Wood sealant "Warm seam": description and reviews. Sealing seams in a wooden house using the “Warm seam” technology

How to correctly calculate cost and volume?

KOPE, P-44, I-155, P-3M are the most common series of mass-built houses, therefore the cycle of repair schemes in them is the most developed, and average consumption materials have already been approximately calculated. On average, the final payment for repair and replenishment work interpanel seams will cost the customer around 350 rubles per meter of seam. So it turns out that in one-room apartment The scope of work will approximately take about 30 linear meters. This corresponds to the amount of work planned with a minimum order.The same volume in meters corresponds to the work carried out in two-room apartment, if it is not an end or corner in the house. For a two-room end living space, the volume increases and amounts to 40 linear meters. For a three-room non-end apartment, the volume of work increases to 45 linear meters.

For a 3-room end apartment this will already be 60 - 90 linear meters of a sealed seam.

The houses of these series are distinguished by architectural diversity, built from the same elements of building parts, therefore, depending on the area façade walls apartments in houses of the KOPE, P-3M, I-155 series may vary.

Construction activities and renovation work carried out by ASSOL LLC using the technology " Warm seam", are certified, the company has a license or SRO (Membership in self-regulatory organization).

About certification of seam sealing work

Sealing of seams is not subject to SRO certification, but to improve the quality of construction, reconstruction, overhaul objects capital construction, everyone must have construction company. The Assol LLC company undergoes a scheduled inspection once a year to ensure that members of the self-regulatory organization comply with the requirements of standards and rules. The warranty period for the work performed is 18 months, and 24 months for the repair of balcony roofs last floor. The warranty period begins on the day the contract is signed.Technically, the service life of filling and sealing materials is no less than 10 years. The contract is signed while visiting the customer, and therefore there is no need to come to our office in person. The price includes work, materials, delivery, and roofing permits. (The company prepares all necessary approvals for you)

Reviews:

- Oksana Dubok

10 months ago

" Our family lived in a panel house and I know firsthand what problems such houses have. The joints are the weakest link in a panel house. There is insulation of interpanel seams using the Warm seam technology, the results are excellent. It immediately became noticeable how cozy and warm the apartment was, that’s what modern technology means. "

- Natalya Lapteva

11 months ago

" It is almost impossible to insulate the seams from the inside. Your apartment renovation It won't really affect the weather. All work must be done outside - it is impossible to avoid the involvement of professionals and, whatever one may say, climbers will be needed. It’s better to cooperate with neighbors on such repairs - it will be cheaper and more reliable: it’s not a fact that a crack that has not been repaired above the floor will not spread even more during rain and frost, destroying your entire repair. So for sealing interpanel seams in your panel houses get together, so to speak, with the whole world =) And housing and communal services, in best case scenario, will make cosmetic repairs. "

- Tatiana Brusentseva

11 months ago

" In panel houses there is often a problem with drafts, unpleasant odors, the heat in the apartments does not stay warm. Sealing interpanel seams in panel houses eliminates all this. I read a lot of reviews about this, and my friends who used this service were satisfied. I recommend the site www.site where everything is explained in detail))) "

- Dmitry Egorov

2 months ago

" Your Warm Seam sealing technology is simply wonderful! Oh, how unlucky I was that it wasn’t your company that sealed the seams in our house. Damn, the wind is howling here. If I had known, I would have recommended you to our HOA. Well, for the future, can you tell me the price for linear meter? Perhaps our residents will be interested. Thank you! "

- Robert Derrick

1 month ago

" these guys did it in our house, respect for the fact that they treated the work differently than usually happens in Russia.. "

- Sergey Sedov

1 week ago

" I watched a video about this in great detail and says that sealing interpanel seams means warmth in the house. A very useful and educational video for beginners. Thank you.. "

Technology of insulation of interpanel seams: WARM SEAM

Advantages of the “Warm seam” technology

Insulation of interpanel seams allows for protection from the cold of the entire building as a whole and the rooms located in it, from the appearance of mold, mildew and leaks. The choice of materials allows this, so insulation from moisture and cold is used successfully in this technology.

