What insulation to choose for the walls of the house. Which insulation to choose

When most of the housing stock was built, no one thought about keeping warm, much less saving. So it turns out that our “Stalin”, “Brezhnev”, “Czech” and all other housing is far from energy-saving technologies. Corner apartments, apartments on the ground and top floors for a long time were generally considered cold. Moisture, cold, and dust enter through cracks, interpanel seams and even walls. To avoid all this and ensure yourself comfortable conditions residence, sooner or later you need to think about insulating your home. Let's review the insulation materials offered by the construction market.

On modern market building materials there are different types of thermal insulation for walls. Right choice will provide warmth in winter and coolness in summer. This is achieved by reducing heat loss and eliminating drafts. Also, in a properly insulated room there will be no dampness and mold, and the microclimate will be healthy. Remember the following properties that thermal insulation must meet:

- low thermal conductivity;

- soundproofing;

- fire resistance;

- environmental Safety;

- durability;

- waterproof;

- breathability;

- biostability.

When choosing, it is worth considering what material the house is built from, how many floors it has, in what climatic zone you live.

So, insulation for walls frame house And wooden house(mezhventsovogo) – this is not the same thing. In the first case, polystyrene foam is suitable, mineral wool slabs, glass wool, penoizol, in the second - ordinary tow, jute, linen felt.

Materials can be organic or inorganic. The first group includes cellulose fiber, wood, rubber, cork, felt, moss, jute or tow. Fibrous (glass wool, mineral wool) or cellular (expanded polystyrene, polyurethane foam, penoizol, etc.) insulation materials, liquid ceramics are inorganic materials. Organic ones are more environmentally friendly, but they are not as functional or durable as mildew-resistant polystyrene foam and polyurethane foam. Development and testing in this industry continues and new types of wall insulation are emerging. Thus, it is gaining more and more popularity liquid insulation for walls. Let's look at how different types differ, their advantages and disadvantages.

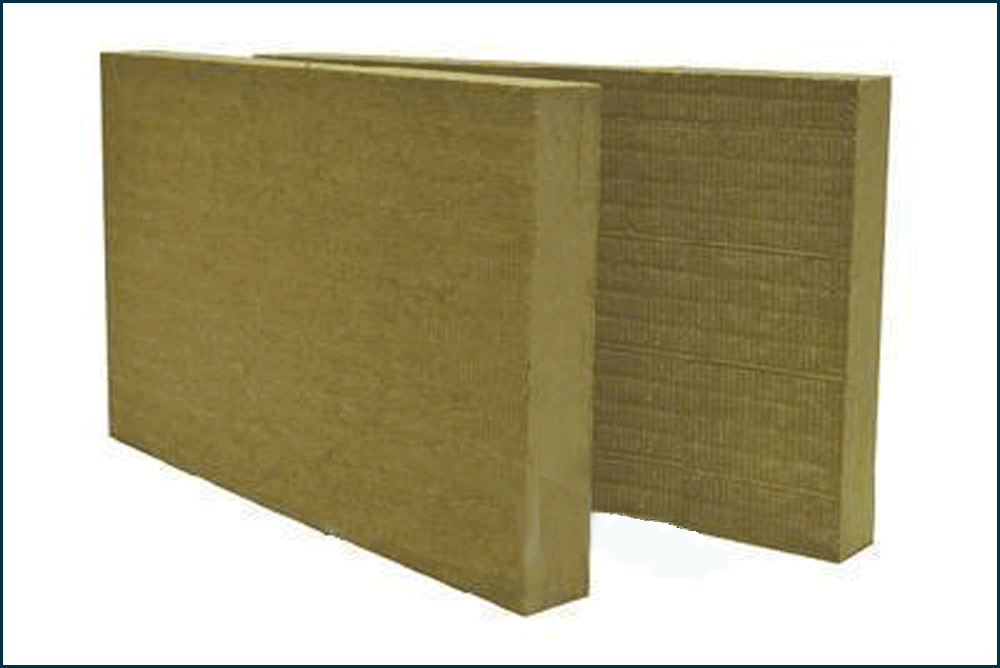

Mineral wool: pros and cons

Construction of a frame from metal profiles

Mineral wool is one of the most common fibrous thermal insulation materials. Mineral wool is produced by heat treatment and pressing of metallurgical slag or basalt. The fibrous structure traps air, thereby forming a barrier to cold penetration and heat loss. Mineral wool comes in the form of slabs and continuous sheets in rolls. It is used for both inside and outside.

