Do-it-yourself homemade rocking chair made of metal and wood: drawings and assembly. How to make a rocking chair out of wood with your own hands Do-it-yourself garden rocking chair drawings

Many of us are familiar with such a piece of furniture as a rocking chair, which can be found in many country houses. For most, it is one of their favorite places to relax, but not everyone knows that anyone can make such a chair. However, first you need to acquire certain knowledge, skills and prepare a tool.

IN last years The rocking chair has become a fairly common piece of furniture. There are many in stock furniture companies you can find a large number of models of rocking chairs designed for use in apartments and offices. Moreover, among them there are models made in classic version by weaving method, as well as modern products, fully satisfying the requirements of high-tech style.

Advantages of a wooden chair

Before you start manufacturing, you need to decide what material to use as a base. Although there are many options, the most common one is the wooden chair. Therefore further Let's list the advantages which this material has:

- environmental Safety. Wooden furniture has been very popular among consumers for many years, which has provided it with such qualities as natural origin, safety and hypoallergenic. Therefore the owners wooden chairs do not encounter any inconveniences when using it, since they are confident in the environmental friendliness of this material;

- strength and long service life. Wood is a fairly durable material, which is also reflected in the furniture made from it. In addition, it perfectly withstands mechanical stress and demonstrates a long service life;

- attractive appearance and variety of shapes.

Rattan rocking chair

We repeat that rocking chairs today offered in large quantities the most various options. One of these products is a rattan rocking chair, which not only has a pleasant design, but can also harmonize perfectly with other elements of the cottage interior. The homeland of rattan is South America, and this plant itself is often called a flexible vine.

Among the features of this material, it is worth noting its high strength, which it is capable of compete with willow twigs.

The technology for making chairs from this culture is characterized by the fact that instead of traditional connections based on screws and bolts, glue and skillful knitting are used. Alas, in our country it is impossible to buy this tree, so most owners country dachas It will not be possible to make such a chair with your own hands.

Wicker rocking chair

A photo of the options available today for this piece of furniture allows us to judge that a wicker rocking chair is quite in demand today. It can be found in dachas and even in apartments in many regions of our country. Willow vine is used as material for it, and the finished chair itself fits well into the interior garden house, cottages and even garden greenery. Consumer rocking chair from willow vine attracts primarily because of its light weight and high strength. However, such furniture has one serious drawback: excess humidity negatively affects the material, so it is not recommended to keep such chairs outdoors in damp weather.

Materials for production

Regardless of what type of wood you decide to use to make a wicker chair, you must have certain skills. Wood is accessible and easy to process, so many owners who are thinking about making a rocking chair with their own hands most often consider the option of using wood as the basis for it. But first it is necessary prepare certain tools for making furniture:

- electric jigsaw with a set of blades;

- disc sander with a set of coarse and fine-grained attachments;

- screwdriver with drills;

- tape measure and angle with ruler;

- hammer and spatula;

- brush and pencil.

Execution of the drawing

Even before you start work, you should take into account that to make a high-quality rocking chair with your own hands, a drawing is required.

Having a sketch in hand, you can avoid serious errors regarding the dimensions of the product and correctly determine the quantity of materials that you will need for manufacturing.

First you need to take metal mesh, each cell of which corresponds to 1 cm, and mark a template for the side of the chair on it. To make it more convenient to work further, it is recommended to transfer the created chair template onto plain paper. This will make it easier for you to mark the outline of the chair on the plywood itself. Don't worry if there are minor errors. Here it is important to maintain the symmetry of the sidewalls and avoid protruding corner elements on the outer rolling part.

To complete this work we will need plywood 3 cm thick, from which three drawers are cut dimensions 120 x 800 mm. The sidewalls are made using an electric jigsaw exactly according to the pattern. After this, you need to take a beam 50 mm wide and 25 mm thick and cut out 35 fragments from it, the length of each of which should be 120 cm. The finished beams will subsequently serve as a seat and backrest.

To complete this work we will need plywood 3 cm thick, from which three drawers are cut dimensions 120 x 800 mm. The sidewalls are made using an electric jigsaw exactly according to the pattern. After this, you need to take a beam 50 mm wide and 25 mm thick and cut out 35 fragments from it, the length of each of which should be 120 cm. The finished beams will subsequently serve as a seat and backrest.

Try to purchase enough timber at the very beginning to minimize waste. This will be quite easy to do, given that you will be able to calculate the total length of the beam before purchasing. Let's say, if it has a length of 2.3 m, then better chair make it narrower. As a result, its width will decrease to 115 cm, however, this will allow you to avoid waste. The given dimensions of the rocking chair do not require their exact observance. Therefore, if during the work it becomes clear to you that it would be better to increase or decrease the size to minimize waste, then you can do it without fear.

Workpiece processing

The surface treatment of workpieces is carried out using a grinding machine. When performing an operation, it is necessary Special attention give them to the ends. If wood fibers appear on them during work, you need to use a hammer and level them, and then treat them with hot drying oil. This way you will make the ends of your furniture more resistant to moisture, which will have a positive effect on its service life. When the drying oil dries, it is necessary to re-process it to consolidate the result.

