Why does the Baxi boiler not heat the water? The boiler does not heat hot water

This video is the solution to your problem!

Watch to the end and you won’t need to call a specialist.

It is impossible to survive without boiler houses in the climatic zones of Russia. Moreover, this also applies to the warmest regions, Sochi, Anapa and Rostov-on-Don. Winters are still harsh and people cannot survive without heating. Because we can do without heating systems And you definitely won’t get hot water. And only boiler houses can provide the city with all this. Today we'll look at the reasons why the boiler does not heat water- how to solve this problem and what to do for this......

They are very different. It all depends on the heat source. It can be either steam or water. They may vary by location. If the house itself decided to build its own boiler room, then it can be specially allocated for it separate room in the house. Or extensions are made to the house for these purposes. One of the main requirements when constructing boiler houses is good ventilation.

If the boiler operates with steam, then very high demands are placed on the quality of water purification, and then steam. Therefore, it will definitely not be possible to manage such boiler houses without a whole complex of cleaning installations. This also includes AquaShield electromagnetic softeners, which are highly valued by boiler house employees today.

If a gas boiler suddenly stops heating water, the reasons may be different, but most often when using water from central water supply without softening units, the cause may be deposits limescale. Moreover, it is hard and difficult to remove. The table shows possible signs of the reason why the boiler stops due to scale formation.

Other reasons for boiler shutdown are simpler. Maybe a piece of scale will get stuck in the pipe and block normal work, and a crack in the gas boiler can also contribute to a shutdown. But in these cases there will definitely be no scale residues on the walls of the equipment. If the boiler room is not installed or wastewater treatment plants, then the root cause will of course be water hardness. If the treatment plant is standing and the equipment has been checked recently, then most likely this is not the problem.

In any case, if there is no cleaning in the system, then you will have to urgently address this cause and solve it. For boiler houses there is a whole range of water softening devices that are suitable:

- AquaShield;

- Ultrafiltration and conditioning for steam boiler houses;

- Ion exchange for economical consumers of gas boilers

The most wasteful process of cleaning and softening will be in steam boiler rooms. There you will have to remove not just all organic and inorganic impurities. Even dissolved gases will have to be removed. Degassing is quite troublesome and costly. But the operation of the boiler depends on the quality of the steam. This is where membrane softeners work to make the water completely isolated.

Many consumers of gas boilers choose AquaShield for the simple reason that it does not require maintenance and does not require spending money on it. But its biggest advantage for boiler equipment was and remains the ability to remove old lime deposits even in the most difficult places. Usually, to eliminate such residues, the equipment needs to be unscrewed, the parts need to be soaked in aggressive acidic environments and kept there for up to two hours. But even after that you have to clean the surfaces metal brushes or cleaners. If your gas boiler does not heat the water to the required temperature, then the reason is scale deposits. The electromagnet does all this work without damaging the surface, at the molecular level.

If gas the boiler does not heat water for hygienic or general technical needs, the problem can be solved by heating required quantity liquid in the pan. Much more problems occurs in winter when the heating system is blocked. If the owners are absent for a long time, the system may freeze. The subsequent restoration of its performance is associated with significant financial and time costs. To eliminate such negative situations, it is necessary to select and apply a set of effective preventive measures acceptance.

Design features of the gas boiler Baxi (baxi), Navien, Ariston

In any case, it will be useful to familiarize yourself with the equipment of this class and its features. modern models. This knowledge will help you choose the right equipment and avoid making mistakes during operation.

IN domestic boilers Baxi, Navien and Ariston burn gas, diesel and solid fuel, electric heating elements are used. For more full use heat exchangers are improving the potential of energy resources. They make long ducts of complex shapes to ensure that the liquid remains in the working area for a long time.

The current trend is compactness. Manufacturers offer gas boilers with square bodies of relatively small thickness. Some models, due to their aesthetic characteristics, deserve to be placed in a prominent place.

The next feature is the implementation automated systems management. They control the combustion process, change operating modes taking into account the readings of temperature sensors on the street and in individual rooms. If the equipment overheats, it turns off without user intervention.

