Long-burning wood-burning convection oven. Long-burning wood stoves for summer cottages. Long-burning wood stoves for home: types and designs

IN Lately people often use wood stoves long burning for heating private houses, cottages and other buildings. Indeed, climatic conditions in Russia require constant heating of premises in winter period. Owners country houses are unable to connect to central systems, and therefore they are looking for alternative options, among which not the least place is occupied by various ovens.

An important source of renewable energy is straw. When burning straw, the same amount of carbon dioxide is produced as in the case of mineralization. Unfortunately, it is difficult to burn due to the troublesome air. As a result most of it doesn't burn. Most important criterion For straw as fuel, moisture content is used. High humidity creates difficulties in straw storage, increased transport costs, incorrect installation and reduced boiler efficiency.

Cereal grains and fruit seeds can also be used for cauldrons. The most common is the combustion of oats, of which 3 kg can consume as much heat as 1 liter of fuel oil. The advantage of all these fuels is their low cost of extraction and the need to process them to make them suitable for combustion in boilers.

If the building only serves as a summer cottage and is rarely visited, then traditional stove options are not entirely suitable. The fuel will burn quickly and warm air evaporates. Therefore, experts advise using wood-burning stoves for heating a dacha with a long-burning function. Between the stages where you need to add firewood, such models have a calculated time period of 6-20 hours.

Briquettes and pellets, i.e. treated wood

The calorific value of wood is low. Additionally, it requires more storage space than coal. Wood chips take up about six times the carbon volume that can generate that much heat. This is also due to the need to refill the boiler more frequently.

Positive and negative sides

Better in this regard are briquettes made by compressing chopped wood and smaller pellets - pellets with a diameter of 8 to 10 mm, obtained from chopped parts of wood, straw, energy crops, hay, grain crops and even sludge without the participation of other chemicals - by pressing under pressure through a matrix with holes. Most important advantage This type of fuel has a higher calorific value than untreated wood, which is due to its mass density and low moisture content.

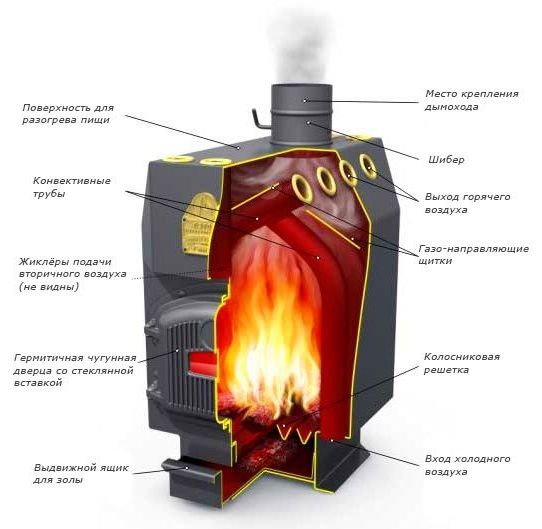

Design and operating principle

In general, design is a characteristic that may differ depending on the manufacturer and the features of a particular model. But absolutely all long-burning stoves are made on the basis of the following elements:

- Metal body;

- Hermetic sections of primary and secondary combustion;

- Air dampers with adjustable function.

Video on the topic

If briquettes and pellets good quality, they burn almost completely, and the resulting ash can be used as mineral fertilizer. Briquettes can be used as a substitute for wood, coal or other solid fuels, therefore not only in boilers, but also in fireplaces. On the other hand, for efficient combustion of pellets, devices equipped with special burners with feeders automatically distribute fuel.

The simplest solid fuel boilers are called top combustion boilers. At the same time, part of the loaded fuel is reduced from below, and the exhaust pipe is discharged through a channel at the top of the furnace chamber. In such a boiler you can burn almost anything, including wood or briquettes. However, they burn relatively quickly and at the same time inefficiently. In top combustion boilers, wood is best used only as a fuel additive, such as coke or coal.

Of course, people are interested in how this design works. These heating devices use the principle of controlled air flow into a special chamber. Thanks to the functions of controlling the air supply to the firebox, it is possible to create a smoldering process of the fuel, and the heat exchanger heats up accordingly. The house becomes warm thanks to the following actions:

Which oven should you choose?

More suitable for burning wood are bottom mountain incubators, where the exhaust port is located at the bottom of the furnace chamber, so that only the lower part of the fuel loaded into the boiler burns intensely. This makes it easier to control the combustion process. They have two or three exhaust gases that allow them to burn volatile substances before they reach the chimney. This facilitates the fan blowing air into the hearth, overcoming the increased resistance to flow. A special electronic pressure control unit automatically adjusts the combustion intensity for heating needs.

- After adding fuel, it is ignited, and the device operates at maximum capabilities with the dampers fully open. This happens until the temperature reaches 200 degrees.

- After this, the dampers will close slightly and the flow of oxygen will decrease.

- The intensity of combustion gradually decreases, and the fuel, in fact, simply begins to smolder.

- Hot heat exchanger in the design it is separated from the metal body, and air circulates freely through it. A heat exchange process occurs during which the air is heated and provides comfortable conditions in the house.

Lower combustion boilers achieve higher efficiency than top boilers, so they use less fuel and release fewer pollutants into the atmosphere, and are a little less of a hassle to handle. Boilers called gasification are built specifically for the purpose of optimal combustion of wood. The higher the efficiency and the lower the emissions, the higher the efficiency. They are achieved by conducting the combustion process in such a way that air flowing from the top of the loading chamber pulls out the wood burning in it and causes gasification of the cellulose contained in it.