The chair is assembled based on the drawing of the rocking chair. Need to fasten two sides, drawers are used. But first you need to mark the places where they will connect.

The chair is assembled based on the drawing of the rocking chair. Need to fasten two sides, drawers are used. But first you need to mark the places where they will connect.

According to common patterns for making rocking chairs, it is recommended to fix them in the head area, in the middle and in the legs. When you have to attach the tension strips to the sidewall, use confirmat for this. This name is given to a special screw tie with which the wood materials. First, before fastening, it is necessary to create 8 mm holes in the sidewall and 5 mm in the end of the drawer.

Next, we begin work on creating the seat and attaching it to the base. Take earlier prepared 35 pieces of timber, in which you need to make four holes for two on each side. After this, the bars must be fixed to the sidewalls. Considering the number of holes present, it is recommended to fix the bars using 3 or 4 mm self-tapping screws. When attaching the boards, constantly check that they are installed horizontally.

Processing of the finished product

If you look at the experience of ordinary owners making rocking chairs from wood and plywood with their own hands, you can identify a number of serious mistakes made after assembly. Among them, I would especially like to dwell on poor-quality finishing or its absence. To do everything correctly and ensure the chair has the longest possible service life, you need to do the following:

- treat the hole above the screws with putty;

- cover with a layer of antiseptic;

- Apply waterproof varnish in two or three layers.

If you carry out all the work described above exactly, you can be sure that a rocking chair made by yourself will be able to please you for many years.

If you are going to start making a rocking chair with your own hands for the first time, then it will be useful for you read the recommendations experienced craftsmen who have performed this work more than once:

Other types

One of the varieties of this piece of furniture is wooden Baby chair . It is made according to the same scheme as described above, but you need to adjust the size to the age of the child. This also applies to the tilt of the backrest and arms. Quite often, children's chairs are made in the shape of a horse.

Of particular interest is the rocking chair for the office. The peculiarity of its production is that leather is used for cladding, as a result of which the product acquires a respectable and solid appearance. Having such a chair at hand, a person will have the opportunity to relax and unwind during the working day.

Conclusion

Although furniture manufacturing offers enough big choice furniture, one of the things desired by many cottage owners is a rocking chair. Having settled down in it, you can relax and allow yourself to forget about everyday affairs for a while.

Although furniture manufacturing offers enough big choice furniture, one of the things desired by many cottage owners is a rocking chair. Having settled down in it, you can relax and allow yourself to forget about everyday affairs for a while.

Moreover, in order to personal experience To feel all the benefits of having such a piece of furniture, you don’t have to spend a lot of money on buying a rocking chair. You can always make it yourself. Considering that for this you can use available materials and tools, this task can be completed by anyone who has at least once held a hammer and saw in their hands. There are many ready-made ones on the Internet manufacturing plans for similar furniture, therefore, if you strictly follow the manufacturing technology of a rocking chair, you can create a fairly elegant and reliable product that can serve you for many years.

Much has been written about the beneficial effects of relaxing in a rocking chair. It also helps to concentrate during intellectual work. Finally, it’s just convenient, after pumping, to take books from the rack behind your back or a cup of coffee from coffee table. The prices of ready-made rocking chairs, as it should be in a consumer society, react to such advantages in their own adequate way: a rocking chair for 5,000 rubles. it's still cheap. And people are artisans and also respond adequately in their own way: there are more and more people wanting to make a rocking chair with their own hands. However, the rocking chair differs from other pieces of furniture, firstly, in that the whole thing moves and swings. Secondly, so that it does not turn from a rocking chair into a kicker or tipper, the entire product with the person sitting in it must have an accurate balance, which must be maintained within acceptable limits for riders different weights and complexion. This publication is devoted to consideration of issues of how to achieve the required qualities of a rocking chair.

Types of rocking chairs

You need to comply with your own needs already at the stage of choosing a prototype. There are several types of rocking chairs, aimed at users with different habits and needs. The main types of rocking chairs are shown in the photo. Rocking chairs on simple radius runners (arches, rocker arms, skis) were the first to appear in everyday use. They are in use to this day, both in modern and classic appearance, pos. 1 and 2. Their main advantage is constructive and technological simplicity.

Radius runners provide smoothness and softness of rocking only with relatively small swings, and with strong swings they do not guarantee against tipping over. Therefore, rockers “on radii” are made with a low landing, ensuring a large excess of the center of the generating circle (CO) over the general center of gravity (CG); For more details on the kinematics of rocking chairs, see below. If a seat of normal height is required, then the runners are equipped with bumpers, pos. 3. The shocks of the bump stops on the floor are noticeably felt at the “fifth point”, and in any case, you have to get out of the rocking chair on the radius runners, straining somewhat.

Note: Stability when swinging with a slightly larger amplitude at a normal landing height is provided by rockers on radius runners with a closing horizontal arc, see fig. on right. But, suddenly the limit is reached, the supporting surface instantly reduces to a point and a sharp push follows in the back.

