Terms of starting heating in an apartment building. How to properly start the heating system in the house: the order of work

Hello friends! This article is about how to launch internal system heating. Usually this procedure is carried out after the issuance of an order, resolution or order of the local administration on the beginning of the heating season. So, in what sequence does the water heating network start up?

It is better to start heating by a team of two or three people. The heating is started at the heating point (ITP) from the opening of the valve on the return pipeline.

Filling the system through the return line is done in order to prevent the destruction of radiators high pressure in submission. The valves should be opened smoothly, without sudden movements. At the same time, you should look at the pressure gauge so that there is no too sharp pressure drop. At the same time, it is necessary to open the air vents at the upper points of the heating system. After the appearance of water in them and the release of air, the air vents are closed.

Then the supply valve also opens smoothly. After the circulation has been established, it is necessary to check the operation of the heating risers. Namely, the presence of water circulation. If there is no circulation, then we discharge air from the upper points of the internal heating system (on the upper floors of the building). From experience, I can say that problems with airing arise in single-pipe systems, where there are jumpers (closing sections) on the riser connections to radiators. tinker to get him out of there.

But usually, if there are a lot of buildings, the operation of the risers is not immediately checked, since there is no time, but it is done later, as complaints are received about the poor performance of the risers. If there is time and opportunity, then it is better to immediately check the operation of the heating risers.

Then it is necessary to check the readings of pressure gauges in the heat point. The readings must correspond to the regime, that is, to those supply and return pressures provided by the heat supply organization.

At the end of the article, a few tips about starting heating when low temperatures outdoor air, that is, in other words, in winter.

To avoid defrosting, the heating system should be filled in groups of risers (5-6 risers), starting from the most distant from the heating unit.

Filling and start-up of risers staircases should be carried out after start-up after filling and start-up of the main risers of the building heating system.

Risers and radiators that are located in rooms communicating with outside air (vestibules, passages, etc.) must be turned off when heating is started, and heating should be started through them last, after all other heating risers are connected .

I will be glad to comments on the article.

Putting the heating system into operation is an extremely important event and can only be carried out after all the necessary preventive and verification work. At the same time, passports, verification acts and operating instructions for heating systems must be correctly and fully drawn up.

Necessary conditions for starting the heating start-up

The schedule for the implementation of measures for the launch of heating systems is Chief Engineer operating organization. When mass connection of consumers, special work must be carried out to remove air in the systems. (See also: )Heating is started by a specially approved team consisting of several pairs of workers. Each pair is assigned several risers. During the filling period of the system, all air collectors located at the upper points of the system open.

If the pressure in the return pipe exceeds the pressure in the system, to reduce it, it is necessary to open the valve on the return pipe slowly. If, on the contrary, the pressure in the return pipe is lower than expected in the system, then the coolant is initially supplied from the return pipe, and then from the supply pipe through the suction line to the return main pipe.

If the return pipeline is equipped with a water meter, then the filling of the system is carried out along the bypass section. In its absence, the water meter is dismantled and a pipe with flanges is put in its place. (See also: )

Rules for starting heating

When starting the heating system in the summer, it is necessary to close the valves first on the return pipe, and then on the supply pipe. Then the heating system is inspected and the coolant is circulated in the external network. In the absence of leaks, the valves are opened - first on the return pipeline, and then on the direct one. Next, the circulation of the coolant in the heating devices is monitored and, if necessary, air locks are removed from them. Air removal is carried out periodically, with an interval of 2-3 hours, until the airing is completely eliminated.Compliance with all norms and rules for putting the heating system into operation will ensure high efficiency and trouble-free operation of the heat supply system in the harsh winter period.

The use of materials is allowed only if there is an indexed link to the page with the material.

font size

DECISION of the Gosstroy of the Russian Federation of September 27, 2003 170 ON APPROVAL OF THE RULES AND REGULATIONS FOR THE TECHNICAL OPERATION OF THE HOUSING FUND (2017) Relevant in 2017

5.2. Central heating

5.2.1. System operation central heating residential buildings should provide:

maintaining the optimal (not below the permissible) air temperature in heated rooms;

maintaining the temperature of the water entering and returning from the heating system in accordance with the schedule for the quality regulation of the water temperature in the heating system (Appendix N 11);

uniform heating of all heating devices;

maintaining the required pressure (not higher than that allowed for heating appliances) in the supply and return pipelines of the system;

tightness;

immediate elimination of all visible water leaks;

repair or replacement of faulty taps on heating appliances;

displacement coefficient at the elevator unit of the water system is not less than the calculated one;

adjustment of the heating system, the elimination of excessively installed heating devices and the installation of additional ones in separate rooms that are lagging behind in temperature conditions.

5.2.2. limiting operating pressure for heating systems with cast-iron heaters, 0.6 MPa (6 kgf / cm2) should be taken, with steel - 1.0 MPa (10 kgf / cm2).

5.2.3. The air temperature in the premises of residential buildings during the cold season should not be lower than the values provided for by the standards. If there are means of automatic control of heat consumption in order to save energy, the air temperature in the premises of buildings at night from zero to five hours can be reduced by 2-3 °C.

5.2.4. Plumbers must monitor the good condition of the heating system, timely eliminate malfunctions and causes that cause excessive consumption of thermal energy.

5.2.5. It is not allowed to increase the surface or number of heating devices without special permission from the housing maintenance organization.