Properties are ensured due to low thermal conductivity. The advantage of this material is its breathability, durability, soundproofing properties, fire resistance, and environmental friendliness.

Installation is a rather troublesome process. On the one hand, the slabs tolerate deformation well, on the other hand, it is necessary to use separate protective equipment to ensure safety.

The thickness, when used indoors, narrows the existing space, which is undoubtedly a disadvantage. The water permeability of mineral wool can lead to the fact that over time it will become wet from condensation and fungus will appear in it. To prevent this from happening, the material must be additionally waterproofed.

Technical properties of glass wool

Morally obsolete glass wool is now used extremely rarely

Glass wool is also a fibrous insulation material, the most proven of all, as it has been used for a very long time. It is formed by melting sand, soda, dolomites, limestones, borax or glass production waste. It is produced in slabs and rolls, and compressed for transportation.

Thin, sharp and brittle fibers of glass wool are dangerous both in direct contact and inhalation of air with glass wool fragments. Therefore, when using it, it is important to provide yourself with goggles, a respirator, and gloves. Manufacturers claim that modern views glass wool is safe for humans.

It does not burn, has good heat and soundproofing properties. It can be used to insulate all types of roofs, internal partitions and external walls. It is cheaper than most analogues, but is more susceptible to shrinkage and crumbling.

Characteristics of cellulose insulation

Application of cellulose

This is one of the newest materials, it is environmentally friendly and functional. This type of insulation is produced from cellulose production residues. It is used for both external and internal insulation - it is blown under drywall, magnesite slabs.

It is breathable, which is the positive side. What’s worse is that it is permeable to water, susceptible to mold, and fire hazards. To get rid of such shortcomings, antiseptics are added to the cellulose base to increase biostability and fire retardants to reduce flammability.

Advantages of expanded polystyrene (foam)

A wall covered with foam plastic will provide a significant reduction in heat loss

Expanded polystyrene is produced by foaming polystyrene at high temperatures Oh. This is a white rustling material, which is characterized by water and air tightness, noise and heat insulation properties, light weight, and ease of installation. He is not afraid of bacteria, fungi and mold, and he is not afraid of bad weather conditions. Just 8 cm of expanded polystyrene can replace 1.7 m of brick wall, 25 cm wooden wall or 9 cm mineral wool.

It is produced in slabs, which... used for interior walls, balconies, attics and house facades. Expanded polystyrene, due to its strength, does not tend to sag. This is one of the cheapest insulation materials.

Extruded polystyrene foam

In order to obtain such a material, polystyrene granules are melted at high temperatures, then extruded from an extruder and foamed. It turns out even more durable, durable, air- and waterproof than polystyrene foam. It has good contact with different wall coverings (plaster, concrete, brick). At the same time, it is completely incompatible with resins and organic solvents.

Fibrolite

The walls are insulated from the inside with fiberboard; installation of the slabs will require laying a waterproofing layer and plaster.

Fiberboard is obtained after drying and compressing wood shavings by mixing them with a binder. It can be Portland cement or magnesium salts. The slabs obtained in this way are made of natural material, A protective layer prevents biological effects (fungus, mold, insects) and water resistance. In order for it to retain its properties longer, additional waterproofing will be required. If the humidity exceeds 35%, then sooner or later it will begin to deteriorate. Additional plastering will increase durability. Fiberboard is easy to process and install.

Eco-friendly cork materials

Cork insulation for walls is not cheap, but the most long-term option

Cork panels– one of the most environmentally friendly materials. It consists of the smallest cells (40 million per 1 cubic cm), has strength, breathability, and the necessary (low) thermal conductivity.

Produced by granulating raw materials, heating them to 400°C and pressing them into blocks. Their thickness can be 10-320 mm.

Such panels are lightweight, resistant to mechanical pressure, and do not shrink. The material is very durable and functional. It also soundproofs the room. And its appearance allows it to be used even for interior decoration.

Liquid insulation is becoming relevant. This is already a new generation tool. Even in the most inaccessible places, liquid ceramics will help get rid of drafts and heat loss. The paste-like suspension consists of closed spheres and is applied to a previously cleaned brick, concrete, wood, metal, cardboard or plastic surface. The color of the material is gray or white.