Tipping is excluded in rocking chairs on runners of variable curvature, pos. 4. All of them are comfortable enough for riders of different body types. They themselves gently unseat the rider of a rocking chair of the Nirvana type who has stood up and leaned forward on runners of variable curvature, pos. 5 and 6. It is also possible, by changing the progression indicator in the law of change of the generating radius (also see about kinematics), to design them for any landing height, within acceptable limits.

Note: mother and baby give good rest with complete unity of souls of the rocking cradle. Reliable rockers with a cradle are made only on runners of variable curvature, see fig. on right. Otherwise, suddenly the little one will get worried and the mother will perk up, and we can tumble together. Which is simply dangerous for a baby.

Nirvana rocking chairs on elliptical runners, pos. 7, provide a gentle, truly blissful rocking, but do not prevent tipping over during strong swings, so they are equipped with bump stops; the front one is often combined with a footrest. Garden rocking chairs with ellipse awnings never tip over, pos. 8.

Nirvana rockers on springs, see fig. on the left, they swing as softly as on ellipses, because mechanical characteristics Progressive springs. But making a spring chair with your own hands is difficult: you need either high-quality boards of special types of wood (teak, boxwood, dogwood) or a rubberized strip of spring steel so that it does not scratch the floor. In addition, dirt gets packed into the gap between the spring and the runner and it can be very painful to pinch your finger. For the latter reasons, spring chairs are now very rare on sale.

Rocking chair 3 in 1

Finally, there are also multifunctional “3 in 1” rockers on runners with smooth bends, see fig. on right. When seated upright, this is a regular chair; by leaning back, it can be switched to rocking mode on radii, and by leaning back even more, it can be turned into a sun lounger. But the dimensions of the 3 in 1 rocking chair are too large for apartments below business class, and transitions from mode to mode are accompanied by rather sensitive shocks. In unsuccessful models, you either have to stand up or twitch, squirm and fidget like a puppet on strings. Therefore, 3 in 1 rocking chairs are a piece of furniture for everyone.

To start

Without any special pretensions, just to relax after work, a rocking chair on radius runners will help. Blueprints simple sample, made, with the exception of the runners, only from straight parts, are given in Fig. For a dacha, veranda or garden, this chair can be made in half a day, using only a jigsaw, a drill and a couple wrenches(assembly - bolted). And having swayed to your heart's content, you might already think about home rocking chair for the more experienced; then you will need a more thorough tool and knowledge.

How does it swing?

Most home craftsmen make rocking chairs according to ready-made drawings, but prototypes often turn out to be developed and tailored to a specific person, and an exact replica is not so convenient. Therefore, before making a rocking chair, it is necessary to obtain at least initial information about its kinematics.

The CG of an upright person of normal build is located on the border of the lumbar and sacrum with inside spinal column. In a sitting individual, it will blend somewhat forward and even less downwards. In the chair-seat system, the overall CG shifts back almost to its original position and a little further down. The downward shift of the general CG for the design of a rocking chair is not particularly significant and we can assume that the projection of the general CG onto the supporting surface (floor) is approximately the same as that of a standing person. In the future, the resulting error can be easily compensated by final balancing of the chair, see below.

The vertical location of the central center relative to the central center has a much stronger effect on the stability and comfort of the rocking chair; the latter is also a determining factor when designing rocking chairs on runners with variable curvature. If the CG and CO coincide, this is an indifferent equilibrium: for any physically possible tilt of the chair, the projection of the CG on the floor falls on the point of contact of the runners O, pos. 1 and 1a in Fig. The chair does not rock, and if you lean back too much, you will instantly somersault with the risk of breaking your neck. Fortunately, an exact match between the CG and the CO is only theoretically possible.

If the CG is higher than the CO, then its projection, at any inclination, “runs” outward, backward or forward, from the point of contact. At the slightest tilt, a tilting moment Mo occurs (positions 2 and 2a), and the rocking chair turns out to be unstable. To avoid such a situation for a family rocking chair, it is designed and balanced for the tallest, heaviest and pot-bellied rider possible so that its CO is 450 mm or more higher than the CO. Then, when the chair is tilted, the point O will “run away” from the CG projection, the restoring moment Mv will constantly act (positions 3 and 3a) and the chair will not tip over when rocking within acceptable limits. For those who are smaller, the excess of the CO over the CG will be too large, and the swaying will be harsh, but this can be easily compensated for by pillows under the back and seat. In general, the lower the elevation of the CO above the CG, the softer and smoother the swaying, but the likelihood of capsizing, suddenly straightening up and standing up in a chair, is higher. Therefore, it is better for novice carpenters to set the CO exceeding within 600-700 mm.

Note: if it is impossible to determine the position of the CG of the largest of the riders (say, in his absence), the radius of the generating circle R is taken equal to the average height of the users minus 5 cm. Suddenly the rocking turns out to be harsh, this can be corrected by placing a permanent pillow on the seat.

There is no need to drag your own pillows with you into a chair on runners of variable curvature: it will itself rise to the position of greatest comfort. At the same time, the big guy will lean back more, and the slender one will sit straighter. When swinging backwards, the point O will run away from the CG projection the further, the greater the angle of inclination, and it will simply not be possible to swing until it capsizes. And if you “pump” forward, which is actually difficult, the chair will smoothly drop the hyperactive person onto the floor: where should you rest? Go do something.