Sealing work is important if moisture and thermal insulation of the apartment is planned. Thanks to professionally performed work, the room will be free from fungus, new peeling wallpaper, and the smell of dampness. Exists following processes seam sealing:

- primary seam sealing is used in new panel houses where the seams have not yet been sealed;

- secondary sealing: repair of previously sealed seams.

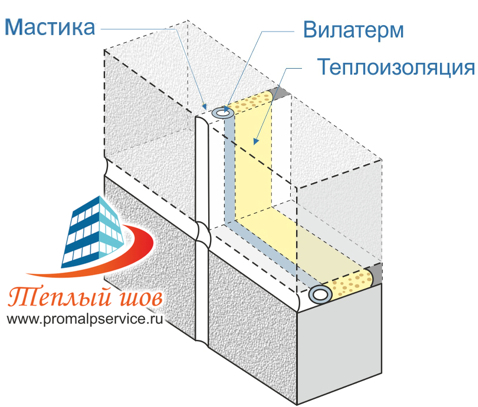

The technology involves sealing seams in three technological steps:

1. Filling the interpanel joints with polyurethane foam with a period of time sufficient for the expansion of the substance filling the voids and its polymerization (solidification).

2. Laying Velaterm insulation, which is a tube made of polyethylene foam, in seams and voids without waiting for the polyurethane foam to harden. Typically used if voids have large volumes. Velatherm is plastic and durable, making it easy to use.

3. “Warm seam” technology, carried out to the fullest extent possible, with filling the Velaterm tube with foam and sealing the outer, facade side of the panel. Typically used in cases of significant spalling or displacement of concrete structures.

“Warm seam” is the best solution

“Warm seam”, made using three-component sealing technology, has a serious difference from traditional sealing seam: a “warm seam” is made using polyurethane foam, and standard sealing is carried out using only two components - sealant and insulation.used for quite a long time. For houses various series the same operation often has various methods implementation. This is dictated by the improvement of the profile of the “locks” at the joints of the panels, so a technique suitable for each specific case is chosen. Only one thing remains unchanged in each of them: the need to protect the joint filler from sun rays, and the joint itself from moisture accumulation. Based on this, it is necessary for a specialist to go to the site and determine the most effective method use of technology. It is he who will determine the final decision on the sufficiency of measures to eliminate seam defects. The work will not be completed with guaranteed quality without carrying out work on outside walls of the house, so our employees are trained to work at heights. They are the same builders, but their distinctive feature possession of climbing equipment. Experience in working at heights shows that the most popular operation is to apply a new protective layer to existing insulation seams before they begin to fail. All this happens if the warranty period has passed or signs of defects were noticed during the previous sealing of seams. More rare cases require cleaning out the old insulation, filling the seam with a new one, and only after this applying a protective layer. Naturally, a larger volume of materials and worker labor will require more expensive payment, but in the future the amount of costs will be incomparable if time is wasted and the necessary repairs are not made in a timely manner.

Sealed seams completely suppress the circulation and penetration of cold air into the premises. Measurements have shown that the difference in room and street temperatures increases by 3-4 degrees when compared with the temperature in a room in which the seams were insulated using a different technology.“Warm seam” is a guaranteed way to save heat in the apartment.

“Warm seam” is the most inexpensive, reliable and durable technology. Such repairs will not take much time; the work is usually carried out on the street side and does not create discomfort for people inside the premises.

Warm seam - a technology developed specifically for panel houses

The company's responsibility is not only to maintain technological discipline and professionalism when performing a task, but also to choose only quality materials. The goal of our company is to earn money, but to earn it honestly, without mark-ups and subsequent squabbles. It’s easier for us to spend this time on increasing the volume of work performed and earn respect from customers in addition to money.

