Gas turbocharged wall-mounted heating boilers. Turbocharged gas boiler for heating

IN Lately Among gas boilers, turbocharged models are the most popular.

What are such boilers and why are they in demand? Features of equipment with a closed combustion chamber. I will try to answer these and some other questions in this article.

Wall mounted gas boilers, depending on the method of removal of combustion products, there are two types:

- natural draft boilers;

- gas turbo heating boilers, or forced draft boilers.

turbo boiler for a residential building  Domestic boilers for are heating systems using thermal energy, released as a result of gas combustion, to ensure the operation of the system itself and to heat the room.

Domestic boilers for are heating systems using thermal energy, released as a result of gas combustion, to ensure the operation of the system itself and to heat the room.

Heat circulation occurs, most often forced (forced using circulation pump), part of which is given for heating, part is returned to the boiler, after which a repeat cycle occurs.

The difference between boilers with a closed combustion chamber

Installation of natural draft boilers ( open type) will be justified if the room already has a traditional chimney and the possibility of taking air from the room to the burner. If these conditions are met, combustion products will be discharged through the chimney due to the presence of natural draft in it.

Gas turbo heating boilers closed type are more modern look heating equipment and have a number of advantages during installation and operation. Boilers of this type can be recommended for installation in almost all types of premises.

For a turbocharged boiler with forced draft, install coaxial chimney, leading out onto the street through the nearest wall.

This chimney consists of two pipes of different diameters. Outer pipe serves to supply air to the burner, the internal one is used to remove combustion products. Built-in fan provides forced exhaust gases and air supply. The coaxial outlet can have a horizontal or vertical configuration.

This chimney consists of two pipes of different diameters. Outer pipe serves to supply air to the burner, the internal one is used to remove combustion products. Built-in fan provides forced exhaust gases and air supply. The coaxial outlet can have a horizontal or vertical configuration.

Also, boilers with a closed combustion chamber can be divided into single and double-circuit.

Single-circuit models are intended only for heating, and gas double-circuit turbocharged heating boilers can not only heat the room, but also heat water for hot water supply.

Popular forced draft models

There is a wide variety of boilers on the market today of this type from various manufacturers.

chimney for forced draft boiler  Let's look at several popular turbocharged models with closed combustion chambers for.

Let's look at several popular turbocharged models with closed combustion chambers for.

THERM PRO 14 TL– wall-mounted closed-type turbo boiler with a power of about 5-14 kW; works for natural gas or propane. This model is best suited for heating rooms up to 120 m2 – small apartments, offices, etc. The average cost is 20 thousand rubles or less.

Eurostar ZWE 24-4 MFA– double-circuit gas heating boiler from the manufacturer Junkers. It has a power of up to 24 kW and is designed for heating medium-sized rooms - up to 230 m2. The approximate cost is 35 thousand rubles.