To construct a profile of runners of variable curvature, the radius of the generatrix of the circle (it is determined as in the previous case) will have to, firstly, be rotated several times by a fixed angle α; usually take α = 10 degrees. Secondly, to build the rear branch of the runner, R is increased at each turn according to the law of geometric progression with the index k = 1.02-1.03. That is, it will be (see position 4 in Fig.) R1 = kR; R2 = kR1; R3 = kR2; R4 = kR3, etc., if required. Actually, R changes according to some trigonometric function, but for furniture accuracy and the size of the rocking chair, it is more convenient to replace it with a progression, so it’s easier to count.

The construction of the anterior branch is carried out at a constant R, but with each rotation of the generatrix of the circle, the CO is raised vertically (ibid., in position 4 of the figure). The initial elevation Δh1 is taken equal to 2-3% R, i.e. (0.02-0.03)R, and the subsequent ones also follow a geometric progression with the same indicator as for the posterior branch. Δh1 in this case is a fairly critical value; its smaller value should be taken for thin people, and its larger value for fat ones.

Finally, the resulting points are connected using a pattern with a smooth curve. Do not be embarrassed if the tangents to it turn out to be not perpendicular to the radii: in order for the chair to be stable, at each moment of rocking it should be on the opposite slope. When constructing, it is advisable to take the scale no smaller than 1:5.

Note: if a nirvana chair is designed, but the front ascending branch of its runners will be an elliptical arc (green dotted line in position 4), tangent to the constructed profile of the runner in volume I there.

Final balancing

It is unlikely that a novice craftsman will immediately find a rocking chair comfortable enough. Most likely, the product will need to be balanced. If the chair doesn't rock well, and when you get out of it it pushes, you need to make the rear overhang heavier. The easiest way to do this is to connect the ends of the rear branches of the runners with a low U-shaped beam of boards, with the notch facing down. Weights are placed in the recess. The lever arm in this case is long, so there is no need to hang weights. Another option, depending on the design, is a transverse pipe beam with a weight inside. But during the balancing process it will have to be removed and put back several times. If the rocker tends to fall back, you need to make the front overhang heavier. The easiest way to do this is by placing a step and attaching weights to its underside.

About materials

Rocking chairs are made primarily of wood. Metal, for all its manufacturability, low waste and greater resistance to outdoors, too heavy. The influence of the chair on the overall CG turns out to be significant, the moment of inertia of the system is large and, as a result, the rocking is too sharp. Or you have to set an extremely small initial elevation of the CO above the CO, risking that the rocking chair will tip over under someone. However, we will return to metal rockers when we consider individual samples.

Plywood is a completely different matter, especially for novice woodworkers. Firstly, making the parts of the rocking chair with 3-layer glued ones, you can only make accurate and strong connections tongue and groove, on the left in the figure, if you follow the following. rules:

- Plywood for the middle layer is taken twice as thick as for the outer layers. For example, if you need a total thickness of 20 mm, then glue 5-10-5 mm.

- The parts are assembled from blanks using 2-component waterproof glue. If it is on PVA, be sure to reinforce it with small nails.

- The connections are assembled with gluing (wedging in this case is unacceptable) and reinforced with diagonal pairs of self-tapping screws on both sides.

- The supporting surfaces are protected with linings made of thin (6-10 mm) strips of hard durable wood or dense sheet rubber 4-5 mm thick. Plywood under a concentrated load cracks very well at the end.

Secondly, plywood makes it possible to use non-standard technical solutions, eg. as on the right in Fig. Such a rocking bowl can be made from plywood, again using only a jigsaw. Convenience is high, stability is absolute, and can serve hanging hammock chair or a swing chair. The thickness of the lamella boards is from 12 mm; connecting half-washers on poles – from 24 mm.

Note: in any case, the finished plywood rocking chair must be soaked twice with a water-polymer emulsion or liquid acrylic varnish on water based. This will not only increase the strength of the product and its resistance to external influences, but will also relieve excess residual stresses in joints and bent parts.

How to install overlays

Wear-resistant wooden pads are installed on the rocking chair runners. way:

- Turn the chair over with the runners up;

- We warm the blank plank thoroughly with a construction hairdryer;

- We place the workpiece on the runner and wrap it tightly along the entire length with cotton braid. Don't get burned, the wood is very hot!

- We also grab the second workpiece onto another runner;

- Once the strips have completely cooled, remove the braid bands and glue the pads with PVA on wood or with 2-component glue;

- We attach the ends of the planks with small nails until the overlays fit snugly along the entire length. Place washers or pieces of plywood under the nail heads;

- Once the glue has completely dried (2-3 days), remove the temporary fasteners. We drill blind holes for screws and secure the ends completely;

- We fill the holes with the fastener heads with putty made from sawdust of the same tree, thickly mixed with PVA.

Note: The linings need to be secured with metal hardware only at the ends. Otherwise, when the lining wears out during use, the fastener heads will stick out and begin to scratch the floor.