Although at first glance the design and operating principle of the device seem quite complex, such a heating device is easy to use and is reliable. Also, long-burning stoves have high efficiency, and some models can operate for about 24 hours in autonomous mode.

Varieties

All furnaces of this type can be divided according to several criteria:

Stove with water circuit for home heating

This burns particulate matter and reduces carbon monoxide and hydrocarbon emissions. Secondary air used to burn volatile substances does not mix with primary air charcoal necessary for combustion and gasification. The combustion chamber is usually lined with a heat-resistant ceramic material. Boilers with fixed grids are used to burn dry fuels, and boilers with movable stacks are used for burning wet fuels. They allow the fuel to evaporate in the first phase, and then when it moves into the furnace, it is completely burned.

- Purpose (for sauna, cooking or universal);

- Depending on the type of fuel used (regular firewood, wood waste or coal);

- By production method (factory models or homemade versions);

- According to the material used (steel, brick, cast iron, etc.).

Undoubtedly the most important characteristic The furnace becomes the material used in production, the performance characteristics, service life of the device and other important details largely depend on this.

For burning pellets, wood chips and sawdust with automatic system fuel supply. They do not require constant maintenance and can cooperate with a weather automation system. The fuel is placed in a special tray, where it is collected using an electric drive and is automatically controlled depending on the temperature in the room or outside. The control unit also controls the combustion air fan.

Fuel is replenished every few days, less often the larger the tank. It is possible to automatically transport fuel from a large silo that stores enough fuel for the entire heating season. Boilers of this type have retort burners and screw feeders. They are designed in such a way that they can be smoked with carbon dioxide and, if necessary, replaced with briquettes or pellets.

On this moment There are three main options for stoves based on materials:

- Steel.

- Cast iron.

- Brick.

In addition, you will have to decide on the type of fuel used; there are options for stoves running on liquid or solid fuel. There are no universal models, so you still have to make a choice. Experts advise not to conduct experiments in such a situation, and to make a choice in favor of a traditional source of fuel - firewood. This material is not very expensive and is always available.

Pellet stoves have pneumatic trays with long hoses that can suck fuel from a hopper even several meters from the boiler. Undoubtedly the most big advantage pellet boilers is almost complete automation of their operation. There are usually built-in igniters that allow the fuel to automatically ignite after complete extinguishing, controlling the oxygen in the exhaust gases and automatic control feeding device, blower air to the hearth and circulation pumps- depending on the temperature indoors or outdoors.

Also when choosing heating equipment It is worth paying attention to the functionality of the models; there are options with automatic refueling capabilities. This allows you to significantly reduce labor costs for maintenance and operation of the device. If a person decides to purchase a gas-generating device and wants to install it in the kitchen, then it is better to take models with hob, which will allow you to conveniently prepare food.

To ensure the safety of the boiler, it can be equipped with an automatic fire extinguishing system and prevent it from returning to the fuel tank. The operation of such a boiler is less burdensome than the operation of other solid fuels. It provides the same comfort as an oil boiler.

How long does a heated cocktail bench cost? The cushions on the bench will be well insulated. Large thermal accumulators, such as our two-person stove-heated bed, stay warm for two or even three days after a longer burn. You can wrap the barrel or partially cover it with an artistic or welded design. There may be less toxic stove paint that you can use to paint the can a fun color, or you can polish it with abrasive paper or a rotary wire brush attached to an electric drill.

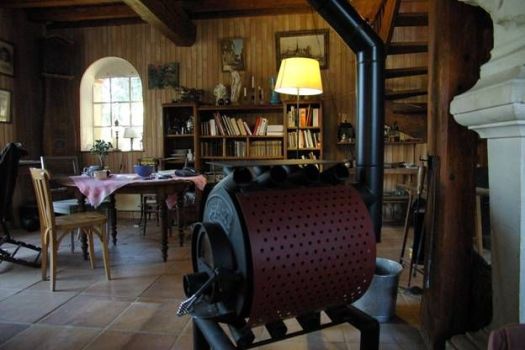

Today, people often buy pyrolysis fireplace stoves, which, in addition to heating the room, also become one of the most important elements of the interior. Such a heating device will significantly improve the design of the room, regardless of its style. Also, such a fireplace is equipped with a transparent fireproof glass door, which allows you to observe the flame during combustion.

As an alternative to barrels, you can use a cylindrical water tank or brick column, a common solution in Denmark. European thermal mass burners are usually covered with decorative glazing. The best way Drying a stove means lighting a small fire to gradually heat it up. The beauty of working with a lot of sand in a sand-clay mixture is that the sand will stabilize the mixture and prevent cracking, so you don't have to wait too long, dry it soft.

Can my children burn? Probably not. At a small child's height, the barrel temperature is quite low, much cooler than most metal furnaces. Fuel cannot roll out of the hearth and there are no exposed coals as they are in open fireplaces. Most other heating options are literally lethal to our offspring: oil, gas, electricity or killers for other species.

Prices

It is worth considering that beautiful appearance, cooking functions or automatic control of operation heating device increases the cost of the furnace. For some models you will have to pay up to 100 thousand rubles.

More simple ovens heating houses with wood is not that expensive, and is not only efficient, but also economical solution. Yes, for heating small dacha the device will be enough Russian manufacturers with a simple design, its cost will be 10-15 thousand rubles. It is worth noting that such a device will help you save money only if you have a chimney; if you don’t have one, then you will have to spend a lot of money on construction.

