Distance between mounting boxes for sockets. How to fix a socket box in the wall: installation and installation

Installing sockets in a concrete wall is quite a complicated matter, like everything related to electricity, because it requires special care. If you decide to do this work, be sure to strictly follow the technological process. Installation of new sockets is an important issue, since after each renovation or simply moving furniture, you change your home. For ease of use of certain devices, they are moved to more “accessible” places. If you want to do everything yourself, you need to know the theoretical minimum, which I will talk about in this article.

When starting the preparatory stage, you should already have purchased an electrical appliance, as well as purchased necessary materials, tools and the work area was brought into proper shape.

Typically, the location of sockets is not regulated in height, so electrical appliances can be installed wherever you want, observing only one condition: heating, gas and plumbing systems should be 1 meter away from your chosen installation point. The exception is the toilet and bathroom; Under no circumstances should electrical outlets be installed in them.

Required tools and materials

To work you will definitely need:

- Electrical socket (better take a product with a ceramic base);

- An appropriately sized installation box;

- Cable and conductor products;

- Alabaster.

For equipment, select:

- perforator;

- chisel;

- putty knife;

- indicator screwdriver.

Types of sockets

There are several main types of sockets. By type of installation there are: built-in for open and built-in for internal wiring. Built-in ones are used when wires run through the wall. This usually happens in apartments, as this is a guarantee of safety. Overheads are more suitable for wooden houses, where the wiring goes over the wall.

Sockets with protective curtains are good because the openings are protected. The curtains move back only when the fork is inserted. They can open upward, with a certain pressure, in a circular motion, etc.

Sockets with ejectors are suitable for using multiple appliances when you need to frequently pull out the plug and replace it with another one.

A socket with a timer is more suitable for children and the elderly. You can program it to turn on a particular device. This, for example, can be done with a teapot.

Sockets with indicator. Using the indicator, you can determine whether there is current in the network.

Installation instructions

Marking

First of all, we start marking - using a tape measure and a pencil, we mark the center of the future outlet on the wall. When installing the block, apply all centers.

Holes in a concrete wall

For further installation of socket boxes, make a hole in concrete wall. To make the job easier, use a hammer drill and prepare a special crown. You use it to make holes with a depth of 50 to 60mm. Then you insert the concrete bit into the hammer drill and use it to mark the future dimensions of the hole.

Make 12 holes along the resulting length. Drill them to the installation depth of the selected socket boxes (usually no more than 50 mm). Using a spatula attachment, remove any remaining concrete.

Electrical wiring installation

After you have made all the holes and punched the grooves to them, you can begin installing the electrical wiring. You must route the power wires to the sockets. The best option: each has its own power cable.

Installation of socket boxes

At this stage, carefully follow the things I described, because durability, reliability, convenience and, of course, your safety depend on it.

Considering the number of socket boxes you want to install, assemble the appropriate block. Let's take two things as an example.

- Connect two sockets together.

- Make the plugs needed to enter the cable.

- Remove unnecessary ones connecting elements that interfere with installation.

- Try on the socket box, placing it in the already formed hole. Once you are sure that it is not sticking out, protruding or tilted, you can proceed to the next step.

- Clean the hole from dust.

- Prime with a special primer that guarantees durability.

- Dilute putty or plaster mixture on a gypsum basis. Then apply the mixture inside the holes. In such cases, the use of alabaster is also allowed.

Important! You need to work quickly because the plaster hardens in a very short period of time.

- “Press” the socket boxes with the wires in them into the solution.

Wall decoration

Next, you need to prime and then cover significant chips, dips and depressions with plaster. The socket boxes themselves need to be coated especially carefully. After the wall has dried, putty and treat sandpaper areas so that everything looks smooth and beautiful.

After this you can safely go to finishing(paint, wallpaper, etc.).

The installation of not a single new point in the electrical network- this plastic or metal box, a wooden plank acts as an intermediate link in the wiring and is responsible for reliable fastening socket or light switch.

This electrical element is irreplaceable, so it is important to know everything about installing a socket box into a wall with your own hands, so that when planning a new line or replacing an old device, you do not waste time and money calling an electrician.

Below we will discuss the main types and sizes of mounting boxes offered by stores, as well as step-by-step instructions for installing them.

Understanding the types and types

Socket boxes are classified according to many criteria, but the main one is their division according to the material of manufacture. So, the following models are found:

Plastic, which are the most convenient and practical, since the base is made of non-flammable material, which increases the safety of wiring and makes it possible to use it on wooden surfaces.

Metal boxes are more durable, but due to their ability to heat up and conduct electricity, they fade into the background, giving way to safer and more practical options. However, these models have not been discontinued since the installation of hidden sockets in wooden houses only possible with a metal socket box.

Wooden pads were previously often used when setting up wiring open type, being a convenient intermediate base for attaching the socket directly to the wall. Nowadays they practically never occur, only when installing homemade wiring in bathhouses, garages and other outbuildings.