5.2.6. The premises of the operating personnel should have:

a) a register of operation of heating and hot water supply systems of buildings;

b) duty schedule of service personnel;

c) a glazed stand at the desk of the duty officer with the placement of diagrams of the main units and risers on it (indicating the numbers of apartments in which these risers pass, shut-off and control valves, air collectors for heating and hot water supply systems);

d) instructions for starting, adjusting and emptying the heating and hot water supply system, approved by the chief engineer of the housing maintenance organization. The instructions should indicate the frequency of inspection and revision of all equipment and pipelines;

e) a graph of the temperature of the supply and return water in the heating network and in the heating system depending on the outside air temperature, indicating the operating water pressure at the inlet, the static and maximum allowable pressure in the system;

f) phone numbers of the housing stock maintenance organization, heat supply organization (CHP, district boiler house, etc.), emergency services, ambulance, fire department;

g) tools, portable self-powered lamps, material for minor preventive maintenance, overalls, towels, soap and first aid kit;

h) a stand for placing keys from basements and attics of buildings;

i) register of issuance of keys to service personnel, which indicates the last name, first name, patronymic of the person receiving the keys, the time of issuance and return of keys.

5.2.7. During the first days of the heating season, the operating personnel must check and make the correct distribution of the coolant throughout the heating systems, including individual risers. The distribution of the coolant should be carried out according to the temperatures of the returned (return) water according to the data of the design or commissioning organization.

5.2.8. Plan (schedule) of the current and overhaul should include hydraulic testing, flushing, trial run and adjustment work, indicating the timing of their implementation.

The plan (schedule) must be agreed with the heat supply organization and approved by the authority local government.

During repairs, worn-out heating devices, pipelines, shut-off and control valves, air outlets and other equipment must be replaced in accordance with the project or recommendations of a specialized organization, taking into account the current level of manufactured equipment.

5.2.9. Detected malfunctions of heating systems should be recorded in the log book. The type of troubleshooting work carried out is noted in the journal indicating the date and names of the personnel who carried out the repair. Identified defects in the heating system should be taken into account when preparing the system for the next heating season.

5.2.10. Flushing of heat consumption systems is carried out annually after the end of the heating period, as well as installation, overhaul, current repair with pipe replacement open systems systems must also be disinfected prior to commissioning).

The systems are flushed with water in amounts exceeding the calculated flow rate of the coolant by 3-5 times, while complete clarification of the water should be achieved. When carrying out hydropneumatic flushing, the flow rate of the air mixture should not exceed 3-5 times the calculated flow rate of the coolant.

For flushing, tap or process water is used.

Connection of systems that have not been flushed, and in open systems flushed and disinfected, is not allowed.

Diaphragms and nozzles of hydraulic elevators must be removed during flushing of the heating system. After flushing, the system must immediately be filled with coolant. Do not keep heating systems empty.

The heat exchangers must be chemically or mechanically cleaned before starting the system.

5.2.11. A test run of the heating system should be carried out after its pressure testing and flushing, bringing the coolant temperature to 80-85 ° C, while air is removed from the system and the heating of all heating devices is checked.

Thermal tests of water heaters should be carried out at least once every five years.

The beginning and duration of test fires must be determined by the heat supply organization, agreed with the local government and brought to the attention of consumers no later than three days before the start of the test fire.

5.2.12. The staff of the housing maintenance organization must systematically monitor the operation of heating systems during the heating season.

5.2.13. Increasing the pressure of the coolant (including short-term) over the allowable when turning off and on the central heating systems is not allowed. To protect local systems from an emergency increase in the parameters of the coolant from emptying, automatic devices should be installed in heating points.

Filling of heating systems should be done through the return line with the release of air from air collectors or heaters. The pressure under which water is supplied to the pipelines of the heating system should not exceed the static pressure of this system by more than 0.05 MPa (0.5 kgf / cm2) and the maximum allowable for heating appliances.

5.2.14. The shutdown time of the entire system or its individual sections in case of detection of water leaks and other malfunctions should be set depending on the outdoor temperature for up to two hours at the estimated outdoor temperature.

5.2.15. The release of air from central heating systems through the air collector, automatic air vents or air outlet valves on heating appliances should be carried out periodically, each time the pressure at the inlet drops below the level of the static pressure of this system, and also after it is recharged, in accordance with the instructions (see p. 5.2.6.d).

5.2.16. In places where risers are connected to distribution pipelines in attics and in basements in accordance with GOSTs.

Pipelines in heating points, attics and basements must be painted and have appropriate labels indicating the direction of movement of the coolant. Gate valves and gates must be numbered according to the scheme (project).

The outer surface of the valves must be clean and the threads lubricated. engine oil mixed with graphite.

5.2.17. Reliable operation of water heating systems should be ensured by the following work:

detailed inspection of distributing pipelines - at least once a month;

detailed inspection of the most critical elements of the system (pumps, main valves, instrumentation, automatic devices) - at least once a week;

systematic removal of air from the heating system;

flushing of sumps. The need for flushing should be set depending on the degree of contamination, determined by the pressure drop on the pressure gauge before and after the mud collectors;

daily monitoring of the temperature and pressure of the coolant.

5.2.18. Checking the serviceability of shut-off and control valves should be carried out in accordance with the approved repair schedule, and the removal of gate valves for internal inspection and repair (scraping discs, checking the density of rings, pressure testing) at least once every three years; checking the tightness of closing and changing the stuffing box seals of control valves on heating devices should be carried out at least once a year (shut-off and control valves with a design defect should be replaced with more advanced ones).

5.2.19. Regulatory bodies of valves and gates should be closed twice a month to failure, followed by opening to the previous position.

5.2.20. The replacement of sealing gaskets of flange connections should be carried out every time the flange connections are loosened, the reinforcement is removed.

5.2.21. Pipelines and heating appliances must be fixed, and their slopes are set according to the level.

Heating appliances and pipelines in apartments and stairwells must be painted oil paint for two times.

5.2.22. Pipelines and fittings of heating systems located in unheated premises must have thermal insulation, the serviceability of which must be checked at least twice a year.