Wood fuel comes from sunlight and reunites after a few years as it grows, absorbing carbon dioxide, allocated by your stove. Preparation takes the most big time- assembly and organization of materials and tools, furnace design. Once all this is done, two people can easily build a nice stove over a weekend or even one day if they have the experience. Completing the heat storage part. Buildings that are not permanently occupied, such as churches, meeting rooms, etc. must heat up quickly and long-term storage is not an advantage.

Long-burning wood stoves are popular not only in countries with harsh climatic conditions; in particular, they are actively used in Western European countries. It's confirmed a large number imported manufacturers of devices of this type. Therefore, when choosing heating devices for country house It is worth paying attention to such stoves. They are especially popular for use in dachas, greenhouses and other similar facilities. The main thing is to correctly approach the choice of a specific model, familiarize yourself with all the advantages and disadvantages, and study the selection criteria.

In large apartment buildings, in very cold areas where heat needs to reach rooms away from the stove, it would make more sense to heat those rooms forced circulation air. In a workspace like a wood shop where someone sits down, the stove will benefit from using a lot of radiant heat instead of heat, so you can quickly adjust your thermal comfort by moving closer to or away from the stove. In outdoor areas or living spaces that are not well insulated, such as tents or terraces, the air heated by the heat accumulator leaves the enclosure before you can enjoy it.

Positive and negative sides

Ovens of this type have many advantages, but it is also worth noting that they also have disadvantages. Therefore, before you go shopping for such a stove, you should weigh the pros and cons, and only make your choice based on this. You should start by studying the positive aspects, and here they are represented by the following features:

It is better to install a stove that radiates at high temperatures, such as a Rumford stove or fireplace. Almost certainly, if you already have a poured concrete floor or wooden floor. Even in the frigid British isles, the Romans warmed their villas from the cold two thousand years ago. The hypocaust contained a series of underground channels that distributed the hot gases emitted from the furnace. Nowadays it is more convenient to use metal pipes, embedded in clay or concrete in the floor, or placed in sand under a brick, stone or stone tile floor.

- Stoves of this type allow you to save heating materials, so the firewood in them will smolder much longer than in traditional options;

- High ratio useful action, in these devices it reaches 85%;

- The dimensions of such a device are small, which saves space;

Be sure to provide rodent-proof or soot-proof mouth cleaners. How long does the barrel last? Doesn't it oxidize? But if all the oxygen is consumed while you keep it dry, it can't oxidize on the inside or rust on the outside, so it should last a very long time. I only have short and thick firewood. They will burn without difficulty, but you may have to set the wood down more often, and the feed tube should be as smooth as possible to prevent the wood from getting stuck and sticking.

Anyway, you'll need a long fire to shoot fire. Is there a direct air supply from outside? Won't she consume all my oxygen in the house? Any furnace burns oxygen. But it doesn't selectively remove oxygen from your home, leaving you suffocating in a nitrogen-filled room. The stove pulls air out of the house, not just oxygen. And no, we are not left without air, because when the air is absorbed by the supply tube, the small draft created in the room draws “spare air” from somewhere else.

- A variety of models allows you to choose an individual option for a specific room interior;

- Working with such equipment is quite simple. You can switch the active mode to smoldering by controlling the amount of incoming oxygen. You only need to add firewood after 6 or more hours;

- Possibility of application various types fuel. Options for solid materials allow you to use not only firewood, but also pallets, wood waste, coal, etc. There are also liquid fuel options.

- A complex chimney design that must meet all requirements and standards. Its construction will also entail a waste of money;

- This device is not compatible with multi-pass curved chimney pipes. The fact is that condensate is intensively produced, which must be removed using powerful draft;

- During combustion, many unnecessary substances are released, so the chimney requires regular maintenance;

- The smoldering mode cannot be activated immediately; first, it is necessary for the house to warm up to a certain temperature, and only then the economical mode begins to operate;

There are no universal options for long-burning stoves. Each buyer will have to choose either liquid fuel or wood stoves; there are no combined models.

How to choose the right oven of this type?

The choice of a long-burning stove for your country house should be made taking into account many characteristics, each of which determines the purchase of one or another option.

- Manufacturer company. Here, as always, you have to choose between domestic and imported options. The former are considered cheaper, and the latter are considered to be of higher quality. Among Russian manufacturers it is worth paying attention to the companies Breneran, Termofor and Ermak, and among foreign manufacturers to Zinger, La Nordica EdilKamin, etc. The best thing to do is look good options in terms of price and quality ratio, so as not to overpay and get truly reliable equipment.

- Functionality. Before purchasing such equipment, you need to determine its role in heating the room, whether it will be the main heating device or just an additional one. Experts also advise buying those options that have the function of afterburning flue gases. For country houses Options with a hob would be useful.

- The speed of heating the air in the room. In this characteristic, everything depends on how often the equipment will be operated. If this is a summer house, and heating of the room is needed only occasionally, then it is better to purchase a steel model, it works much faster.

- The area of the heated building. Compact options wood stoves long burning are used as an additional heat source. Such devices will help to heat rooms without dividing walls. A conventional stove with an installed water circuit can be installed as the main heat source. This option heating system will cope with heating even large country houses.

Features of application

If you buy wood stoves for heating a private home, the manufacturer always adds instructions to them that allow you to familiarize yourself with the basic operating rules. Such documentation contains absolutely all the comments, even the recommended fuel humidity is stated. But even careful study of the instructions and compliance with all operating rules does not always allow you to avoid troubles.

- When installing the device, the pipes must be assembled against the movement of gases, this will prevent soot from settling on the floor of the room;

- There is no need to be fancy with the installation diagram; it should be simple so that it can be easily disassembled if necessary;

It is worth considering that the surface of the device gets very hot, and the space near it should be safe and inaccessible to children.