It is necessary to carefully consider situations when the Baxi gas boiler does not heat the water. This happens, for example, when the supply of energy resources is cut off. It is not difficult to carry out an appropriate check even without special professional training.

Circulation pumps, valves, and other typical components and assemblies rarely fail. Their designs are designed for many years of operation without mandatory Maintenance. Electronic circuits have no moving parts at all. Their breakdowns occur due to defects. Subject to the rules established by the manufacturer, the service life of modern gas heating boilers is more than 10 years.

Damage electrical part equipment are capable of voltage surges in the power supply network. To eliminate such influences, an external stabilizer is installed. It will be useful to check the grounding system. This completes the set of preventive measures for this group of problems.

It is much more difficult to provide protection against the most common cause of breakdowns of gas boilers - scale. It is this that will be studied in detail in this article. When heated, calcium and magnesium salts are converted to a solid state. It is these impurities that clog narrow technological openings in heat exchangers. They also form a porous structure on the surface of electrical heating elements. If normal heat dissipation is significantly disrupted, their housings are damaged.

To prevent the formation of scale and lime inside the boiler, it is advisable to install non-chemical filters (water converters), magnetic and electromagnetic, which will ensure a long “life” of your boiler and uninterrupted supply of hot water, and also protect the heating circuit.

Filters (scale converters) such as AquaShield or MWS are not used in their work chemical reagents and replacement cartridges. Once you install such a device in front of the boiler, you will forget about the problem of scale on the boiler. long years!

Troubleshooting: why does a gas boiler not heat hot water well?

If the gas boiler does not heat well hot water due to clogging or rupture of the tube in the heat exchanger, repair is necessary. It is performed by replacing a failed unit. Threaded connections in this case they are not used, so disassembling and subsequent installation yourself will be difficult. To create a high-quality connection by soldering, it is better to invite experienced craftsman. Qualified specialist will ensure the required level of quality and provide written guarantees.

Finding out about the problem in advance is not easy. The scale layer grows slowly, so it will not be possible to register a clear decrease in power. Extraneous noise can be caused by the passage of sand and other mechanical impurities through the pipes. Technological openings are too small for visual inspection. To complete this, dismantling is required.

The information provided explains why emergencies of this type occur unexpectedly. To prevent them from developing into a more complex problem, you can equip your boiler equipment modern system remote control. Some manufacturers offer ready-made solutions in the form of an additional electronic unit and specialized software.

The corresponding application is downloaded to the smartphone. The advantage is the ability to remotely change settings and check temperature sensor readings. If the Navien gas boiler does not heat hot water due to scale, replacing the heat exchanger is not enough. These same contaminants reduce the internal diameter of pipes and narrow the ducts in radiators. A complete cleaning of the system is necessary.

This procedure is performed according to the following method:

- Pour the water into the drain.

- Rinse all circuits sequentially or simultaneously with a special solution.

- It is also used to clean the heat exchanger if it is only clogged and can be used further.

- After assembly, the functionality of the system is checked under pressure.

- Eliminate identified defects (cracks, loose connections).

To remove calcium solutions, aggressive chemical compounds are used. The duration of the standard procedure for one household object is several hours. Appropriate corrections are made taking into account the actual state of the system. Strong acids can damage metal parts and solder joints of an Ariston double-circuit boiler. For this reason, experienced teams take repair tools to complete orders.

It is possible to carry out such procedures independently. But for many ordinary users it is not advisable for several reasons:

- You have to purchase expensive equipment for pumping liquids that will be used.

- Independent selection of the optimal composition of the solution will cause difficulties.

- There are no mechanisms during this procedure operational control processes within the pipeline system. This increases the likelihood of breakdowns.

- When performing transactions in person, you will not receive official guarantees from a third party. Any problems that arise in the future will have to be resolved at your own expense.

Additionally, it should be noted that careless handling of aggressive chemical compounds may cause harm to health.

Preventive actions

Specialists from companies offering flushing recommend doing this every heating season. It is combined with a general inspection of the equipment. The frequency is adjusted taking into account the level of rigidity, the intensity of operation of Baxi gas double-circuit boilers, and other significant factors.