Examples of rocking chairs

Metal

Let's start our review of rocking chairs with metal ones, because... making rocking chairs out of it is justified in few cases. Forged rockers, imitating classic wicker ones from wicker or rattan, as requiring special equipment, a forge, etc. We don’t touch qualifications. But a metal rocker “like a braid” can be made by welding from profile pipe; preferably elliptical section. In this case, you need to choose the kinematic diagram of the nirvana rocking chair as the least sensitive to the excessive elevation of the CO above the CO; it also corresponds well in design to wicker rocking chairs, see Fig. In order not to increase the moment of inertia, the seat is made of braided cables, belts, etc.

It also makes sense to make garden tumbler rockers from metal, see below, due to its strength and resistance to wear. But a welded frame like the one in pos. 1 pic. on the right – the solution is not optimal, it is too complex, labor- and material-intensive. Much easier to do steel frame garden rocking chair, Concept type, pos. 2. Pipe – round from 40x2. The bed itself can be sewn like a hammock; balancing - by changing its tension and, accordingly, sagging. As a result, the work and costs are much less than repeating the established forms of rocking chairs that come “from the tree,” and the comfort is no worse.

Here we can see another interesting option: the frame of a rocking chair Concept made from... gymnastic hoops. Just not aluminum or propylene, but carbon fiber (carbon). Strength is monstrous, durability is absolute, weight is negligible. The same cannot be said about the cost, however.

Vanka-Vstanka

IN Lately Garden rocking chairs - tumblers - have gained popularity. If you lean back completely in this one and tuck your legs, it falls back almost 90 degrees without losing stability; the rider will find himself lying on his back with his knees at the zenith. And if you stretch your legs forward, the rocking chair - the vanka-stand-up chair becomes its normal position and then you can rock as always.

The Vanka-Vstanka toy with a spherical bottom sways quite sharply. Comfortable rocking of the tumbler rocker is achieved by profiling its runners according to a complex law. It will not be possible to build their sidewalls “school style”, as described above. You need to be guided by proven samples and draw markings on the grid, see fig. The inset version, with cladding made of planks 30-40 mm thick, is more expensive, but less labor-intensive. It also allows you to increase the length of the rocking chair by installing intermediate supports-runners.

Note: wooden balls are placed on the protruding ends of longer rods (1050 mm) and form handles for rocking and carrying.

Rocking bench

Rolling your heels into the sky, throwing your hands behind your head and admiring the clouds floating in the blue heights through the fluttering foliage is a heavenly pleasure, but it doesn’t suit everyone. Some people want to look more impressive while relaxing. This is more suitable garden bench– rocking chair, see fig. It is a little difficult to swing on it, its own moment of inertia is large, but it also swings for a long time. The maximum span between supports with runners is 750 mm with cladding made of 40 mm thick slats. The back covering is decorative.

Sun lounger with awning

Both those and other requests will be satisfied by a garden rocking chair on elliptical runners and with an awning. The dimensions of its sidewalls are given in Fig. their material is 24 mm plywood. The width of the bed is up to 900 mm, its covering is made of 50x50 slats. The places of the sidewalls, indicated by gray circles, are connected by round ones wooden crossbars with a diameter of 60 mm.

Rocking chair

We are not talking about rocking horses here; they are toys, not furniture. But it’s also not harmful for children to rest while rocking, so it makes sense to give your child a rocking chair. Its proportions will be slightly different than for adults, due to the influence of the square-cube law.

The structure of a children's rocking chair, its assembly diagram and specification of parts are shown in Fig. material – wood. More or less experienced home handyman building a rocking chair for a child, guided by these data, will not be difficult, and beginners can first watch a master class on making an almost identical children's rocking chair.

6652 0 1

Do-it-yourself rocking chair from a profile pipe: drawings plus photo report on assembly

Do you want to build a rocking chair that will be comfortable, reliable and inexpensive at the same time? In this case, the chair must be made from a profile pipe. In this article you will find recommendations for making metal furniture And detailed instructions for self-assembly of a simple and comfortable chair.

Most popular options

There are many types of rocking chairs that differ in appearance and type. decorative finishing. However, when choosing an option for self-assembly, first of all we pay attention to the design.

What to do if you don’t have a profile pipe, but you need to assemble a durable and beautiful chair?

Turns out, metal pipe with a round cross-section is no less durable than a pipe with a rectangular cross-section profile. Therefore, to make furniture you can use ordinary tap water. steel pipe. Another thing is that round section complicates installation, since the flying ones are more difficult to dock to each other.

Determination with chair type

Now that we know which chairs can be made from a profile pipe, all that remains is to choose suitable option. If you are assembling metal furniture for the first time, I recommend choosing simpler models. For example, it is not at all difficult to assemble a rocking chair on ordinary bent runners. To do this, you will have to bend two skis and attach a separately assembled metal chair with a backrest to them.

How to design correctly

If you are assembling a rocking chair for the first time, you can use one of the many ready-made drawings that have been tested in actually manufactured furniture. At independent design We take into account separate requirements for seat configuration and requirements for ski configuration.

The chair you design should be comfortable and durable. Both conditions are ensured by correctly selected sizes.

You can correctly determine the dimensions as follows. Find a ready-made chair or armchair that is very comfortable to sit in. Copy the dimensions of this furniture and transfer them to your drawing.