Video

The problem of conservation and economical use of energy resources is currently very acute. City residents usually do not have many opportunities to save, since all apartments are connected to the system central heating. Prices for housing and communal services for all apartments of equal size will be the same, so everyone finds themselves in the same conditions. Another thing is the private sector with an individual heating system. This is where you can be smart and get space for creative approach to solving the problem. In this article we will learn that long-burning wood stoves for summer cottages are one of the most optimal options way out of such a situation.

Actually, the effectiveness of our home heating will depend on two main factors:

- Quality of insulation (thermal insulation) of the walls and windows of the building;

- The efficiency with which our heating installation (furnace or boiler) uses fuel.

The purpose of this article is to introduce you to one of the types of economical and productive wood-burning stoves that allow you to ensure the most complete combustion of logs. These heating installations are called pyrolysis furnaces. Every year their popularity is increasing, so many are thinking about building such a heater with their own hands. How do long-burning pyrolysis furnaces work? internal organization, as well as instructions for self-assembly– you will learn all this by reading our article.

Combustion process. The mechanism of pyrolysis

Basics physical phenomenon, without which it is impossible to imagine the operation of any furnace, is the oxidation of various substances by oxygen contained in the air. Fire, tamed by our ancestors millions of years ago, has become so familiar today that we don’t even think about how combustion occurs, with which each of us has been familiar since childhood. The seemingly simple question “how does wood burn?”, in fact, requires a separate explanation. After all, without understanding the basics, we will not be able to understand how economical pyrolysis furnaces work and why they are so good and economical.

Actually, the formation of a flame occurs in several stages:

- First, the firewood is heated and dried, releasing environment water vapor that prevents fire. This requires an external source of energy, which is usually flammable paper, kindling liquid, or a pile of small burning wood chips.

- Firewood, which from a chemical point of view is a complex organic structure, consists of three main elements: carbon, hydrogen and oxygen. When heated, wood disintegrates, and these components, in the form of various simple gaseous compounds, begin to be released into the surrounding space. The general name for all substances formed during fuel heating is pyrolysis gases, and for the process itself is pyrolysis.

- At the next stage, the wood decomposition products ignite and accelerate the pyrolysis of the remaining logs more and more, providing the fire with fresh fuel.

- In the end, the tree burns, leaving behind some of the coals that did not have time to react with the oxidizing agent.

Actually, the idea that made it possible to build long-burning furnaces is to ensure the most complete decomposition of fuel in such a way that after its use there is practically no unburned waste left. To do this, it was necessary to slow down the pyrolysis as much as possible so that the entire volume of firewood would gradually and completely disintegrate into pyrolysis gases.

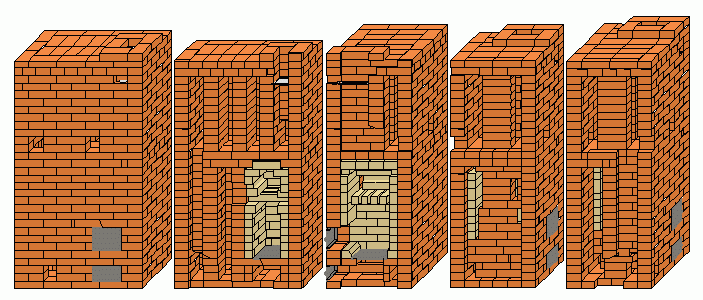

What stoves are called long-burning stoves?

A long-burning stove is quite easy to distinguish from a regular one. The fact is that the implementation of the idea of high-quality and complete pyrolysis required the introduction of not one, but two combustion chambers into the stove design. In the first, the firewood slowly smolders, emitting a gas mixture of methane, hydrogen and other components. Smoldering is ensured by an artificially created lack of oxidizer supplied to the firebox. Further, entering the second chamber, the gaseous pyrolysis mixture begins to burn fully, providing heating to the room in which the boiler is installed. Often, the secondary firebox is also additionally blown with air using a special fan. This ensures the most complete oxidation and combustion of the entire volume of gases, and leads to a significant increase in the efficiency of the entire heating installation.

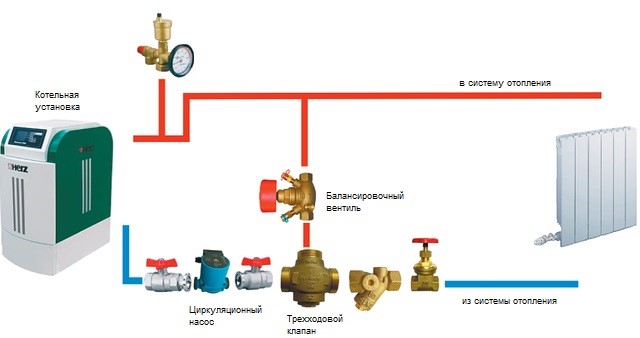

Pyrolysis ovens are often also equipped with a separate cooling circuit, which evenly distributes heat throughout all rooms in the house. Such a heating boiler copes well with even the most severe winter frosts, providing high-quality heating of the entire living space. An example of a block diagram revealing the internal structure of a pyrolysis stove with a water block can be seen in the figure below.

Advantages and disadvantages of pyrolysis furnaces

Nothing in this world is perfect, so even long-burning wood stoves are not without their drawbacks. The main ones are the following:

- The price of modern high-tech long-burning pyrolysis furnaces with good efficiency indicators will be quite high. However, you can save a lot of money by designing a heating device yourself.

- Pyrolysis boilers industrial production often require additional uninterruptible power supply its auxiliary units: air injection systems (combustion chamber pressurization), water pumps heating circuit, sensors, etc.

