Wall-mounted boiler for heating a private house. How to choose a double-circuit gas heating boiler

Dual-circuit gas boilers heating units are universal units that solve two important issues: creating a comfortable microclimate and hot water supply at home. Such equipment is in great demand because manufacturers pay due attention to the development and implementation innovative technologies. There are heating devices on the market from German, Italian, Korean and domestic companies, so the choice is huge.

How does dual circuit equipment work?

All heating units have a similar design. In general, they consist of several main elements:

- frame;

- automation – it controls the functioning of all components;

- chamber - a metal container covered with a layer thermal insulation material;

- burner - it is located at the bottom of the chamber and ignites automatically;

- expansion tank;

- heat exchanger - depending on the specific features, it can be dual or bithermic. The dual heat exchanger consists of two components. First - copper pipes and plates coated with an anti-corrosion layer. They transfer heat. The second is plates designed to provide hot water supply. As for bithermic heat exchangers, such devices are a pipe in a pipe. Interior used for preparing hot water, external - to create a normal microclimate in the rooms;

- circulation pump– it is used for pumping cold/hot water.

The principle of operation of the units is that the system has two circuits. One is designed to supply radiators and radiators with heat, and the second provides residents with hot water. It is also necessary to emphasize that when using the second circuit, several operating modes are possible:

- The equipment heats water when people open the tap.

- The unit operates in boiler mode - hot water is accumulated in a tank to a certain temperature and then supplied to consumers.

This is important to know: the boiler mode is more economical, but for this you need to install a heating tank in the house.

A few words should be said about the fact that there are turbocharged double-circuit gas heating boilers. They are a full-fledged boiler room located in a compact building. The fundamental feature of such equipment is the use of powerful fans responsible for supplying air and removing waste products.

What to look for when purchasing equipment

Imported and domestic double-circuit gas heating boilers are presented in a rich assortment, so consumers have difficulty choosing suitable models. To make the right purchase you need to take into account important criteria:

- power - this parameter depends on the size of the country cottage. This indicator is directly related to fuel consumption: the higher the power, the more gas is consumed and the faster the water heats up;

- type of ignition – piezoelectric element or electric ignition;

- material, type of heat exchanger - this component is an important component. It can be steel or cast iron;

Scale settles faster on bithermic heat exchangers. Therefore, they should be used if the water contains a large number of salts

- one- or two-stage - with one power level and with two. The second option is more preferable. Why? There are several reasons: increased service life due to a significant reduction in on/off cycles, gas savings, lower volume of harmful substances emitted into the atmosphere;

- circulation method - this indicator must be paid attention to. IN heating devices With natural circulation The coolant is supplied by gravity. For forced circulation, an electric pump is used;

- type of installation - floor-mounted gas ones are more suitable for owners of private houses double-circuit boilers heating. They have good power, equipped with a steel heat exchanger, are characterized by long-term operation. Wall-mounted double-circuit gas heating boilers save space, are small in size and light in weight;

Wall-mounted double-circuit gas boilers fully comply with efficiency and safety standards

- method of removing waste substances - in boilers with an open chamber, the products are discharged through the chimney, and in units with closed camera the movement is provided by a turbine.

This is important to know: non-volatile double-circuit gas heating boilers - best option, because they do not require electricity to operate.

Of course, when choosing heating equipment, you should also pay attention to the brand. This will be discussed further.

What are the benefits of Baxi double-circuit gas boilers?

Italian double-circuit gas heating boilers are deservedly popular because the company has a strong research and development platform. The priority task of the employees is the development of new technologies, which is why the company occupies leading positions in the markets of Spain, France, Russia, and Turkey. The global brand produces units for country cottages, apartment buildings. Moreover, all products meet the requirements of international standards.

Baxi double-circuit gas heating boilers have many advantages:

- reliability - the equipment is made of high-quality materials, and the design is thought out to the smallest detail;

- low level noise – the operation of the devices does not disturb the atmosphere of comfort;

- safety - the devices are equipped modern systems protection;

- compact dimensions;

- aesthetic appearance.

Gas boilers « Baxi ECO Four 24" have an LCD display indicating operating parameters

Boilers famous trademark presented in a wide range of models. For example, “Baxi Main” is equipped with a bithermal heat exchanger, a high-speed circulation pump, a pressure gauge, an automatic bypass, a gas pressure regulator, and an electronic self-diagnosis system. The Luna series units operate optimally and are characterized by good performance. They are also equipped with a simple user-oriented control system. With its help, you can obtain information about the current settings, set the necessary parameters, and diagnose the status of all nodes.

"Vaillant" - heating equipment of a new generation

German double-circuit gas heating boilers are in steady demand among the most demanding consumers. This is explained by the fact that the company produces high-quality products with excellent characteristics. The leading manufacturer has extensive experience and has a large number of prestigious awards and international awards. There is nothing surprising here, since the company’s mission is to create “smart” secure systems to ensure a comfortable life for people.

