool as a single-pipe heating system with forced circulation in multi-storey and individual construction. In the early 90s, it was rejected by domestic heating engineers after three decades of uncontested and widespread predominance in buildings of any number of floors and purposes. Traditional, fundamentally uncontrollable single-pipe heating did not fit into the concept of energy-efficient housing, and in the last two decades it has been widely replaced by two-pipe heating. But modern single-pipe designs combine their traditional advantages (hydraulic stability, efficiency) with the ability to regulate heating devices, as in their two-pipe counterparts.

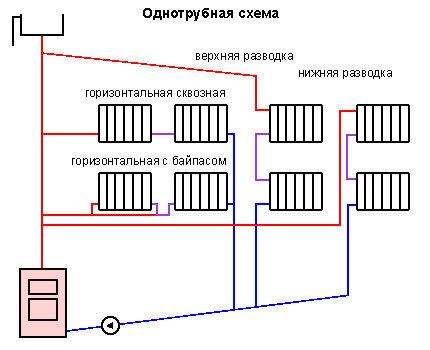

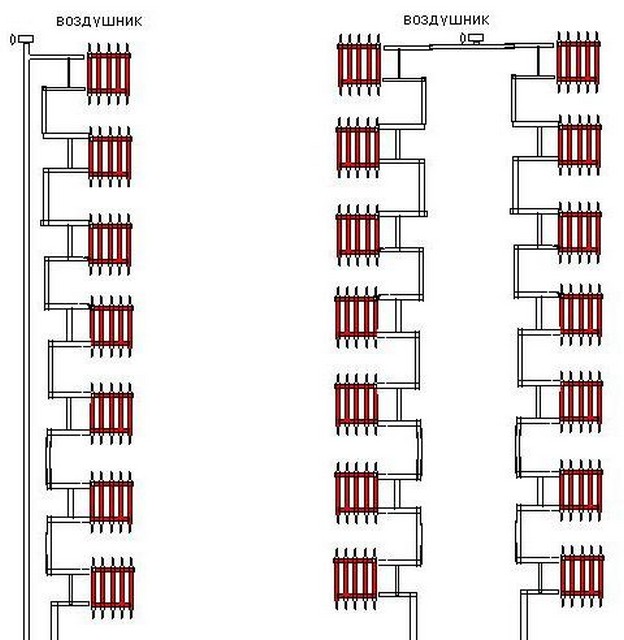

Traditional radiator piping for single-pipe heating

If you live in apartment building buildings of the Soviet period, then take a look at the battery connection. A vertical pipe emerges from the ceiling, bends horizontally and enters the upper manifold of the heating device. A second horizontal pipe emerges from the lower manifold, bent vertically downwards and passing through the floor to the lower floor. A vertical closing section, the bypass, is welded between the horizontal pipes. This is a vertical single-pipe system with lateral battery connections.

Features of the operation of traditional single-pipe heating

Typical diagrams of vertical single-pipe risers are shown below

On the “tying” of batteries in Soviet time no control devices were installed. The first devices along the water flow are heated hotter than the last ones. The temperature difference in the batteries is calculated using the formula ∆T_р=∆T⁄N, where N is the number of floors. One-pipe risers force N and 2N times more liquid to circulate than two-pipe risers, with 80% of its volume flowing through bypasses.

This irrational (from the point of view of energy costs for pumping liquid) design was used because of its extreme simplicity and efficiency. The low price of electricity, maintained for political reasons, did not stimulate energy savings when forced circulation of excess coolant volume.

Single-pipe heating systems are hydraulically very stable and insensitive to unauthorized replacement of radiators or increasing the number of their sections. Disabling individual batteries almost does not change the heat transfer of other devices. After all, water mainly passes through bypasses. But two-pipe heating systems will inevitably become unbalanced.

New single-pipe heating systems for apartment buildings

Russian new buildings are equipped with single-pipe radiator units with thermostatic valves (thermostats). They look as shown in the photo below.