- Long-burning stoves are more finicky in terms of moisture requirements for wood logs. Insufficiently dried firewood placed in the firebox of a pyrolysis boiler can easily go out, stopping the operation of the entire heating system.

- Compared to gas (electric) boilers, boilers or water heaters, long-burning stoves have significantly big sizes, and also require additional free space for storing firewood.

- You will have to add fuel to the pyrolysis boiler manually; this operation cannot be fully automated 100%.

- A more complex water circuit design compared to other types of heating installations. The fact is that too supercooled coolant, returning from the batteries to the boiler heat exchanger, can interrupt the smoldering of the wood and extinguish the firebox. To avoid such a situation, you have to install an additional pipe (the so-called “bypass”), which allows you to mix already heated water with cold water. Naturally, as the complexity of the heating circuit design increases, the total cost of the entire device also increases.

At first glance, the list of disadvantages of long-burning wood stoves seems very impressive. And many people have a logical question: why is this type of stove so popular and in such good demand? The answer is simple and obvious: all the disadvantages of a pyrolysis installation are more than compensated by the advantages that the owner of such a device receives:

- Fuel energy is used almost 100%. All loaded firewood will burn to the ground, completely transferring its heat to the heated room. High-quality long-burning stoves industrial production have fantastic efficiency indicators, up to 90 percent. For greater clarity, we provide a table below that compares the operating efficiency of different types of boilers.

![]()

- Long-burning wood stoves are convenient and easy to maintain, and produce almost no waste. There is nothing left of the firewood except a handful of ash.

- Environmental friendliness of the heating system. With full pyrolysis combustion Only water vapor and carbon dioxide are released into the atmosphere. During operation of a high-quality pyrolysis furnace, you will not feel any outsiders unpleasant odors, compared to a conventional stove. This is explained by the fact that the source of such aromas are unburned complex organic compounds. In a long-burning furnace, fuel oxidation occurs 100%, so it can easily be heated even with industrial waste.

- One “filling” with logs is enough for 10-15 (and sometimes more) hours continuous operation. No ordinary wood stove can burn for that long.

- The heating system based on a pyrolysis boiler very quickly warms up the house and enters operating mode.

- Work power heating device, using the pyrolysis effect, can be easily and smoothly adjusted, just like gas or electric. Unlike conventional solid fuel installations, in a long-burning furnace the main heat is generated by gas burned in a separate chamber. Accordingly, by controlling the level of oxygen supply to the firebox, we can easily change the heat release of the entire system.

Choosing a long-burning stove for a summer residence

Actually, having decided to acquire a long-burning stove, the future user faces the question: which one is better to choose? If you are planning to make a pyrolysis boiler with your own hands, then available options will be limited only by the materials you have, as well as your engineering ingenuity and imagination. We will tell you more about how to make a long-burning wood stove for a summer house later, but now let’s try to give a few useful tips for those who decided not to bother and buy a ready-made heating system.

The main parameters that should be followed when selecting available boiler models are:

- Limitations of the budget allocated for the purchase of a gas generator furnace.

- The area of the house that is to be heated using a pyrolysis unit. Depending on the characteristics and configuration, long-burning stoves can heat from 80 to 250 square meters living space.

- Operating time of the unit when fully loaded with fuel. There are three subcategories of gas generator boilers: with a minimum operating time (up to 4 hours), with an average heating period (up to 8 hours) and, in fact, long-burning furnaces (they burn at one gas station for more than 8 hours).

- Other technical and functional characteristics of the device.

- Appearance and design of the pyrolysis furnace. Functionality and efficiency are, of course, a priority, but do not forget that a gas generator boiler is also an element of the interior of the house. It is highly desirable that the heating installation fits harmoniously and naturally into the interior space of the room in which it is located.

A few words about the main characteristics according to which they are classified pyrolysis boilers long burning. Based on materials of manufacture, they are distinguished:

The first two are suitable for those who want to get the most compact device, and the last type will appeal to lovers of the classics. Such a brick stove can easily become a highlight in the interior of any home.

According to the method of loading firewood: manually or semi-automatically. The second type will cost more, but will reduce labor costs for boiler maintenance.

Pyrolysis plants can be equipped with various “add-on components”, so they should also be classified according to the presence of additional functional units. They can serve as hob or a special transparent fireproof door that can turn an ordinary solid fuel heater into a full-fledged and aesthetic fireplace.

Naturally, you should understand that you will have to pay extra for any design and technological delights. It is for this reason that prices for long-burning gas generator stoves vary in a wide range from 10 to 100 thousand rubles and above.

Installation of a purchased gas generator furnace

Installation of a finished industrial gas generator boiler requires special attention, so we will devote a separate section of the article to this issue. Actually, general scheme connecting a pyrolysis furnace with a water circuit looks something like this:

It should be noted that this is only one of many options for wiring the heating circuit. Different manufacturers may offer their own schemes, which will differ in some ways. Therefore, in each specific case, carefully study all technical documentation accompanying the device. As for this scheme, the so-called three-way valve deserves special attention: it is he who is responsible for the mixture hot water when cold and prevents the oven from overcooling.

Heating mechanism cold water can be implemented in another way. Below you can see two more possible connection diagrams for pellet pyrolysis boilers:

The combustion room in which they plan to place the boiler must meet certain requirements:

- be spacious and have high ceilings. Preferably from eight square meters; area and with a ceiling height of two and a half meters;

- have a special platform for installing the boiler;

- the ceiling, like the walls themselves, must consist of a material resistant to temperature and fire;

- the room must be equipped with at least one window opening;

- the distance from the wall to the front of the boiler should be about two meters;

- it is advisable to surround the boiler with an additional brick jacket;

- the room must have a chimney and a ventilation system (exhaust).