The products also differ in their shape: round (universal), square (more spacious) and oval (or “double” socket boxes for installing a double socket or a set with a switch).

Models also differ in design features:

- The presence or absence of fixing tabs (in hollow plaster walls they are necessary, and socket boxes for plasterboard, concrete, brick and aerated concrete are secured with a layer of alabaster).

- Open or hidden.

- Single and composite (composite ones have special fastenings that allow you to assemble up to five glasses into one block).

- Standard and advanced.

The sizes of socket boxes may also vary. A round model with a diameter of 65 cm and a depth of 40 cm is considered standard, but there are narrow options 25 mm high or 80 mm deep. Box dimensions square shape most often 70 by 70 mm, but there are also deviations from the standards.

We mount the socket box

Installation of this product is not difficult, but for wood, concrete, brick and plasterboard wall the algorithm of actions will change slightly. Below are step by step instructions how to install a socket box with your own hands in each indicated case with detailed description and photo.

Preparation

On preparatory stage it is necessary to choose the right type of socket box depending on the required functionality and wall material. Also common to all cases will be a set of tools and consumables:

- Hammer or drill;

- Suitable attachment for wall slitting;

- Building level;

- Meter;

- Pencil;

- Chisel;

- Hammer;

- Putty knife;

- Putty.

Installation of a socket box

At this stage, the procedure and technology of actions for each type of wall will vary.

When installing in concrete and brick, the following must be taken:

- Mark the outline of the future wiring on the wall surface in accordance with the previously planned diagram.

- Determine the location of the outlet or switch, mark the area with a cross.

- Attach the purchased socket box to the “cross” (so that the mark is strictly in the center) and trace the outline.

- Drill a groove, where the drilling depth for the socket box will be the sum of the height of the glass and a margin of 5 mm.

- Clean the resulting hole and try on the socket box.

- Bring the wires inside the drilled circle, also make a hole in the back wall of the socket box and pull the wires through it.

- Moisten the hole and apply thin layer putty and carefully place the glass.

- Level the surface, remove excess, wait until dry.

It is somewhat easier to install a socket box in drywall:

- Apply markings and mark the outline of the socket box.

- Cut a hole of appropriate size.

- Make a hole in the glass for the wires and pull them out.

- Insert the socket box into the groove.

- Tighten the screws located on the sides of the housing until the glass sits tightly.

Installation of a socket box in a wooden wall is considered unsafe even with the use of metal protection. If you nevertheless decide to do hidden wiring, then drill suitable sized grooves, bring the wiring out and install metal cups.

It is important to act absolutely precisely, as with drywall, since it will be problematic to disguise unevenness or extra centimeters. However, it is still recommended to install exposed wiring on wooden surfaces.

When installing a socket box, it is a good idea to follow some tips that will significantly save effort, time and money.

Install the mounting box after applying plaster to the wall, but always before finishing with putty and gluing wallpaper. This procedure will eliminate errors, will not spoil the interior, and will help hide errors in local repairs.

Check that the markings are correct with a level so that you don’t end up with sockets placed at an angle. This is especially true for installing socket blocks.

It is not necessary to use the old holes when replacing sockets and switches - it is enough to cover up the old entrance.

If the wall is too thin for the socket box standard size, then it is recommended to install overhead sockets. As a last resort, it is allowed to independently trim the height of the mounting cup.

It is not advisable to use for fastening polyurethane foam because it is a fire hazard.

Given step by step photos installation of the socket box clearly demonstrate that its installation is not difficult even for a beginner in electrical engineering. If there is a need for such repairs, then feel free to get to work, armed with the instructions, tips and recommendations described above.

Photo of socket boxes

An integral part of any major renovation is the installation of sockets. According to all the rules, at this stage a box for an outlet is required, which is one of the main elements of installation and is a guarantee of safety.

It is mounted directly into the wall, followed by wiring and connecting the socket to the mains. If necessary, this simple electrical element allows you to repair or replace the outlet.

Socket boxes and their purpose

Not many people know what a socket box is and what it is needed for. This question may arise only if repairs with a change in wiring are necessary. But the solution to the problem usually depends on experienced builders. A small repair involving changing the installation boxes for sockets can be done independently.

The socket box is usually represented by an original glass made of metal or plastic, fixed in a hole made in the wall. Necessary for the internal location of the socket mechanism. Switches are also installed in it. From above, the entire structure is covered with a decorative frame, which makes the socket boxes invisible to the eye, which is why not everyone knows about them.

And not everyone understands why you can’t just place the outlet directly into the wall without a box. First of all, it is necessary that the socket complex is assembled with high quality and works perfectly.

Other purposes of socket boxes include:

- Guarantee of strong fixation of the mechanisms of sockets, switches and similar devices. The fastening function is usually performed by screws of the socket box or spacer legs of the installed devices.

