Insulation of a brick foundation. Do-it-yourself insulation of the foundation of a private house from the outside

A strip foundation is not just the basis of a building, the support of its structure, but can perform quite utilitarian functions, being the walls of inhabited basements, basements or semi-basements. In order for such rooms to be warm and cozy, the foundation should not be a simple concrete casting, but a structure that will provide reliable thermal insulation of the interior. To do this, not only horizontal, but vertical surfaces of the strip concrete foundation are subject to insulation.

Concrete itself, despite its high strength and great resistance to loads, is a rather poor heat insulator. It easily receives heat and gives it off just as easily. A bare concrete wall will not be a good barrier between the cold of the winter soil and the warmth of the inhabited room.

Note that the degree of cooling of the foundation is also affected by its depth. If the strip foundation is not buried in the ground below the soil freezing level, then areas of frozen soil may form under the house, which will negatively affect the climate in your home.

In what ways can you insulate the foundation?

There are two main ways to insulate foundations. They differ depending on the period during which the work is carried out. One option is to insulate the foundation at the stage of its pouring, and the second is subsequent insulation, carried out after maturation. concrete casting.

The most preferable is to insulate the foundation during the construction phase. This integrated approach allows you to get good results. In order to achieve reliable thermal insulation of the foundation, even in the conditions of central Russia with harsh during winter periods– the insulation process must be carried out on both sides.

The most logical approach to insulating the foundation during construction is permanent formwork.

Insulation of the foundation with permanent formwork

Permanent formwork is a spatial structure into which concrete mortar is poured. At the stage of hardening of the solution, it acts as a regular wooden formwork, that is, it limits the spreading of the concrete solution. However, unlike wooden formwork, after the concrete has matured, permanent formwork is not removed, but remains on the thickness of the concrete as an insulation layer.

Permanent formwork can be made from various materials. Particularly popular is the construction of permanent formwork from polystyrene foam boards. These are plates made of foamed polymer material containing many tiny air bubbles.

At first glance, the disadvantage of such formwork is its high cost. The costs of its purchase and installation are several times higher than the costs of classic wooden formwork. However, such a foundation will not need to be subsequently insulated, so the final costs will be quite comparable.

Insulating the foundation after pouring it

It is best to begin work on insulating a poured foundation immediately during the process of its maturation. If you are not attentive to this stage of building a house and return to it later, then you will not be able to carry out insulation work efficiently.

The classic way to insulate a foundation after it has been built is to lay a layer of expanded clay on the basement floor, which is subsequently filled with a leveling screed. Expanded clay is clay baked in special ovens and its mass is an excellent heat insulator. Also, to increase the level of thermal insulation between the ground, basement and living rooms, thermal insulation of the floor of the first floor of the house is carried out.

We insulate the foundation with earth

This option for insulating the foundation is extremely economical on the one hand, but very labor-intensive and voluminous on the other hand.

The essence of this insulation is very simple - all foundation walls up to the level of the first floor are covered with earth. Thus, it turns out that under a layer of earth, inside a kind of mound, all the basement rooms are located. Earth or sand in themselves are good heat insulators, but in order for this insulation to be effective enough even for central Russia, the foundation will have to be sprinkled with a very substantial volume of sand. So, to fill a foundation with rather modest dimensions of 10 by 10 meters, you will have to spend about a hundred cubic meters of sand.

A significant advantage of this approach will be the elimination of the impact of heaving soils on your site on the foundation. In some cases, backfilling the outer wall of the foundation with sand is recommended not even for thermal insulation purposes, but in order to eliminate the impact of soil movements on the foundation.

When filling the foundation with soil or sand, it is necessary to provide channels for air ducts that will provide ventilation to the basement. Naturally, work on this method of insulation must begin immediately after dismantling the wooden formwork, even before erecting the walls of your future home.

We insulate the foundation with a layer of expanded clay

As already mentioned, this is also one of the classic ways to insulate the foundation. In principle, expanded clay insulation can be combined with earth insulation.

In addition to the usual backfill, expanded clay can also be used as a filler for concrete castings. Expanded clay is small lumps of clay fired in a specially rotating kiln. Inside each lump there are many air cavities, which provides excellent thermal insulation properties this material. Thus, expanded clay can be used as a filler in concrete mortar instead of crushed stone.

Thus, expanded clay filler can be used in the construction of low-depth strip foundations. In this case, expanded clay can be added not only to the concrete mortar for the foundation walls, but also when screeding the floor, thereby providing a completely closed thermal insulation loop basement.

We insulate the foundation with expanded polystyrene

The development of chemical production has led to the widespread use of synthetic insulation materials. One such material is polystyrene foam, which is a board. Inside which there are many air bubbles.

Expanded polystyrene sheets can be glued to both concrete castings and brick walls. When installing such slabs on a foundation consisting of concrete blocks, that is, having joints between individual parts, they must be positioned so that the joints of the slabs are not above the joints of the concrete blocks. This will prevent the formation of “cold bridges”.

Expanded polystyrene boards can be glued from the lowest level of the foundation base and right up to the roof - to the entire outer surface of the wall.

Insulation of the foundation with mastics

A certain insulation of the foundation can also be achieved during waterproofing work. So, vertical walls To prevent the penetration of moisture from the soil, it is recommended to cover the foundation with a layer of bitumen mastic. In addition to protection from moisture, several layers of such mastic will help you isolate cracks and tiny holes, joints of foundation slabs through which heat can leak from the room.

After applying several layers of bitumen mastic, a layer of rolled waterproofing material can also be applied to the side surfaces of the foundation. Just like mastic, it will serve as an additional layer of thermal insulation.

Video - do-it-yourself foundation insulation

In this article we will give answers to the most popular questions that arise among novice builders, especially those who have decided to build

There are always two ornate solutions to this question, and they depend not on engineering knowledge, but on the quantity Money. Therefore, most customers and owners argue that if there is no base or basement, then there is no point in doing “empty” insulation. But there are also statements about this issue: heat loss from a living space does not occur evenly over the area, but from bottom to top. In fact, it is easier and smarter to insulate walls, windows or ceilings than to insulate the base.

Insulation of the foundation by spraying polyurethane foam

For those who still do not trust the opinion of the masses, they recommend extruded polystyrene foam rather than polystyrene foam as insulation for the blind area or foundation.

Why insulate the foundation, and is it possible not to insulate it?

Modern private construction involves the creation of a room protected from dampness and moisture. Therefore, even without a basement or plinth, foundations are usually insulated as profitably (cheaply) as possible. If you need a warm basement, then this question is not even worth asking. But when there is nothing below the first floor, they insulate it due to the formation of cold bridges.

Here's how it works. A proper private residential building is insulated over all areas, because these “bridges” can form where the walls meet the base. And destruction will begin due to temperature changes.

Which insulation is better in this case?

General characteristics for this material:

- Does not undergo deformation under soil pressure.

- Does not absorb moisture/is resistant to its effects.

And the search for the material needed in the work narrows:

- Extruded polystyrene foam.

- Polyurethane foam spraying.

It is important to know that the artificial material intended specifically for insulation is not exposed to rodents and can withstand compressive pressure well.

But with each Goth, they stopped using the previously familiar expanded clay as insulation. It is being replaced by technologically advanced, specialized materials.

How to insulate a floor if there is no foundation

Of course, such a case is very rare in our time. But earlier, to preserve heat without a foundation, they made a primitive pile. Now the work of insulating the subfloor and the entire area of the house can be done as follows:

- The entire subfloor is covered with foil foam insulation. Required thickness- this is 10 millimeters. The material is mounted with the foil side facing up. And to preserve the result, they cover the entire area with plywood, 10 mm or more thick.