Tips like this are really helpful. Regular cleaning will prevent more complex procedures. Simultaneous testing will help identify problems on early stages. However, it is necessary to emphasize the main disadvantage of this technology - it itself can damage the equipment. It is especially unpleasant if defects appear during heating season. It will be quite difficult to prove the guilt of the workers who did the cleaning.

Instead of using potentially dangerous techniques, effective protective measures are used. They are based on modern technologies water treatment

To prevent scale from forming in the Navien or Ariston heating boiler, install it in front of it. They dissolve when a stream of water passes, creating dense shells around microscopic scale particles (in the first stages of growth). After such a “modification”, harmful impurities are not able to attach to the walls and to each other. They pass freely along the circuit and are removed into the sewer system.

The second method is to replace harmful compounds with sodium ions. This procedure is carried out using special resins. They are poured into two large containers, which work alternately. As contaminants accumulate, washing is carried out using an inexpensive regeneration solution from table salt. Such equipment is used for general protection of apartments, cottages, and other real estate objects.

The next reason why a gas boiler does not heat hot water and its solution is a protective technology that appeared recently, although it has been known for more than a hundred years. The fact is that previously only permanent magnets were used for descaling treatment. They're losing theirs beneficial features with time. Moreover, a “habituation” effect was experimentally discovered when calcium and sodium compounds stop responding to the corresponding influences.

Nowadays the technique has been improved! Today, electromagnetic converters with high-frequency oscillation generators are used. At minimum costs energy (5-20 W per hour) they operate at a distance of up to 2 km along the length of the pipeline from the installation site of the Baxi or Proterm heating boiler. This technique maintains its initial efficiency throughout its entire service life.

Ultrasound can grind scale particles and remove old formations. But this technology is rarely used. Like acids, it can destroy the structural components of the water supply system. It should also be noted the likelihood of harmonic vibrations occurring in the audio range.

Membrane technologies provide high level purification from various impurities, including hardness salts. But standard household installations process no more than 200 liters. liquids per day. This is not enough for the needs of the Vailant heating boiler and hot water supply.

Features of different boiler cleaning technologies and conclusions

If a gas boiler stops heating water, it has to be repaired. To extend the life of the Buderus or Ferroli heating boiler and prevent accidents, various techniques are used. To choose suitable option, you need to pay attention to the following details:

- Flushing with aggressive chemical compounds does not eliminate the problem, but eliminates scale that has already formed.

- Polyphosphates pollute water, so this protection is used only for the heating circuit.

- Sodium compounds are harmless (this is ordinary, well-refined table salt). However, after appropriate treatment, the water will acquire a distinct taste.

- Ion exchange fillers are sensitive to temperature, humidity, and various impurities. You should clarify the requirements that are set out in the official instructions of the manufacturer of the Navien double-circuit boiler.

- To connect electromagnetic converters, you need a current source of appropriate power. To provide it continuous work V difficult conditions apply stand-alone circuits emergency power.

When determining the reason why the Navien gas boiler does not heat or does not heat hot water well, these are 3 methods of protection that must be taken into account: water hardness, architectural characteristics of the property.

Vailant boilers are particularly reliable and safe. Breakdowns are so complex equipment must be fixed by a master. But, minor faults can be removed yourself if you have the basic level knowledge about the design of heating and heating boilers.

Most faults are indicated on the boiler display. Having deciphered the errors, you can figure out the reason for the boiler’s failure to heat water. Where to start searching if water heating in the Vailant boiler does not work and the indicator does not show an error or can it be interpreted in different ways?

Vaillant boiler does not heat hot water due to blockages

This is one of the most common problems. Most often, the reason is poor water quality - scale appears, components, filters and pipes become clogged.

If the flame does not light up in the boiler, start checking with the flow sensor. Finding this cylindrical device is quite simple. The flow sensor is located near the pump; the wires go to it. There are two sensors installed near the pump:

- Pressure sensor in the heating system.

- Flow sensor.