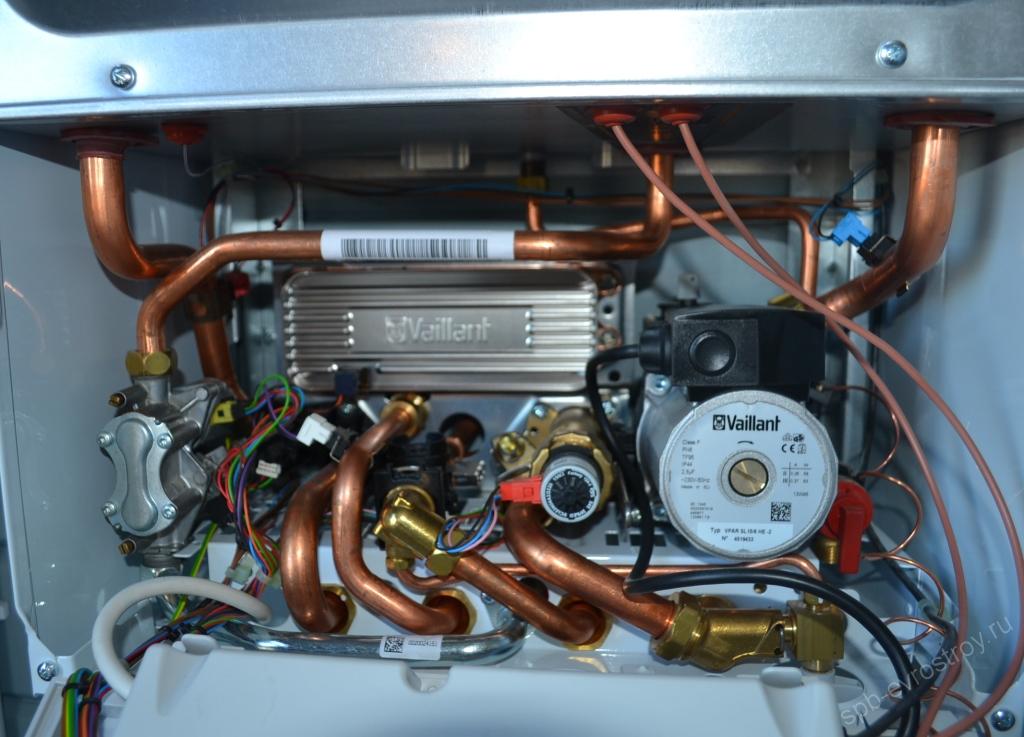

Vaillant turboTEC Plus/Pro– a medium-power single-circuit turbo boiler with good performance characteristics and designed for heating rooms of 30-220 m2. The approximate cost is 30-40 thousand rubles.

Viessmann Vitopend WHO A617- a double-circuit boiler with a strict design and designed for heating rooms up to 230 m2. Operating power – 10.5-24 kW. The approximate cost is 38-39 thousand rubles.

Perhaps only in hot equatorial countries there is no need to use stationary heating systems. The rest are forced to make a lot of effort to create coziness and comfort in their home, installing and operating various kinds heaters. It is obvious that in megacities and major cities the issue is resolved by connecting to central heating systems, as well as hot water supply. True, a number of nuances may arise that will make connecting to central systems impossible. In this case optimal solution can be considered the installation of gas turbocharged double-circuit boilers, with the help of which you can arrange an individual heating and hot water supply system.

The general appearance of almost any standard dual-circuit heating system consists of a combination of a boiler and a boiler operating in a traditional closed-loop manner, while at the same time the boiler is connected to the water supply system.

In general, we can say that a double-circuit gas turbo boiler plays the role of a full-fledged mini-boiler, successfully placed in a compact housing. If necessary, you can turn off any of the circuits, for example, in the warm season, when there is no need to heat your home, but you need to ensure the organization of hot water supply.

Such separation makes it possible to significantly optimize the consumption of blue fuel, reducing its consumption to a level that is determined by the operation of separate independent systems with boiler and boiler. Such quality double-circuit boiler along with its other technical and economic indicators and compact dimensions make it the most popular device for creating an “ideal” hot water supply and heating system.

What is a turbine for?

In most cases, heating boilers are large in size, which is due to the need to obtain a significant volume of oxygen required for fuel combustion. Obviously, expanding the air duct and increasing the size of the combustion chamber can increase the power of the boiler.

In this regard, a double-circuit gas turbocharged boiler differs from its standard counterparts in its rather small combustion chamber. What are its design features, which made it possible to significantly reduce the dimensions?

The design of the boiler provides for the supply of air into the combustion chamber not naturally, but through its injection under pressure. To remove combustion products and supply air in double-circuit turbocharged gas boilers, powerful turbines (fans) are used. It should be noted that the combustion chamber remains isolated from the room in which the boiler is located, which determines not only the high power of the equipment, but also its high level security.

A boiler with a closed combustion chamber should be installed next to outer wall to ensure sufficient air supply. If this is not possible, you should resort to the use of pipes large diameter, through which air will be supplied. It is important to place the boiler in such a way that the length of these pipes is minimal. The allowed air duct length is 3 m; if this figure is exceeded, the boiler power can be significantly reduced due to air shortage.

When installing a turbocharged gas boiler It is necessary to provide good wind protection because the wind can change the incoming flow into the chamber. In addition, it would not be superfluous to prevent atmospheric moisture from entering the combustion chamber.

Installation diagrams

Features of the installation of gas turbocharged boilers are determined by their design features and dimensions. In addition to floor and wall-mounted models, you can also find those that can be built into pieces of furniture. Such capabilities are achieved by the small dimensions of fairly powerful turbocharged boilers, as well as the presence of an insulated combustion chamber, which minimizes the likelihood of a fire. Below we will discuss the main options for installing turbocharged gas boilers.