At the same time, ceramic insulation is easy to apply, it is safe, does not burn, and does not lead to a reduction in the size of the room. Such insulation is also air and waterproof. After it dries, an elastic coating forms on the wall. Thin walls made of brick needs to be processed at least 5-6 times. Ceramic insulator is not cheap (its consumption per 1 layer is 1 l/4 sq.), but it will last a very long time. You will have to forget about insulation for a quarter of a century. That's what the manufacturers promise.

Insulation with liquid foam plastic

Another option for liquid heat insulation is cast foam, called penoizol. It is poured from hoses between walls, into cracks, and formwork during the construction process. And this option is almost 2 times cheaper than all the others. It is resistant to biological organisms, breathable, does not burn well, and is durable. Its properties are 8% better than those of foam plastic, and 12% better than those of glass wool. But its service life is up to 50 years.

Knowing beneficial features all materials, you can use them by skillfully combining them. Insulate the walls with foam plastic or mineral wool, pour penoizol into hard-to-reach places, and treat a small area under the window sill with liquid ceramics.

The modern trend of external wall insulation for private and apartment buildings requires homeowners to make decisions about which type of insulation to use for this process. In most cases, this choice is based on the proposals of the contractor who will perform the work or the advice of neighbors and friends who have already passed this stage. Unfortunately, most companies performing insulation work do not offer the option that will be better for the customer, but the one on which they can earn more. And recommendations from neighbors or friends are based only on their personal experience, which is often not optimal in terms of choice correct system insulation, since in the decision-making process many factors must be taken into account, which will depend, for example, on the material and thickness of the wall, wall unevenness, wind load, etc.

All types of insulation materials that are used today for building envelopes can be divided into the following groups:

Spray insulation

The share of the use of different thermal insulation depending on the type of building in the CIS countries has significant differences. So for new residential and administrative buildings the share of mineral wool is up to 80%, second place is taken by extruded polystyrene foam 15%, the remaining 5% comes from other types. For old apartment buildings, as well as private households, this share is significantly different. Up to 60% is extruded polystyrene foam and polystyrene foam, 30% mineral basalt wool and 10% comes from other insulations. This redistribution is explained primarily by the desire of private homeowners to save on this process by choosing a cheaper option.

Let's compare the following insulation materials according to the main indicator - thermal conductivity:

Mineral wool – 0.045 W/m*K

Extruded polystyrene foam – 0.028 W/m*K

Foam plastic – 0.034 W/m*K

Foam glass – 0.052 W/m*K

Sprayed thermal insulation – 0.025 W/m*K

Effective highly porous thermal insulation – 0.017 W/m*K

A comparison of insulation in terms of thermal conductivity shows that the most effective in terms of this indicator is highly porous thermal insulation based on aerogels, which is 2 times more effective than polystyrene foam and 2.5 times more effective than mineral wool.

Now let's compare thermal insulation by price:

Mineral wool for ventilated façade (density 80 kg/m3) thickness 100mm – $6 per sq.m.

Mineral wool for a plaster facade (density 130 kg/m3) thickness 100 mm – $6 per sq.m.

Extruded polystyrene foam thickness 50 mm – $4.5 sq.m.

Foam plastic 50 mm thick – $2.5 sq.m.

Foam glass 120 mm thick – $13 sq.m.

Sprayed insulation 30 mm thick – $5 sq.m.

Effective highly porous insulation 10 mm thick – $70 sq.m.

A cost comparison shows that insulation with the lowest thermal conductivity is much more expensive than other types, so the feasibility of its use is limited only to areas where the use of other thermal insulation is impossible.

Let's compare insulation materials according to the complexity and price of installation, based on a 10-point scale, where 10 is the greatest complexity and installation price and 1 is the least installation complexity and price:

Mineral wool – 7 points

Extruded polystyrene foam – 5 points

Foam plastic – 5 points

Foam glass – 10 points

Sprayed thermal insulation – 8 points

Effective highly porous thermal insulation – 1 point.

The roll type of highly porous insulation, its small thickness and weight allow it to be installed quickly and inexpensively; in addition, it does not require additional materials(For example, windproof film) or a special fastening scheme.

Let's compare thermal insulation by service life:

Mineral wool – 20-30 years

Extruded polystyrene foam –15-20

Foam plastic – 10-15 years

Foam glass – 100 years

Sprayed thermal insulation – 20-25 years

Effective highly porous thermal insulation – 20-25 years.