Such heating systems are 30–40% cheaper than their two-pipe counterparts and have high hydraulic stability. But do they provide a level of operating comfort? two-pipe schemes, determined by the following components:

- automatic stabilization mode set temperature in each room;

- overall energy savings in the heating system;

- possibility of hidden pipe laying;

- apartment heat metering.

Let's evaluate the single-pipe heating option according to these criteria.

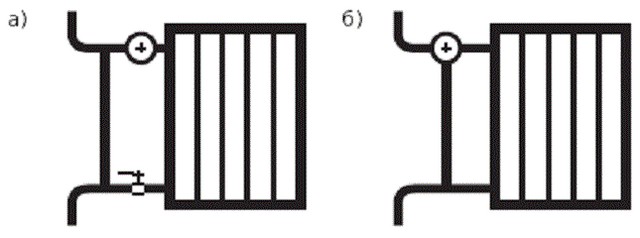

Local automatic temperature stabilization

An adjustable radiator unit for vertical single-pipe heating can be made with a straight-through (Fig. a) or three-way (Fig. b) thermostatic valve (thermostat). The piping unit branches the coolant into two flows: through the device and through the bypass. The diameters of the thermostat valve plunger and the opening for the passage of liquid are made to the maximum. The thermostat does not clog when the coolant is contaminated and ensures its free flow (when fully open). Unauthorized replacement of the radiator, accompanied by removal of the thermostat, does not lead to imbalance of the entire heating system, as in the two-pipe version.

If the temperature room air exceeds the set value, the valve will close (go to minimum mode), directing the liquid through the bypass past the radiator. Closing (minimum opening) the valves of all thermostats of a given riser increases the proportion of coolant passing through the bypasses from 80% to 90%, while simultaneously reducing the flow through the radiators, i.e. without changing the total flow rate.

Does a single-pipe forced circulation heating system save energy?

In the two-pipe heating option, heat energy is directly saved. When rooms overheat, thermostats reduce the flow of coolant through heating devices, and at the same time its flow through the risers decreases, i.e. the excess volume does not circulate through the pipes.

In a single-pipe heating system with thermostats, when the rooms overheat (when their valves close), the overall forced circulation of liquid does not decrease - it simply does not enter the batteries, and, accordingly, does not cool down in them. Heat energy is not saved here, but it is not wasted either, remaining in a stable volume of heated coolant. But its temperature in the “return” increases, which leads to an increase in losses in pipelines. However, in heating points apartment buildings powered from the return line DHW heat exchanger(if available), in which the water cools before returning to the boiler room.

Hidden pipe laying for single-pipe heating

When hiding pipes in the walls, thermal insulation for heating pipes is used, which increases the efficiency of such installation. Shown below general form laying hidden single-pipe risers and horizontal connections from them to radiators in niches.

To install apartment heat metering, if there are two-pipe vertical risers in the house, you can use horizontal single-pipe apartment heating distribution with hidden pipes laid under the floor or behind a decorative baseboard.

Combination of two-pipe and single-pipe options

In private two-story (or higher) houses, both two-pipe and single-pipe vertical risers can be used, along with horizontal single-pipe wiring to rooms with a variety of ways to connect heating devices.

The temperature difference in room radiators in this case is calculated by the formula ∆T_р=∆T⁄P, where P is the number of heating devices connected in series (in this case P=3). A horizontal single-pipe main must carry P times more liquid than through horizontal pipes with two-pipe wiring. This will require an increase in pump power for its forced circulation and high energy costs, but the hydraulic stability of the circuit will be high.

Options for single-pipe heating of a private house

Below is a simple diagram with bottom connection of radiators.