- Acts as an additional dielectric insulator between the socket (switch) and the wall of the room.

- Performing the distribution function. boxes when installing electrical wiring without it.

- Provides additional protection against accidental fire.

In order for the mounting box for sockets and switches to correspond to the listed functions, you should make a responsible choice. This will serve as a guarantee for the future uninterrupted operation devices and electrical network.

Choosing the right boxes for sockets

Boxes designed to accommodate sockets and similar devices are divided into several types. Such a classification is necessary for their proper installation and subsequent implementation of the purposes listed above.

There are a number of classification parameters, among which several main ones should be highlighted.

By type of installed surface

Socket boxes may be necessary for installation in various rooms, made from different materials. It can be brick, concrete, foam blocks or aerated concrete.

According to this parameter, their design may differ in some way. For example, a box for mounting in plasterboard has additional tabs for secure fastening.

According to the material of manufacture

Socket boxes can be plastic or metal. To install the box, the first option is usually used, which has a large assortment models and forms:

- Round - have become widespread. It is easy to make a hole in the wall for them and select the necessary groups of devices for installation.

- Oval - characterized by the presence of a large amount of space, which allows you to make a supply of wires necessary for mounting devices and the disconnection process. If necessary, you can purchase boxes that can accommodate up to 5 mechanisms.

- Square - they have a large amount of space for wires and allow the installation of dimmer elements, “ smart home"and a number of other devices. Capable of holding up to 4 mechanisms.

Metal socket boxes are not widely used because they are conductors electric current. But this is the option of choice in houses made of wood.

By number of sockets

Single boxes designed for mounting single sockets are in demand. But boxes for placing 2, 3 and 4 sockets are also gaining popularity. The distance (center-to-center) in such socket boxes is 71 mm in accordance with the standards.

It is customary to subdivide boxes by size - internal diameter and depth (40 - 60 mm). Additionally there is an installation diameter (60, 64 and 68 mm). The best option The choice is the socket box, which has a diameter of 68 mm and a depth of 42 mm. If it is necessary to carry out wiring without distribution boxes, a depth of 60 mm is suitable.

List of necessary tools

When carrying out large-scale repair work, the necessary list of tools is usually at hand. But also minor repairs requires preliminary selection of tools.

For installation of the liver socket box necessary tools should be presented as follows:

- Level with pencil and compass. Necessary for marking the walls and subsequent alignment of the block of boxes for sockets (if installation is necessary).

- Drill. Required for making holes for boxes. The drill will need crowns for drilling - if they are missing, a concrete drill will do. If you don’t have a drill, a hammer drill or grinder will do.

- Hammer with chisel. They will be needed at the stage of forming holes to knock out excess pieces of the wall.

- Spray. It will be needed during drilling to water the crown, it will prevent cracking tiles and prevent dust from flying away.

- Spatula (trowel). Necessary at the stage of attaching boxes.

Additionally, you will need a solution of alabaster, cement or gypsum to securely fix the boxes in the wall. Dowels are often needed for this purpose. Do not forget about socket outlets, the presence of which must be ensured before performing the listed actions.

Installation of socket boxes in rooms made of various materials

The process of installing the box should be treated responsibly, since the reliability of fixing the sockets and subsequent work directly depends on this.

Depending on the wall material, the installation procedure has some characteristic differences.

Concrete

Concrete is one of the most common materials for indoor walls, so the installation of socket boxes in this case is worked out to the smallest detail:

- Carrying out marking. A serious stage, especially when installing several socket boxes, where the same level of location is especially important.

- Making holes. The diameter of the holes for sockets must exceed the diameter of the installed socket by 5 mm. The easiest way to do this is with a crown or a pobedite tip. It is necessary to drill holes around the perimeter of the marked circle and knock out inner part(in the absence of a hammer drill and a drill, you can use a grinder), making rectangular holes in the wall, covering the corners with mortar.

- Trying on the box. Proper installation must be flush, so do not forget to check how freely the cables pass through the pre-prepared holes.

- Installation process. You need to place a layer of putty in the hole so that the glass fits. After installation, you need to leave everything for a few minutes for the solution to set, after which you need to remove the unnecessary part from the wall.

If the fixation is insufficient, the socket box should be additionally secured with dowels.

Brick

Mounting boxes for sockets in brickwork similar to installation in concrete, but there are a number of nuances.

The boxes should be installed with outside the walls are flush. It is necessary to take into account that an additional layer of plaster and sometimes tiles (kitchen, bathroom) will be laid on the wall. It will be difficult to calculate in advance how many mm the socket box should be pulled out from the wall or tile.

You can use the following scheme:

- make a recess (diamond, pobedite);

- hide the wire in the hole and cover it with a lid (for example, made of cardboard);

- putty the wall, remembering the location of the future outlet (if necessary, lay tiles);

- proceed to the first stage of installation of the socket box (after the tile adhesive and plaster have dried), carefully drilling holes at the required coordinates.