The flow sensor looks like a small fan; it begins to rotate as water moves through the pipes. If the flow sensor detects the movement of water, the automation receives a signal to turn on the gas and heat the water. If the flow sensor is clogged, water will flow but the fan will not move. Accordingly, the signal to turn on the heating is not received. There are two ways to solve the problem:

- Don’t rush to disassemble the boiler and try to “blow out” the system first. Turn off the main water supply valve to the house. Open the hot water tap and drain the system. Now the percentage of air in the pipes has increased. Start sharply opening and closing the water tap immediately in front of the boiler. These simple manipulations will help create pressure and clear the flow sensor fan of debris.

- If “blowing” does not solve the problem, you need to open the boiler, unscrew the flow sensor and clean it manually.

If the Vaillant boiler does not heat hot water, the secondary heat exchanger should be checked. It also tends to get clogged quickly. But, fortunately, it can be easily removed, cleaned and reinstalled.

Clogging three way valve can also cause the boiler to fail to heat water. And you can remove this unit yourself, clean it and install it back.

Having bought the Vailant boiler, be sure to check with the seller information about the places where filters are installed. You can clean and change these components yourself.

Faulty pump

Heating of water in a Vailant boiler largely depends on the operation of the pump. To repair or replace this unit, you must call a specialist. But, you can check for yourself whether this is the reason for the boiler’s failure to work.

Set the water temperature on the boiler to 0 °C and turn on the water heating mode. During this time, monitor the operation of the pump. If after 20 minutes of operation it does not heat up, then the problem is with the pump.

The reason for the boiler’s failure to heat water may also be due to a simple loosening of the bolts at the connection areas. Carefully examine the boiler diagram and check that all connections fit tightly. Perhaps simply tightening the bolts will solve your problem.

One of the problems that may occur during use double-circuit boiler. The boiler does not heat hot water. The main and most common reason why the boiler does not heat water well is that the heat exchanger is clogged.

In this article I will describe how I treat this problem. This way you can also get out of the situation if you have a double boiler with a plate heat exchanger.

My house has a well and the water is very hard, so I constantly have problems with hot water To remedy the situation, I use citric acid.

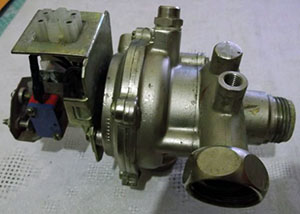

This is the task. How to deliver this acid to the inside of the heat exchanger with the least effort. I found this way. At the entrance to the boiler I have a magnetic converter, which is supposed to remove water hardness, but it does not remove it, in my opinion this is a fiction. But the good thing for me is that it is installed right at the entrance to the boiler. You can see it in the photo below.

There is an American nut on it; after unscrewing it, you can easily pour citric acid into the inside of the pipe.

But to do this you need to turn off the water. I have a collector next to the boiler. He is in the photo below.

Now all the channels on it are open and with one easy movement I turn off the water supply to the boiler.

All water is shut off, now you can unscrew the American connection on the magnetic filter. And don’t forget to come up with something from the flowing water from the boiler, there isn’t a lot of it, but it is there. I wrapped up the rag.

Then I pour citric acid into the inside of the pipe.

I screw the American valve back and open the supply valve tap water into the boiler.

Now it is important to understand when the acid will enter the heat exchanger. Since my water tap is located a meter from the boiler, I determine whether the acid has reached the heat exchanger to taste. I just open the tap in short jerks and taste how “sour” it has gone, which means the entire system from the magnetic filter to the tap is full citric acid.

Next, you need to turn off the tap so that your household does not drain all the acid ahead of time.

I charge the system at night and it stays acidic until the morning. In the morning I open the water supply tap to the boiler and drain all the acid. The water will hiss, don’t be alarmed.

The question may arise, will the acid eat away at the heat exchanger? I did some digging on the chemists' forum and came to the conclusion that organic acid (citric acid) is harmless to copper.

I use this method when necessary. If you don’t like how the boiler heats the water or the pressure of hot water has become weak, I take the heat exchanger and treat it with citric acid.

If you have connections to the boiler made of polypropylene, and there is no place to put the acid, then come up with something similar; it won’t take much time.