The most durable insulation is foam glass, which is resistant to environment, does not contain organic compounds and is solid in structure, which prevents its weathering or mechanical destruction.

Let's compare insulation materials in terms of environmental friendliness:

Mineral wool - environmentally friendly, made on the basis of basalt

Extruded polystyrene foam - made on the basis of chemical compounds, relatively environmentally friendly when used for external insulation

Polystyrene foam – contains volatile chemical compounds and is not recommended for indoor insulation and prolonged contact with people

Foam glass - environmentally friendly based on glass chips

Sprayed thermal insulation – contains volatile chemical compounds, is especially dangerous during the application process, requires special measures precautions and ventilation of the room for a long time, recommended for external insulation

Effective, highly porous thermal insulation is relatively environmentally friendly, made from foamed polyethylene, which is chemically neutral.

The safest from the point of view of isolating various chemicals. substances are mineral wool and foam glass, although all of these types of insulation are suitable for outdoor use.

Let's compare insulation materials in terms of flammability:

Mineral wool is not flammable

Extruded polystyrene foam - flammability class G3-G4

Polystyrene foam is highly flammable and is prohibited for insulation above the 2nd floor.

Foam glass is not flammable

Sprayed thermal insulation – flammability class G3-G4

Effective highly porous thermal insulation – flammability class G1-G2

From point of view fire safety The safest are mineral wool and foam glass, which have a flammability class of NG, other types of insulation are flammable or even highly flammable, as is the case with polystyrene foam.

Often during the process of new construction or renovation, the question of comprehensive thermal insulation arises, which includes not only walls, but also roofing, floors, and communications. In addition, the type exterior finishing(plaster, ventilated façade, etc.)

Let's compare thermal insulation in terms of versatility of application:

Mineral wool – external and interior walls, floors, roofing, pipelines. Under plaster and ventilated façade.

Extruded polystyrene foam – external and internal walls, floors, roofing. Under plaster and ventilated façade.

Polystyrene foam – external walls, ready for plaster.

Foam glass – plinth, external walls, used roof, basements.

Sprayed thermal insulation – external walls, slopes, roofing, floors, basement, pipelines.

Effective highly porous thermal insulation – slopes, pipelines, internal walls.

The most universal in use is mineral wool, which, due to the variety of types in thickness and density, is used for various options insulation.

In addition to the listed characteristics, when comparing insulation materials, it is also necessary to take into account the ability to allow moisture to pass through and “breathe”. For example, extruded polystyrene foam, which is often used to insulate houses, has almost zero water absorption, which leads to the appearance of a dew point in the thickness of the building wall and its gradual destruction. In this case, the use of mineral basalt wool is more preferable.

Analyzing comparative characteristics insulation for external wall insulation, we can conclude that the most optimal in terms of quality and efficiency is mineral basalt wool, which is perfect for finishing with plaster and ventilated facades, is non-flammable, has a long service life, allows moisture to pass through, and is relatively inexpensive.

The use of other types of insulation also makes sense, but it is necessary to focus on specific conditions. If you need to insulate and waterproof the base, then the choice is definitely foam glass, budget insulation - extruded polystyrene foam or polystyrene foam, insulation of pipelines - polyethylene foam or sprayed liquid thermal insulation.

- 775 views

A properly insulated house will not only make living in it comfortable and cozy, but will also save money on heating the house. It is necessary to insulate floors, external walls, interfloor ceilings and the roof. More than a third of all heat loss occurs through the roof, because warm air according to the laws of physics, it rises and tends to leak through the ceiling and roof to the outside. Therefore, special attention should be paid to roof insulation.

There are several types of roof insulation. They differ in composition, density, shape, thermal conductivity and environmental friendliness. Let's consider these types.

1. Foam-based insulation - polystyrene foam, penoizol, polyurethane foam. It is obtained from various polymers by expansion and molding. The heat-shielding properties of polystyrene foams are due to the air bubbles they contain. Air is a poor conductor of heat, so the materials containing it inside also have low thermal conductivity.

Advantages of foam insulation:

- High degree of thermal protection, the thickness of polystyrene foam is 12 cm in terms of thermal conductivity. brick wall meter thick or 45 cm wooden.