Subsequent stages of installation should be carried out by analogy with the installation of socket boxes in concrete.

Gas silicate

When installing socket boxes in gas silicate blocks It's worth preparing for a lot of dust. You need to use a vacuum cleaner.

Since plaster, putty for painting or wallpaper are used in finishing walls made of gas silicate, phased implementation installation of socket boxes is similar to that when installing them in brick walls. The only caveat is that the holes should be made using a drill with an inventory drill. Impact drill should not be used.

Depending on the material, the installation process will differ. The most important thing is to comply with all safety requirements.

Mounting boxes in PVC and MDF panels and more

The number of different materials used in modern construction, amazes.

It is worth knowing about some of the nuances of each material in order to competently carry out the process of installing socket boxes.

Drywall

When installing boxes in plasterboard walls no punch or mortar required. The work will be completed several times faster compared to installing socket boxes in walls made of concrete or brick.

You need to purchase special boxes that have additional legs to ensure best mount to a sheet of drywall. After marking, you can make holes using a drill with a crown or a regular drill. Then you need to bring the wire out and thread it into the socket box, and then insert it into the hole. The bolts from the adjustment tabs should be tightened on it.

If there is a risk of the box falling out of the hole, you can first glue a sheet of plywood or other dense and non-crumbling material to the inside of the drywall. All other steps (attaching the socket mechanism) are standard.

Tree

Performance hidden wiring in a house made mainly of wooden components is not a cheap pleasure. According to the requirements of the PUE, the installation wire should never come into contact with wood.

Standard plastic socket boxes are not suitable as there is a risk of fire. The only option is iron, capable of withstanding an electrical arc in the event of a short circuit.

Wires during installation should be laid in iron pipes, and carefully seal the joints with the socket box. We should not forget about grounding, for which you will need to additionally weld a fastening bolt to the ends of the pipes converging in the box. To provide additional protection, the bottom of the holes can be lined with asbestos.

PVC and MDF panels

Modern window sills or loggias are often made of polyvinyl chloride and act as places for installing sockets.

To implement this process quickly, you need to buy boxes for sockets with spacer legs. For additional fastening, you should buy self-tapping screws. At the assembly stage, the power cable should be laid in advance.

The holes for the socket boxes in the panels are made in advance using a crown (diameter 68 mm). They must be strictly sized so that the socket fits quite tightly. Then you need to pull the cable through the prepared holes and connect the socket terminals. After this, you can attach the panels to the main location. It is necessary to try to ensure that the socket is close to the wall.

When installing a whole complex of devices, you should always maintain a distance between sockets of 71 mm. To maintain this distance to the millimeter, you can make your own original template. To do this, you need to take any rigid material (pipe profile, aluminum frame) and mark in the center of the rib where the socket boxes will be attached.

To do this, you need to find the center using a tape measure and mark the line with a pencil. You need to drill holes along the finished line with a metal drill. Then you need to use a tape measure to measure the distance between the holes of the box and drill a second point according to it. Make holes for the remaining boxes in the same way. In order not to perform so many manipulations, you can simply purchase a stencil for socket boxes.

Conclusion

The glass under the socket greatly simplified the process of installing various electrical sockets. Allows you to mount sockets into the wall without any problems, making them almost invisible. This allows them to fit harmoniously into the interior of the premises and serves as a guarantee of safety.

If necessary, socket boxes allow you to repair electrical sockets or replace them. They have become widespread and have become an integral part of the immediate process of installing electrical outlets.

When installing lighting and socket circuits in buildings for various purposes, one of the main elements are socket boxes. They are designed for reliable fixation of sockets or switches, in wooden walls prevent fire in the event of a short circuit. Products come various types and materials for hidden and external wiring. Depending on installation conditions and functional purpose network, a specific type is selected and the appropriate installation methodology is applied. In this article we will tell you how to install a socket box in a wall made of different material, let's study the installation features.

All socket boxes for installation in walls can be divided according to the following criteria:

- According to the material of manufacture;

- For open or hidden wiring;

- By design, depending on the building material of the walls;

- By size.

How individual look You can select socket boxes for installation in the structure of baseboards, when the wiring is laid in the cable ducts of plastic or aluminum baseboards.

Materials for making socket boxes

The main materials for making socket boxes are metal and non-flammable plastic.

Metal socket boxes are stamped with a press from galvanized iron sheets.

Metal socket boxes are stamped with a press from galvanized iron sheets.

In most cases, they are used for installing hidden electrical wiring in wooden walls, this reduces the likelihood of a fire due to a short circuit.

Modern plastic socket boxes are various forms and sizes, depending on the functional purpose, on which walls they are installed.