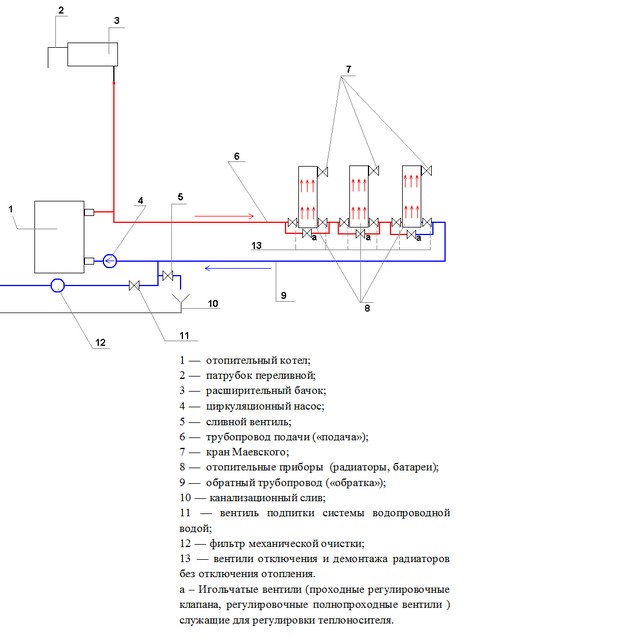

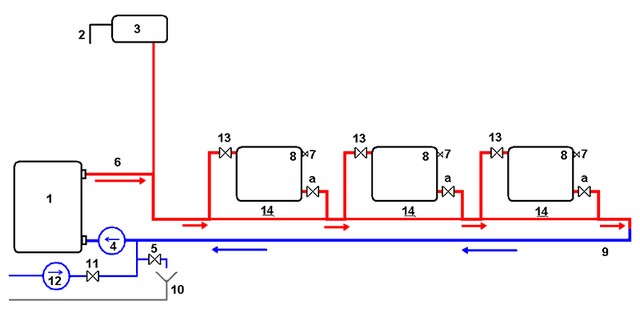

The system refers to open type– its expansion tank 3 is connected to the atmosphere. Overflow pipe 2 serves to release air and drain water during the initial filling of the circuit. Shown above is a single-pipe heating system with forced circulation, which is provided by circulation pump 4 installed on the “return” in front of the boiler. This is due to the fact that the temperature of the liquid in the “return” is lower than in the “supply”, and operating the pump at a lower temperature of the pumped coolant simply increases its service life.

There is a supply of network water through filter 12 and make-up valve 11 (the system is also initially filled through them). Drain the water (for repairs and upon completion heating season) through valve 5 and sewer drain 10 with valve 11 closed.

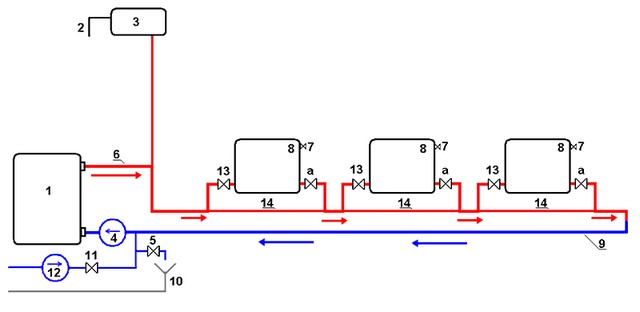

Applied bottom connection 7 radiators, i.e. Only their lower collectors are connected to the pipes, and the outlets of the upper ones are plugged. Devices are installed in the bypasses (indicated in the diagram by the letter “a”) to regulate the flow (needle valves), but more is possible simple circuit without them. It is shown below and is called “Leningradskaya”.

In it, the closing sections 14 are bypasses in their pure form without shut-off or control valves with a diameter less than the main pipeline. At the same time, part of the flow through the batteries increases, but it also cools faster, since more cooled water is mixed into the general flow as it flows. In private homes, this is done in order to reduce its overall consumption (and, accordingly, the electricity consumption of pump 4 for forced circulation), as well as to increase the heat transfer of the batteries, although they warm up very unevenly.

It is possible to connect heating devices diagonally, as shown in the diagram below.

Here, the uneven heating of the batteries in the chain remains (and even becomes higher), but the heat transfer of each of them increases by several percent due to the intensive flow of water around them with the simultaneous presence of forced and natural circulation. After all, its temperature at the entrance to the upper collector is several degrees higher than at the exit from the lower one, due to cooling in the device itself. Therefore, conditions arise for the natural circulation of water through the batteries (as in corresponding systems without pumps). The pressure in bypass 14 will not allow this flow to close, but it will rise up to valves 13 quite intensively.