5.2.23. In places where pipelines cross (in attics, basements or technical undergrounds), it is necessary to arrange transitional bridges without relying on the thermal insulation of pipelines.

5.2.24. Shut-off valves must be installed at the entrance to the building of the central heating pipelines, before and after it - instrumentation devices (pressure gauges, thermometers, heat energy and coolant metering devices).

Control and measuring devices, control and shut-off valves must be in technically sound condition and meet the established requirements.

5.2.25. The service personnel must daily enter the readings of the control and measuring instruments installed at the heating point into the registration log.

5.2.26. Registration of the temperature and pressure of the coolant should be carried out according to the readings of thermometers and pressure gauges, and heat consumption - according to the readings of heat meters.

5.2.27. Automatic regulation of heat supply to the heating system should be carried out by regulators installed according to the project or according to the recommendations of the commissioning organization.

During the reconstruction of the heating system, it is recommended to provide for the installation of expansion tanks of the membrane type and central heating, automatic front-facing regulation or the installation of individual automatic regulators for heating appliances and an automatic heat flow regulator at the heat input of the building.

Maintenance of automatic regulators (adjustment to the required control parameters, periodic cleaning, etc.) must be carried out in accordance with the instructions of the manufacturers or the requirements of the project.

Inspection technical condition of a heating point equipped with automatic control means should be carried out according to the schedule approved by the specialists of the housing stock maintenance organization, but at least once a day (in the absence of dispatcher control).

Maintenance check automatic regulators specified parameters of the coolant should be made at each inspection.

5.2.28. The start of centrifugal pumps in manual mode must be carried out with the discharge valve closed.

Before each start-up of the pumps (when the pump is running at least once a day), the condition of the pumping and other related equipment and automation should be checked.

When starting the pumps:

a) impellers of centrifugal pumps must have the correct direction of rotation - in the direction of rotation of the casing;

b) there should be no shaft runout;

c) bolts securing centrifugal pumps to the base must be securely tightened;

d) pump seals must be tightly packed, tightened and not have excessive leaks;

e) the coupling of the unit must be protected by a removable casing.

Pump bearings must be relubricated at least once every ten days, and for grease lubrication at least once every three to four months.

The temperature of the pump bearing housings must not exceed 80 °C, otherwise the grease must be changed.

5.2.29. Soft inserts and vibration-isolating bases of pumps must comply with the project and be in good condition. Rubber vibration isolators and gaskets should be replaced once every three years. The noise level in residential premises from operating pumps should not exceed sanitary standards.

5.2.30. At negative temperature outdoor air, if the circulation of water in the heating system has stopped and the water temperature has dropped to +5 ° C, it is necessary to empty the heating system.

When disconnecting the heating system from the heating network, first close the valve on the supply pipe. When closing the valve, it is necessary to make sure that the pressure in the supply network must be equal to the pressure in the return pipeline, only after that - on the return.

One of the most important issues faced by utilities is the start of heating. The risk of errors in apartment building, of course higher than in private. But in each case, it arises mainly due to non-compliance with the rules. To avoid unpleasant situations when heating is connected, it is necessary to follow the sequence of necessary actions.

When does it start heating season, it often happens that heat is distributed unevenly on the upper floors. The reason for this is too fast start of the heating system, which forms air locks, which interfere with the uniform heating of all apartments in the house.

When the heating season ends, the system remains stationary, which causes the pressure to drop in it. That is why the question of how to properly do heating, as well as its further adjustment in an apartment building, is a rather relevant issue.

The main mistakes that are made when carrying out the procedure for starting and adjusting heating in an apartment building

In order not to encounter many problems during the start-up of heating, as well as during its operation, you should know the main mistakes that are made in this process:

- Too abrupt start of heating by means of the flow line.

- Getting rid of water or coolant in the basement. It would be correct to skip this step, because in any case, the air will not leave the system like that - it rises up.

- Also, you do not need to drain water and air from all living quarters in the house.

If everything is done correctly, this need will disappear by itself.

At the same time, it should be borne in mind that in order for the system to connect smoothly, 2-3 people are required. This is necessary so that the speed of actions, their coordination is as effective as possible.

How to start heating without making mistakes in an apartment building

So, in order for the functioning of the heating system to be as efficient as possible, you must first start it correctly. For those who do not know how to properly and safely start heating in an apartment building, the action plan is as follows:

- Carry out a slow start of the coolant into the system. Make-up pumps must be turned on at the lowest power so that filling occurs gradually.

- So that the procedure is not violated, it is necessary to fill the system through the return line. The bottom-up start system is suitable for all types of houses. With this option of operation, the coolant will smoothly displace the air that has accumulated during the entire period of inactivity of the system. With these actions, you can adjust the start in such a way as to avoid the occurrence of air pockets.

- The next step is to get rid of any remaining air in the system. This is necessary so that the heating works correctly and there are no complaints about its malfunction throughout the next season. Do it in attics high-rise building where the air vents are located. They need to lower the starting valve, waiting until the characteristic suite stops, which indicates the absence of air.

- Continuing to connect the system, you need to remove water from the system, finally getting rid of the remaining air. This should be done very carefully, using any container, so as not to flood the residents of the upper floors.

- If the house does not have an attic, the water must be drained on the top floor using the Mayevsky faucet. The system starts only after this action.

Ways to properly connect the necessary heating radiators in an apartment building

If the heating is carried out correctly, the house is warm and comfortable. To achieve this, you need the correct connection of the radiators. There are many schemes for this action:

- parallel connection;

- diagonal;

- one-pipe;

- single-pipe with a jumper;

- single-pipe lower;

- single-pipe lower with a jumper or a tap;

- two-pipe;

- two-pipe lower;

- two-pipe on a diagonal.