Modern plastic socket boxes are various forms and sizes, depending on the functional purpose, on which walls they are installed.  Plastic socket boxes for baseboard wiring have a square body and a relief that matches the shape of the baseboard on the back wall.

Plastic socket boxes for baseboard wiring have a square body and a relief that matches the shape of the baseboard on the back wall. Standard shapes and sizes of socket boxes

Old style metal socket boxes

Old style metal socket boxes When manufacturing socket boxes, manufacturers adhere to the standards of the main models of sockets so that their fastenings and dimensions match.

The metal socket boxes are of the old type and therefore the choice of their sizes is not wide. There are models with internal diameter 65 mm, glass depth in all cases 45 mm.

The technological holes can be closed, but stamped with lines; if necessary, they can be easily opened by squeezing out the closing part with pliers the right side. Read also the article: → "".

Plastic socket boxes for installation in concrete and brick walls have several types of designs:

- Standard;

- With increased glass depth;

- Oval shaped for installing several sockets from 2-5 pcs;

- Prefabricated blocks on one platform up to 5 pcs.

- Socket boxes for drywall

Plastic socket box with clamping strips for installation in hollow walls, drywall, chipboard and other materials

Plastic socket box with clamping strips for installation in hollow walls, drywall, chipboard and other materials - Socket boxes for baseboards

Installation of metal socket boxes in wooden walls

Preliminary markings are made of the installation locations of sub-sockets and wire routes, which are laid in rigid or corrugated metal pipes. The holes for the socket cups are drilled with special wood bits of the appropriate diameter. The wires are laid in cut grooves and entered into the sub-socket through technological holes made on several sides. The grooves are masked with clapboard or other decorative materials. This method significantly complicates finishing.

It is easier and safer to lay external wiring on wooden walls using corrugated pipes and plastic cable ducts made of non-flammable material. Some cable ducts are colored with the structure of wood of various species, which allows you to successfully select harmony with common interior. Sometimes wires are laid over ceramic insulators evenly spaced along the line.

Wooden socket boxes for external wiring are rarely used, mostly for decorative purposes.

Wooden socket boxes for external wiring are rarely used, mostly for decorative purposes. Surface-mounted sockets and switches do not need to be buried; they can be screwed directly to the walls, through a metal or asbestos gasket. Read also the article: → "".

Installation of socket boxes in concrete and brick walls

The difficulty in installing socket boxes in these walls lies in drilling holes in a solid surface.

For this purpose, special crowns with diamond, tungsten or pobedit teeth are used. After drilling, a number of standard operations are carried out:

- Wires are laid along the walls and secured to the concrete with plastic clips with nails of increased rigidity. When struck sharply with a hammer, they penetrate perfectly into concrete and brick surfaces.

- The ends of the wires are inserted 15-20 cm into holes drilled in the concrete, after which the walls are plastered.

- After the plaster has dried, the wires are threaded into the socket box, which is gypsum mortar installed in a hole in the wall.

- When the plaster dries, they will paint the walls or make another decorative finishing, it will be possible to cut wires, connect and attach a socket or switch.

Tip #1. Please note that the socket box is installed after plastering the walls, otherwise it will be difficult to calculate the installation depth of the glass. If you recess it completely level with the wall surface, it will be 1-2 cm deeper after plastering. Set above level concrete surface This is not possible due to the unknown exact thickness of the plaster in this place. To avoid level changes and to ensure that the socket is pressed tightly against the wall surface, the socket box must be installed on a plastered wall.

Socket boxes with increased glass depth are used when several more sockets, switches or other wiring elements are connected to the network from one socket. In this case it starts a large number of wires, to accommodate them the socket box is made deeper.

Installation of socket boxes in plasterboard, plywood, chipboard walls with hollow space

For this case, the socket boxes have special design with clamping bars. The installation sequence includes the following operations:

- In most cases, the wiring is installed behind a plasterboard wall;

- When installing the structure, marks are made on the front side of the wall where the socket boxes will be placed;

- Then in drywall special device holes are drilled, wires are pulled out 15 -20 cm;

- Wires are threaded into the technological holes, the socket box is inserted into the hole;

- By rotating the screwdriver of the bolts on the body of the socket box, the strips press it with reverse side to the wall surface;

An example of how a socket box is pressed against drywall

An example of how a socket box is pressed against drywall - After finishing the front surface of the wall, you can install and connect sockets.

Approximate prices for fastening elements and socket boxes for hollow walls

| Elements | Dimensions in mm | COST in RUB. |

| Screw for fixing sockets | 3.1:10 mm | 6 |

| Screw for fixing sockets | 3.1:25 mm | 8 |

| Single box box | Ø 68mm, glass height 50mm | 75 |

| Regular box | Ø 68mm, cup depth 65mm | 90 |

| Box with two glasses | Ø 2x68mm, cup depth 50mm | 180 |

| Box for installing sconces | Ø 35mm, cup depth 40mm | 130 |

Installation of socket boxes for wiring laid in baseboards

Plastic skirting boards with cable ducts provide for the installation of specially shaped socket boxes in their design. These socket boxes have the shape of a box with holes for mounting the socket:

- At the installation site, a hole is made in the plinth for the wires to exit, or on the laying line, gaps are provided between the sections of the plinth.