Vaillant turboTEC plus VUW double-circuit boilers are equipped with two heat exchangers: with a patented SUPRAL coating and with protection against scale formation

Vaillant double-circuit gas heating boilers have many significant advantages:

- high level environmental friendliness - the condensation system reduces the content of harmful substances in combustion products;

- many models are equipped with an automatic air vent, built-in circulation pump, bypass valve, closed expansion tank;

- presence of a backlit liquid crystal display;

- units are equipped with burners made of modern materials;

- boilers can be adjusted to partial power.

This is important to know: some models have a “Hot Start” function, thanks to which the water heats up in a minimally short time.

What are the advantages of Feroli brand boilers?

Products Italian company has proven itself well in the market and is widely used almost all over the world. The heating equipment of this brand brings to life advanced developments and interesting ideas. In the basic configuration, Feroli double-circuit gas heating boilers are equipped with overheating/freezing protection systems, copper bithermic heat exchangers, and atmospheric burners with electronic ignition. It is also necessary to name other positive indicators of the units:

- excellent functionality;

- attractive design;

- hardware support remote control;

- convenient arrangement of internal elements, which simplifies Maintenance;

- The combustion chamber inside is insulated with environmentally friendly material.

Wall-mounted gas boilers “Turbo Domina F 24 N Gray” operate on liquefied and natural gas

It is worth paying attention: Korean double-circuit gas heating boilers “Kiturami” are no less popular because they are reliable and durable.

Warmth is the main component of the cozy atmosphere of any home. For this reason, the choice of heating equipment must be approached wisely. But the installation of units should be trusted to qualified craftsmen, because gas is not something to joke about.

Video: double-circuit gas boilers

The fact that double-circuit gas boilers for heating a private home are purchased more often than others has two good reasons:

- Nothing has been invented yet that is cheaper than heating a room with gas. Gas is the most affordable fuel.

- Double-circuit heating is convenient, since two devices are combined in one housing (boiler and boiler).

Let's take a closer look at the advantages, capabilities, and types of such units. How to choose and install a double-circuit gas heating boiler with your own hands.

A double-circuit boiler heats the heating fluid and water for water supply to the house.

A double-circuit boiler heats the heating fluid and water for water supply to the house.

According to the method of heating water, they are distinguished:

- Cumulative (with a boiler tank).

- Flow devices.

The volume of the internal boiler is usually 30 - 100 liters. Which is quite enough for 3 - 6 people.

But there are large devices, with a tank of up to 500 liters (of course, they are floor-mounted and expensive, such a device is placed in a separate room).

Flow-through ones are more economical, because heating is turned on only when the water opens. The boiler takes longer to heat up and is not as economical.

The design of heat exchangers can be:

- Bithermic.

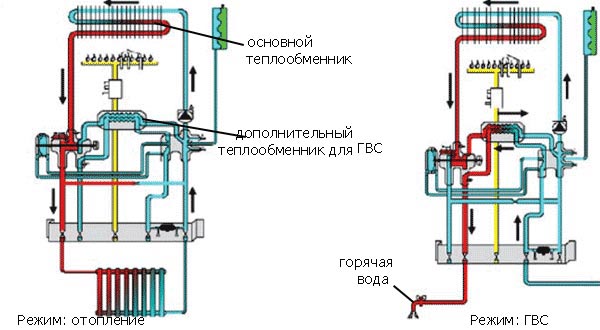

- Duothermic (separate).

In the first case, these are two tubes, one inside the other. Water flows through the internal one for hot water supply, and through the external one - for heating. The downside of the device is that they only work in pairs.

The duothermal model consists of two separate heat exchangers. The system is cheaper and easier to repair.

The duothermal model consists of two separate heat exchangers. The system is cheaper and easier to repair.

Connectivity room thermostat will make using the boiler even more enjoyable.

The owner sets a temperature that is comfortable for himself, for example, 22 °C.

The thermostat takes readings in the room, and when the temperature gets higher, the boiler turns off. But as soon as t drops, the flame lights up again.

Winter-Summer is the function of gas boilers to heat only water in summer period. During the off-season period, the device can be switched to a reduced operating mode.

Since a certain amount of energy is spent on heating water for domestic hot water, fuel consumption increases.

But this fuel is gas, the cheapest option, which means that a boiler with heated water is better than a boiler + a separate electric water heater.

Advantages

Advantages of using gas double-circuit boilers:

- Economic benefits of using main gas.

- No installation required in a separate boiler room.

- The safety of gas combustion is ensured by automatic control.

- There is an option to install a coaxial chimney, which is easier and cheaper to install and use.

- High efficiency.

- Uniform temperature in the house, set to the wishes of the residents.

- Floor and wall version provides a choice of placement location, makes it possible to embed and hide the device.

- Providing hot water to houses where hot water supply is not provided and to apartments where scheduled outages and accidents occur at heating plants.

It is also important that modern gas boilers have a well-thought-out design. Sizes, shapes and colors may vary and it is easy to choose a boiler that will fit into the interior.

Wall-mounted double-circuit gas heating boilers

Wall-mounted heating boilers occupy less space and can be easily integrated into kitchen furniture. They are hung on the wall using anchor bolts.