Sealing work is carried out not only around the perimeter of the building, it can also be carried out in a separate apartment, which, knowing its dimensions, makes it possible to make a preliminary estimate of the volume and price. The perimeter of the seams to be sealed in a standard, non-end 2-piece room apartment, without adjustments for the series of the house, will have approximately 30 linear meters.

Alternative methods, when the apartment is located on the 16th floor of a 22-story building, will require the rental of special equipment, and this will create additional high costs.

Specifics of work during the cold season:

The main material used as insulation is low-temperature sealant "Macroflex". Polyurethane sealant allows you to seal cracks in doors and window blocks for the purpose of sealing and thermal insulation, as well as interfacing panels. An operation is added to clear the end surfaces of the panels from snow and ice. To protect the seam, Oxyplast sealant is used, which must be heated to positive temperatures, approximately +25 - +30 ° Celsius. Foaming of joints is carried out using a nozzle for an aerosol can and with a sufficient number of passes. Before starting work, the cylinder must also be warmed to a temperature range from up to +25°C.

Compliance with these conditions is mandatory and necessary for successful sealing of the seam in winter period. When working with Oxyplast sealant, you can also negative temperatures not lower than -15°. Sealing in external joints of reinforced concrete walls, as well as window and balcony blocks, is carried out by trained builders who specialize in the field of sealing and have an entry in the certificate.

/ Typical mistakes in sealing seams between panels

/ How to get rid of fungus and mold on the walls of an apartment

/

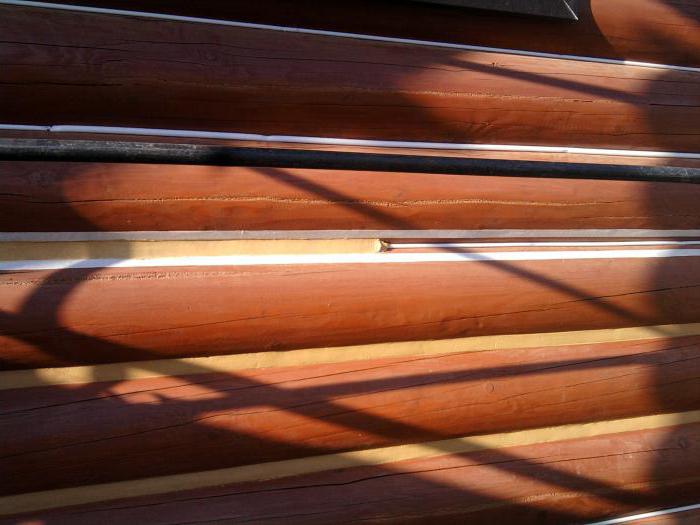

Construction volume wooden houses is growing every year. This is explained by several factors - the aesthetics of antiquity new way"and good operational properties. But there is one important problem that is characteristic only of wooden log houses, especially new buildings. Over time, gaps appear between the crowns, which significantly impair thermal insulation, noise absorption and protection of walls from premature destruction of wood. One of effective ways The solution to the problem is to seal the cracks that appear using the warm seam technology.

Causes

During construction wooden house A layer of sealant is mounted on the upper plane of each crown. Often this is linen tow or felt, which are optimal material for sealing gaps between logs or beams (more on this). But over time, owners of wooden houses may notice the appearance of gaps and cracks in the walls of the building. This usually happens 1.5-2 years after construction.

There are several reasons for such defects:

- Natural uneven shrinkage of the house.

- Inconsistency linear dimensions logs This is typical for houses made of non-rounded timber. During construction, the distance between the crowns may be slightly larger than the norm, but due to shrinkage it often increases.

- Incorrectly calculated layer interventional seal. Its excess can be squeezed out under the influence of the weight of the wall.

- Changing the geometric dimensions of timber or logs. This problem is typical in bathhouses where big differences temperatures and humidity. During operation, drying or moisture absorption occurs, which leads to changes in size and geometry.

Eat traditional way solutions to these problems - cracks and gaps. To do this, sealants are installed in the formed “cold bridges”: tow, linen felt or jute. However, they do not guarantee that the home will remain sealed. Therefore, a new technology was developed - a warm interventional seam.