The situation with skis is a little more complicated. The length of the skis must be combined with the radius, so that assembled structure It swung with little effort, but did not turn over in extreme positions.

A universal rule: a ski 1.2 m long along the edge should bend upward from the floor surface by no more than 20-25 cm. Of course, the bend of the ski should be uniform without visible creases, which can lead to uneven swinging

Sketches of simple options

When it comes to simple options, we choose sketches of structures on curved skis, since such furniture is much easier to make than a chair on a pendulum or hanging cocoon. The simpler the sketch you choose, the better, especially if you do not have sufficient experience in making metal furniture. However, it also makes no sense to oversimplify the design of the chair at the expense of operating comfort.

Materials and tools

To work with a profile pipe, you will need the following tools:

- Pipe bender with rollers for a pipe with a rectangular cross-section;

- Welding machine with related accessories;

- Clamps for metal;

- An angle grinder (grinder) with a cutting disc and an attachment for grinding metal;

- Electric drill with a set of metal drills;

- Measuring tool (tape measure, square, marker, etc.).

What materials to choose for assembly simple chair? To make skis, a pipe with a cross-section of 40×25 mm will be sufficient. To assemble the chair we use pipes 30x30 mm or so. After assembly, it is advisable to cover the seat and back with a wooden board, since sitting on bare metal is not very comfortable.

And finally, so that the finished chair retains its presentable appearance for a long time appearance, take care of purchasing high-quality paints and varnishes. You will need an acidic primer, which will prevent the formation of rust, and paint to apply in a couple of layers. However, you can do without a primer if you use special paints for unprepared metal. For example, Hammerite compounds are applied directly onto the rust.

Description of work

| Illustrations | Step-by-step installation of a metal frame |

|

Making skis. According to most, this is the most difficult stage. In fact, if you have a pipe bender, there are no difficulties. Simply cut 2 blanks 1.3 m long and roll until you get an acceptable radius and a distance between the edges of the skis of 96 cm.

|

|

Assembling the sidewall. In accordance with the sketch, we weld diagonal posts to the ski. A cross brace is attached in the middle of the pillars - the seat guide. An armrest is welded at the top point of the diagonal posts. |

|

Assembling the second side panel. The second side panel is assembled in the same way as the first, but during installation structural elements We apply them to the finished part and make sure that they are identical. |

|

We connect the finished sidewalls. We weld cross braces at the front of the skis. At this stage, be sure to use a square and check that the angle between the crossbars and the runners is straight. We weld another cross brace at the top of the diagonal posts. The angle between this spacer and the diagonal posts must be straight. |

|

We weld the backrest guides. Two pieces bent pipe We weld it to the seat frame and to the armrests. The backrest guides should be parallel to each other so that later, when covering with wood, the structure does not warp. |

|

Painting the frame. The finished frame is cleaned of visible traces of corrosion and primed. After the primer has completely dried, a couple of layers of paint are applied with a break for the previous layer to dry. |

So, the frame is ready, but the frame, even if it is well assembled, is not yet a chair. What to do with a metal frame to make it comfortable furniture?

There are several options for finishing metal furniture. For example, you can cut metal strips from sheet steel and weld them to the frame as slats that will hold pillows or a mattress. Another, more preferable option is to cover the metal frame with wooden boards.

From planed wooden board lamellas are cut and attached transversely to the frame. For fastening, holes with a diameter of 3 mm are pre-drilled in the metal frame. Lamels are applied over the drilled holes, which are attracted to the pipe with metal screws.

After the chair is completely assembled, the upholstery of the frame needs to be painted or varnished. Choosing a method finishing depends on what materials were used for the upholstery.

Let's sum it up

Now you know which chairs can be assembled from a profile pipe and how to do it yourself. If you still have questions about assembling metal furniture, ask them in the comments to the article.

October 25, 2018If you want to express gratitude, add a clarification or objection, or ask the author something - add a comment or say thank you!

There are many models available on the Internet and in various stores. various chairs this type - their color, material and style are different and successfully combined in such a way that everyone can choose a successful model for themselves that will satisfy them in all respects.

It’s not difficult to create a rocking chair out of wood with your own hands. It takes effort and skill to ensure that your homemade rocking chair made your whole family happy in a corner designed for relaxation.

Scroll necessary materials and tools for a rocking chair cannot be limited due to the fact that the choice of frame, backing options and some other details are different. But there is a mandatory list of necessary tools:

- hammer;

- screws and screwdriver;

- pencil for marking and brushes for painting;

- jigsaw and files (in case of using a wooden frame);

- level (a successful option would be right angle with a long ruler and a built-in level - these can be found in specialized stores).

Step-by-step instructions for creating

Option one - standard wooden rocking chair

A wooden frame is the most common in creating such projects - it is reliable, practical and easy to process.

When creating a rocking chair with your own hands, the drawings are important element for subsequent project development.

A rocking chair made of wood is durable, environmentally friendly and attractive

In the case of using wood as the main material, you can find many options for templates and drawings with detailed explanations and calculations of small details.