As a rule, wall-mounted devices have less power than floor-mounted gas double-circuit heating boilers. However, there are models with a power of 32 kW, which are enough to heat a cottage with an area of 320 m2. Considering that ordinary houses have areas of 50-60 m2, it becomes clear that wall-mounted boilers Great for most households.

The weight of wall-mounted equipment is 32 – 38 kg.

Gas boilers, double-circuit turbocharged

All double-circuit boilers can be divided into two categories:

- With an open combustion chamber (atmospheric burner).

- Turbocharged or closed chamber.

In the latter case, a fan is built into the system, which provides the unit with sufficient draft. And since there is draft, then there is no need for a long chimney pipe, precisely calculated according to the height of the roof. Instead, you can install a short coaxial pipe.

Gas boiler with a closed combustion chamber

What does it give:

- The pipe consists of two layers. One removes hot combustion products to the street, while the second brings air into the house for the combustion process.

- A sealed system isolated from the room prevents smoke from entering the house, which means it is safer.

- The pipe can be routed through a side wall or even a window, which significantly simplifies and reduces the cost of installation.

Double-circuit gas boilers - how to choose?

The main thing that the boiler will do is heat the room. Whether he can cope with this depends on the correctly selected power. The following formula is often used:

For 10 m2 of room area - 1 kW of boiler power.

However, this calculation is only suitable for perfectly insulated houses with all plastic windows.

You need to add a few percent to the power if:

You need to add a few percent to the power if:

- The house is located in a harsh climate zone, where there can be severe frosts in winter.

- There are regular windows.

- The floor is “cold”.

- The ceiling is poorly insulated.

The performance margin should not be too large. Constant operation in power moderation mode will not benefit the boiler.

What else to consider when choosing

Before you go shopping, read all the listed characteristics, decide which ones are not important to you and which ones are important. Write them out. This way, you will be prepared for conversations with store consultants.

- Safety. Pay attention to the protective elements in the design. They must be present, especially if the gas pressure in the system is not stable, there are gusty winds, and the weather is changeable. For example: the gas supply should be automatically shut off if the flame goes out; protection against freezing, scale, overheating; self-diagnosis against accidents; safety valve; from blocking the circulation pump, etc.

- Smooth temperature control. This will help not only make your stay comfortable, but also save money by not wasting gas. Pay attention to the possibility of connecting a thermostat.

- Heat exchanger material. There are copper, steel and cast iron heat exchangers. Cast iron is heavy, but durable. Steel is lighter, but not resistant to corrosion (chrome steel does not have this drawback). Copper is not afraid of corrosion and transfers heat 8 times better than steel. Can be used different material for hot water supply and heating.

- Dimensions, weight. Compare the size of the device with the space allocated for it. Walls in older homes may not be able to support equipment that is too heavy.

- Gas consumption. The higher the power, the higher the consumption. For a 20 kW unit, the approximate flow rate will be 2.4 m 3 / hour.

- Type of water heating, boiler volume. There should be enough water for the family. In the flow-through version, there is hot water while the boiler is heating. In the storage tank, a certain supply of water is stored for some time.

- Control. It can be in the form of knobs, buttons or with an LCD display. There may be a remote control.

Features of self-installation

Putting gas equipment into operation is not so easy. You need to coordinate with the services and call specialists. To save money, there are some things you can do yourself.

Do not delay installing the boiler until the first cold weather! The installation phase can take up to 3 months!

Stages of creation

Conventionally, the entire installation process can be divided into:

Conventionally, the entire installation process can be divided into:

- Preliminary preparation.

- Paper approvals.

- Direct installation.

- Connection to the main line.

At the first stage, a place for the equipment is selected and the device itself is purchased.

The area of the room should not be less than 4 m2. And the width of the door is at least 80 cm. The decoration of the walls of the room must be made of non-combustible materials. The location of the pipe outlet is being considered.

Design and installation

- An agreement is concluded with the gas supplier.

- Employees of this enterprise are developing the project.

- To receive these documents, an application is written from you. It will need to indicate gas consumption (taken from the instructions for the boiler).

- You will have to wait about 2 weeks.

- The project will also have to wait (depending on the complexity of the development - from 1 week to 3 months).

- Now you can install the pipes and boiler. But you won’t be able to do everything yourself – it’s prohibited by law.

Installation

Step by step instructions:

- Using the paper template included in the kit, the boiler mounting locations are marked on the wall.

- Holes are drilled with a drill. Dowels or anchors are driven in.

- The front panel is removed from the boiler, allowing access to the casing.

- Using a hanging angle or slats, the boiler is attached to the wall. (Height – at least 80 cm from the floor).

- The level checks parallelism and verticality.

![]()

Connection gas boiler

If carried out welding work on heating pipes, then before connecting the boiler, rinse them thoroughly so that scale and debris do not get into the heat exchanger pipes.

Connecting a double-circuit gas boiler

To connect the boiler to the water supply, the water supply is shut off. The connection is made using flanges or couplings.

- All pipes included in the kit are installed. A filter is installed at the inlet to protect the boiler from debris.

- Before and after the filter, ball valves are installed on the nozzles.

- Leak tightness is checked.

- The chimney (regular or coaxial) is connected.

- The boiler is connected to an individual electrical wiring line, which is equipped with a circuit breaker and a stabilizer.