Description of technology

The reason for the emergence of warm seam technology for wooden houses was the emergence of new thermal insulation materials. Due to the fact that caulking needs periodic updating, the technology for the construction and operation of wooden houses has been supplemented.

The reason for the emergence of warm seam technology for wooden houses was the emergence of new thermal insulation materials. Due to the fact that caulking needs periodic updating, the technology for the construction and operation of wooden houses has been supplemented.

With this type of thermal insulation, 2 types of materials are used:

- Sealing cord made of insulating material. Most often this is foamed polyethylene. It is lightweight, has good thermal insulation properties, and most importantly, it is plastic. The polyethylene cord is easy to install into the resulting cracks and crevices. Important - the cord should not be adhesive. If as building material timber was used, then small gaps in it can be eliminated by using non-adhesive tape.

- Sealant. It performs several functions - fixing the cord and additionally sealing the entire area of the gap formed. It is necessary to use special brands of sealants designed for working with wooden surfaces.

Works on additional insulation and it is recommended to eliminate the resulting defects after 1.5-2 years after the construction of the house. During this time, final shrinkage will occur, which is 4-6%.

To complete the work you will need following materials and tools:

- Sealant and sealant. The footage of the compactor is calculated according to the perimeter of the house multiplied by the number of logs. The amount of sealant depends on its type, packaging and density. In the vast majority of cases, manufacturers indicate the estimated consumption on the packaging.

- Spatulas and wooden spatulas, if the sealant is packaged in plastic buckets. Mounting gun for sealant in tubes. It is recommended to use the latter, as it will make it possible to make a seam with uniform application of the material.

- Masking tape. Necessary for the formation of an even layer of sealant. It is deleted after the work is completed.

On preparatory stage Contaminants and dust are removed from the wall surface. The inter-crown end must be degreased for better adhesion of the sealant. The wall must be dry and the air temperature must correspond to the installation conditions.

Stages of work:

- Installation masking tape along the seam boundaries.

- Installation sealing tape. The thickness of the tape should exceed the inter-crown gap by 1-1.5 mm. It is installed using a wooden spatula.

- Applying sealant. For a uniform layer, nozzles with a diameter of 0.6 to 2.5 cm are used. The layer thickness should not be less than 5 mm. If necessary, the material is applied to the seam using a spatula.

More detailed instructions using warm seam technology is shown in the video.

Wood sealant “Warm seam” can become the basis for the thermal insulation protection of a building. Undoubtedly, there are other ways, but this one is the most convenient. If you have started to think about insulating your home, then you should resort to this technology. When making a comparison with the traditional system of thermal insulation of inter-crown gaps, which uses hemp, jute or flax batting insulation, it is worth noting that filling cracks in the inter-crown space with sealant increases the thermal resistance of the walls and reduces heat loss. If we are talking about natural insulation materials, then they are able to let cold air inside, which significantly reduces thermal resistance log walls.

Consumer reviews about the effect

Warm joint wood sealant has many advantages. According to users, with its help you can achieve a comfortable indoor microclimate. Such thermal insulation makes the temperature and humidity conditions optimal, while saving energy, because there is no heat leakage from the inter-crown gaps. House heating costs are minimal.

Owners of private wooden houses say that after thermal insulation work using the described technology, drafts disappear, log walls are not blown through in cold and damp weather. You can count on the material not being damaged by biological organisms. The gaps are sealed as much as possible, mold no longer forms in them, and insects do not penetrate inside.

If you use Warm Joint Wood Sealant, you can save money. According to buyers, they no longer have to invest additionally, which is required for periodic caulking. Among other things, you will end up with quite attractive walls, the joints of which will match the shade of the wood.