Floor-standing

Floor standing boilers have high power and are therefore the largest among model range turbocharged gas equipment. As a rule, for an apartment or small private house such power is excessive, and therefore floor standing boilers used in production or in homes with large area at least two floors high.

In addition to high power, another positive aspect of floor-standing boilers is the ease of installation and connection work due to the external location of the structural elements. It is possible to carry out installation work independently, however, when connecting to the gas main, you will still have to resort to the services of qualified specialists, who will not only connect the boiler, but also carry out commissioning work.

The disadvantages of powerful turbocharged boilers floor type This can be attributed to their high cost, heavy weight and dimensions. When installed in small rooms the operation of such a boiler may be associated with excessive fuel consumption due to excessive installation power.

Wall and built-in

In this category there are boilers of medium and low power, used in organizing hot water heating for small houses and apartments. These devices are compact and light in weight, and equipped with a mounting system, they can be built into furniture or hung on a wall.

When installing a heating system in limited space, wall-mounted gas turbocharged boilers are the most optimal solution. Obviously, the operation of such boilers guarantees a reduction in costs, which is due to lower fuel consumption. At the same time, built-in boilers can be installed in almost any room of the house - in the bathroom, kitchen, dining room and even in the pantry.

The only drawback of a wall-mounted turbocharged double-circuit gas boiler is its low power, which is enough to heat a house with an area of no more than 200 sq.m. True, this figure is considered sufficient for a spacious apartment and one-story house medium size.

How to choose

When installing heating systems, one of the most significant difficulties The choice of an appropriate heating device is considered. When purchasing a double-circuit gas turbocharged boiler, you need to focus on the most important indicator- its power. In some cases it is indicated in kW, but in most cases manufacturers base this indicator on the area of the heated room. To independently determine the required boiler power, divide the heated area by ten, and multiply the resulting figure by the ceiling height, divided by 2.5.

Another important selection criterion is the volume of the boiler, on which the quantity directly depends. hot water when organizing hot water supply. On average, this figure when operating double-circuit turbocharged boilers is within 10-12 liters of hot water, which is enough for a family of 2-3 people. For big family you will need a boiler with a large boiler that can produce up to 20 liters of hot water.

As for specific manufacturers of double-circuit turbo boilers, the following German and Italian companies have proven themselves best, the quality of their products has been tested for many years under various operating conditions:

- Ariston Hotpoint;

- Vaillant;

- Immergas;

- Jankers.

Despite the apparent simplicity of installation work, when installing turbocharged gas boilers you will have to take into account a lot of subtleties, so the best solution a specialist will be involved. In addition, in the dynamically developing heating sector, there may be many optimal innovative solutions that you won’t even be aware of - they can not only make it easier installation work, but also provide a more stable and reliable operation the entire system in the future.

It is a double-circuit turbocharged boiler running on gas that will be an excellent option for the heating system of a private home or cottage. These are predominantly wall-mounted compact devices that have a closed combustion chamber. The turbocharged boiler is designed to operate in a local heating system with forced circulation water as a coolant.

Technical and design features of turbo models

The main design features of turbo boilers are the active flow of oxygen into the system, thanks to the built-in fan, creating forced draft through a two-channel chimney. This is the key difference from other types of gas boilers. The special structure of the chimney is a pipe in a pipe. The outer one is a more voluminous pipe, it serves to allow air to enter the system, and the inner one, a narrow one, removes smoke and combustion products.

Of course, a turbo boiler can be single-circuit; there are different models.

Such boiler models are especially appropriate, where compact dimensions and a chimney pipe built into the boiler are a tangible advantage if it is not possible to make a full-fledged chimney system in the house.

The principle of the structure of the chimney pipe of a turbocharged boiler is shown in the diagram.

Type of chimneys in turbocharged boilers:

- vertical;

- horizontal;

- vertical two-channel;

- connecting to an existing chimney.