Connection to gas pipe, the last stage, is carried out by gas specialists. They will also install a meter, ball valve and indicator. The first commissioning of the boiler is carried out in the presence of the same specialists.

When choosing a gas boiler, you need to take into account the main characteristics, as well as the manufacturer of the device. In the first case, the selection is carried out according to individual parameters, and when choosing a company, it is not only about reputation, but also about price. In this regard, domestic devices win. , popular manufacturers, models and prices.

When choosing a gas boiler, you need to take into account the main characteristics, as well as the manufacturer of the device. In the first case, the selection is carried out according to individual parameters, and when choosing a company, it is not only about reputation, but also about price. In this regard, domestic devices win. , popular manufacturers, models and prices.

Let's look at how to properly install a coaxial chimney for a gas boiler.

Before purchasing a gas boiler, you need to study the characteristics of the device. Here detailed description parameters of gas appliances, as well as an overview of companies. The article will help you make the right choice.

Cost of a double-circuit gas boiler

The average price of a double-circuit gas boiler is 25 – 60 thousand rubles. Russian goods are traditionally cheaper. The cost of equipment is formed from:

The average price of a double-circuit gas boiler is 25 – 60 thousand rubles. Russian goods are traditionally cheaper. The cost of equipment is formed from:

- Power.

- Equipped with electronic filling.

- Brand advertising.

Here are approximate prices for gas wall-mounted double-circuit heating boilers:

- Protherm Leopard 24 BTV. Wall-mounted, electric ignition, winter-summer function, bithermic, 23 kW, closed chamber, 74 x 41 cm. = 25,000 rub.

- Ferroli Divatop micro C, Separate heat exchangers, wall-mounted, LCD display with backlight, remote control, electric ignition = 52,400 rub.

- Mora Top Sirius 20kt (Mora Sirius). Wall-mounted, 20 kW, closed chamber = 60,000 rub.

- Alphatherm Sigma BT 24. Wall-mounted, bithermic, closed chamber, electric ignition.

- Vaillant (Vailant) VuwInt 322. Double-circuit gas boiler, wall-mounted, turbocharged, 32 kW, 80 cm x 44 cm, copper heat exchanger, designed for a pressure of 3 atm. = 76300 rub.

Where to buy a double-circuit gas boiler

You have the opportunity to connect to the gas main and there is room for a boiler room. In this case, a double-circuit floor-standing gas boiler for heating a private house is a good option, since it can provide not only heating, but also hot water supply. Moreover, compared to a wall-mounted unit, such a unit can have more power. But since they exist various designs and models of such boilers, difficulties often arise when choosing the optimal option. Therefore, in this article, we will look at how they may differ and what to look for when choosing.

What is common to all models of double-circuit floor-standing gas boilers is that for their installation it is necessary to allocate space on the floor or separate room. At the same time, they may differ:

- Power and method of its regulation;

- Dependency on electricity;

- Type of traction;

- Burner type and gas consumption;

- Type of heat exchanger;

- Additional equipment;

- Manufacturer and cost.

In order to find out what features a double-circuit floor-standing gas boiler should have, which will the best option for your private home, let's consider them in more detail.

Power and ways to regulate it

When choosing a double-circuit floor-standing gas boiler, first of all, you need to decide on its power, which will be sufficient to heat a private home and provide hot water. It is usually recommended to focus on the average value: 1 kW for every 10 m 2 of its heated area. But in practice, such a power of a thermal unit may be small or, conversely, large. It depends on the thermal insulation properties its walls and other enclosing structures, as well as climate zone and location. It is best to calculate the heat loss of the premises of the house, taking into account all these factors, and only then choose the boiler power. If it is difficult to make such a calculation yourself, you can order it from a specialist.

It should be remembered that the maximum power of the selected unit should be 15-20% greater than that required to compensate for heat loss, since it is undesirable for the gas boiler to operate at the limit of its capabilities. On the other hand, there is no point in choosing a gas boiler with a large power reserve of more than 20%, since the more powerful the unit, the more expensive it is.

The power of a double-circuit floor-standing gas boiler can have one-, two-stage or smooth adjustment. The cheapest option is single-stage regulation (on or off), and the most convenient is smooth.

In addition to choosing the power of a double-circuit floor-standing boiler for heating your home, you should also pay attention to how much water a particular model can heat and how this performance relates to your needs.

Traction type

Floor-standing gas double-circuit boilers can be designed for natural or forced draft. In the first case, the combustion air comes from the room where the boiler is installed, and the draft can only be adjusted by the diameter and height of the chimney, which must be at least 0.5 m above the roof. The advantage of such draft is that there is no need to create it the need for a fan, the operation of which depends on the availability of electricity.

In the second case, a special fan is used to create forced draft. In this case, two options are possible: when combustion products are removed, as in the first case, into the usual chimney or when a so-called coaxial chimney is installed, which is a “pipe-in-pipe” structure and allows air to be simultaneously supplied into a closed combustion chamber and flue gases removed from it. At the same time, the air coming from outside is also heated. Such a chimney is vented outside, usually through the wall of the building.