In general terms, the boiler installation algorithm is as follows:

| Preparing the furnace room. We remove everything unnecessary and prepare tools and materials for work. |

Laying the foundation (installation of a concrete slab) for a gas generator boiler. Preparing the foundation for a purchased stove is not much different from that for a homemade stove; we will discuss this process in detail below. In general terms it consists of the following steps:

|

|

|

|

| Direct installation of the pyrolysis furnace on the foundation. |

| Connection to the heating system (piping the water circuit). |

| Installation of a chimney and exhaust ventilation system. |

| Switching on and setting up relays and boiler automation systems. Test run and testing of the system in action. |

Making a long-burning stove with your own hands

We have figured out the main guidelines in choosing a ready-made long-burning stove for a summer house, and now let's find out how to make such a device at home yourself. In the next two sections of the article we will look at the manufacturing technology of both metal and brick pyrolysis boilers. It should be noted right away that without minimal bricklaying skills, as well as the ability to work with welding machine there is no way around it, so only get down to business if you are 100% confident in your abilities.

Pyrolysis oven from improvised means (barrels, cylinders)

The easiest and cheapest way to assemble a gas generator stove is from an old cylinder or metal barrel. Such a device will not be particularly attractive appearance, however, it is quite suitable for heating a summer house, garage, utility room or greenhouse. In addition, this type of stove is very mobile and can easily be moved to any other place.

![]()

Materials and tools for work. Workplace requirements

| The basis for our masterpiece of engineering fantasy can be: | |

| Volumetric metal barrel. Ideally, it should hold at least two hundred liters, have no external damage or signs of corrosion. The metal must be thick enough and durable. It is advisable to choose barrels made of steel - this will have a positive effect on the durability of our heating device. |

| A used fire extinguisher or gas cylinder, which has outlived its service life. Naturally, their dimensions should be comparable to the volume recommended above for the barrel. |

| The cylinder body is one of the most popular for making homemade stoves |

| In addition, the body of the future stove can be welded from scratch using sheet steel or cuttings of thick-walled pipes. |

| Once you have made your choice and decided on the body of the future stove, start looking for additional materials. Namely, support legs for the heating installation. Most simple solution will make supports from: | |

| Fittings |

| Pieces of thin pipes |

| Metal profile scraps |

In addition to all of the above, we will need:

- Sheet steel from which we can cut a circle equal in diameter to the body of our furnace;

- Pieces of metal profile for making a pressure piston;

- Stove door, which you can order ready-made or make yourself;

- Two metal pipes. One with a radius of about 5 centimeters and a height equal to the height of the stove body +15 centimeters from above, and the second with a radius of 7.5-8 centimeters and a length of about 5 m. The first will be useful in the manufacture of the pressure piston air duct, and from the second we will make a chimney.

Having got everything necessary materials, we begin to search for a suitable workplace to carry out all the necessary installation operations. The room in which we will assemble the stove must meet a number of requirements, namely:

- Have good ventilation so that welding can be used in it;

- Good lighting at any time of the day;

- Have an uninterrupted power supply;

- Have reliable noise and sound insulation. During the installation process you will have to use a grinder and welding, and insulation will allow you to disturb your neighbors to a lesser extent;

- Be spacious enough so that we can safely store all the structural parts and tools there;

- Be protected from any atmospheric influences that could lead to damage to the metal parts of the oven.

Instructions for assembling a homemade gas generator stove

| The sequence of operations for installing a pyrolysis furnace will look like this: | |

| We are preparing the body. It will be enough to simply remove the top cover from the barrel, but you will have to tinker a little with the cylinder or fire extinguisher. They need to cut off the top. This should be done using a grinder, evenly and carefully. The cut off part will later serve as the main cover of the structure. You should start sawing a cylinder or fire extinguisher only after you make sure that they are empty and pour water inside. |

| If sheet steel was chosen as the basis for the gas generator furnace, remember that the housing square shape have better stability than round ones. |

| Having prepared the body, we proceed to install the legs. They need to be welded to the bottom of our homemade heater in such a way that the entire structure stands level and stable on them. The correct installation of the legs can be checked using a plumb line or level. If you make a mistake with the length of any of them, just shorten them with a grinder. |

| Let's start making the pressing piston-feeder. We cut a circle from sheet steel with a diameter slightly smaller than inner diameter stoves. If the stove is not round, then we select the dimensions of the piston so that it has a small gap with the inner surface of the housing and moves freely up and down. |

| In the center of the circle we cut a hole that is suitable for our air duct pipe. We connect the circle to the pipe by welding. After this, we check how the piston will move inside the barrel and how much the pipe protrudes from above the body. This height should be about 15 centimeters. |

| We attach pieces of metal profile to the bottom of the piston by welding. They will not allow smoldering firewood to “suffocate” and go out, and will also help improve the quality of pressing the logs to each other. |

| Let's start making the oven lid. If this is a barrel, then the old lid will serve as it. Well, in the case of a cylinder and a fire extinguisher, the previously sawed off upper part will come to the rescue. It is necessary to cut a hole in the lid for the air duct, and it is also advisable to weld handles to it, which will make it more convenient to remove it for loading firewood. Remember that the hole should not interfere with the movement of the duct: its pipe must slide freely up and down. Leave a small gap. |

| We fasten the door to remove ash. Using a grinder, we cut a hole according to the dimensions of the door, weld the hinges and install our hatch. |

| We attach the chimney pipe. The hole for it must be made with a grinder at the very top of the body of the gas generator boiler. We weld a section of the previously prepared pipe under the chimney, taking into account that its shortest length should exceed the diameter of the cylinder body. |

| It is also necessary to design control valves for the chimney and air duct. They will help you control the draft and operating time of the heater on one load of wood. Various condensate very actively collects in the chimney of a gas generator stove. Therefore, the pipe must be protected heat-insulating materials, clean regularly, and also install a container at its base to collect condensate. In addition, it would not hurt to install a protective umbrella-reflector on the top of the pipe, which will prevent precipitation from getting inside it. |