Despite the abundance of radiator connection schemes, in practice one-pipe and two-pipe connections are used. In order to know how to set up, and then start heating in an apartment building, you need to know the advantages and disadvantages of each type. The first connection method has a number of disadvantages, although it requires less cost. The main one is the loss of heat as you go. In this case, water is supplied vertically from the basement to all floors, enters each of the apartment's radiators, and, when cooled, enters the same pipe. In the end, it almost reaches the last floor cold water, causing dissatisfaction with the tenants in the house.

Concerning two-pipe system heating, it is open and closed. However, in any case, the level of heat retention is an order of magnitude higher than with single pipe scheme. This effect is achieved by the fact that the cooled water no longer enters the pipe, but leaves through the return channel. This maintains a constant temperature feed order.

How is the heating level adjusted in an apartment building

In order for the heating system to be adjusted properly, pipes of different diameters are installed in an apartment building. The speed and pressure of the liquid together with steam, and accordingly the level of heat, is directly related to the size of the pipe opening. That is why, in order to ensure that the adjustment is carried out correctly, pipes of different diameters are used. Maximum size, which is 100 mm, are located in the basements. It is with them that the connection of the heating system begins. As for the entrances, for even distribution of heat, pipes are installed there, the diameter of which does not exceed 50-76 mm. However, this adjustment does not always give the desired heating effect. Residents of the last floors in the house suffer from this, where the temperature drops significantly. To adjust this process, use the start of the hydraulic heating system. This connection is circulating vacuum pumps, which ensures the launch automatic system pressure adjustment. Installation, as well as the subsequent start-up, is carried out in the collector of a separate building. Accordingly, the order of heating distribution along the entrances, floors in the house changes. If the number of floors is more than two, then it is mandatory to start the system together with pumping for water circulation.

What is needed in order to properly connect the heating system.

Requirements for the order of start-up and correct operation of the heating system are regulated project documentation. In order for the adjustment of the heat supply in an apartment building to be done correctly, it is carried out in accordance with the requirements of this documentation. All radiators of the heating system have thermostats, thermometers, manual balancing valves, as well as automatic start-up and regulation. Regulation of radiators does not require special tools, they are made by the residents themselves. As for the start-up and adjustment of other types, they are carried out directly by professionals in this field. This achieves the maximum effective work radiators, and, accordingly, the heating system itself as a whole.

Thus, in order to know exactly how to regulate the heating, as well as to implement a uniform supply of heat in an apartment building, many details must be taken into account.

Starting the heating system. Work order

The first launch of the heating system into operation is an extremely important event, on which the durability and trouble-free operation of heating equipment largely depends.

Works preceding the start-up of the heating system

Before the first start-up of the heat supply system, it is necessary to make an external inspection of the heating units, heating devices, pipelines. Compliance with the project of slopes, diameters, color, integrity of thermal insulation, correct installation and serviceability of shut-off and control valves, mud collectors, pumps, instrumentation are checked.

Before putting the system into operation, mandatory measures are flushing and pressure testing. The quality of the work carried out by invited specialists must be documented by acts and work schemes.

If mass switching on of heating systems is carried out, then for efficient removal air locks, it is necessary to follow a certain procedure for starting up consumers in the operating mode.

Measures to protect the system from defrosting

Heating systems are put into operation during the warm period of the year with a cold coolant. If the temperature in the street has approached zero, then a number of conditions must be observed that will help protect the system from defrosting.

In this case, the heating system is filled in groups of 3-5 risers. The beginning of filling should occur in the areas most remote from the input. After the main risers have been launched, the appliances and pipes of the stairwells are filled.

If risers and heaters that are in contact with cold outside air or located in non-insulated rooms are connected to the system, they must be cut off with shutoff valves.

Procedure for filling single-pipe and two-pipe systems

Heating systems with a lower wiring diagram, as well as single-pipe horizontal systems filled with coolant through the direct and return lines. If a horizontal single-pipe heating system is being filled, then the pipes and appliances of one floor are first filled, and then all the following in succession.

In gravity systems, the filling of heating equipment with water occurs entirely, without division into parts. If the pressure tap water sufficient, then the system is filled by gravity, and if small - with the help of pumps.

After filling the heating system, it must be adjusted so that a hydraulic balance is achieved in all parts of the system. If the equipment is not adjusted, then some devices may be completely filled with coolant, while others may not be enough.

After implementation preparatory work and further launch of the heating system, the heat energy consumed for heating this object is calculated. If the heat load in the network does not correspond to the established one, then the system must be regulated.

Adjustment can be qualitative, at which the temperature of the coolant changes, and quantitative, which requires a change in the intensity of the flow of liquid.

The first type of regulation is carried out centrally - at the heat supply point, and the second method - directly in the heating system of the building.

A carefully tested, balanced and adjusted heating system is a guarantee of its trouble-free and efficient operation in the winter.