Turbo boilers are also divided according to the type of connection:

- single-circuit;

- double-circuit.

is intended only for heating the coolant in the heating system. A single-circuit option is purchased in the case when hot water supply is provided by an already installed boiler or the like. If you don’t have or don’t want to buy two separate devices, if you can save money and buy one instead single-circuit boiler choose dual circuit type connections.

is intended only for heating the coolant in the heating system. A single-circuit option is purchased in the case when hot water supply is provided by an already installed boiler or the like. If you don’t have or don’t want to buy two separate devices, if you can save money and buy one instead single-circuit boiler choose dual circuit type connections.

The design of turbo boilers, which includes two circuits, conducts the coolant into the heating system of the house using the external circuit, and the second, internal circuit, provides hot water for household purposes.

The best-proven dual-circuit connection system for heating boilers is the key to savings and stability of operation not only local network heating the house, but also hot water supply at any time of the year.

Any model of gas boiler with connection has a secondary heat exchanger, which is one of the main parts of the multifunctional device. This structural element is designed specifically to provide hot water, which through inner circuit, through taps, returns to the system and to the heating circuit.

The mandatory presence of a fan in turbo models is required to ensure the required thrust and stable removal of gas combustion products.

Gas heating boilers, depending on the dimensions and design features, can be floor-mounted or wall-mounted. Floor-standing models are more powerful than wall-mounted ones, but wall-mounted ones are used to save space in small rooms. Differing in their dimensions, floor-standing models take up more space and often require a separate room for their placement.

Principle of operation

The combustion chamber in heating boilers is closed. Through a coaxial chimney pipe, with the help of a fan, air enters the chamber, which supports the gas supplied from the nozzles (this process is shown in the diagram). Gas combustion products are removed by the turbine to the outside through inner tube chimney, which is much better if a similar process occurs through a regular chimney.

With the help of automation that monitors the process, the operation of the device becomes safe. The combustion chamber of a wall-mounted device is made of copper or copper alloys. The floor-standing boiler has a chamber made of cast iron and, thus, lasts longer than the wall-mounted prototype - 20-30 years or more, depending on the duration and nature of operation. A wall-mounted unit will not always last longer than 10 years.

Gas heating boiler – best option heating country house in the case of a centralized gas main. Gas heating boilers differ in design and functional characteristics.

Double-circuit boiler

- Number of heating circuits;

- Power;

- Design;

- Functionality and use of automatic controls.

Advantages and classification of double-circuit boilers

Among this set, a double-circuit turbocharged gas boiler stands out, which, unlike single-circuit boilers, provides thermal energy not only to the heating system, but also to the hot water supply system of the house. This is the best option, since there is a constant need for hot water.

Double-circuit heating boilers have a number of advantages:

- Economical gas consumption;

- Compact dimensions;

- Easy installation;

- Light weight;

- There is no need to equip an additional boiler room.

By design, double-circuit heating gas boilers are:

- Floor-standing;

- Wall-mounted.

By functional features they are divided into boilers:

- WITH open camera combustion;

- With a closed combustion chamber (turbocharged).

About how much they cost cast iron batteries, what they are, as well as advantages and disadvantages at this link:

Operating principle of a turbocharged double-circuit boiler

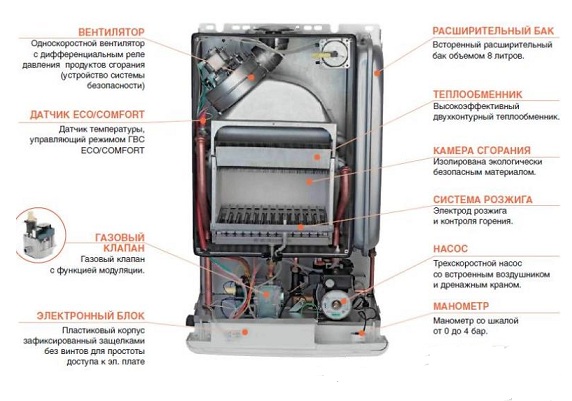

Boiler structure

The principle diagram of the operation of a double-circuit heating boiler is quite simple. The primary circuit provides hot coolant water to the components of the heating system: radiators, heated floors, coils in the bathroom for drying clothes. The secondary circuit is designed to supply water to the hot water supply system. Moreover, heated water can be used in two ways:

- After heating, it enters the boiler for storage, from which it goes into faucets in the kitchen, bathroom, shower, etc.

- Water flows from the heat exchanger of a gas heating boiler directly to consumers.