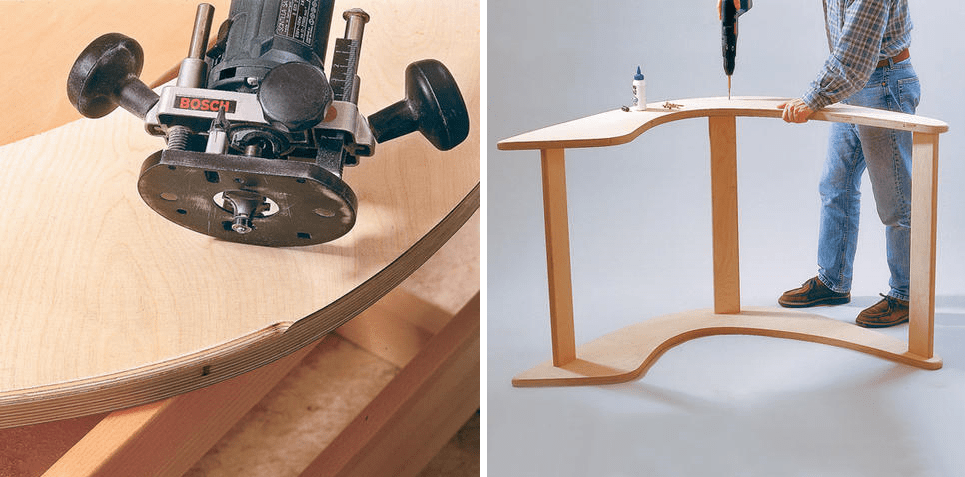

To create such a chair, you need to use a jigsaw and a sander to cut out the parts for the chair.

In the future, you can simply lay a blanket on the chair, or attach sewn pillows - this will add originality and uniqueness to your rocking chair.

The second option is the atmosphere of nature

Using wood as a frame, you can also use small branches as “upholstery”. They can be collected in the forest in April or October.

Having made all the wooden parts and fastened them together, you need to carefully place all the collected branches into the empty space.

Such a system can be connected and strengthened using glue or liquid nails.

It is important to remember that it is necessary to fill all the space allocated for the branches - if there are large gaps in the structure, it may break.

The third option is an eternal classic

The most popular material in creating a rocking chair is plywood.

Cut two side panels in the shape of a boomerang from a sheet of plywood

It is necessary to cut a number of narrow long strips of plywood and nail them to the two base parts on which the chair will roll.

Regarding the distance between the “stripes”, it is customary to use the rule of the golden mean - the elements should not be close to each other, but also big gap between each element is undesirable.

Do not skimp on screws or other material with which you nail the plywood to the base - it should be nailed in two places on each side, for a total of four attachment points.

The shape of a plywood swing chair can vary, the decor depends on your imagination

How to properly plant and care for thuja Smaragd, read.

How to properly plant and care for thuja Smaragd, read. The fourth option is part of the soul

Having asked the question of how to make a rocking chair with your own hands, a person wants to make a unique, unique project.

You can make the parts on which the chair will swing from wood, the support system from metal frame. The seat itself is made of wool - knitted.

The pattern and technique of embroidery can be different, the main thing is to accurately measure the space for embroidery and leave loops for attaching to the frame.

Such a chair will look natural both at home and on the street - you will really put your soul into it.

These are just a few of the many types of chairs that exist. I would like to note that under seat there may be, for example, a place for your animal. Complement the rocking chair made with my own hands, you can use any elements - it all depends on the person’s imagination and priorities.

A homemade rocking chair will cost many craftsmen less than a store-bought item. Self-made furniture will be of higher quality and more environmentally friendly; you can think through your own design and construction concept. A rocking chair will be a successful addition to the interior design of a room, a device that will calm you down, give you a good mood for work, and relax you. This product will also become indispensable when rocking a child. For the baby himself, such a chair is a real swing.

If a person has nothing to do with carpentry, then a natural question arises: how to make a rocking chair with your own hands? Initially, you should decide on the type of rocking chair; there are several of them. There are different types regarding design features:

- A rocking chair that has radius runners. This model is classic and most popular. It has a low landing, since on rounded “radii” it is very difficult to maintain balance when swinging.

- Chair with runners of variable curvature. In this case, the “radii” do not represent part of the roundness, which means the swing can have a large amplitude. In this case, use will be safer and more comfortable.

- Armchair nirvana. There are two subtypes: elliptical and spring. The first is considered unsafe, as capsizing often occurs, but the swing is soft and smooth. Spring models are more suitable for widespread use, but making a rocking chair with your own hands such an upgrade requires skill and experience.

- Rocking chairs 3 in 1. All three modes are presented here: chair, rocking chair, lounger. Depending on the degree of reclining of the structure, the position of the body is determined. Multifunctional furniture, but large in size.

The presented design options can be made from almost any material: wood, metal, wicker, rattan. The seat can be hard, soft or a combination. Materials can be combined, and in some models it is even necessary. Thanks to photos on the Internet, you can choose the model of the product you like.

Wicker model

Making furniture from wicker or rattan with your own hands is quite difficult. Rattan is an expensive material, but a product made from it has a long service life, and the body is more resistant to mechanical stress. The same cannot be said about the vine, but it is more accessible and pliable to work with.