How to properly start the heating system in the house: the order of work

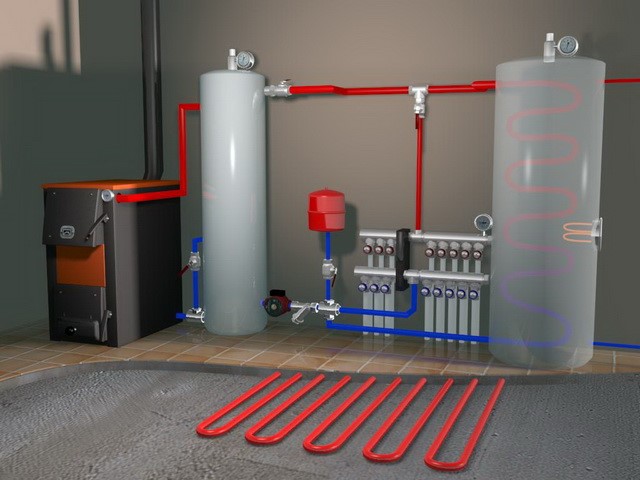

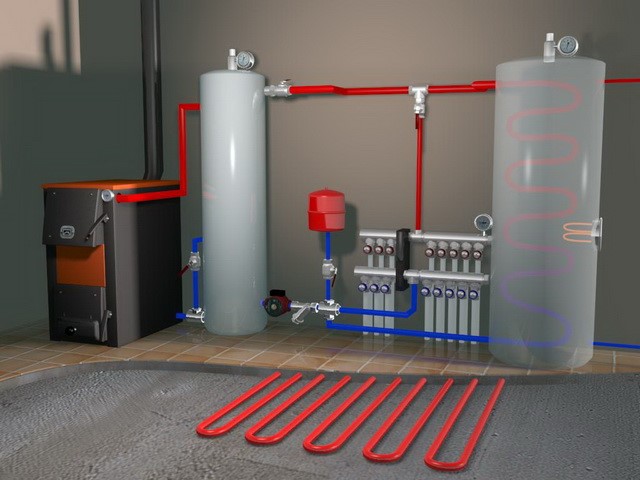

What determines the normal functioning of the heating system? There are several objective factors that directly affect the efficiency, reliability and maintenance of its performance. Therefore, first of all, you need to know how to properly start the heating system in the house. The best way to see this procedure is with an example. autonomous system country cottage.

Preparing the heating system for start-up

Heating system private house

In the vast majority of cases, heating is inactive in summer period. Therefore, it is necessary to check the safety and reliability of its main components, as well as to carry out a number of preparatory work. Before you start a closed heating system, you need to find out the degree of deviation of its actual parameters from the calculated ones.

First carried out visual inspection lines and radiators. For the owner, the first question should not be how to start the heating battery. It is necessary to check its body for possible mechanical damage, as well as to check the reliability of the connection with the pipeline.

Along with this, the monitoring and preventive work of the following plan is carried out:

- Chimney system check. How to start the heating boiler if the draft in the chimney is not enough to support the combustion process? Therefore, they clean the internal cavity from soot, and also check the integrity of the pipe. Brick structures can be "upgraded" by replacing broken bricks. Rust may appear on galvanized pipes, which should be removed;

- Visual inspection of pipes. Since it will be simply dangerous to start heating without this, you need to find out if all the pipes have retained their tightness, if there are any cracks or obvious defects in the system;

- Monitoring the condition of radiators. You need to know that before you start heating in an apartment building - Management Company residents should be warned. They, in turn, check the condition of the batteries. It is not allowed to disconnect individual radiators from the network. During the filling of pipes with coolant, the absence of leaks is checked.

it general rules, without which the first start-up of heating is not recommended. But how to start heating in a private house correctly? To do this, it is recommended to perform a number of procedures.

A test run of heating in an apartment building is carried out 1.2-2 months before the start of the heating season. During its implementation, it is recommended to stay at home to check for leaks.

Filling the heating system with coolant

Filling the system with coolant

It must be recalled once again that before starting the heating system at home, a visual inspection of all elements is performed. If necessary, individual components and components are replaced. Only after that you can proceed to the procedure of filling with coolant.

In the absence of water, a slight rust coating will inevitably form on the inner walls of the radiators and the heat exchanger. Therefore, before the coolant is filled, it is recommended to clean the system.

Flushing the heating system

If there is still coolant in the pipes, you need to remove it. This can be done through a special pipe located at the lowest point of the system. There should also be a recharge node. Only after that you can continue to solve the question - how to properly start the heating system.

For closed schemes heating with forced circulation hydrodynamic flushing is recommended. To do this, you should purchase (or better, rent) a special pump with filtration and a chamber for cleaning fluid.

Flushing procedure:

- Connecting the pump nozzles to the system;

- Start-up and visual control of the degree of contamination of water that has gone through a full cycle through the pipeline;

- If necessary, replace the fluid with a new one;

- Do several flushing cycles until the water is completely clear.

After that, pressing is performed. Before starting the heating radiator, you need to check the condition of its connection to the pipeline. It is recommended to replace the gaskets, as well as to check the integrity of the couplings.

For start closed system heating, an increased amount of coolant (or air) is injected into the pipeline. It is necessary to check the reliability connecting elements systems. The pressure value must exceed the nominal value by 1.2 times.

The liquid after flushing must not be disposed of into the sewer. It contains harmful components that will adversely affect the operation of autonomous sewage.

Adding coolant to heating systems

Make-up heating unit

As a coolant, you can use ordinary distilled water or antifreeze. Filling is done through the sub-picture node located at the lowest point.

This is important, because if you try to add water through other nozzles located above, the likelihood of air pockets will increase. In order to make the correct start of the heating battery, it is recommended to check the presence of Mayevsky cranes and their performance. To do this, open each of them. Then you need to follow the following procedure:

- The air and drain valves located at the highest point of the system open;

- The faucet of the file unit opens smoothly. The water pressure should be small so that air jams do not form;

- After the coolant flows from the nozzles of the air and drain valves, they should be closed;

- Mayevsky's taps remain open until a coolant starts to flow from each instead of air. This is important, since starting the heating boiler in the presence of air pockets can damage the entire system.

If pressure testing has not been done before, it can be done while filling with water. Pressure control at the start of heating at the stage of filling with water is carried out using pressure gauges installed on the boiler, safety group and collectors.

If you plan to fill the system with antifreeze, you need to use propylene glycol. Unlike ethylene glycol, it is completely safe for humans.

First start of the heating boiler

The procedure for the first start-up of the boiler before the start of the heating season depends on its model and type. But despite this, a visual check of its condition is performed. This is one of milestones, preceding the final launch of heating in a private house.