- Water resistance. Expanded polystyrene does not absorb moisture, but steam can penetrate between the particles of the material, both penetrating inside and leaving it.

- Polystyrene foam is not susceptible to fungi, mold, or rot. Bacteria do not multiply on it.

- Expanded polystyrene does not support combustion and self-extinguishes in the absence of a flame.

- Polyfoam has high soundproofing properties due to the presence of air bubbles in its structure.

- Its low weight allows it to be used where high loads on structures are not allowed.

- This material is not damaged by rodents, which plays an important role in insulating country houses.

Disadvantages of polystyrene foam:

- its biggest disadvantage is that over time it can release harmful substances, especially at high temperatures. At temperatures above 80°C its use is unacceptable. Therefore, it cannot be used for thermal insulation of roofs that heat up in the sun.

- second negative trait This material is susceptible to deformation during use. This chemical compound may change its properties even after manufacturing, especially if the production technology is not followed. Therefore, polystyrene foam slabs can gradually dry out and gaps form between them. Manufacturers claim that this will not happen if the polystyrene foam is sealed from exposure external factors, for example, clapboard, wood boards, or other material.

2. Insulation made of mineral wool and glass wool. They can be in the form of mats or slabs. This material is produced by melting minerals, slag or glass.

Advantages of this type of insulation:

- Good thermal insulation. Thermal conductivity, depending on the type, is from 0.03 to 0.05 W/(m K).

- High degree of sound insulation. Some types of these materials have the highest sound insulation rates and are recommended by the manufacturer specifically for protecting rooms from noise.

- The material is not subject to rotting, mold and bacteria do not settle on it.

- This is a non-flammable material that can withstand temperatures up to 700°C.

Disadvantages of mineral insulation and glass wool materials:

- Although the material itself from which these insulation materials are made is harmless to humans, the binders that glue mineral fibers together are no longer so harmless. In addition, the very structure of these materials allows particles of mineral dust or fiberglass to enter the air, which, if inhaled, can harm human health. And you need to wear gloves and a respirator when working with such material.

- These insulation materials can absorb moisture, thereby partially losing their thermal insulation properties. Some types are supplied with special additives that make the material water resistant. To insulate the roof, it is advisable to use these types of insulation.

3. Materials from natural fibers. These are ecowool (cellulose wool), fibreboards, mats made of coconut, cotton, hemp or flax fiber. Most These materials are produced from recycled materials (waste paper, sawdust, etc.), which improves the environment.

Positive qualities of these materials:

- In terms of heat-protective and noise-protective properties, these materials are not inferior to the first two groups. Due to their fibrous structure, they retain room temperature well and do not allow noise to pass through.

- These are breathable materials; they do not need to be protected with special membranes from steam penetration. Steam penetrating into them from the room is easily removed outside, while the heat-shielding properties of the material do not change.

- These are environmentally friendly materials that do not harm health and create a comfortable indoor microclimate.

- Ecowool is applied to insulated structures using special equipment through pipes and fills all cavities, leaving no cracks or gaps through which heat could escape. This makes a house protected in this way even warmer.

Negative sides:

- These materials are flammable, but many of them contain fire retardants that prevent combustion.

- To insulate ecowool, you need appropriate equipment. Now there are enough companies ready to insulate your house using this method or rent it out. necessary equipment and material.

4. Vermiculite, ceramic foam, foam glass, perlite and other natural expanded materials. They are obtained as a result of swelling of natural minerals such as volcanic glass, perlite, clay and others.

The advantages of this group of materials:

- Fire safety. These materials do not burn, do not spontaneously ignite, and can withstand high temperatures.

- Safety for humans and animals. Such insulation does not emit harmful substances at any temperature.

- Light weight allows it to be used for insulating any surface.

- Good heat and noise protection, the ability to tightly fill insulated structures without gaps or cracks.

- Fungus does not appear on these materials and bacteria do not multiply. They do not rot or mold, and rodents do not grow in them.

- long, almost unlimited service life. These materials will last as long as the house lasts.

Disadvantages of natural expanded insulation:

- Perhaps the disadvantage is the form of release of these materials; not everyone is comfortable using loose insulation.

Based on this information, you can decide which insulation to choose for your roof.

The choice of insulation also depends on the roof design. This may be an unheated attic or attic for permanent residence, or maybe a flat roof, used or not. What insulation for the roof would be better suited for each of these options?