Reviews about the advantages of “Warm seam” over caulk

Previously, the insulation of wooden houses was often carried out using the caulking method, today this technology is replaced by a system called “Warm seam”. The latter technique has many advantages. For example, caulking walls is quite labor-intensive, and it must begin no earlier than a year after completion of construction. According to the owners of private houses, this cannot be called convenient. Among other things, the caulking process will need to be repeated regularly, since flax and moss are pulled away by birds, and the seams also increase due to shrinkage. Modern consumers emphasize that appearance the log house after completion of the caulking stage cannot be called attractive. Over time, the walls completely lose their aesthetic appearance.

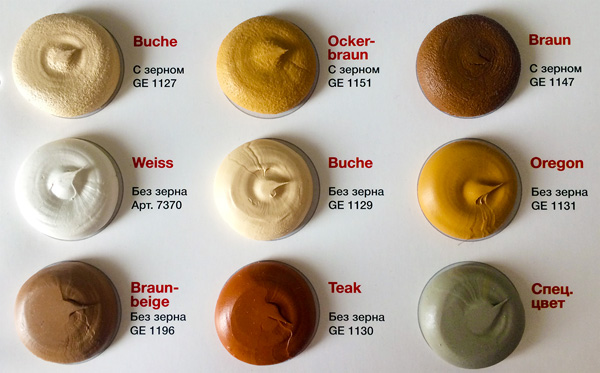

Reviews on the characteristics of sealants for performing work using the “Warm seam” technology

Wood sealant “Warm seam” is chosen by customers because it has many advantages. According to home craftsmen, these compositions are not at all afraid of temperature changes; harmful microorganisms and mold do not appear or develop on their surface. As practice shows, the described sealants are not exposed to sunlight, and over time they do not lose their original color. According to buyers, sealants have a high level of adhesion to wood and are characterized by elasticity, which is especially evident when the crown gaps are compressed. This allows you to complete these works and forget about them forever. You can apply “Warm Seam” sealant for wood, which has only the most positive reviews, at any time of the year. At the same time, residents will not experience inconvenience such as dust, odor or noise. The house can continue to be used. Using acrylic compounds, you can hide some wood defects, and after completion of the work, the house will acquire an aesthetic appearance.

With the use of acrylic sealants, the master has the opportunity to carry out work both outside and inside the building. According to users, the use of these compositions makes it possible to create original interior. This is also due to the fact that sealants of different shades can be found on sale. For example, in the product range you can find beige, cream, as well as white and brown shades. The “Warm Seam” sealant can be made on an acrylic rubber base; it can be used to seal seams not only in wooden houses, but also in other places. After drying, this composition can be sanded several times, as well as subsequent painting.

Why else is it worth insulating a wooden house using the “Warm seam” technology?

If you decide to choose “Warm Seam” sealant for thermal insulation work, it is recommended to read reviews about it before going to the store. This will allow you to understand that acrylic compounds can even prevent the processes of wood rotting; they will not let dampness into the house. According to users, with the help of these compositions it is possible to carry out thermal insulation work in the shortest possible time. After applying this technique, there is no need to additionally seal the inter-crown seams, as well as eliminate cold bridges.

Features of using Neomid sealant

Wood sealant “Warm seam” “Neomid” has gained popularity among consumers; its use requires compliance with certain rules. For example, before final application it is necessary to caulk the seams, for which jute or linen tow is used. Then, using a spatula, a sealant is applied to the surface, which makes it possible to insulate the resulting gaps using a combined method.

A wooden house is not just a beautiful, environmentally friendly and cozy home. Wood retains heat well, so if the sealing of a wooden house is carried out correctly, heating costs will be reduced by 30-40%.

Insulating a house using the “Warm seam” technology

With the advent of new insulating materials, it became possible to insulate a wooden house more reliably and efficiently. The log house is sealed using the “Warm seam” technology just once, and the service life of such seams is more than 20 years.

The main material used to eliminate “cold bridges” in a log house is acrylic sealant. It is elastic, that is, the seam stretches or contracts depending on seasonal fluctuations in the size of the log house, adheres perfectly to the wood and prevents moisture, dirt, mold, and pests from entering the joints.