The heat exchanger is one of the most "vulnerable" element of the boiler. Its verification is mandatory, because during the operation of the device it is constantly exposed to high temperatures. Along with the task of starting the heating radiator, the preparation of the boiler is one of the most important during the process.

solid fuel boiler

Design solid fuel boiler

Before the start of the heating system has not yet taken place, a comprehensive monitoring of the state of the solid fuel boiler is carried out. Its surface is cleaned of rust, the performance of the pressure gauge and thermometer is checked.

Then follow these steps for the correct start of the heating system:

- Sedum firebox and ash pan from soot. This can be done with a metal brush;

- Checking the condition of the chimney. Its pipe must be securely connected to the boiler nozzle.

For pyrolysis and pellet models, the operation of the electronic control unit, fans and nozzles is tested. When the heating system starts up correctly, the malfunctioning of these elements can lead to sudden temperature fluctuations, which directly affects the condition of other components.

In the room where the solid fuel boiler is located, flammable substances must not be stored. For fuel storage, you also need to allocate separate room or an outbuilding.

Gas boiler

General scheme gas boiler

Before you start the gas heating boiler, you should read its instructions. For various models The order in which the steps are performed may vary slightly. It's connected with various types designs. In particular, this applies to condensation models, in which during operation it is necessary to trace the correct formation of condensate. Without it, heating the secondary heat exchanger will not be possible.

How to properly start heating with a gas boiler? After filling the system with water, you need to do the following:

- At the bottom of the boiler there is a valve that shuts off the flow of water into the circuits. After the end of the heating season, it can be closed. Therefore, you need to open it - while the pressure gauge readings will change. The pressure value should not exceed 3 atm;

- After heating the coolant, you need to open the make-up valve again. If air plugs remain in the system, you can remove them using Mayevsky taps. The pressure in the system during this stage may decrease slightly;

- In fact, you will have to start the sinking radiator 2 times. The first - during filling with coolant, and the second - when the boiler is turned on;

- The correct functioning of the boiler is controlled by the values on the dashboard.

The result of starting heating in a private house should be a stable temperature regime the entire system, as well as the absence of pressure surges in the pipes.

Often, the service for the first start-up of a gas boiler is provided by specialized service centers from manufacturers. Their rates are much lower than other companies.

Checking the elements of the heating system

You need to remember about other elements of the system. Indeed, without their correct operation, it is impossible to properly start the heating system. First of all, you should check the normal functioning of measuring instruments - pressure gauges of thermometers.

The operation of protective components must also be monitored. Proper start-up of the heating system can be thwarted if the vent or bleed valve seats are unable to move due to rust or limescale. To do this, you need to manually open each of them.

AT expansion tank air chamber pressure is controlled. It should be higher than the nominal value in the system by 5-7%. If the design of the tank provides for the possibility of replacing the membrane, you need to disassemble it and check its condition.

Currently, the service for starting the heating system is very rare. It is impossible to indicate at least approximate prices - in most cases, the price is formed on an individual basis. Its size directly depends on the current state of the system and its complexity.

In the video material you can get acquainted with the technology of filling the heating system with coolant.

How to properly start heating in an apartment building

One of the most important problems that utilities face is starting heating. The risk of errors in an apartment building is, of course, higher than in a private one. But in each case, it arises mainly due to non-compliance with the rules. To avoid unpleasant situations when heating is connected, it is necessary to follow the sequence of necessary actions.

When the heating season begins, it often happens that heat is distributed unevenly on the upper floors. This is due to the too rapid start of the heating system, which forms air jams that prevent the uniform heating of all apartments in the house.

When the heating season ends, the system remains stationary, which causes the pressure to drop in it. That is why the question of how to properly do heating, as well as its further adjustment in an apartment building, is a rather relevant issue.

The main mistakes that are made when carrying out the procedure for starting and adjusting heating in an apartment building

In order not to encounter many problems during the start-up of heating, as well as during its operation, you should know the main mistakes that are made in this process:

- Too abrupt start of heating by means of the flow line.

- Getting rid of water or coolant in the basement. It would be correct to skip this step, because in any case, the air will not leave the system like that - it rises up.

- Also, you do not need to drain water and air from all living quarters in the house.

If everything is done correctly, this need will disappear by itself.

At the same time, it should be borne in mind that in order for the system to connect smoothly, 2-3 people are required. This is necessary so that the speed of actions, their coordination is as effective as possible.

How to start heating without making mistakes in an apartment building

So, in order for the functioning of the heating system to be as efficient as possible, you must first start it correctly. For those who do not know how to properly and safely start heating in an apartment building, the action plan is as follows:

- Carry out a slow start of the coolant into the system. Make-up pumps must be turned on at the lowest power so that filling occurs gradually.

- So that the procedure is not violated, it is necessary to fill the system through the return line. The bottom-up start system is suitable for all types of houses. With this option of operation, the coolant will smoothly displace the air that has accumulated during the entire period of inactivity of the system. With these actions, you can adjust the start in such a way as to avoid the occurrence of air pockets.

- The next step is to get rid of any remaining air in the system. This is necessary so that the heating works correctly and there are no complaints about its malfunction throughout the next season. This should be done in the attics of a multi-storey building, where air collectors are located. They need to lower the starting valve, waiting until the characteristic suite stops, which indicates the absence of air.

- Continuing to connect the system, you need to remove water from the system, finally getting rid of the remaining air. This should be done very carefully, using any container, so as not to flood the residents of the upper floors.

- If the house does not have an attic, the water must be drained on the top floor using the Mayevsky faucet. The system starts only after this action.