- When insulating an unheated attic, it is not the roof that is insulated, but the attic floor. I usually lay several layers of material, each layer should overlap the joints of the previous layer. It is better to use two layers of thicker insulation than three layers of thin material, with the same total thickness of insulation.

- If the attic is being insulated, then the insulation is laid under the roof, making sure to leave ventilation gaps between the insulation and the roof itself. It is also necessary to protect the insulation from the inside with a vapor barrier membrane, and from the outside with a moisture-proof film.

- Insulation flat roof places high demands on the strength of the insulation material. The density of the insulation is also of great importance. Flat roof experiences high snow loads and loads during its operation. Therefore, the density of roof insulation should be at least 40 kg/m3.

It is very important to follow the technology when insulating the roof. If you do not make the right “roofing pie,” then various problems may arise during the operation of the roof. This includes the appearance of icicles and icing of the roof, which can lead to destruction roofing. An improperly insulated attic will be hot in summer and cold in winter, and flat roofs may leak if the roof insulation is not installed correctly.

It is advisable to entrust the work of roof insulation to specialists, and if you do it yourself, carefully study the technology of this process and strictly follow the instructions. Then the roof will not cause you trouble in the future.

Which insulation is better for the walls of a house outside and inside, how to choose the most effective one? We will also consider the dependence of their characteristics and basic properties on the place of application.

What is the best insulation for a home, and which for the floor, ceiling or roof? We will try to answer these questions by carefully studying the properties that different types of insulation have. What is insulation, types of insulation and their characteristics, we will tell you everything you need to know.

In the production of these heat insulators, raw materials of organic origin are used. The composition of modern organic insulation no longer includes toxic substances - phenols and formaldehydes, but may include cement and various plasticizers.

First, let's look at the type of insulation that is used to insulate walls from the inside, as well as for the floor and ceiling.

Chipboards

Produced from pressed small chips. In modern construction it is used extremely rarely due to its flammability and susceptibility to rotting, due to its high hygroscopicity.

The thermal conductivity of particle boards is from 0.09 to 0.18 W/m*K depending on the density, which can range from 500 to 1000 kg/m3.

Wood fiber insulation board

During production, organic raw materials are used with the addition of antiseptics and water-repellent substances, which makes this material more suitable as a heat insulator for a house to be insulated from the inside.

Thermal conductivity - from 0.09 to 0.18 W/m*K. The main advantage of this material is its environmental friendliness and ease of installation on internal walls, as well as the variability of their final processing.

Polyurethane foam

Some people believe that it can be used for both external and internal wall insulation and that it is the best insulation for walls, but I strongly disagree with this (it is not environmentally friendly).

Has the following characteristics:

- density – 40–80 kg/m3, which provides good water resistance, noise and heat insulation;

- thermal conductivity – 0.019–0.028 W/m*K;

- durability - 30 years.

Thanks to the spraying method, the formation of cold bridges is completely eliminated when using this insulation. According to its flammability properties, polyurethane foam is a self-extinguishing, difficult to ignite material. The main disadvantage of this heat insulator is its high cost and application using special equipment.

Penoizol

The scope of application of penoizol is quite wide: it is used for facade walls, ceilings and floors. It is not recommended to use penoizol for walls inside a building, since the material contains formaldehyde resins and is not environmentally friendly.

The material is produced in the form of loose crumbs or in the form of blocks. Penoizol in liquid form is poured into previously prepared cavities. This technique can most often be found when internal insulation foundations, however, there is an opinion that this heat insulator cannot be used in humid environments due to the high moisture absorption parameter.

Characteristics of penoizol:

- density – up to 20 kg/m3;

- thermal conductivity index – 0.03 W/m*K;

- service life -50 years;

- flammability class - G3, ignition temperature - over 500 degrees.

The disadvantages of penoizol include: it is not environmentally friendly, exposure to aggressive environments, and high moisture absorption.

Expanded polystyrene

The composition of expanded polystyrene includes polystyrene - organic compound, obtained from petroleum. Expanded polystyrene is used for insulation of facades, floors and roofs.

No insulation causes as much controversy as expanded polystyrene. Many professional builders believe that this is one of the best insulation materials, despite its many shortcomings; others recommend under no circumstances using it for walls, since it is not environmentally friendly, is flammable, and leads to the formation of condensation and mold.