- The relief of the back wall of the socket box perfectly matches the external relief of the baseboard, so they fit tightly together, the body of the socket box is screwed to the wall or floor;

- The wires are pulled out and connected to the socket terminals;

- The socket is inserted into the socket box and secured with screws.

Tip #2. In the absence of a socket box of the appropriate profile, the socket can be installed closely above the baseboard, with a design for hidden or external wiring. Surface-mounted sockets are easier to install; the wire from the plinth passes through a small recess in the wall into the socket body and looks very aesthetically pleasing.

Tools and attachments used for drilling holes for socket boxes in walls made of various materials

To drill holes, use a conventional hammer drill with replaceable attachments:

- For drilling concrete or brick walls, crowns of various diameters with diamond, pobedit or tungsten teeth are used.

In the center of the cylinder there is a guide drill, which holds the bit within the specified diameter when drilling.

In the center of the cylinder there is a guide drill, which holds the bit within the specified diameter when drilling.  After the crown has passed to a given depth, the brick or concrete components inside the diameter are knocked out with a regular chisel and hammer

After the crown has passed to a given depth, the brick or concrete components inside the diameter are knocked out with a regular chisel and hammer Sizes and costs of crowns from different manufacturers

| Brand | Manufacturer | Length in mm | Cutting elements | Ømm | |

| Messer | South Korea | 70 | 3 pcs | 68 | 3 090 |

| Projahn 81565 | Germany | 50 | 6pcs | 65 | 3 310 |

| Versio Projahn 852065 | 100 | 16pcs | 68 | 7 400 | |

| Bosch 2.608.550.0 | 60 | 6pcs | 5 190 | ||

| Practice 035-172 | Russia | 68 | 8pcs | 830 | |

| Master Stayer 29190-68 | Germany | 133 | 740 | ||

| Santool SDS Max | China | 140 | 520 |

- For drilling wooden surfaces The principle is similar, but the teeth have a shape and material suitable for drilling wood.

The advantage of this nozzle design is that there is no need to knock out the internal elements; they are completely cleaned.

The advantage of this nozzle design is that there is no need to knock out the internal elements; they are completely cleaned. Thickness and other parameters of some types of drywall:

| GKL | |||

| Material grade | Length in mm | Width in mm | Thickness in mm |

GVL | 1500 2000 2500 2700 3000 | 500 1000 1200 | 10 12.5 15 18 20 |

Moisture resistant | 2000 — 4500 | 1200 — 1300 | 6 — 13 |

The plates with teeth must be made of high-quality hardened steel, otherwise they will be enough for 2-3 holes. The depth of the crowns varies and is selected according to the thickness of the material to be drilled.

- Drywall can be easily drilled with any attachments for wood or concrete.

Grooves in concrete, brick and wooden walls are sawn through with a grinder using special discs.

There are industrial wall chasers, but they are very expensive and only pay for themselves when working in large volumes. construction companies.

Wood cutting disc

Wood cutting disc

Errors when installing socket boxes

- Drywall, plywood chipboard are drilled in drilling mode, hammer drills often forget to switch from impact mode, as a result of which the surface immediately breaks, especially gypsum board.

- During installation open wiring on wooden walls, they often forget to install asbestos plates under cable ducts and sockets. This is required by the governing documents of the PUE and is necessary for reasons of one’s own safety. Such measures significantly reduce the likelihood of a fire. Read also the article: → "".

- During installation, the top edge of the socket box should be installed flush with the front side of the wall and decorative coating. Otherwise, the socket may not be attracted to the wall or the mounting bolts will not reach the socket;

- The level of plaster within the socket box must be perfectly level, then the socket will fit tightly to the wall; if the level of plaster changes, gaps may form between the wall and the body of the sockets;

- The wires are inserted into the socket box before it is secured with a plaster solution, the length of the ends is not shorter than 15-20 cm, so that it is enough to remove the insulation and fasten the contacts. With short wires, it will be inconvenient to connect sockets and switches and install them in a socket box.

FAQ

Question No. 1. The wall is made of chipboard, there are no metal socket boxes with clamping strips, can you put plastic glasses on wood?

Most modern building materials are made non-flammable, including plastic socket boxes and chipboard.

Question No. 2. I'm going to plaster a concrete wall, do I need to make grooves for wiring?

It is enough to secure the wire compactly with clips and plaster it, but at the same time make recesses for inserting the wires into the technological holes of the socket cup; they cannot be inserted from above.

Question No. 3. Possible in wooden log house lay the wire between the logs and cover it up?