Ways to properly connect the necessary heating radiators in an apartment building

If the heating is carried out correctly, the house is warm and comfortable. To achieve this, you need the correct connection of the radiators. There are many schemes for this action:

- parallel connection;

- diagonal;

- one-pipe;

- single-pipe with a jumper;

- single-pipe lower;

- single-pipe lower with a jumper or a tap;

- two-pipe;

- two-pipe lower;

- two-pipe on a diagonal.

Despite the abundance of radiator connection schemes, in practice one-pipe and two-pipe connections are used. In order to know how to set up, and then start heating in an apartment building, you need to know the advantages and disadvantages of each type. The first connection method has a number of disadvantages, although it requires less cost. The main one is the loss of heat as you go. In this case, water is supplied vertically from the basement to all floors, enters each of the apartment's radiators, and, when cooled, enters the same pipe. In the end, almost cold water reaches the last floor, causing dissatisfaction with the residents in the house.

As for the two-pipe heating system, it can be open and closed. However, in any case, the level of heat conservation is an order of magnitude higher than with a single-pipe scheme. This effect is achieved by the fact that the cooled water no longer enters the pipe, but leaves through the return channel. This maintains a constant temperature feed order.

How is the heating level adjusted in an apartment building

In order for the heating system to be adjusted properly, pipes of different diameters are installed in an apartment building. The speed and pressure of the liquid together with steam, and accordingly the level of heat, is directly related to the size of the pipe opening. That is why, in order to ensure that the adjustment is carried out correctly, pipes of different diameters are used. The maximum size of 100 mm is located in basements. It is with them that the connection of the heating system begins. As for the entrances, for even distribution of heat, pipes are installed there, the diameter of which does not exceed 50-76 mm. However, this adjustment does not always give the desired heating effect. Residents of the last floors in the house suffer from this, where the temperature drops significantly. To regulate this process, use the start of the hydraulic heating system. This is the connection of circulation vacuum pumps, which ensures the launch of an automatic pressure control system. Installation, as well as the subsequent start-up, is carried out in the collector of a separate building. Accordingly, the order of heating distribution along the entrances, floors in the house changes. If the number of floors is more than two, then it is mandatory to start the system together with pumping for water circulation.

What is needed in order to properly connect the heating system.

Requirements for the order of start-up and correct operation of the heating system are regulated by project documentation. In order for the adjustment of the heat supply in an apartment building to be done correctly, it is carried out in accordance with the requirements of this documentation. All radiators of the heating system have thermostats, thermometers, manual balancing valves, as well as automatic start-up and regulation. Regulation of radiators does not require special tools, they are made by the residents themselves. As for the start-up and adjustment of other types, they are carried out directly by professionals in this field. At the same time, the most efficient operation of radiators is achieved, and, accordingly, the heating system itself as a whole.

Thus, in order to know exactly how to regulate the heating, as well as to implement a uniform supply of heat in an apartment building, many details must be taken into account.

Gas heating in an apartment building Payment for heating in an apartment building  Heating system in an apartment building

Heating system in an apartment building

In the last article, we talked about installing a heating boiler. but other than that, important point is its launch. In order to perform the first start-up of the boiler, it is not necessary to invite specialists from the service center. Judge for yourself, this condition, under which a brand new boiler is put on a “free” warranty service, is not worth a penny - anyway, in the future, if a breakdown occurs, you will have to pay for spare parts and for the work of the master.

So what free warranty repair can talk? Moreover, for first start of the boiler you will also be charged a fee, and a rather big one, motivating it with commissioning. Don't want to waste money? Then we read further and learn to start the boiler on our own and debug the operation of the heating system, all the more, it is not difficult.

How to start a heating boiler correctly

Starting a gas boiler

The initial stage, which involves the first start-up of the boiler, is filling the heating system with water. I think you will definitely cope with this task without outside help. We look under the boiler, where all the communication pipes are connected, and look for something resembling a faucet there - it can be made in the form of a lamb familiar to us, or it can be a flag or just a rotating pin. In any case, it is difficult not to recognize it, but in which case, its location can be determined by looking at the instructions for the boiler equipment.

Found? We slowly open it, draw water into the system and wait for the pressure indicator on the boiler to reach 3.0 atm, and while the system is being filled, we go and look at all pipes and batteries for leaks. And along the way, we immediately eliminate them - we tighten the nuts and close Mayevsky's open taps.

After the pressure in the system reached 3 atm. we close the make-up tap, go through all the batteries one by one and use the Mayevsky tap to bleed air from them. We return to the boiler again and add water to the system until the pressure indicator on the boiler shows 2-2.5 atm.

Well, the system is dialed, you can start directly starting a gas boiler or an electric one, in principle, there is no difference in the process of starting them. To do this, you will have to disassemble the boiler a little - do not be afraid, anyway, we will not climb where something can be broken. Our task is to get to circulation pump- it is he, or rather the air accumulated in it, that is the reason for not turning on the boiler equipment at the first start.

The location of this pump is easy to see - it is a cylinder, located end to us, in the center of which there is a wide screw with a slot for a screwdriver. This is the screw we need.

Did you find this stumbling block? Then you can plug the boiler into a socket and install the necessary levers in working position- from this moment it happens first start of the boiler. Immediately after the boiler receives its energy supply, the circulation pump will turn on and the electronics will make futile attempts to turn on the rest of the equipment. It is at this moment that there is no need to rush, slowly unscrew the central screw of the circulation pump and let the air out of it.

As soon as water flows from under the screw, we quickly close it and calmly observe the noisy operation of the boiler. Now it will open electronic valve gas supply, the electronic ignition will work and the boiler will start. It will gurgle, grunt, make some strange sounds, but this is normal - the boiler just expels air that has hung in some places from the heating system. The design of the boiler equipment includes the so-called expansion tank, which is equipped with an automatic air release valve - it is through it that the remaining air is removed.