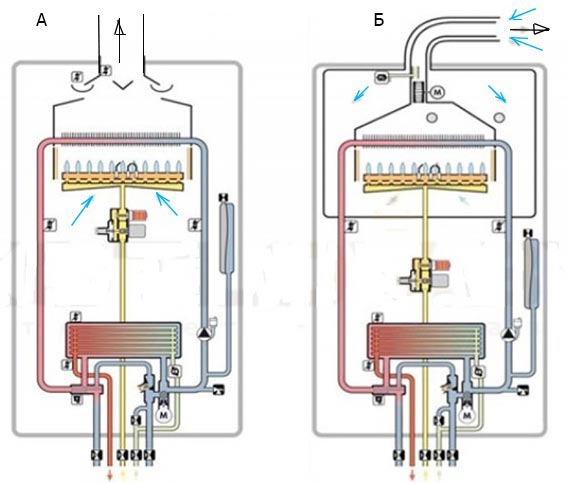

Fig. 1 Diagrams of a double-circuit gas boiler with natural (A) and forced (B) draft

Electricity dependence

Most modern double-circuit floor-standing gas boilers are energy-dependent and for them normal operation electricity is required. Such units are characterized by high efficiency, ease of operation and the ability to automate their operation.

But there are units that do not require electricity, that is, they are energy-independent, which is their main advantage, especially in areas where there are problems with power supply. As a rule, such gas boilers are designed for natural draft and manual power control. The operation of such a boiler is controlled using an automatic gas valve and a mechanical thermostat. When the water in the heating system heats up to set temperature, the thermostat is activated and the valve closes the gas supply and the burner goes out. At the same time, only the igniter continues to burn. When the temperature drops, the valve opens the gas supply and the burner is ignited by the igniter. Most often, such units are equipped with cast iron heat exchangers. Water for hot water supply is heated in them using an additional flow-through heat exchanger, in the form of honeycombs, which are located parallel to the tubes of the main heat exchanger (for heating) and separated from them by thin walls. The main disadvantages of a non-volatile gas boiler:

- Lower efficiency – no more than 90%;

- To ensure good draft, you need a sufficiently high and reliable chimney, creating a vacuum of at least 16 Pa in an open firebox;

- Its power must be adjusted manually.

Burner type

The following types of gas burners can be installed in floor-standing double-circuit gas boilers:

- Atmospheric;

- Supercharged or fan;

- Diffuse-kinetic;

- Combined - for different types fuel.

In addition, according to the method of regulating gas combustion, they can be:

- Single stage;

- Two-stage;

- Modular.

Let's consider the operating features, advantages and disadvantages of each type.

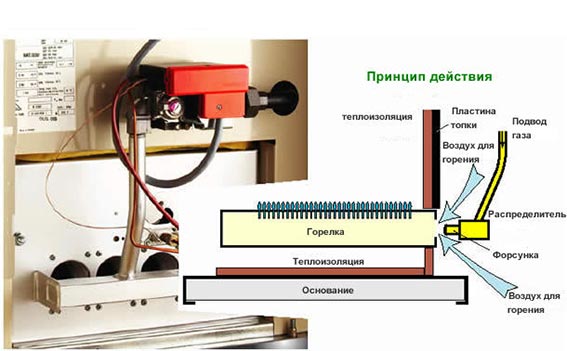

Atmospheric burners

Such burners are hollow tubes with many small holes through which gas flows from the main line. They are usually installed in combustion chambers open type, into which the air necessary for gas combustion is supplied from the room using natural traction. The mixture of air and gas is ignited using piezo or electric ignition.

Rice. 2 The principle of operation of the atmospheric burner of a gas boiler

Such burners are usually equipped with inexpensive low-power gas boilers designed for heating a private house with an area of up to 100 m2. Their advantages include:

- Simplicity of design and reliable operation;

- Silence;

- Compact size and light weight.

Supercharged or fan

In burners of this type, air is forced through a built-in fan, mixed with gas and fed into a closed combustion chamber. This allows you to increase the efficiency of the unit and use gas more economically to heat the coolant and water for hot water supply. In modern floor-standing gas boilers, such burners are included in one unit with a fan, the operation of which is regulated automatically, ensuring the safe operation of such equipment. Another advantage of units with this type of burner is that they operate effectively at any gas pressure in the line.

Pressurized burners can be direct-flow or vortex. For direct-flow outlets, the outlet openings can be round, slot-shaped or rectangular, while for vortex outlets they can only be round, but provide swirling of the jet of air and gas.

Along with obvious advantages, fan or forced-air burners also have disadvantages:

- Higher noise level due to forced air supply;

- Dependence on the availability of electricity and its additional consumption;

- Higher cost.

Diffusion-kinetic

Such devices are something between an atmospheric and a forced-air burner. In them, the air that is necessary for burning gas does not first enter the chamber in full, but is added later to the flame. A variety of such devices are the so-called hearth burners, located in the lower part of the combustion chamber of the boiler. In household floor-standing gas boilers intended for heating private houses, such burners are used very rarely.