- Naturally, the floor cannot be insulated from the outside. But you can do work to preserve heat. The purpose is as follows: to prevent cold air flows from entering under the floor. It is best to create trenches around the perimeter of the missing foundation and create simple fences. But before filling or filling the space from the walls to the bottom of the trenches, it is more correct to waterproof it. Then you can lay out narrow walls of brick or pour concrete onto the protective part. Having completed the “walls”, polystyrene foam is attached to the outer part, and on top of it they are lined with moisture-resistant bricks or other building materials.

- You can eliminate the fill or brickwork, replacing it with aceid sheets. The latter are also used in two layers, and in the middle is the aforementioned polystyrene foam.

AND modern look The heaps will insulate the floor no worse than any foundation.

Asbestos-cement electrical arc-resistant board (aceid)

How to insulate the foundation of an old house

An old house is in most cases wooden building, similar to the “pentate wall” or “house of the cross”. With rare exceptions, there may be a question about insulating a brick building that has sank into the ground over many years. With heavy houses, everything is very deplorable, because without equipment such buildings cannot be repaired.

But old wooden houses can and should be insulated. For this, the work plan is as follows:

- Dismantling homemade formwork or rubble. Wooden structures are and have always been placed on piles; in the old days, the pile was simply laid out of brick below the freezing depth.

- Having cleared the entire space below the level of the walls from earth and construction debris, you need to dig shallow trenches. It is not necessary to deepen it by 1.5-2 meters. Half a meter is enough.

- The trench is filled with a cushion of sand or gravel. It is desirable, but not always convenient, to drain groundwater.

- The first row of protection is laid on a half-brick cushion. It is best if it stands vertically just below the level of the walls. But the purpose is heat preservation, not support, so when laying, they simply follow the standard rules for creating a flimsy brick wall.

- Having completed one row, proceed to the second - the front one. But between them you need to ensure a distance of at least 15 cm. It is covered with expanded clay. This insulation will be much cheaper, and rodents will avoid expanded clay.

- Having made both rows and filled the space between them with expanded clay, a “cap” of concrete mortar is poured on top. It should have a slope towards the street, and after drying, iron covers are installed on top for protection, whose drains are also directed away from the building.

- Each of the four sides of the house now needs ventilation. To do this, ventilation pipes are installed in the corners or in the center. They are planned from the very beginning, covering the required small area with a horizontal plastic pipe. IN winter time ventilation ducts closed, but when it’s warm, they are released for the flow of fresh air and the movement of condensation.

How to insulate a rubble stone foundation

This material, or rather part of the building made of rubble stone, is insulated from the outside. In work they use:

- Expanded clay.

- Styrofoam.

- Polyurethane foam.

- Roll insulation.

Repairing and insulating rubble stone in the foundation is simple. It is enough to dig trenches from which comes a layer of insulation, foam or polystyrene. Well, the front part can be made of brick, slate or any other material.

Rubble foundation

How to properly insulate the foundation and the soil underneath it

Most foundations can be insulated from the outside and inside. And by internal insulation we mean work similar to the walls. They simply insulate the basement or basement with the same materials that were used during the construction process.

But the floor depends on the temperature of the soil, which means that the overall temperature in the house is also related to this factor. It turns out that it is necessary to insulate the soil, especially in cold regions, under a strip or slab foundation.

The following options can be used:

- Insulation with permanent formwork.

- Take care of comfort after pouring.

- An ordinary rubble from the earth.

- Outer layer of expanded clay.

- Expanded polystyrene and mastics.

This is insulation of the foundation itself from the outside. Soils are insulated in advance, during the creation process. It is easier and more convenient to do such work when creating a slab base. And the total height of the base does not matter, because between concrete slab and a floor screed usually provide a good layer of insulation (15 cm or more). This is the only way to really achieve a goal, and it is usually used as a project following types foundations:

- "Russian stove".

- "Swedish stove"

- "Finnish plate".

How best to insulate the foundation of a private house

Let's talk about efficiency. The following techniques are currently practiced:

- Slab insulation. You can use extruded polystyrene foam 200 kPa, foam glass, polyurethane foam or synthetic rubber.

- Bulk materials. This is expanded clay or boiler slag (budget version).

Time-tested materials (expanded clay, slag) are beneficial, but not as effective. It is best to use slab insulation. When a new building is erected, such material is put into use after the floors are installed. The residential property is already insulated by preparing a meter-long trench in advance. Moreover, insulation boards must be laid after latex-based primer and waterproofing.

It is better to insulate the foundation according to this scheme:

- The insulation is secured with special glue.

- The plates need to be placed against the base and pressed firmly. Each sheet is attached one by one, with an overlap to better connect the grooves.

- If the foundation is high, then the technology changes - they work in stripes or adhere to a checkerboard pattern. And the difference in the seams must be filled with foam or a sealant composition, otherwise cold bridges will disrupt the insulation.

- Polystyrene sheets must be secured with fasteners. Plastic dowels with large heads are suitable. To do this, you need to drill holes of at least 50 mm. That part of the sheet that is already below ground level is simply pressed against the ground.

- Slab insulation requires front finishing. They are plastered with glue with plastic mesh. This type of work takes at least three days to dry.

Specialist consultation

There are a lot of “armchair” specialists and theorists on Youtube. The blog "Zigurd Skrodelis" attempts to provide viewers with expert-level information. This video concerns the issues of foundation insulation.

How to insulate a foundation from the outside

Thermal insulation of the foundation is an important and critical stage in the construction and renovation of a house. An uninsulated foundation means not only serious heat loss, but also the danger of freezing and subsequent destruction of the building’s underground structures. Insulating the foundation from the outside allows you to reduce heat loss several times; in addition, it reliably protects the foundation of the house from the effects of groundwater and low temperatures.

Why is insulating the foundation from the outside more effective?

To understand this issue, you need to imagine the operating conditions of the foundation. The foundation takes on both the load from the building and soil pressure. Its underground part is constantly exposed to groundwater and atmospheric waters, while the porous foundation material can become wet, absorbing moisture. When the ground temperature drops below zero, not only the soil freezes, but also the wet foundation. At the same time, cracks and chips form in porous concrete. In addition, seasonal movements of heaving soils also have a destructive effect. These factors gradually lead to partial destruction of the foundation, followed by damage to the walls of the building.

To avoid harmful effects environment on the foundation, they resort to a set of measures, and the two main protective measures are waterproofing the foundation and its insulation. In this case, insulation is most often carried out from the outside, since with external insulation, not only the premises of the house are protected, but also the foundation itself. In some cases, they resort to insulating the foundation from the inside, most often when external insulation is impossible.

Materials and methods of foundation insulation

There are several ways to insulate the foundation from the outside:

- Backfilling with sand or expanded clay. The oldest and fewest effective method, based on the property of these materials to remove moisture and create air gap near the foundation walls.

- Insulation using polystyrene foam boards and its modern analogues: penoplex, polystyrene.

- Insulation using mineral mats followed by covering the foundation with a protective screen;

- Spraying polyurethane foam onto the surface using a special installation. The result is a seamless layer that is resistant to mechanical damage and has high thermal insulation properties.

Backfilling the foundation with sand and expanded clay

The advantages of the method include the low cost of the material and the ability to perform thermal insulation yourself, without using professional help. In addition, the backfill layer simultaneously acts as waterproofing and compensates for soil pressure during heaving, which makes it possible to effectively use this method on wet clay soils with a high frost heaving coefficient.

- A pit is prepared along the perimeter of the foundation from the outside. Its depth should be slightly lower than the depth of the foundation, and its width depends on the region and soil moisture. The lower the temperature in the winter months and the higher the groundwater level, the wider the pit should be.

- Drainage is performed at the bottom of the pit: geotextiles are laid, covered with crushed stone, a perforated pipe is placed on the crushed stone, and again a layer of crushed stone. Pipes are tied into unified system and taken to the well.