A few minutes later, when the operation of the boiler stabilizes and the gurgling sounds subside, we check the pressure in the system and, if necessary, bring its value to 2-2.5 atm. by opening the faucet for filling the system with water. At first, while the heating is just getting better, the system can be replenished with water several times - periodically you will have to check the pressure gauge readings and, if necessary, replenish the volume of water in the system.

Well, we figured out how to start the heating boiler, the equipment is working fine, the batteries are starting to warm up - it's time to start debugging the operation of the entire system.

How to set up the heating system after starting the boiler

Adjustment of the heating system

To adjust the heating system, we need to carry out small manipulations with the control valves. The fact is that almost all installation schemes for an individual heating system have one small drawback - the last batteries from the boiler, as a rule, do not have enough thermal energy. She just doesn't get there. the right amount and we will be required to eliminate this drawback by distributing the supply evenly hot water between all heaters.

This is not difficult - the control valves of the first two or three batteries need to be screwed a little. If you go from the boiler, then the tap of the first battery is twisted halfway, the second is a little less, and the third is even less. Here you have to experiment - to achieve uniform heating of all batteries, it may take several days. But this does not matter anymore, because in general the heating system works fine, and the house is warm.

How to start a heating boiler

This is how, without making any effort, the first start-up of the boiler and the adjustment of the heating system are performed. As you can see, there is nothing complicated about this, and the money that representatives take for it service centers she's not worth it. Better spend them on the purchase of an electronic room temperature control system - this programmer will reduce energy consumption wall boiler heating!

Having completed the arrangement of the heating system of a private house with their own hands, the owners cannot yet use it. Must be carried out in a certain sequence preparations. First, at this stage, shortcomings can be identified and quickly eliminated. Secondly, some equipment, such as a pump, can simply fail at the first start.

We will describe below how the heating system starts up. We will also tell you how to properly start the operation of heating in the cold season.

Coolant filling.

Start-up begins with pouring coolant into the pipelines - water or non-freezing liquid. But before that, we bypass the system and make sure that all the taps on the mains and radiators, and especially on expansion tank, open (no need to install a tap on the safety group), with the exception of the units for draining water on radiators.

A pump is needed to fill the pipelines. Acquiring it is a costly business, so it is better to rent. We connect the pump to the coolant drain and fill unit, mounted at the lowest point of the pipe on the return. We continue to pump liquid until the pressure gauge shows a pressure in the system of 1.5 atmospheres - this is the normal operating value for heating in private homes.

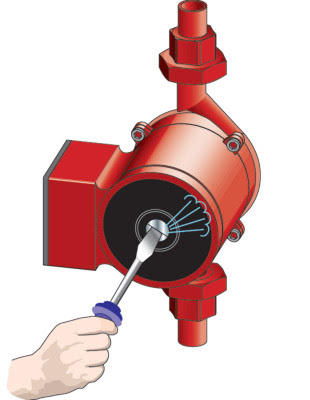

Bleeding air from the pump

The pipelines are full, which means that we will soon move on to work on pressure testing of the system - checking it for the strength of all connections, for leaks. But before that, it is important not to forget to bleed the air from the pump. Without doing this, the first time you start the device, it may fail.

On pumps designed for heating systems with forced circulation, valves are arranged in the form of a screw for quick air download. We just turn the valve, air enters with noise, we twist it into place. It is more convenient to use a screwdriver with a wide, flat head-slot for these manipulations. You can continue to start the system.

We bleed air from the radiators.

The pressure in the system is kept at 1.5 atmospheres. Now you need to go through all the heaters again and manually bleed the air from them. On each radiator, with the help of Mayevsky taps inserted into the upper free connection unit, slightly open them. We bleed until one water flows out of the hole.

After we have de-aired the pump and heaters, we check the pressure on the pressure gauge. If it drops below 1.5 atmospheres, top up the coolant. Now once again, be sure to bleed the air from the pump, and preferably from the radiators.

Do not flatter yourself that there is no air left in the pipelines at all. If the system is equipped with automatic air vents, it will clear itself in 2-4 weeks. In other cases, the owners themselves must bleed the air manually again 2-3 weeks after the completion of the work. But on this moment the start of the heating system can be continued - it is necessary to carry out pressure testing.

Crimping

The task of crimping is to test the system for strength. If all the nodes were assembled with high quality, then this stage of work is the fastest. It is carried out as follows - we pump water into the pipelines with a pump until the pressure gauge shows a pressure that is 1.5-2 times higher than the norm, that is, about 2.5-3 atmospheres.

In this state, leave the system for a quarter of an hour, then measure whether the pressure gauge readings have changed. If not, then there are no leaks. We drain the excess coolant and return the working pressure.

Boiler start.

Finally, we turn to the main thing - starting the boiler of the heating system. It is already connected to the network, ready to use. To begin with, we set a low system temperature on the thermostat - 40-50 ° C. We give time to warm the entire volume of the coolant, then we go around the heating devices, we check whether all areas are heating normally. Often the upper parts of the sections on the radiators are noticeably colder - you will have to bleed the air again.

Now set the temperature of the coolant to 70-80 ° C. Leave it like this for a few hours. If even now the radiators are functioning normally, and the temperature of the water in the return pipe is about 20 ° C colder than the heated one, then heating a private house with your own hands is of high quality.

Temperature sensor.

If a temperature sensor - a thermostat - is used to control the temperature, it must be connected to the boiler. The cover is removed from the boiler, terminals with the designations "air temperature sensor" must be provided on the control panel. The contacts of the wire leading to the thermostat are fixed in them. There are wireless connection options.

The presence of a temperature sensor does not just make the temperature in the house comfortable all year round. Also, the device allows you to use fuel more economically (on average, in the cold season, costs are reduced by 30%), the load on the boiler itself and the pump is reduced - their service life is extended.