The advantage of the first method is the economical operation of the boiler, since heating water using the second method requires a boiler of greater power. However, in the first case, it is necessary to purchase an additional water container - a boiler.

Also, gas double-circuit boilers for home differ in the type of heat exchangers:

As noted above, the boiler can have an open combustion chamber. In this case, for its operation, it is necessary to install the chimney in accordance with all the requirements. Also, to maintain the combustion process, a constant supply of air from the room is required, so such boilers are installed in spacious rooms.

In case of installation closed chamber combustion boiler is called turbocharged. In this case, it does not need a chimney system. To remove combustion products, a fan built into the boiler is used; a similar fan provides the air necessary for combustion.

For these purposes, a coaxial double-circuit pipe is used, through the external circuit of which combustion products are removed, and air from the street is supplied through the internal circuit.

As a result of use turbocharged With the gas heating boiler option, there is no need for additional boiler room space, since there is no chance of smoke entering the living space. Also all heating installation takes less space, since there is no chimney in its design.

- Thermal insulation of the structure;

- Tightness;

- Economical gas consumption, since forced supply sufficient quantity air ensures more complete combustion of gas;

- Fully automated operation of the air-injecting turbine;

- Such boilers are equipped with special gas supply sensors, so the amount of gas consumed is minimal;

- High productivity – up to 12 liters of hot water per minute.

Design options

As noted above, double-circuit turbocharged gas boilers can be wall-mounted or floor-mounted. Let's take a closer look at their features.

Floor-standing gas boilers are characterized by high power, and gas consumption remains almost the same as that of less powerful wall-mounted ones. Most designs of floor-standing gas double-circuit boilers are equipped with a cast iron heat exchanger, which has a long service life, as it is resistant to high temperatures and corrosion damage.

Also, floor-standing boilers have a large water storage volume, therefore they provide more comfortable use of hot water in the hot water supply system when implementing a flow-through supply system.

The disadvantages include the rather large weight and high cost.

The design of a wall-mounted turbocharged heating boiler includes the following elements:

- Turbocharged burner;

- Circulation pump and expansion tank;

- Measuring automation.

Main difference from floor option– installation method. Mounted double-circuit gas boilers using anchor bolts are fixed on the wall.

The advantages of a wall-mounted gas boiler include:

- Compact size and light weight;

- The cost is approximately 2 times lower than that of the floor option;

- Ease of operation and inexpensive maintenance;

However, the disadvantage wall-mounted boiler, in comparison with the floor one, is the use of a steel or copper heat exchanger, which quickly burns out and needs to be replaced.

Bottom line

As you can see, a double-circuit gas boiler - great option for organizing heating and hot water supply systems in the house. It's better to give preference turbocharged option that requires less room space for installation.

Regarding the choice between floor and wall-mounted option, then choosing a wall-mounted one is worth it for a compact room with small planned material costs Oh.

A floor-standing double-circuit gas boiler for a home requires more installation space and material costs, but is more reliable and productive.

Video on how to choose a double-circuit turbocharged gas boiler

The video will tell you about the types of double-circuit boilers and their functionality

What is a double-circuit heating system?

Turbocharged gas boilers

Probably only in hot countries close to the equator do they not use stationary heating systems. The rest have to use various types of heaters to create comfort and coziness in their house or apartment. Of course, in large cities in most cases this problem is solved by connecting to central system heating and hot water supply. However, this possibility is not always available. In this case, experts recommend installing a double-circuit turbocharged gas heating boiler.

IN general view any dual circuit heating system is a combination of boiler and boiler. In this case, the boiler operates according to the traditional scheme using a closed circuit, while the boiler uses its own tank connected to the water supply system. In general, a gas double-circuit turbo boiler is a full-fledged boiler room located in a convenient compact building.

If necessary, one of the circuits of such a system can be turned off - for example, in the summer there is almost never a need to heat a house or apartment. This opportunity allows you to significantly reduce gas costs by reducing its consumption to the level of a separate system with a separate boiler and boiler operating independently of each other. Combined with unrivaled ease of use, this makes the dual-circuit heating system ideal for residential areas.

Why is a turbine needed?

Heating boilers, as a rule, have quite large dimensions. This is due to the need to obtain a large volume of oxygen needed for fuel combustion. Accordingly, to increase power it is necessary to expand the combustion chamber and air ducts. However, a turbocharged dual-circuit engine takes up quite a bit of space and is content with a very small combustion chamber. What is his secret?