Video. How to make a pyrolysis oven from a gas cylinder

Rules for igniting a pyrolysis furnace

| The process of lighting a gas generator furnace consists of the following steps: | |

| First, you need to remove the internal feed piston by first removing the top cover of the device. |

| Next, we put firewood into the combustion chamber, pressing the logs tightly together. Remember that to light a pyrolysis stove you only need dry logs. Otherwise, it may go out at any time. The highest point for loading firewood should be considered the beginning of the exhaust pipe-chimney opening. |

| Throw a pile of wood chips on top of all the logs and cover them with a rag soaked in fire starter fluid. If flammable liquid If you don't have it at hand, you can replace the rags with pieces of paper. |

| We put the piston with the air duct in place and close our gas generator stove with a lid. We light a piece of rag and throw it inside through the air duct. In this case, matches will not be able to help us, since they will go out as they fly through the pipe. |

| We give the fire about 20-30 minutes to burn up. Then we cover the chimney with a damper so that the wood stops burning and begins to smolder. From this moment on, the stove will enter its operating mode, and you will fully enjoy the warmth, comfort and coziness it gives. | |

Tips for using a gas generator stove

Remember that when installing a long-burning gas generator stove in any room, you must strictly adhere to the rules for its use:

- The body of the heater reaches significant temperatures, so keep away any items that may spontaneously combust or are heat sensitive.

- Leave enough free space around the gas generator boiler. Furniture cannot be placed next to it, and the walls themselves can also be damaged under its influence. It is advisable to build a special protective jacket made of bricks around the stove. Brickwork will not only protect things around it, but will also help retain heat for a longer period.

- When cleaning the firebox of a homemade stove, leave a certain layer of ash after each time. It will serve as a protective cushion and prevent rapid burning of the lower part of the gas generator boiler, which can lead to breakdown of the entire device.

Laying a brick pyrolysis furnace

A gas generator furnace can be assembled not only from metal parts, but also laid out using bricks. Before proceeding directly to consideration of this issue, we will need to understand the meaning of some fundamental terms that characterize the qualities of materials for furnace work. Actually, there will be only 3 such concepts: heat resistance, heat resistance and fire resistance.

Heat resistance is the ability of a material to withstand heating up to high temperature and subsequent cooling. During such thermal changes, the substance must not change its structure, geometric shape and chemical composition. At the same time, over the entire range of operating temperatures, heat-resistant connections must withstand the initial design physical exercise and not be destroyed.

As for heat-resistant materials, their main advantage is the ability to maintain initial mechanical characteristics when heated or cooled. The coefficient of thermal expansion of such compounds practically tends to zero. Heat-resistant materials are the basis not only for furnace business, but also in the production of mechanisms and machines designed to work in extreme conditions.

Refractory are heat-resistant or heat-resistant substances that are resistant to aggressive chemical environments. In the stove business, they are used to construct chimneys, the inner surface of which is constantly exposed to gaseous combustion products, which often settle during cooling in the form of caustic condensate.

Materials and solutions used for laying various elements of the furnace

Since individual elements of the stove structure carry different functional loads, the brick (as well as the mortar) must be selected individually for each of them. Let's look at everything using the example of a classic wood-burning stove.

- The “pillow” (also called the “root”) of the stove is the basis of the foundation of the stove made of reinforced concrete. It is poured in such a way as to be mechanically independent from the foundation of the entire building. This condition must be met without fail, since the stove and the house differ in the rate of shrinkage. Filling is carried out in the usual way, no distinctive features V this process There is not.

- A layer of waterproofing material. It can be constructed from ordinary roofing felt, folded in a couple of layers on top of the stove cushion.

- Furnace foundation. Its laying requires a careful and scrupulous approach. An error when assembling the foundation will lead to the fact that the entire structure will have to be rebuilt. Red solid brick - this part will not feel strong temperature effects. Kiln mixtures should be complex, cement-lime, with three or more components.

- Fireproof blind area with a heat-insulating layer. It is made from a mineral sheet of asbestos placed on top of a sheet of iron. The third, top layer, completes the structure with a felt cloth treated with clay impregnation (liquidly diluted clay, the so-called “clay milk”).

- The main part of the “body” of the stove, which performs the function of a heat exchanger. The operating temperature of this element very rarely exceeds the threshold of six hundred degrees Celsius, but it is constantly exposed to acrid smoke and the chemically aggressive compounds it contains that can settle in the form of acid condensate. Therefore, the brick for this part of the stove requires a specialized stove, red, solid ceramic type M. The mortar, in turn, is clay, one-component.

- Stove firebox. In a pyrolysis oven, it will consist of several chambers, each of which is subjected to very powerful thermal influence. The temperature inside the firebox can reach values of up to one and a half thousand degrees. You need a special brick, the so-called fireclay, and you need a clay-fireclay mortar.

- The “source” of the chimney pipe. It must withstand the same impacts as the furnace heat exchanger, so the materials that need to be used for its laying are similar to those in point No. 5.