Combined

Such burners allow you to use other types of fuel in addition to gas: diesel fuel or fuel oil. Boilers equipped with such burners are popular among owners of private houses that are not connected to the main gas, but if there is a prospect of such a connection in the near future. The operation of such devices is usually regulated and controlled automatically. Units with such burners are not very common due to the following disadvantages:

- The complexity of the device itself and the process of switching it from one type of fuel to another;

- Lower efficiency;

- Higher cost.

Single stage

Such burners have the most simple design can operate only in one mode - at full power. Its operation can be adjusted manually or automatically. In the second case, maintaining the required temperature of the coolant in the heating system occurs as a result of automatically turning on and off the burner. Since such on-off switching occurs quite often, this negatively affects the service life and performance of such equipment.

Two-stage

Burners of this type have two stages of flame power adjustment: 50-60 and 100%. In modern floor-standing gas boilers, the transition from one stage to another, more economical, occurs automatically when the specified coolant temperature in the heating system is reached or when the gas pressure in the line changes. This allows you to save gas and increase the service life of the equipment. Some models of burners of this type can switch smoothly to different operating modes.

Modulated

Such burners allow you to smoothly regulate the flame strength, and therefore the power of a double-circuit floor-standing gas boiler, within significant limits: from 10 to 100%. This allows you to significantly reduce the number of starts and stops, increase the efficiency of the equipment, as well as increase its service life and save gas (up to 15%).

Modulating gas boiler burner

Heat exchanger type

The design of a double-circuit floor-standing gas boiler for producing hot water for domestic hot water may require the presence of a flow-through heat exchanger or a built-in boiler.

The design of flow-through heat exchangers assumes the presence of channels with a small cross-section and thin walls, which makes them vulnerable when using hard water from a well or well for hot water supply without first softening it. In addition, such a heat exchanger is not designed for high flow rates and does not allow for a supply of hot water, since it begins to heat up only when the corresponding tap is opened. Most flow-through heat exchangers of double-circuit boilers are designed to simultaneously provide hot water to one point of intake. When you open the second tap, the water temperature in the first will decrease. In addition, it is recommended that the hot water intake point be removed from such a boiler at a distance of no more than 7 m. In this case, two options for a flow-through heat exchanger are possible:

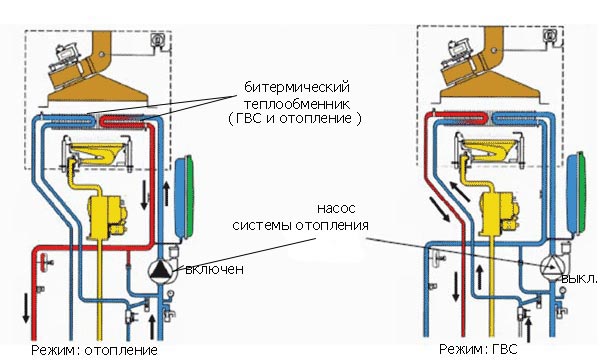

- When DHW heat exchangers and heating are combined in one main, heated gas burner, the so-called bithermic heat exchanger (Fig. 3);

- when is the water for DHW systems it is heated in a separate additional heat exchanger, with water heated in the main heat exchanger (Fig. 4).

Rice. 3 Scheme of operation of a double-circuit gas boiler with a bithermal flow-through heat exchanger

Rice. 4 Scheme of operation of a double-circuit gas boiler with an additional flow-through heat exchanger for hot water supply

If you need a larger volume of hot water, as well as the availability of a certain supply, then for heating a private house you should choose a double-circuit floor-standing gas boiler with a built-in or remote boiler. The first has a smaller volume and is mounted inside the housing. The remote one is similar in design to an indirect heating boiler.

Rice. 5 Floor-standing double-circuit gas boiler with built-in boiler

The heat exchanger of a double-circuit gas boiler can be made of different materials:

- Made of cast iron - has a long service life (up to 50 years), resistance to high temperature and aggressive coolant environment. The disadvantages of this material are its heavy weight and fragility (it is afraid of shocks and sudden temperature changes).

- Made from ordinary steel - the most economical option. In addition, compared to cast iron, they have less weight and are not afraid of shocks and sudden temperature changes. But, on the other hand, they are susceptible to corrosion and their service life is much shorter (5-15 years, depending on the grade of steel).

- Copper is the most expensive option, but has the best heat transfer and a fairly long service life. They are not afraid of shocks or sudden temperature changes, like cast iron ones. They are not subject to corrosion, like steel ones, although they are sensitive to the acidity of the coolant.

Additional equipment and functions

Many of modern models double-circuit floor-standing gas boilers are additionally equipped with a circulation pump, the pressure of which is selected in accordance with the thermal power of the unit. The pump allows you to provide forced circulation in the heating system of a private house, and if there is a cast iron heat exchanger, they protect it from temperature changes. To do this, a three-way electric valve is included in its piping, which shuts off the supply of water from the “return” to the heat exchanger when its temperature sharply drops. In this case, a valve controlled by an electronic unit ensures the movement of water in the heat exchanger in a “small circle” with the gradual addition of water from the “return”.