- The foundation is cleaned and dried, after which the foundation is waterproofed. The choice of type of waterproofing depends on the operating conditions of the foundation, but it should be taken into account: when backfilling with expanded clay, coating waterproofing with bitumen or polymer compounds cannot be used due to the possibility of damage to the waterproofing film.

- The prepared trench is backfilled with sand or expanded clay, compacting it in layers.

Insulation of the foundation with polystyrene foam and its analogues

A modern and highly effective method that allows high-quality thermal insulation of foundation walls. The advantages of the method are high thermal insulation characteristics of the material, ease of thermal insulation, resistance of the material to mechanical loads and damage, ease of finishing. Disadvantages - it requires preparation of the foundation surface, protection of the insulation layer from rodents, as well as waterproofing suitable for this method.

- The surface of the foundation is dug out to its full depth, cleaned, and dried. Remains of bitumen waterproofing, fats, and oils must be removed from the surface—foam plastic and its analogues are destroyed upon contact with these substances.

- The foundation is waterproofed using one of the following methods: coating waterproofing using mastics on polymer based; impregnating waterproofing or roll waterproofing foundation.

- Plates of thermal insulation material are laid on a special glue - it is sold in the form of a dry mixture. The slabs usually have grooves that facilitate their joining and prevent the appearance of cracks, gaps and cold bridges.

- The surface of the foundation is protected from damage by rodents with reinforcing mesh, laying it on the same glue. After the glue has dried, the underground part of the foundation is backfilled with sand, and the above-ground part is additionally secured using special dowels with a wide head.

Insulation of the foundation using mineral insulation (Mineral wool)

This method is used quite rarely, since, along with good thermal insulation, it has a number of disadvantages: its implementation requires the construction of a frame, good protection of the insulation from getting wet, as well as the construction of a protective wall made of brick or other finishing materials. It is usually used to construct the above-ground part of the foundation and the basement as a continuation of the thermal insulation of the walls of the house.

- The surface of the foundation is cleaned and dried, defects are eliminated.

- They make a frame for heat-insulating mats on it from metal profile.

- Stacked thermal insulation mats onto the frame and secure them. The surface of the insulation is protected from external moisture with a vapor-permeable wind- and waterproof film.

- A protective brick wall or a ventilated frame is erected.

Insulation of the foundation with polyurethane foam

One of the most effective ways to insulate the foundation both outside and inside. To carry it out, special equipment is required - a spraying installation, with the help of which insulation components are supplied to the surface of the foundation under high pressure. The result is a seamless layer of foam with high thermal and waterproofing properties. To perform such waterproofing, it is better to contact specialists, since the quality of the coating largely depends on the correctly chosen mode and the installation itself.

Thermal insulation of the foundation from the outside allows you to reduce the heat loss of the building by 20-25%, while increasing its service life. Thermal insulation of the foundation can be carried out both on a facility under construction and on a building in use.

How to effectively insulate the foundation of a private house from the outside

Most owners of private houses do not consider it necessary to insulate the foundation, believing that it is a waste of money. Thoughts about the need to insulate the base from the outside come when problems with dampness and mold on the walls become visible, and the base begins to become covered with cracks. High-quality self-made waterproofing will help you avoid these troubles; we’ll tell you how to do this in the article.

Most owners of private houses do not consider it necessary to insulate the foundation, believing that it is a waste of money. Thoughts about the need to insulate the base from the outside come when problems with dampness and mold on the walls become visible, and the base begins to become covered with cracks. High-quality self-made waterproofing will help you avoid these troubles; we’ll tell you how to do this in the article.

Why does the foundation need heat?

Insulating the basement is as important as insulating the walls of the house. The room loses about 20% of heat through the foundation. Many people think that it is enough to insulate only the basement, but this is a grave mistake. Since the destructive force of water and low temperatures continues to act on the base. Moisture entering the pores of the foundation freezes when exposed to low temperatures and, expanding, destroys the structure. Microcracks appear, which become cold bridges, and as they increase, they can lead to the destruction of the building as a whole.

External insulation neutralizes the effects of low temperatures and groundwater. The dew point shifts into the insulation layer, and the foundation concrete does not change its properties. Insulation is especially important in regions with harsh climates and heaving soil. Such soil, freezing by 15%, can move by 35 cm, which entails deformation of the base. On such soils, the depth of the foundation should be below the freezing point, and insulation is done not only vertically, but also horizontally.

Advantages of insulation

If the foundation is not insulated, cold air from outside enters the living space through the flooring. Therefore, when building a house, the floors are raised above the ground level. Without insulation from the outside, constant dampness in the basement and cold floors in the house are guaranteed, which reduces the level of comfort. So, what facts speak in favor of insulation:

- The heat loss of the building is significantly reduced, which means that the financial part of the heating budget will also be reduced;

- the effect of soil heaving forces is leveled out;

- prevents the formation of condensation and mold;

- extends the service life of the foundation structure;

- protects waterproofing from mechanical damage;

- it is easier to block cold bridges.

Advice. The corners of the building require special attention. In these places, the thickness of the heat-insulating material is doubled.

Insulation methods

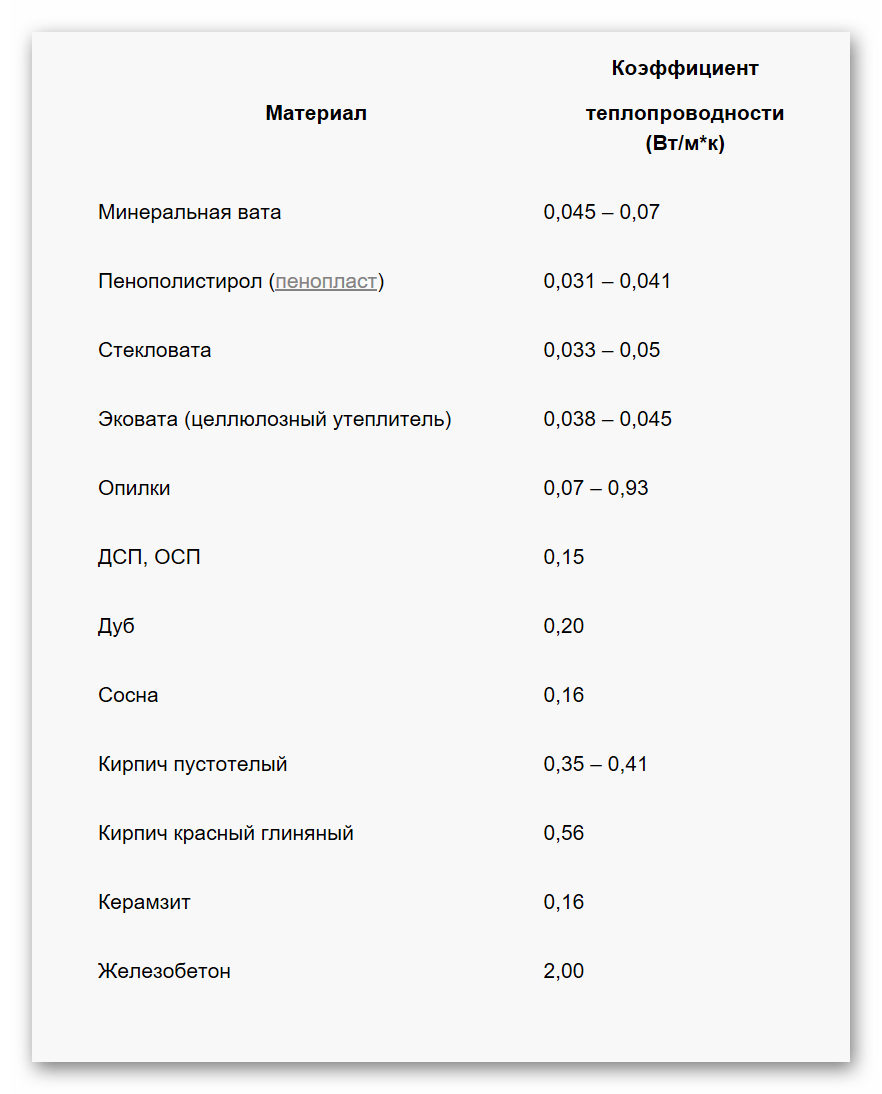

When choosing a material for insulation, attention is paid not only to cost, but also to its main characteristics, namely: hygroscopicity and resistance to deformation. There are several methods of insulation:

- Plate insulation: extruded polystyrene foam 200 kPa, foam glass, polyurethane foam and synthetic rubber in the form of foam.