In this design, air does not enter the combustion chamber naturally, but is forced under pressure. Powerful fans (turbines) are used as a means of supplying air and removing exhaust gases. In this case, the combustion chamber itself remains closed and does not communicate with the room in which the boiler is installed. Thanks to this, turbocharged boilers not only have great power, but are also absolutely safe.

Boilers with a closed combustion chamber must be installed close enough to external wall to ensure the required air flow. If this is not possible, large-diameter pipes are used to supply air, but they should not be long. Experts indicate that the optimal length of the air duct is up to 3 meters.

Important! When installing a turbocharged boiler, it is necessary to ensure high-quality protection from wind, which can significantly change the characteristics of the air flow inside the combustion chamber. In addition, it is desirable to prevent moisture from the ambient air from entering the combustion chamber.

Installation diagrams for a turbocharged double-circuit boiler

Depending on the size and design features a gas double-circuit turbo boiler can be installed both on the floor and on the wall or even in pieces of furniture. This is made possible thanks to the relatively small sizes powerful heating installations with a turbine, as well as the presence of a closed combustion chamber that does not create fire danger. Let's consider the features of the main options for installing a turbocharged boiler.

Floor standing boilers

Vaillant atmoVIT

Boilers intended for installation on the floor have sufficient large sizes, and, consequently, high power. Often this power is excessive for small house or apartments. That is why, in most cases, floor-standing double-circuit boilers are used in enterprises or in large private houses with a height of 2 floors or more.

In addition to high power, the advantage of such models is ease of connection. All structural elements the floor-standing boiler is located outside, which allows it to be connected to the gas pipeline and water supply system, as well as included in the heating circuit. At the same time, work on installing such a boiler can be carried out by workers without special skills. However, to supply gas it is still necessary to use the services of a specialist.

The main disadvantage of large and powerful floor-standing boilers, of course, is their high cost. In addition, they have a large weight, which does not allow them to be placed in apartment buildings. And, of course, high power also means high fuel consumption, which can be excessive for a small room.

Wall-mounted and built-in boilers

Wall boiler

This category includes small heaters of low and medium power intended for heating private houses and apartments. Unlike floor models, they are quite light in weight and have a fastening system that allows them to be placed on a wall or in furniture. Wall-mounted are perfect solution for those cases where the heating system must be installed in limited space.

Of course, such boilers consume less fuel and require lower costs. In addition, they can be installed hidden - that is, built into certain interior items. Built-in boilers can be located in various parts apartments or houses - in the kitchen, bathroom or even pantry.

There is only one drawback that a turbocharged double-circuit wall-mounted gas boiler has. This is his power. As a rule, the heat produced by such models is enough to heat 180-200 sq.m. However, this indicator is quite enough for heating large apartment or medium sized houses.

How to choose a double-circuit turbocharged boiler?

One of the most significant problems associated with heating systems is choosing a suitable boiler. When purchasing a dual-circuit turbocharged unit, you need to focus on its power. As a rule, the manufacturer indicates the area that the boiler can provide heat. However, if it is not indicated, you should pay attention to the power in kilowatts.

Important! To determine the required power, you need to divide the area of the room by 10 and multiply by the ceiling height, divided by 2.5.

Kitchen with built-in boiler

In addition, the choice should be made regarding the provision of hot water supply. On average, double-circuit gas boilers produce 10-12 liters of hot water, which is enough for one or two consumers. However, for a large family a larger volume is needed - about 20 liters, which requires an appropriate boiler volume.

And finally, it’s also worth mentioning the manufacturers. The most famous are Italian and German companies producing double-circuit heating systems:

- Vaillant

- Junkers

- Ariston Hotpoint

- Immergas

The quality of their products is confirmed by decades of experience in a wide variety of conditions.

Finally

Despite the apparent simplicity of installation of gas double-circuit turbocharged boilers, it is necessary to take into account a lot of nuances. Therefore, to install such a unit, it is best to invite a specialist in this field. In addition, in the heating sector, as in all sectors of construction, innovative technologies are constantly emerging. technical solutions. Therefore, before making your final choice, you should carefully study the various offers on the boiler market.