Joint sealant for wood is resistant to UV rays and temperature changes, does not emit toxic substances and can be safely used even indoors. Interventional sealant for wood can be painted in different colors, due to which the seam becomes peculiar decorative element log house

ADVANTAGES OF “WARM SEAM” TECHNOLOGY

Sealing allows you to optimize the temperature and humidity conditions for living in the house

The absence of heat leaks from the inter-crown gaps will reduce the cost of heating a wooden house

Sealing allows you to reduce costs and avoid additional investments in periodic caulking

Sealed roof gaps will prevent the log walls of a wooden house from blowing through in damp and cold weather.

![]()

Sealed inter-crown gaps will prevent the appearance of insects and the formation of mold in inter-crown joints

A wide range of colors and textures of sealant combined with wood enhance the appearance of your home

Warm seam prices for services for a wooden house

*The cost of all materials is already included in the price of the work.

| Warm seam for rounded logs | |

|

diameter up to 220mm |

*150 rub. per linear meter |

| diameter up to 260mm | *170 rub. per linear meter |

| diameter up to 300mm | *195 rub. per linear meter |

| Warm seam for log house | |

|

from *195 rub. per linear meter |

|

| Preparing to install a warm seam | |

|

Removal old caulking from 20 rub. per linear meter |

|

| Removing old sealant from 40 rubles. per linear meter | |

Why is it cold in a wooden house?

Any wood influenced environment changes its parameters over time. Gaps form between the logs, drafts begin to circulate in the house, and the heat leaves. Our ancestors knew well about this feature of wood. Therefore caulking wooden log house was important stage construction. The space between the crowns was densely filled with moss. The first time is during the construction process, and the second time is a year later, when the log house is “settled”.

This is how they do it in most cases now, only the insulation of wooden houses is done with tow, jute, and flax. Natural materials They look beautiful, protect joints well and retain heat. But they require regular updating, since the insulating material cannot fill the increasing gaps, it is blown out by the wind, birds take it away, and insects can settle in it.

New technology for insulating a house with wood sealants, which is used by the company " Warm house", is devoid of all these shortcomings.

REMMERS sealant color palette

How is a log house insulated with sealant?

The insulation of a log house using the “Warm seam” technology is carried out 1-1.5 years after the completion of construction, when the process of shrinkage of the house is completed. The technology includes several stages:

- The seams between the logs are prepared for processing: the old insulation is removed, the cracks are cleared, dust and dirt are removed, and they are coated with a special impregnation.

- The prepared surface is primed.

- A caulking cord is laid which fills deep cracks and cracks, creating the basis for a layer of sealant.

- Using a pneumatic mechanism, the seams are filled with sealant, which is leveled with a spatula. The recommended seam thickness is 4-6 mm.

- The joint is finalized by smoothing the surface of the sealant, giving it a neat appearance.

- The sealant hardens within 2-7 days. The curing time depends on the initial moisture content of the wood and the ambient temperature.

It is better to entrust the insulation of a wooden house with a warm seam to professionals. The specialists of the Teply Dom company will help you choose the most suitable suitable type sealant, and our craftsmen will quickly and accurately carry out all the work.

| Material, type of work: | Price for 1 linear meter: |

|

| For rounded logs up to Ø 240 | ||

| For rounded logs from Ø 260 to Ø 300 | ||

| For rounded logs over Ø 300 | Price is negotiable |

|

| For log house(depending on the diameter and laying of the log) | 200 – 260 rub. |

|

| Primer, seam cleaning, punching, tow cutting | ||

| Laying the Vilaterm cord | ||

| Prices are indicated for a set of turnkey services: measurement, sealant, cord, delivery, installation scaffolding, Job. |

||

Modern insulation of houses built from wood includes filling cracks and joints of logs with sealant. Such manipulations will eliminate the leak as soon as possible. warm air and improve the thermal insulation of the entire building.