- Backfilling with bulk materials: expanded clay, boiler slag.

Most often, polyurethane foam or extruded polystyrene foam is used for insulation.

Insulation with expanded clay

Before the advent of new generation insulating materials, expanded clay was often used. Its main advantage is its low price, but the level of thermal conductivity of the material suggests its use in large quantities. Thus, dignity becomes a disadvantage. It is rational to use it as additional insulation.

Warming is carried out as follows:

- the foundation is dug up to the base, to a trench width of 1 m;

- clean the surface from dust;

- in the absence of waterproofing, apply bitumen mastic;

- arrange drainage if the groundwater level is high;

- a film is placed at the bottom of the trench from the wall to the drainage;

- the trench is filled with expanded clay and a blind area is made.

Sheet material insulation technology

When constructing a new building, insulation work begins after installation of the floor slab. If the house has already been built, then the foundation is dug around the perimeter to the base a meter wide. The walls are dried and all dirt is removed. If the groundwater level is close, drainage is arranged. After complete drying, a latex-based primer is applied to the foundation walls. It fills small voids and ensures strong adhesion of the waterproofing to the surface of the base. Roll waterproofing is laid, pressing firmly with a roller. The joints are covered with sealant for reliability. They wait until the waterproofing dries, and then begin laying the insulation.

- Sheets of insulation are attached to the waterproofing with glue specially designed for this work. If the waterproofing is bitumen, then bitumen mastic is used as glue, which does not contain aggressive components for the insulation board. Apply it in a strip along the perimeter of the sheet, retreating a couple of centimeters from the edge, and with several dotted strokes in the center.

- The slab is placed against the foundation and pressed well. The adjacent sheet is laid in a similar way, overlapping, connecting the grooves.

- High foundations that require laying insulation in several strips are glued slightly differently. It is important here to avoid large seams, so the slabs are glued in a checkerboard pattern.

- Wide cracks are filled with foam or puttied with sealant to prevent the formation of cold bridges.

Advice. Do not use slabs torn from the surface or displace them after the glue has hardened.

Advantage of extruded polystyrene

Expanded polystyrene boards are considered the best option for private construction. Because they have a long service life and high compressive strength. They practically do not absorb or allow moisture to pass through. It retains its thermal insulation characteristics for a long time precisely due to its low hygroscopicity.

These plates are produced with special grooves. They drain moisture into the drainage. In tandem with geotextiles, polystyrene, in addition to insulation, serves as waterproofing and wall drainage.

Insulation with liquid polyurethane foam

Polyurethane foam is applied in foamed form to the cleaned surface of the foundation. It combines the properties of waterproofing and thermal insulation. 50 mm of polyurethane foam is equal to 1.2 m of polystyrene foam. The material hardens very quickly, forming a cellular structure. The foam hermetically envelops the foundation, leaving no gaps or forming seams, unlike tile insulation. To the advantages polyurethane foam insulation should include:

- no seams in the coating;

- high adhesion of the material;

- there is no need to install waterproofing;

- low vapor permeability;

- service life more than 40 years;

- low thermal conductivity;

- environmentally friendly and biologically neutral.

There are only three disadvantages. This is high cost and the need to purchase special equipment for installation. Polyurethane foam is destroyed under the influence of solar ultraviolet radiation.

Drainage of water from the base

Along with insulation, it would be good to provide drainage so as not to dig up the foundation twice. Drainage pipes are laid below the level of the base of the foundation or below the level of the basement, if there is one. A gravel bed is poured with a slope of 5 degrees. Placed on top of it drainage pipe, wrapped in geotextile, and again gravel on top. Geotextiles will prevent clogging drainage holes. Groundwater will flow through pipes into a drainage well.

Having knowledge about the advantages and disadvantages of insulation, you can choose the material that suits you best. Carry out construction work competently, and you will ensure comfort and warmth in the house for a long time, as well as long service buildings.

Insulating the foundation with polystyrene foam: video

Do-it-yourself insulation of the foundation of a private house: outside and inside + Video

Thermal insulation of the foundation – the most important stage in building a house. She has the same important as wall insulation. Especially in harsh climatic conditions characterized by freezing of the soil to great depths.

Thermal insulation of the foundation – the most important stage in building a house. She has the same important as wall insulation. Especially in harsh climatic conditions characterized by freezing of the soil to great depths.

An uninsulated foundation causes serious heat loss and is dangerous due to freezing and subsequent destruction of underground structures.

Thermal insulation of the foundation from the outside significantly reduces heat loss and serves as reliable protection for the foundation of the house from the influence of groundwater and negative temperatures.

Freezing of heaving soils, on which houses with pile-screw foundations are usually built, is especially dangerous for building foundation structures.

Why is it necessary to insulate the foundation?

To avoid the negative impact of the external environment on the foundation, they resort to measures such as waterproofing the foundation and its insulation.

The largest volume of cold air enters the building through the foundation. And if the house has a basement used for any functional purposes (garage, billiard room, laundry room), then special attention should be paid to its thermal insulation.

An unheated basement does not need thermal insulation. But it is necessary to insulate the basement part of the foundation, especially in houses built on stilts, in order to reduce heat loss at the floor level of the residential floor. Insulating the basement helps retain heat in the house by cutting off the path of cold air into the house.

In addition, the foundation insulation layer plays a partial role in its waterproofing.

This means the thermal insulation of the foundation:

- reduces heat loss;

- reduces heating costs;

- reduces the impact of soil heaving on the foundation;

- stabilizes the temperature inside the building;

- prevents the formation of condensation on the internal planes of the walls;

- performs mechanical protection of waterproofing and foundation structures.

Which insulation is more effective?

There are two ways to insulate the foundation - insulation at the pouring stage and subsequent insulation performed after the concrete casting has hardened. The first one is the most preferable.

The most correct approach to insulating the foundation during the construction process is permanent formwork. It is a structure into which a concrete solution is poured. At the stage of its hardening, it plays the role of ordinary formwork, but after that it is not removed, but remains as an insulation layer.

Typically, permanent formwork is made from polystyrene foam boards. This type of thermal insulation has a high cost, but in the future, such a foundation does not need additional insulation.

Insulation is most often done from the outside, because with external insulation, unlike internal insulation, both the premises of the house and the foundation itself are protected. Insulation of the foundation from the inside is most often resorted to if external insulation is not possible.

Materials and methods of foundation insulation

Insulation work begins with the selection of a thermal insulation material that should not deform under soil pressure and absorb moisture.

Today, the choice of materials and methods for insulation is very diverse:

- covering with sand, expanded clay or earth.

- insulation with slabs of polystyrene foam and its analogues: penoplex, polystyrene.

- insulation with mineral wool;

- insulation with polyurethane foam.

All these materials are suitable for insulating private wooden, brick and block houses and differ in thermal insulation parameters and cost. To make the best choice, you need to study their pros and cons.

Insulation of the foundation with sand and expanded clay

Until recently, this was the most popular method of insulating a foundation from the outside, due to their ability to remove moisture and create an air gap near the foundation walls.

The advantages of the method include the low cost of the material and the ability to make thermal insulation with your own hands. At the same time, the backfill layer simultaneously functions as waterproofing and reduces soil pressure during heaving, which makes it possible to use it on clay soils.