Only in metal pipes or non-flammable cable ducts.

Question No. 4. Can deep socket boxes be used as distribution boxes?

Yes, there is a special installation method in this way; this issue requires separate consideration.

Most often in our apartments and houses there are walls made of brick or concrete, and in new buildings it is not uncommon to see walls made of foam blocks. How to install socket boxes in such walls. Correct marking of the wall for socket boxes.

Apartment in a secondary building, a private house or a new building that we have just moved into - we have brick walls in front of us and since we are thinking about updating the electrical system, or making it anew, sooner or later we will have to install socket boxes in them.

There are no difficulties in installing socket boxes in brick walls. The main thing is to follow the rules correctly technological process and perform each stage of work responsibly and carefully. If all conditions are met, everything will turn out beautifully and efficiently, even if you are doing it for the first time. Of course, it’s better to entrust such work to professionals, but it doesn’t always make sense when you need to make a couple of socket boxes. And some people just like to do everything themselves.

Let's first figure out at what point we should start installing socket boxes and at what point we can start doing this? Many people do it differently and motivate it in their own way.

- Installation of socket boxes before laying the cable– first we make crowns for the socket boxes and only then lay the cable to them

- Installing socket boxes after laying the cable- most often done this way

- Installation of socket boxes after roughing finishing works – first, the cable routing is done, then the finishers apply a leveling layer of plaster and only after that the socket boxes are installed.

Over time, we came to the latter option. This is especially true for brick walls and walls made of foam blocks. Why in this order? Everything is very simple. If possible, in the process of communicating with the finishing team, we agree that the guys install beacons so that we can see where a groove is needed and where we can do without it. Why should customers pay extra money, but we should do absolutely nothing? the right job? Immediately after installing the beacons, we install the electrical wiring and secure the cable terminals where the socket boxes will later be located. Finishers perform rough finishing work, after which we come and install the socket boxes.

Why is this option best?

- We already have a final plane of the wall and the socket box will no longer sink into it. After all, it often happens that the layer of plaster, especially in the old foundation, is 3-10 cm long. If we install the socket box before the plaster, we have every chance of simply not finding it, and it will no longer perform its functions. And in our case, all socket boxes will be installed correctly.

- If you install the socket boxes before plaster, then you will then have to rake out a bunch of this frozen plaster from the socket boxes, and why do this if you don’t have to do it.

- It’s just more convenient for us and everything looks much more beautiful. And contemplating your own work should bring pleasure.

So let's imagine that plastering work completed and in front of us is a wall with protruding cable leads. Where to start and what are our next steps?

Let's start by preparing the tools and everything we will need in the process.

- Crown for brick socket boxes. The diameter of the crown can be 68 mm and 80 mm. Why can you use crowns with a diameter of 80 mm, because the diameter of most crowns is 68 mm? It's simple - to make it easier to install the socket box, we make the hole a little larger than necessary. A group of socket boxes fit into such holes just fine; there is enough space for maneuvers, cable insertion, and adjustments. With 68 mm crowns it is somewhat more difficult. Our walls are brick and making holes for socket boxes in them is quite simple, so an 80 mm crown will not complicate our task at all.

- Level– regular or laser in order to position groups of socket boxes horizontally.

- Measuring tool– ruler or tape measure for marking

- Brick sockets– prepare in advance required amount socket boxes, and how to choose them, read the article about.

- Construction vacuum cleaner – making holes for socket boxes is a rather dusty process. You can make 2 – 4 crowns and look like a hedgehog in the fog. A construction vacuum cleaner will make the job cleaner and save your lungs.

- Spatulas– are necessary for fixing the socket boxes; you should also prepare in advance the container in which you will knead gypsum mixture. Small containers in which mixtures for 2 to 4 sockets are mixed are very convenient.

We have prepared everything and can begin the process of installing socket boxes in brick walls. I will show you everything using the example of a foam block wall.

We have prepared everything and can begin the process of installing socket boxes in brick walls. I will show you everything using the example of a foam block wall.

Stages of work on installing socket boxes in a brick wall

- Taking the project in hand, we measure required dimensions and we mark the wall for a group of socket boxes; you can read about marking in detail in the article about. There is no point in repeating myself, the process is completely identical.

After marking the wall, we insert a brick drill with a diameter of 6 mm into the hammer drill and mark holes in the wall in the centers of the future socket boxes. We do this in order to further center the crown on the brick and make the work easier.

After marking the wall, we insert a brick drill with a diameter of 6 mm into the hammer drill and mark holes in the wall in the centers of the future socket boxes. We do this in order to further center the crown on the brick and make the work easier. Next, we change the drill to a crown and begin to drill holes, do not rush and put too much pressure on the crown. If you purchased an impact bit, as in our photos, you can turn on the drilling + impact mode, but usually just the drilling mode is enough.