In addition, double-circuit floor-standing gas boilers, depending on their type and model, may have:

- Traction sensor;

- Flame sensor;

- Protection against overheating of the coolant in the heating system;

- Protection against coolant freezing;

- Fan performance control;

- Ability to program work for a specific time;

- Burner operation control function;

- The function of periodically turning on the circulation pump during the break between heating seasons and others.

Condensing gas boilers

When gas burns, water vapor is released. In conventional gas heating units, this steam, together with the thermal energy it possesses, is removed into the chimney. In condensing boilers, this energy is used to preheat the heating fluid. For this purpose condensing boilers equipped with additional heat exchangers. They are usually made from of stainless steel, since such steam is essentially a weak acid solution. The steam condenses, heating the coolant before it enters the main heat exchanger of the boiler. Aggressive condensate is collected in a special container and removed or neutralized. As a result of using an additional source of thermal energy, the efficiency of a condensing gas boiler is higher than a conventional one and reaches 95%. Although their cost is also higher.

Operating principle of a floor-standing condensing gas boiler

Cost and manufacturers

The cost of a double-circuit floor-standing gas boiler is quite a significant factor when choosing such a unit for heating a private home. It depends on the design, material, additional functions, and the quality of workmanship, and therefore the reliability of the manufacturer.

The most expensive are quality models gas boilers from European manufacturers such as Buderus, Viessmann, Valliant, Protherm, Electrolux, the cost of which is from 75 thousand rubles and above.

Average price segment are represented by such manufacturers as Viadrus, Alphatherm, BAXI, Navien, Kiturami, quite high quality gas unit which can be bought for 40-70 thousand rubles.

The cheapest thing, for 15-35 thousand rubles, you can buy double-circuit floor-standing gas boilers domestic producers, for example: AOGV, AKGV, ZIOSAB, etc.

Video on the topic

What is the difference between a double-circuit gas boiler and others? heating devices? First of all, the compactness of the equipment should be noted, and secondly, its functionality. They not only warm the premises, but also give consumers hot water. Double-circuit models cannot be called a novelty in the heating market, since they have been on sale for quite a long time. But not every consumer can boast of being familiar with them.

If you have accumulated questions about double-circuit boilers, we will try to give complete answers to them. What will this review be about?

- About functionality and operating principle dual-circuit models boilers;

- About the selection criteria;

- About popular models and prices.

Finally, you can read user reviews.

The principle of operation of a gas double-circuit boiler

A double-circuit gas boiler resembles a gas boiler in its format instantaneous water heater, differing only in size. If you look into its filling, then we will find equipment for the operation of two circuits - heating and hot water supply. In order to understand how this device works, you need to understand its internal structure. What will we find inside?

![]()

Construction of a gas heating boiler with two circuits.

- Main (primary) heat exchanger – heats the coolant in the heating circuit;

- Secondary heat exchanger – responsible for hot water supply;

- The burner is a heat source (there is one burner for two circuits);

- Combustion chamber - the primary heat exchanger is located in it and the burner burns in it);

- Three-way valve - responsible for switching between heating mode and DHW mode;

- Circulation pump - circulates coolant through the heating system or in a small circle DHW circuit;

- Automation (electronics) – ensures the operation of the above and many other components, controls parameters and is responsible for safety by collecting signals from sensors.

The design of double-circuit boilers also contains many other components. But in order to understand the principle of operation, it is enough to know the purpose of the modules described above.

In some models there is no secondary heat exchanger, and hot water is prepared using dual combined heat exchangers.

Scheme of operation of the device in heating mode and in hot water supply mode.

Now we will understand the principles of operation. We have already said that double-circuit gas boilers can operate in two modes - heating and hot water supply. When starting the boiler it starts working heating circuit– the circulation pump starts, the burner turns on, three-way valve is in a position in which the coolant circulates freely throughout the heating system. The burner operates until the control module sends a command to turn it off.

The operation of the burner is controlled by automation, which can evaluate the temperature of the coolant, the air temperature in rooms and outside (support for room and internal sensors is available only in some models).

If you need hot water, you should open the tap. The automation will detect the current through the DHW circuit, and the three-way valve will turn off heating system and will start circulating part of the coolant in a small circle. This coolant will enter the secondary heat exchanger, through which the treated water flows. As soon as we close the tap, the three-way valve will switch to heating mode.

Despite the complex device, the principle of operation is quite simple, and double-circuit gas heating boilers are becoming increasingly widespread. They are chosen for their convenience, compactness and good performance. You also need to pay attention to the fact that these boilers cannot operate in two modes at once - either the heating or the DHW circuit is working. But if you consider that we don’t use hot water very often, then we can put up with this drawback (it’s unlikely that you will consume water for so long that all your batteries will have time to cool down).

What to look for when choosing

Are you going to buy a double-circuit gas boiler? You can make a purchase in any online store by choosing the most optimal prices using commodity aggregators, or in regular store plumbing and heating engineering. Let's look at the main differences between boilers from each other.

Equipment with an open combustion chamber burns oxygen located indoors, unlike devices with a closed combustion chamber.