Execution technology:

- The first step is to prepare a pit from the outside of the perimeter.

- Drainage is made at the bottom of the pit: geotextiles are laid, covered with crushed stone, on top of which a perforated pipe is placed, and then again a layer of crushed stone. The pipes are tied and drained into the well.

- The foundation is cleaned and dried, and then waterproofed.

- Fill the prepared trench with sand or expanded clay, compacting it layer by layer.

Insulation with mastics

A certain amount of insulation can be achieved during waterproofing work. For example, it is recommended to cover vertical foundation walls with several layers of bitumen mastic. This insulates cracks and small holes at the joints of the slabs through which heat can escape.

After this, a roll of waterproofing material is applied to the side surfaces. It will be an additional layer of thermal insulation.

Insulation of the foundation using mineral wool

This method is used extremely rarely, because to carry it out it is necessary to build a frame, provide good protection for the mats from getting wet, and also build a protective wall from some finishing materials.

Execution technology:

- The surface of the foundation is cleaned and dried, defects are eliminated.

- It is used to make a frame for mineral mats made of metal profiles.

- Thermal insulation mats are laid on the frame and secured. The surface of the insulation is protected from external moisture by a vapor-permeable wind-waterproof film.

- Protective brick walls or a ventilated frame are erected.

Insulating the foundation with foam plastic

A modern and very effective method that qualitatively insulates foundation walls. Its advantage lies in the high thermal insulation characteristics of the material, ease of work, and the material’s resistance to mechanical damage and stress.

The disadvantage is the need to prepare the foundation surface, protect the foam from rodents, and provide suitable waterproofing.

Execution technology:

- The foundation is dug out, cleaned and dried. Remains of bitumen, fat, and oil are removed from its surface.

- The foundation is waterproofed.

- Foam boards are laid on glue, sold in the form of a dry mixture.

- The surface of the foundation is protected from rodents with reinforcement mesh, laid on the same glue. Then the lower part of the foundation is backfilled with sand, and the upper part is secured using dowels intended for this purpose.

Insulation with polyurethane foam

Polyurethane foam is a modern material for thermal, waterproofing and sound insulation both outside and inside the room. To use it, you need to have special equipment that sprays polyurethane foam layer by layer under high pressure. required surface. The thickness of the polyurethane foam layer should be 5 cm. A similar insulating effect can be achieved using a layer of polystyrene foam 12 cm thick.

The advantages of polyurethane foam insulation are:

- longevity;

- high adhesive properties;

- no need for additional vapor and waterproofing.

- low vapor permeability;

- seamless coating;

- reliability;ne

- low thermal permeability;

Disadvantages include the need to use special equipment and gradual destruction from solar exposure.

Insulation with polystyrene foam

Plates made of extruded polystyrene foam almost do not absorb or allow water to pass through. Therefore, this material retains its thermal insulation characteristics for a long time.

Advantages of insulation with this material:

- long service life;

- strength;

- constancy of thermal insulation properties;

- "inedible" for rodents.

When insulating with expanded polystyrene, remember that:

- the corners of the building need “reinforced” thermal insulation,

- to insulate the soil around the perimeter of the building, a layer of expanded polystyrene should be placed under the blind area,

- The width of the blind area must correspond to the depth of soil freezing in the given climatic conditions.

- before insulating the foundation of the house, the surface of the walls must be leveled and waterproofed;

- The slabs are fixed by applying glue to them or by “melting” bitumen waterproofing, to which the slab is then pressed and held for the time necessary for hardening.

How to insulate a shallow strip foundation

The installation of the slabs should begin from the bottom, the rows should be joined end to end. The thickness of the plates must be the same. The vertical seams of adjacent rows should be staggered.

Seams between slabs more than 0.5 cm thick must be filled with polyurethane foam.

The adhesive must be selected based on the waterproofing material. When using rolled and mastic materials based on bitumen, bitumen mastics that do not contain aggressive ingredients for polystyrene foam are used as glue.

Before insulating the foundation from the outside, be sure to wait until the bitumen waterproofing has completely dried.

Glue is applied pointwise to slabs located below the soil level, which allows condensation between the insulation and the foundation wall to flow down.

The slabs located in the ground are attached only with glue and pressed with a layer of earth.

For slabs located above ground level, it is imperative to use fastening dowels.

How to insulate a monolithic foundation slab

For the most effective thermal insulation of the floor and basement, you need to take care of the insulation of the foundation slab.

For the most effective thermal insulation of the floor and basement, you need to take care of the insulation of the foundation slab.

To do this, the insulation is laid on top of the waterproofing layer. Then, when using a power floor to fill, they use knitted reinforcement; in this case, it is enough to cover the heat insulator with plastic film with an overlap of 10 - 15 cm and gluing with double-sided tape.

When using a welded reinforcement structure, a protective screed of concrete or cement-sand mortar will need to be made on top of the film, and welding work will be performed on top of this.

It should be noted that it is more correct to lay and insulate the foundation in the warm season, with a fairly high air temperature and not much humidity.

How to independently and correctly insulate the foundation of a private house

When wondering how to properly insulate the foundation of a private house, many do not even realize that there are several ways and options for creating thermal insulation. Basically, everything will depend only on the wishes of the owner, his financial capabilities, and, of course, the operating conditions of the building itself.

Causes of heat loss

As is clear, the foundation of any modern room must be reliably insulated, otherwise the heat from the building will escape outside. By the way, according to experts, heat losses of over 20% are due to poorly executed foundations and poorly insulated floors.

Mainly in our country there is clayey soil, which belongs to the category of heaving soil. As a result, during freezing it is possible to observe some displacement and deformation of the base itself. The use of insulating materials helps not only to provide reliable thermal insulation, but also to avoid compromising the integrity of the foundation and reduce the effect of soil heaving.

Insulation materials are usually laid on top of the waterproofing layer, thereby creating additional protection from various mechanical factors that may arise when the earth is backfilled. However, it must be taken into account that the base of the base does not require the creation of a layer of thermal insulation, since it is located slightly below the soil freezing mark.

How to insulate with expanded clay?

Let's look at an example of how to insulate the foundation of a wooden house. And not only that, since the actions in this case will be almost identical to insulating the foundation of a building made of any material.

So, there are 2 types of insulation: outside or inside. Let's consider each method individually.

- Option 1 – at the stage of pouring the base.

- Option 2 – with an already erected building.

The optimal time for insulating the foundation is the initial stage of construction, before the walls are erected and the subfloor is laid. It is also logical to carry out measures to create thermal insulation before the process of laying the box.

By the way, for information! The earthen embankment is inferior to expanded clay in its thermal insulation qualities.

And if you decide to keep the basement, filling with this bulk material should not be done to the full height of the box, but only 0.4-0.5 m from the walls located inside. So the basement will be preserved, and the communication lines and their nodes can be located in part of the underground.

So, insulation with expanded clay. The process itself is performed as follows:

- Removable formwork is installed along the internal perimeter of the building. To create, use any available material (remnants of slate, boards, sheets of plywood and tin).

- The inner surface is covered with expanded clay. Waterproofing or mineral wool is laid on top. Sometimes already laid communication lines do not allow filling the entire box from the inside, and then the external filling method is used, while creating waterproofing protection in the form of brickwork.

Attention: polystyrene foam!

Now let's look at thermal insulation using polystyrene foam materials, and how to insulate the foundation of a wooden house from the outside using this technology.

By the way, pasting the outer walls of the foundation with slabs of extruded polystyrene foam or a cheaper type of this material - polystyrene foam - is the most common method today. The foam structure does an excellent job of both heat retention and moisture penetration. And for regions where there is no severe cold, penoplex can be used. With this option, the corners should be sealed most carefully, since it is in these areas that freezing occurs most.