Properties of expanded polystyrene:

- thermal conductivity index – 0.037–0.042 W/m*K, which is its main advantage;

- resistance to aggressive environments – average;

- excellent hydro and sound insulation;

- flammability class G2, when burned, it releases toxic substances hazardous to human health;

- vapor permeability – 0.015–0.019 kg/m*hour*Pa;

- The hygroscopicity of a material depends entirely on its density.

Extruded polystyrene foam

Warm insulating material, made by extrusion, due to which the material has a cellular structure. The cells are filled with air, providing heat-insulating and noise-absorbing properties.

The technical characteristics are as follows:

- density 35 kg/m3;

- thermal conductivity – from 0.037 to 0.048 W/m*K;

- flammability class – G2.

This is the best insulation for thermal insulation of foundations: it has a low degree of moisture absorption and is resistant to rodents. We do not recommend using it to insulate the walls of a house for two reasons: it is not environmentally friendly; when heated, extruded polystyrene foam emits toxic fumes, and it is flammable.

Ecowool

A unique heat insulator of its kind, with very high heat and sound insulation rates. The disadvantage of this insulation is a decrease in basic properties over time.

This material is made from waste from pulp and paper production. Another disadvantage is strong moisture absorption. The use of this organic insulation is possible only in dry rooms for thermal insulation of ceilings and floors by bulk method.

Inorganic insulation materials and their characteristics

In the production process of heat insulators of this type, substances of a mineral nature are used: asbestos, glass, basalt rocks. Such insulation materials are resistant to aggressive environments, non-flammable, and have greater specific gravity in comparison with organic heat insulators. Insulation materials of this type include: mineral wool, glass wool, basalt-based wool, etc. Let's consider the most popular types.

Mineral wool

On the modern market, mineral wool is presented in two versions: slag and basalt (stone).

Slag wool is considered not environmentally friendly, because industrial slag is used in its production. However, it is this wool that is often used to insulate non-residential industrial buildings. Basalt mineral wool is considered more environmentally friendly, so it is often used for thermal insulation of walls, floors, roofs, as well as for the construction of ventilated facades.

The main advantage of mineral wool, which manufacturers always point out, is zero flammability. Mineral wool is also an excellent sound insulator.

Disadvantage - reduction thermal insulation properties over time and the high price of the material itself and components.

Characteristics of mineral wool:

- thermal conductivity – 0.0035–0.042 W/m*K;

- flammability class - NG;

- vapor permeability is high.

Glass wool

The material is based on silicate production waste.

The advantages of glass wool include:

- thermal conductivity - 0.03 to 0.052 W/m*K;

- good noise insulation properties;

- flammability class - NG;

- hygroscopicity – low.

A significant disadvantage of glass wool is its brittle fibers, which can penetrate the skin, lungs, and clothing. IN Lately There are many fakes on the market that contain harmful substances, but they can be distinguished by their color and smell.

Insulation made of porous concrete with density D-140 “Velit”

If you ask the question which thermal insulation is better or which insulation is the best, I would answer that it is Velit or the Velit Plus insulation system.

This is a thermal insulation material made of porous concrete with a density of 140 kg/m3. This is a slab insulation material that consists of environmentally friendly pure materials: sand, cement, lime and air.

The material is not flammable and is not subject to destruction. They can be used to insulate walls both outside and inside the house, and also very well insulate floors, ceilings, and flat roofs.

Main advantages: environmentally friendly, non-flammable and durable. The insulation system with this material is 20 percent cheaper than insulating the facade with mineral wool.

Thickness matters

Now let's talk about the thickness, on which the thermal conductivity of the entire layer of the structure of the structure depends. When choosing one or another insulation, it is necessary to calculate its required thickness to ensure thermal insulation properties. Simply put, you need to know how thick the selected insulation should be to keep the house warm.

This indicator will depend on the properties thermal insulation material: density and thermal conductivity. Calculation required thickness insulation in each specific case is produced according to special formulas that take into account not only the characteristics of the insulation, but also the conditions under which they will be used. The calculation is very simple, I won’t show it here so as not to scare you with formulas, it’s all easy to find on the Internet using relevant queries.

Conclusion

Which insulation materials are best to choose for the walls of your home? Here I express my opinion, and you can agree with it or not. When asked what the best thermal insulators are, I would answer basalt wool, mineral wool. As for the question of which insulation is the best today, it is definitely Velit.