To create original wicker furniture, you can watch the master class. Such instructions will be quite sufficient to implement the project. First, the material is prepared:

1. Rattan cannot be collected by yourself - it is a tough vine that grows in certain areas of America. The vine is harvested independently: branches are collected throughout the year. Length and thickness may vary. When the vine is collected, it is placed vertically outside to dry.

2. Processing of rods involves stripping. The branches are placed in a bath with warm water, where the material should spend about 12 hours. The branches will become elastic. When each twig bends well, you can remove the bark from them.

3. To continue working, you need to give each element the appropriate form. Thick branches are fixed in clamps in the appropriate position, and thin branches are divided into several parts, called shreds, using a splitter.

4. Each shank must be passed through a press so that they become flat and suitable for weaving.

5. The prepared vine is placed in a dryer for three days, where the shape of each element of the future product is permanently fixed. Only from such a vine can a rocking chair be made.

The next stage will be the manufacturing itself:

1. First, a frame is made from thick branches or wooden planks. The sizes are determined independently. All parts are fixed with nails or wire. The item is placed in the dryer for several days.

The frame is being made

The frame is being made 2. Braiding consists of covering the back and seat with tires. Apply to the body furniture glue, which will serve as an additional connection. The shanks themselves braid the sheathing rods in a checkerboard pattern.

We braid the back and seat

We braid the back and seat 3. When the body is ready, the runners are attached and the product is tested. The chair needs to be slightly rocked; if this process proceeds easily, and the chair itself does not tip over when rocked, then the center of gravity is determined correctly.

4. The last step is to open the vine with furniture varnish.

The made rocking chair can be used in the country house, veranda, balcony, garden, hallway. In addition to the positive feelings while using this piece of furniture, this element will become a wonderful authentic design decoration.

On video: making a fully wicker rocking chair

Wooden rocking chair

Making a rocking chair from wood with your own hands is quite simple, the main thing is to make the appropriate preparation. If this is the first time such work is being done, a master class will help with this. . First we prepare the tools:

- wood hacksaws, jigsaw;

- sanding machine or sandpaper;

- screwdriver;

- set of drills;

- measuring tape;

- hammer;

- putty knife;

- level;

- construction corner;

- brushes, pencil.

Preparation of the material is also important. A wooden rocking chair is made partly from plywood. It is better to choose the remaining wooden parts from an elastic material. It would be great if it were flannel.

After collecting tools and material, you can begin to work. Initially, a drawing of a rocking chair is made in accordance with the parameters of the future product. The diagram is an exact copy, but on a reduced scale:

1. You need to cut out the side elements from plywood with your own hands, which are semicircular bases with grooves for flannel. A jigsaw, wood saws and a sander will come in handy here.

Making the sides

Making the sides 2. Flannels are prepared; you can make them from plywood with your own hands, but provided that the plywood is at least 30 millimeters thick and flexible in its base.

We make flannels

We make flannels 3. The side parts made of plywood are connected to each other using 30x50x600 mm bars. Crossbars (flannels) are attached to the frame from above using a screwdriver at a distance of 2-3 cm from each other.

Assembling the structure

Assembling the structure 4. We attach the flannel to the frame; for this we use a screwdriver.

Screw the flannel to the frame

Screw the flannel to the frame 5. The plywood rocking chair is awaiting finishing. Places where flannel is attached to the sidewalls are covered with putty. When the putty has dried, you can coat the product with wood varnish.

Finishing

Finishing A rocking chair made of plywood can be additionally equipped with other elements. For example, you can make the seat soft. To do this on wooden base A foam base is laid on top of which the fabric is laid.

On video: how to make a rocking chair out of wood.

Metal chair

There is another class of product - metal rocking chairs. Not every master will be able to make such a design, since this requires more serious equipment and skill. Although, it’s worth trying to make a rocking chair out of metal with your own hands. This can be done by looking at the photos, or by watching the master class.

To work we need the following components:

- steel rods;

- galvanizing;

- steel corners;

- welding machine;

- drill with special drills;

- Bulgarian.

Often, arcs for runners are made from a profile pipe, and corners are cut from the profile itself, which will serve as fasteners. From profiled metal sheet everything can be made necessary elements to create a design like this:

1. First, drawings are made according to the product design. To do this, you can take a ready-made chair and transfer this sketch, but also think about a way to attach the rounded runners.

2. Steel rods are cut into 1 meter lengths. After this, the frame is welded, to which the rods will be welded. The distance between them is about 1 centimeter. The metal curls into an oval.

3. After this, the master must attach the seat to the oval base. The seat itself is made of galvanized steel. Fastening is carried out using bolts, and holes for them are made using a drill.

4. The final stage will be painting and sanding the sharp parts.

If we compare the operating conditions of wicker, metal and wooden furniture, then the most universal option is precisely wicker. It does not damage the floor surface, is easy to move, and can be used in any room or outdoors.

You can decorate such a piece of furniture with textiles, in particular decorative pillows, quilted bedspreads, warm blankets. Thus, a note of comfort and coziness is introduced into the overall idea.