Is it necessary to insulate the foundation of a house without a basement? This is a problem that novice builders often face when they decide to install thermal insulation with their own hands. Basically, if there is no basement, you should approach the issue of insulating the foundation with all responsibility and seriousness.

If a basement is not planned, the area allocated for the box should be filled with earth or expanded clay up to the floor level. This will create an additional protective layer between the base and the floor.

- A trench of the required estimated foundation depth is dug along the perimeter of the building. Polystyrene slabs need a rigid base, and for this you need to fill the finished trench with sand and fine-grained crushed stone and compact it.

- Then all elements need to be cleaned of mortar and all uneven areas must be leveled.

- The prepared, even base is primed.

- Waterproofing is being carried out. First, the surface of the slabs is coated with liquid rubber or bitumen. When creating waterproofing using bitumen material, you must be able to handle the burner. All joints are heated with special care to avoid the appearance of seams (their presence violates the integrity of the insulating layer).

- The slabs are fixed to the surface of the foundation using construction adhesive. You can use bitumen or polymer mastic.

The slabs are laid from the corners below (from the sand cushion). After the first row is laid, the next one is laid. In this case, it is necessary that the seams are located in the center of the lower sheets. The plates are connected by grooves using the lock principle. The joint between the corners is covered with polyurethane foam (this way you can avoid cold bridges).

Then the part of the foundation located underground is covered with roofing material or filled with soil. A film with waterproof characteristics is glued on top of the roofing felt.

On the outside, using a fiberglass mesh, everything is reinforced, plastered and decorated with finishing materials.

But insulating the foundation from the inside in a wooden house is not recommended; with this option, thermal insulation can be done correctly if the room has good underground ventilation. Professionals say that when insulating the inside, there is some shift in the dew point, as a result of which the foundation may begin to collapse due to the influence of external negative factors on it. So the question of how to insulate the foundation of a house from the inside is not entirely appropriate in this case.

However, this does not mean that insulation can not be carried out. Many owners, for example, using the same polyurethane foam in liquid form, can completely avoid such consequences as excess humidity and heat loss during installation of thermal insulation not only inside, but also outside.

A few words in conclusion

So, as is clear, the foundation can be insulated with your own hands both from the inside and from the outside. The main thing is to decide on the necessary materials and method of insulation, and do not forget to be guided by the principles and advice of professionals, correctly applying them in practice!

Do-it-yourself well cleaning

Today the topic of how to insulate your home is more relevant than ever. In order not to waste money while warming the soil, it is easier to thoroughly insulate the most consumable part buildings - the foundation and the basement of the walls. High-quality insulation of the foundation from the outside will require certain costs, but, fortunately, most The work is quite possible to do with your own hands. If you save, it will be on someone else’s services, and not on the quality of the material used.

Work on insulating the foundation of a house from the outside by an amateur

To get rid of the troubles associated with hypothermia and freezing of the foundation system, you can use several options for installing thermal insulation:

- Increase the efficiency of the drainage system and thereby reduce the level of moisture in the soil outside the building. This will automatically reduce the thermal conductivity of the soil adjacent to the foundation walls and reduce heat loss;

- Use the classic method of insulation with your own hands, lay the insulation on the basement sections of the walls, cover foundation blocks foamed heat-insulating material;

- Perform thermal insulation of the joints between the floor slabs of the basement, blind area, and place the backfill thermal insulation mass in the foundation cavities;

- In the case of insulating a columnar foundation with your own hands, it is necessary to additionally cover the inlets with heat-insulating material or masonry that retains heat in the space under the building.

Do-it-yourself foundation insulation

Conventionally, the insulation of the foundation plinth from the outside can be divided into two groups according to the scope of work: the first is to ensure thermal insulation due to the soil, the second is to ensure heat savings by laying insulating materials on the structure of the foundation and wall plinth.

Loose-fill forms of thermal insulation

Ground thermal insulation has a number of characteristics that, at first glance, are not obvious, but, nevertheless, are very important for effective insulation of a house:

- Skillfully organized drainage from the surface of the soil adjacent to the blind area of the foundation of the house makes it possible to reduce the water saturation of the soil several times, which means that the thermal conductivity of the top layer of soil, 50 cm thick, which makes the main contribution to heat losses, will decrease by at least half. This will be much cheaper and more effective than covering the blind area a huge amount expanded polystyrene;

- Effective drainage of accumulated groundwater, its removal from under the base of the building and adjacent soil layers outside, correctly laid barriers and insulating membranes at the base of the foundation can reduce heaving and water filling of the soil by 3-4 times;

- The most effective of the soil thermal insulation methods is the backfill form of insulation of the foundation structure. If polystyrene foam materials glued to the concrete surface of the foundation can be destroyed, chipped, or crushed by the ground in very cold weather, then backfill forms are practically insensitive to such problems.

Foam glass is considered one of the most effective fill-type heat insulators. The material has high hardness, comparable to the hardness of concrete, and excellent thermal insulation characteristics. If you make a ditch or trench outside with your own hands to the depth of the foundation and fill the formed cavity with foam glass granules, this will sharply reduce the heat loss of the foundation, improve water drainage, since the backfill layer plays the role of a sponge, and increase the stability of the foundation. In addition to ordinary granules, manufacturers suggest using compositions of glass granules and bitumen filler to insulate the surfaces outside of foundation blocks.

The currently used expanded clay or vermiculite backfills are not so effective in insulating the foundation of a house, but due to the low price of the material, the width of the insulating layer outside the foundation can be increased several times.

Traditional methods of thermal insulation and insulation of the foundation of a house

If you need to insulate the outside of foundation blocks in the shortest possible time, instead of traditionally gluing polystyrene foam boards on the outside of the foundation base, insulate the concrete surface with polyurethane foam. A layer of foamed polyurethane foam is easily applied with special equipment to the most humpbacked and uneven surface of concrete blocks.

If it took days and weeks to lay polystyrene thermal insulation, then applying polyurethane foam even with your own hands can be done within one working day. Laying a polyurethane foam-based insulation system to a depth of 30 cm to 2 meters creates comfortable conditions to maintain the performance characteristics of insulating materials. Firstly, there is no ultraviolet radiation from the sun, and secondly, a minimal temperature difference is maintained. The cost of such insulation is slightly higher than traditional slabs, but it can be used externally as a means of insulating any, even the most complex and problematic foundations.

For relatively flat surfaces of the external foundation walls, tiles are most often used. thermal insulation materials. They are used to assemble the insulation of the outer walls of the foundation, basement and blind area, as in the video:

Installation of insulating material outside can be done either on a layer of bitumen waterproofing or without it. In the first case, the blind area, the outer surface of the foundation walls and ground floors, is mechanically cleaned from all contaminants, mortar buildup, and unevenness, then treated with a waterproofing compound. Depending on the characteristics of the soil, waterproofing can be strengthened with your own hands using a sticker of roll insulation polymer films.

Typically, the manufacturer of insulation materials recommends plastering and leveling the walls from the outside, thereby ensuring the tightest and most uniform fit of the insulation system to the foundation walls. After waterproofing the outside of the foundation walls, the structure is faced with foam polystyrene slabs. To attach the slabs from the outside, it is most convenient to use bitumen mastic or acrylic glue.

A metal mesh is mounted outside the laid heat insulator. A layer of protection can be applied on top of the laid thermal insulation cake. Most often, this is a durable waterproof plaster that protects the surface of polystyrene foam from the destructive effects of soil or mineral backfill. In the same way, insulation is laid on the basement surface of the walls and on the blind area.

If you need to insulate a columnar or pile foundation, you can reduce heat loss by filling the soil around the supports to a depth of 30 cm with a dense, heavy mass based on foam glass. In this case, the main part of the insulation should be carried out on supports located outside the building. This type of filling is best combined with a viscous and dense mass like resin or roofing bitumen. Thus, the amount of moisture entering the base of the supports is sharply reduced, and the level of soil freezing outside the supports is reduced.