Sealing the seams of a house can be done inside or outside the building. It is important to carry out insulation at a high level of quality so as not to waste money and time, because this the most important moment for a wooden log house. Warm seam is latest technology, demonstrating excellent results compared to other methods of insulating log and timber houses. But it is important to order such a service only from qualified craftsmen, because any minor or large-scale mistakes can ruin everything.

Seams in a wooden house and sealants for their insulation

Quality acrylic sealants, presented by several manufacturers, are ideal for working with log houses. This material for insulating seams does not contain harmful substances. Thanks to its elasticity, the sealant instantly masks cracks, seams and chips. He is resistant to ultraviolet rays and negative irritating natural factors. A warm seam for a wooden house does not burst when the building shrinks, which is important for real estate that is located on soft ground. Apply sealant only after preliminary antiseptic work.

![]() The Master Seam company works with several and the highest quality sealants. For the attention of customers, seam insulation is provided with two main types of insulating material:

The Master Seam company works with several and the highest quality sealants. For the attention of customers, seam insulation is provided with two main types of insulating material:

- "Accent". Sealing the seams of a house with this wood material is easy. The product is designed for long-term masking of crevices and cracks in wood. And also for insulation and insulation of seams between wooden beams.

- "Remmers". This sealant has high level firmness and elasticity. Subsequent painting of warm seams is allowed. It is resistant to external irritating factors, including adverse weather conditions.

Sealing of log seams in our company is carried out in the most short term. The Master Seam company offers the best prices, high service and quality assurance. The company has been operating for several years and therefore only offers high quality and free consultation at all stages of cooperation. Seams in wooden house require processing. Call the professionals and save yourself the hassle.

Vilaterm cord for your home

When sealing the “Warm seam”, Vilaterm sealing cord is also used. Such cords are made from durable polyethylene by foaming it under pressure. The resulting liquid mixture is poured into special molds, where it hardens and acquires a special cellular structure. The Vilaterm cord ranks high in its strength; it is able to withstand numerous compressions and stretches. The material is moisture resistant and environmentally friendly. It has special sound and thermal insulation properties and can be used in various fields of construction activities. The cross-sectional diameter of the cord can be different and ranges from 6 to 80 mm.

If we talk about the scope of application of the Vilaterm cord, then it is immediately important to note the insulation of joints and seams. A durable seal protects the cracks from moisture, which prevents the formation and penetration of fungus/mold. The Vilaterm cord has a long service life. It greatly facilitates installation work and is easy to use. This cord is fixed using sealant. The gap is cleaned of dust and dirt and degreased. Next, a polyethylene cord is inserted and covered with a sealing construction agent.

The role of the Vilaterm sealing cord in the "Warm seam" technology

- The cord fills the seam, which saves sealant;

- Additionally, it insulates the building;

- Serves as a gasket between the wood and the sealant. In the absence of a cord, if the tree begins to lead, the entire seam will become unusable. And if there is a Vilaterm cord, the sealant will be attached to the cord and touch the logs only at two points.

If we compare classic caulking and “Warm seam” sealing, then the second method certainly demonstrates the best results.

Comparison of sealing "Warm seam" and caulk. Advantages and disadvantages.

| Sealing "Warm seam" | Caulk |

|

| pros | Single application; Stretches without forming cracks when wood shrinks or seams become deformed; High and long-term thermal insulation of the building. | Low price (relative to sealing). |

| Minuses | Higher price compared to caulk. | Formation of cracks between logs during tree shrinkage; Average thermal insulation of the building; Mandatory replacement after 2-5 years. |

Warm seam in winter and summer

You can order sealing of log seams at any convenient time. The price of a warm seam will not change. The Master Seam company works according to clear pricing policy and does not change the price depending on weather conditions.

The seams of a wooden house in winter are treated according to unique technology. Wooden scaffolding is installed outside the building, and the entire structure is covered with film. An additional temporary room is formed, where craftsmen, using special equipment, create favorable temperature conditions for work. This sealing of seams in wooden houses is durable and safe.

Trust the work to professionals. Choose a warm seam for your home, the price of which is affordable for everyone today.