- The chimney fluff is a structural element designed to provide an elastic connection between the chimney and the ceiling, preventing its possible subsidence. The brick here needs a stove M150, and the mortar is lime.

- A fire separator is an iron box, inside of which there is a layer of non-flammable heat-insulating material.

- The main part of the chimney pipe. They lay it with ordinary red brick, since it is not subject to strong thermal or chemical influences. The solution is lime type.

- The chimney fluff, which completes the stove structure, is also made from the same materials.

Preparation of materials and tools for masonry

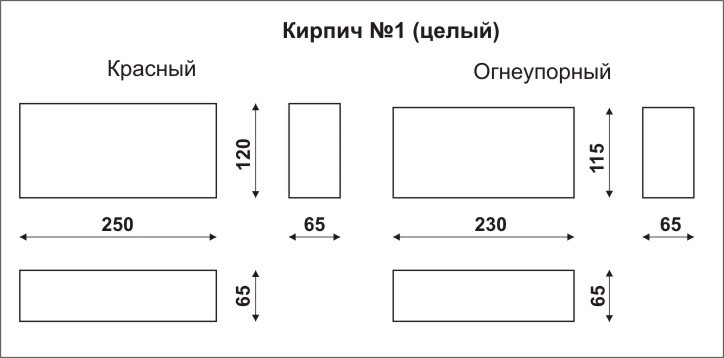

As it has already become clear to you from what you read above, for the stove masonry we will need to stock up on three types of bricks:

- red solid - it will be used to make the foundation and part of the chimney

- red ceramic stove M150 – for assembling the main part of the stove body

- fireclay for laying combustion chambers

Further, we cannot make the foundation of the furnace without cement. Accordingly, it also needs to be purchased. In addition, we additionally buy roofing felt, sheet steel and various auxiliary stove accessories: doors for adjusting the air supply, a hatch for loading firewood, etc. The quantity and type of materials chosen will depend on the specific stove laying scheme that you choose for yourself. We will consider one of them in our article, but you should not limit your flight to your engineering imagination only within the framework of a single instruction.

As for stove solutions, you can easily prepare them yourself. This process is quite labor-intensive and takes some time, but it allows you to significantly save on materials and reduce the final cost of creating a brick pyrolysis furnace. More details and with everyone necessary instructions this issue is discussed in the article .

The tools we will need are:

- Master OK

- Roulette

- Construction level and plumb line

- Hammer

- Containers for preparing furnace solutions and pouring foundations

- Shovel

- Sieves for sifting sand and straining clay

Making the foundation of a brick gas generator furnace

Long-burning stoves are distinguished by the fact that they must quickly heat up and switch to operating mode within a minimum period of time. For this reason, the foundation of a gas generator stove must be placed at least at a distance of 70 centimeters or more from the foundation of the building itself. In addition, it is advisable to fill the gap between both foundations with sand.

| The process of creating a furnace base consists of the following steps: | |

| We dig a hole for the foundation. It should exceed the dimensions of the oven by 10 centimeters in each direction. According to our specific order scheme, this is approximately 1.20 m by 85 cm. The depth of the hole should be 70 centimeters |

| We put a bitumen-based waterproofing layer on the bottom and sprinkle it with a layer of sand about 10 centimeters high. |

| Place a layer on top of the sand broken bricks or crushed stone, on top of which the base of the furnace foundation will be located directly. |

| We construct formwork from boards and reinforcement cage, fill it all with concrete. |

| After waiting for the solution to dry, we place a layer of roofing felt waterproofing on the concrete base. Then we lay the foundation of the stove on top in two layers of solid red brick, checking the quality of the masonry with a level. |

Oven with fire protection area | We complete the structure with a fire-resistant blind area and thermal insulation made of asbestos and steel sheets, covered on top with felt soaked in clay milk. |

Basic rules for laying a pyrolysis furnace. Ordinal scheme

When starting to lay a gas generator furnace, remember that you must strictly adhere to the following rules:

- Each of the furnace elements must be assembled from the appropriate type of brick that will withstand all temperature and chemical influences. We have already written about this above.

- The laying should be carried out clearly according to the chosen order plan in order to avoid mistakes and the need to redo the work again.

- After every 2-4 rows, be sure to check the quality of the masonry with a level or plumb line. You don’t want the oven to turn out crooked, do you?

- In each row (as well as between rows), it is necessary to perform a complete dressing of the seams.

- Seam width in uniform brickwork should be about three millimeters. At the junctions of fireclay and red bricks, the size of the seams must be increased to six millimeters. The same rule applies to connections between brick and steel elements.

- Seats for various doors and valves should be made with a small margin, taking into account the possibility of thermal expansion of parts. Between the metal and the brick, it is imperative to place asbestos gaskets, or intermediate layers of special building mixtures based on sintered compounds. For example, you can use fireclay or silicone for fireplaces - these materials can withstand high heat and, at the same time, ensure the tightness of all connections of the body and stove fittings.

Finally, as an example, we will give you one of the possible row diagrams of long-burning furnaces. Naturally, before starting construction, you must definitely evaluate the dimensions of the room and the size of the space that you plan to allocate for the gas generator boiler. In accordance with these initial parameters, you should choose the scheme that suits you. It will be quite easy to estimate the size of the future heating installation, because the dimensions of one brick are standard and for a solid red brick they are 25x12x6.5 centimeters.

As an added bonus, we also invite you to watch a video that shows one of possible options self-made brick pyrolysis oven. The author demonstrates step by step each stage of stove laying, and also conducts a practical test of his device in action.

Video. Do-it-yourself long-burning brick oven