In addition to insulating the supporting elements, it is necessary to thermally insulate the space under the building. The most simple method is to hang a false plinth on the foundation grillage. The heat emanating through the bottom of the building will partially warm the piles or support pillars themselves and part of the air space underneath. If the inside of the columnar foundation is covered with a layer of expanded clay, and the false base covering the structure from the outside is made in the form of sandwiches made of wood and polystyrene foam, then an acceptable level of insulation can be achieved.

Conclusion

When carrying out measures to insulate a building, relatively little attention is paid to such forms as deep drainage of groundwater, drainage and drying of the soil, and improvement of the thermal insulating properties of the earth adjacent to the foundation structure. It is believed that it is easier and faster to insulate the foundation from the outside on your own by gluing sheets of foam material or applying a foamy polymer mass. However, the use of ground thermal insulation can be no less effective than the use of polymer thermal insulators.

bouw.ru

Insulation of the foundation of a wooden house from the outside

Insulating the foundation of a house performs several functions: it not only prevents heat from escaping through the base of the house and reduces heating costs, but also acts as waterproofing and protects the foundation from frost heaving of the soil. Without thermal insulation of the foundation, the first floor of the house will be cold and damp. Practice shows that insulating the foundation of a wooden house from the outside solves all these problems. It is much more effective than insulating only from the inside. In some cases, thermal insulation of the foundation is done both from the inside and outside.

Why is it better to insulate the foundation from the outside?

Experts believe that this option is preferable for several reasons.

It is recommended to insulate the foundation from the inside only if the basement has good ventilation. Otherwise, the humidity in the basement will increase, in addition, inner layer the insulation shifts the dew point, because of this the entire base is exposed to moisture and cold. This reduces its service life and leads to rapid destruction.

Wooden houses are usually placed on a columnar, pile or strip foundation. These types differ in their design, which means their insulation is done differently.

For thermal insulation of any type of base, extruded polystyrene foam (EPS, penoplex) is used. It is durable, has a long service life, does not emit toxic substances, is resistant to compression loads, does not allow water to pass through, and does not grow mold or moss. It is easy to use, attached to the foundation with special glue or with the help of umbrellas; the foam boards have a convenient connection to each other.

Strip foundation

First, they dig a trench all the way to the bottom of the foundation. Its width is 80-100 cm, since the blind area is also insulated at the same time. If the foundation is of a recessed type, then the first 40 cm deep trench is dug to the width of the blind area, and then, to save effort, you can make it 50 cm wide.

If the house was built some time ago, cracks may appear in the concrete. They are covered with a mixture of cement and construction glue if the cracks are small. Larger damage is repaired with cement mortar.

The next step is waterproofing. To do this, the surface of the foundation tape is covered with bitumen mastic, onto which roofing material is glued. The sheets are glued overlapping, the seams are additionally coated with mastic. More modern roll materials are also used, such as self-adhesive roll waterproofing.

After this, the insulation is glued. Although penoplex is often attached to dowels, it is still better to give preference to glue or liquid nails - they do not violate the integrity of the sheets. How to insulate a strip foundation with polystyrene foam, watch the video:

The joints between the sheets are foamed liquid foam.

After installing the insulation, geotextiles are glued onto it. It will reduce the effect of soil heaving on the heat-insulating layer.

Next, the trench is backfilled to the level of the blind area. Sand and small crushed stone are poured under the blind area in a layer of 0.15-0.2 m, and the cushion is thoroughly compacted. This layer will protect the blind area from loads arising from soil movement. A layer of dense insulation is placed on top. The same penoplex is suitable due to its resistance to compression loads. Concrete is poured on top; it can additionally be reinforced with mesh.

Attention! To reduce the effect of frost heaving, the insulation layer is placed at the level of the base of the foundation. The most effective combination of penoplex insulation up to the level of the walls in combination with insulation of the blind area at the level of the sole.

Pile foundation

How to insulate the foundation of a wooden house on stilts? For a pile foundation, as for a columnar foundation, a fence is built - an imitation of a base, closing the space between the piles. This will already reduce heat loss to some extent. For effective thermal insulation pile foundation need to:

- arrange a basement,

- insulate it inside and out,

- insulate the floor.

You can build a thin brick wall around the perimeter, or you can use slab materials that are attached to the sheathing. If you select the option with brick wall, you need to pour a shallow concrete strip 20 cm thick on which the wall will be built. It is not necessary to use exactly ceramic brick, you can take foam blocks or foam glass.

Important! The space under the floor should not be sealed. After installing the intake, vents must be made in it - ventilation holes measuring 10-15 cm. They are placed evenly on all sides of the house so that they are opposite each other.

To fasten panels or slabs, a sheathing is made from a metal profile or wooden blocks. For example, DSP can be used as outer cladding. There are already insulated façade panels, which perform decorative and thermal insulation functions.

A shallow trench is dug under the casing, into which a layer of sand (2-3 cm) is poured, expanded clay is placed on it, and the trench is covered with earth on top, so that there is no gap between the soil and the casing.

The video shows the structure and insulation of the false base:

To insulate a pile foundation, use

- expanded polystyrene,

- Styrofoam,

- foam glass in blocks,

- liquid penoizol (urea foam).

The first two options are most often used. Foam glass is too expensive for a private home, and liquid foam insulation requires special equipment or the work of specialists, which is also expensive. It’s easier to insulate the foundation of a wooden house with your own hands using polystyrene foam or expanded polystyrene from the outside. The main thing is that the material does not absorb water, so mineral wool will not work here. The foam is glued to the adhesive foam; for reliability, you can use additional wooden planks, which are attached with self-tapping screws to the sheathing through the foam.

Important! It is advisable to attach polystyrene foam or polystyrene foam to the guides, and not between them. In this case, there will be no gaps or cold bridges, since the thermal conductivity of wood, and especially metal, is greater than that of foam plastic.

You can insulate a pile foundation with polystyrene foam or EPS from the outside or the inside. If this is done outside, then the insulation is attached before finishing. If the finishing is already attached to the base, for example, if these are facade panels or DSP boards, then the insulation is mounted from the inside.

Floor insulation

To insulate the floor in a wooden house on a pile foundation, I usually use mineral wool, basalt wool, expanded polystyrene, polystyrene foam, liquid insulation.

Thermal insulation is done during the construction and installation of the floor as follows:

- They make a subfloor on which the insulation will lie.

- A vapor barrier and windproof layer is first placed on the sheathing.

- Then they put insulation.

- Vapor barrier and waterproofing are placed on top.

- After this, a finishing floor is constructed.

The layer of mineral wool must be at least 10 cm. If it is necessary to lay wool in two or more layers, this is done in a checkerboard pattern (so that the seams do not coincide). The video shows floor insulation in a house on a pile foundation.

For waterproofing, you can use glassine, polyethylene, isospan, and wind- and moisture-proof film. Polyethylene is the most cheap option, but he's not the best.

Important! In a house made of wood on a pile foundation, everything must be processed wooden elements floor with antiseptic.

The insulation of a columnar foundation differs little from the insulation of a pile foundation; the same materials and techniques are used.

Conclusion

Insulating the foundation helps not only retain heat and reduce heating costs, but also protects the foundation, makes it more durable, performs a waterproofing function, and prevents dampness in the house. Wooden houses are usually made on a strip or pile foundation, which you can simply insulate with your own hands.

bouw.ru

Insulating the foundation from the outside with your own hands

Each of us wants to have a warm and comfortable home, but not everyone thinks that in order for the house to be warm, it is necessary to insulate not only doors, windows, balconies, but it is better to start insulation from the foundation. By insulating the foundation of a log house, you can significantly reduce heat loss and reduce energy costs in the winter.

Why is thermal insulation needed, and its types.