Next, we change the drill to a crown and begin to drill holes, do not rush and put too much pressure on the crown. If you purchased an impact bit, as in our photos, you can turn on the drilling + impact mode, but usually just the drilling mode is enough.

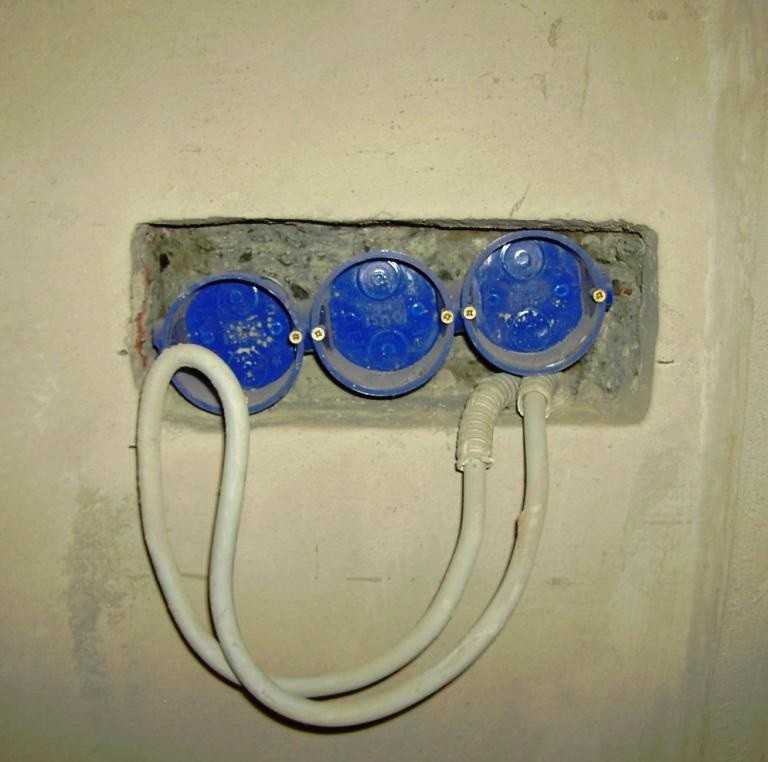

We knock out the centers from the prepared holes and break the jumpers between them, this is necessary so that the group of socket boxes fits into the resulting hole. It is best to purchase socket boxes like those in our photographs; they are very convenient to install.

We knock out the centers from the prepared holes and break the jumpers between them, this is necessary so that the group of socket boxes fits into the resulting hole. It is best to purchase socket boxes like those in our photographs; they are very convenient to install.- Using a vacuum cleaner, carefully remove all dust from the hole and treat it with a primer. We wait a little for the primer to absorb into the surface. At this time, we can clean the wires from the plaster, align them and prepare them for insertion into the socket box.

We assemble the required number of socket boxes into a group, break out holes for cable entry, and try them on in the prepared hole. Nothing should interfere. The socket boxes should fit very freely and not deform inside the hole.

We assemble the required number of socket boxes into a group, break out holes for cable entry, and try them on in the prepared hole. Nothing should interfere. The socket boxes should fit very freely and not deform inside the hole. As soon as everything is ready, take the prepared mixture (for example, rotband) and fill each hole with the mixture about halfway, spread it over the walls and more or less evenly. We take our socket boxes, insert the cable into them and press them into the holes. The excess mixture will be squeezed out through the holes, it’s okay, that’s how it should be - you can’t leave voids.

As soon as everything is ready, take the prepared mixture (for example, rotband) and fill each hole with the mixture about halfway, spread it over the walls and more or less evenly. We take our socket boxes, insert the cable into them and press them into the holes. The excess mixture will be squeezed out through the holes, it’s okay, that’s how it should be - you can’t leave voids.- Using a level, level the socket boxes horizontally and remove excess mixture with a spatula.

- We leave the socket boxes for 30 - 40 minutes and check the quality of the work done. If everything was done correctly, the socket boxes will not crawl anywhere and will be level with the plane of the wall. Let the mixture that has come out inside the socket dry first, this will make it easier to remove. The fact that the mixture was squeezed out inside the socket boxes indicates that we installed the socket box very well and it will stay in the wall very well.

Now we can admire our work. Now we can wait for the finishing work to be completed - puttying and wallpapering - and continue installing the fittings. If we use, we make the necessary connections; you can read about how to do this correctly in the article about. Next, install the fittings and enjoy what we get.

What important points may be in the process of installing socket boxes in a brick wall?

What important points may be in the process of installing socket boxes in a brick wall?

- It is necessary to accurately mark the wall

- Carefully and without haste make a hole for the socket box

- Be sure to remove dust and treat with primer.

- Do not skimp on the mixture - the excess will be squeezed out and the socket box will be securely fastened.

That's all. Socket box in brick wall We learned how to install. If you didn’t find something in this article, then ask questions, we will definitely answer and add to it.