When building a wooden house or bathhouse, one of the most important tasks is the thermal insulation of the foundation, which can be both external and internal.

Each person decides for himself when and with what materials to insulate his home

Let's consider the advantages external thermal insulation:

- Regardless of the material used for thermal insulation and the design of the foundation, any external thermal insulation prevents the penetration of low temperatures into the room, that is, it “protects” the foundation from freezing;

- savings (heating bills are reduced by about a third);

- extends the service life of communications;

- extends the service life of the foundation of a wooden house;

- protects against groundwater and moisture entering the foundation (foundation waterproofing);

- protects the foundation (lower and basement parts) from seasonal temperature changes.

Insulation cake diagram

Sometimes it is impossible to insulate the foundation from the outside with your own hands, then you should insulate the foundation from the inside.

Let's consider the advantages of insulating the foundation from the inside:

- forms the microclimate of the basement and the entire house;

- protects against groundwater;

- prevents condensation accumulation.

But internal thermal insulation There are also a number of negative points, these are:

- it does not prevent the foundation from freezing;

- As a result of temperature changes, the foundation may deform, cracks may appear, and the soil may swell.

Let's consider how to carry out work on internal insulation of the foundation.

To carry out such work there are various materials, these are: polystyrene foam or polystyrene foam and polyurethane foam.

You need to know how to work with each of them correctly.

Styrofoam pretty cheap material, but when working with it you must remember that it crumbles, it must be cut out, and then glued with a special mastic. It will take a lot of time to install it.

Polyurethane foam is easy to work with. It is used to insulate basements and subfloors. Available in the form of a spray can.

It is used by spraying the contents of the can onto the surface that needs thermal insulation (in this case, the basement floor). They also spray it on part of the basement wall. If they want to more reliably protect the basement from cold and moisture, then polyurethane foam is sprayed on both the floor and the ceiling. After it hardens, it is necessary to carry out Finishing work walls and floor. First they are puttied, sanded, and then veneered. Drywall may also be suitable for this.

Insulation of the foundation. Necessary materials. Methods of thermal insulation.

For external thermal insulation of the foundation, the following are used: polystyrene foam, polystyrene foam and polyurethane foam.

In order to insulate the foundation from the outside with your own hands, follow these instructions, which will tell you what materials will be needed and what materials should be used correctly.

This is what an insulated foundation with polyurethane foam looks like

The method of working with polyurethane foam is the same as when carrying out internal insulation, with the only difference being that in this case it is necessary to completely expose the foundation of the house. For this:

- It is necessary to dig a ditch along the perimeter of the house, the depth of which corresponds to the depth of the foundation, and the width should be approximately 0.50 m.

- Clear the outer foundation from the ground and level it if necessary.

- It is necessary to wait until it dries, clean the surface of the foundation of dust and use bitumen mastic and roofing material to waterproof it.

- For more reliable protection to prevent moisture, the joints of the insulation must be filled with special foam.

- To protect the foundation from groundwater, the top sheets of insulation are raised 30–40 cm above ground level.

- After the work described above is completed, sand is poured onto the bottom of the dug ditch (layer thickness 10–15 cm), and the remains of the insulation are placed on top and sprinkled with gravel (50–60 cm).

- Then the top is sprinkled with earth or sand, or poured with concrete (blind area).

- You can also then lay a mosaic of ceramic tiles or marble.

After the advent of polystyrene foam and polystyrene, expanded clay began to be used less and less for thermal insulation of houses.

The method of working with expanded clay is almost the same as with polystyrene foam, but there are differences:

- when insulating the foundation with expanded clay, it is necessary to dig a wide ditch - about 1 m,

- then lay down the waterproofing and cover it with a fairly thick layer (poor thermal conductivity) of expanded clay, or rather with its granules.

- Next, roofing material is laid as waterproofing and sprinkled with a layer of sand or earth.

Types of foundations and methods of their insulation.

In order to correctly carry out external foundation insulation work with your own hands, you need to know what types of foundations exist and how to properly insulate them.

Let's consider the existing types of foundations for a wooden house (shallow, columnar, monolithic, strip, pile) and methods of their insulation.

This foundation is made of brick or concrete.

A shallow foundation can be of a strip or slab type, so the shrinkage of such a structure is uniform.

A shallow foundation can be of a strip or slab type, so the shrinkage of such a structure is uniform.

When insulating such a foundation, it must be borne in mind that if the width of the insulation is greater than the depth of soil freezing, then under the insulation (which is located at a distance of 1-1.5 m), a zone of soil is formed that does not freeze.

A columnar foundation is made of pillars dug to a depth of 2 m (below the freezing depth). The house is subsequently placed on the upper ends of the pillars and therefore their level should be the same (40 - 50 cm) - this is the floor level of the house. This distance is necessary to avoid getting wet and subsequently rotting the wooden house.

To fill columnar foundation There are two technologies:

- They dig a hole 40–50 cm larger than the required post, make formwork, install reinforcement or frame, and fill it with concrete. After drying, remove the formwork. This is how a monolithic reinforced concrete pillar is made.

- Using a special drill, you can independently drill a widened well and fill it with concrete.

- Read more in the article: columnar foundation with grillage.

A columnar foundation is suitable for building buildings on slopes, but houses with such a foundation cannot be built on groundwater. It is difficult to insulate such a foundation; more precisely, you will have to make a thick base, and you will have to carefully insulate the wooden floor.

Screw foundation almost the same as the columnar one, but instead of monolithic pillars or metal pipes, they use piles that are screwed into the ground. Insulation of such a foundation is also problematic.

A monolithic foundation is a homogeneous slab under the entire house, but it should be noted that there will be no basements in the building. Houses with such a foundation are called floating, since under the influence of groundwater the entire house moves and does not sag or settle. Monolithic foundations can be shallow or deeply buried. For shallow foundations, only remove upper layer soil (that is, shallowly deepen it), and for a deeply buried foundation you need to dig a pit.

A strip foundation for a log house is a closed structure that runs under all the walls of the house. Such a foundation is suitable for any type of structure that will have a basement in the future. Such a foundation can be made monolithic or made of concrete blocks. You can make a monolithic strip foundation yourself, but keep in mind that it is very massive for wooden houses.

Useful tips

- For external and internal insulation of the foundation, it is better to use polystyrene. Compared to other insulation materials, it is more expensive, but more reliable, since it completely covers the surface without seams or gaps.

- To insulate baths, it is better to use foil penotherm as insulation, since a room lined with this material looks impressive and comfortable.

And in conclusion

Insulating the foundation from the outside with your own hands is not an easy task, but it is a feasible task and anyone can do it.

If you want to save time and costs on this work, then first find out the prices for this or that building material, take into account the type of foundation, and only then purchase the required building material in the required quantity.

Also, after you insulate the foundation yourself, do not forget to insulate it from the inside (for better heat retention in the house). To do this, also spare no expense and purchase quality material.

It is better not to delay or neglect the work described above. If you live in a region where there are no seasonal temperature changes, then you also need to carry out work on insulating the foundation. This will ensure thermal insulation of the foundation and prevent cold air and moisture from entering the house.

And then and a private house, and the bathhouse will be cozy and comfortable. Also, the microclimate in the house will be preserved.

profibrus.ru

How to insulate the foundation of a house from the outside with your own hands with a diagram

An important part when building a house is the foundation, as it forms the foundation of the house. Reliability and strength are the main purpose of the foundation. You should not skimp on quality, because the service life depends on the material from which it is made. The climate in the country, especially in winter, is not the warmest.

Cold weather creates cracks in the foundation, thereby damaging it. To prevent this from happening, you should take care of the foundation of the house, namely, insulate the foundation and brick base protruding above the ground from the outside, this will prevent freezing and waterproofing. Methods include: foundation insulation with polyurethane foam, polystyrene foam, penoplex, thermal panels.