All gas double-circuit boilers are divided into two categories - with an open and closed combustion chamber. Open camera combustion involves burning gas fuel with the natural removal of combustion products through a classic chimney. Such boilers (atmospheric) are simpler in design and less prone to breakdowns. In addition, they have a reduced noise level.

Models with a closed combustion chamber are good because they do not require a chimney, and they can be installed in rooms without windows or ventilation shafts. The sealed combustion chamber provides air intake from outside the building through a special double chimney. Through it, combustion products are removed. A powerful fan with adjustable rotation speed is responsible for air suction and smoke removal.

To install atmospheric double-circuit boilers, you need a chimney and a normally ventilated room so that the device does not lack air. Models with a closed combustion chamber are installed in any premises, with an outlet coaxial chimney behind the nearest wall.

Let's consider another selection criterion - dual or separate heat exchangers. The first option is cheaper, but it has significant shortcomings. The main disadvantage is that scale often occurs in a double heat exchanger. Another negative feature is low maintainability. Models with separate heat exchangers are more intricate, but they are easy to repair and scale does not form in them, and their disadvantages are the low efficiency of the DHW circuit and a higher price.

Boilers with a double heat exchanger, although cheaper, are less durable.

You also need to pay attention to the availability of condensing boilers for sale. They work on a similar principle, only they involve additional system removal of heat from combustion products. Such boilers are characterized by higher efficiency and allow you to save gas fuel. However, some experts are confident that an efficiency rate of over 100% is nothing more than a marketing ploy.

How to calculate the power of a gas boiler

Please note that when choosing a gas double-circuit boiler, you need to pay attention not only to its power, but also to the performance of the DHW circuit. According to the classical formula, for 10 sq. m. area requires 1 kW of heat. If your home has an area of 200 sq. m, a 20 kW boiler is required to heat it. You also need to take into account a small margin - if the house has normal windows and it has good thermal insulation, then the optimal power of the equipment will be 24 kW.

You should also pay attention to the performance of the DHW circuit. This parameter is indicated in the passport data and depends on the set temperature. For example, for boilers with a power of 24 kW, the average productivity is 11-13 l/min when the water temperature increases by 30 degrees. When the temperature rises by 50 degrees, the productivity drops to 6-8 l/min. If you need a large amount of water, for example, for the simultaneous operation of two water points, you should pay attention to boilers of higher power.

Popular models of double-circuit boilers

Gas double-circuit boiler - which one to choose? Typically, consumers tend to buy the most popular equipment, taking into account reviews from friends, acquaintances or reviews on the Internet. Let's look at the most popular models and get acquainted with their technical characteristics.

This boiler is a double-circuit boiler, it is equipped with a closed combustion chamber and a copper primary heat exchanger. The power of the model is 24 kW, with the minimum figure being only 7.2 kW. The device can operate on liquefied and natural gas . Inside it there is already all the necessary equipment - a circulation pump and expansion tank. The performance of the DHW circuit ranges from 6.8 to 11.4 l/min. Maximum temperature in the heating circuit is +82 degrees.

The boiler is housed in a strict rectangular body, on the front panel of which there are controls and an LCD display. Interesting functionality includes electronic flame modulation, anti-freeze mode, and built-in security systems. According to user reviews, the model turned out to be interesting, reliable and inexpensive.

If you think that double-circuit gas boilers are produced only by foreign brands, then you are deeply mistaken - their production has long been established in Russia. A typical example is the Buderus Logamax U072-24K model. Its power is 24 kW, operation at reduced power is allowed - at least 7.2 kW. The boiler is equipped with a closed combustion chamber, a copper primary heat exchanger, numerous safety systems, electronic flame modulation and convenient controls.

The performance of the hot water circuit varies from 6.8 to 11.4 l/min, depending on the set temperature. The efficiency is 92%, which is quite a high figure. The device can work on natural and liquefied gas, in the latter case, its reconfiguration is required. In general, the model turned out to be successful, there are almost no negative reviews about it - perfect solution for a private house or apartment with autonomous heating.

Double-circuit gas boilers heating Protherm Cheetah 23 MTV have a power of 23.3 kW, the minimum is 8.5 kW. DHW capacity is 11 l/min when heated to 30 degrees. The unit can operate on natural or liquefied gas; it includes a circulation pump and a 5-liter tank. The efficiency of the model is 93.2%. The combustion chamber - closed type, To install the equipment you will need a coaxial chimney.

Inside we will find electronic flame modulation, various safety sensors and protective components. It is possible to connect heated floors, and self-diagnosis is implemented to record errors. The boiler is controlled using a built-in or plug-in control panel. This model is intended for installation in buildings for various purposes.

Average prices for boilers

Prices for dual-circuit gas engines vary widely and depend on the power of the selected model and the presence of additional functions in it. It should also be noted that samples with separate heat exchangers are more expensive. The average cost of a 24 kW model varies between 35-40 thousand rubles, but if this is a unit from Baxi, then the average price is approximately 45 thousand rubles.

Low-power double-circuit wall-mounted gas boilers with a capacity of 12 kW can be purchased for 28-32 thousand rubles. But prices for models from well-known brands may be higher - up to 37-38 thousand rubles. The cost of even lower-power samples varies around 24-28 thousand rubles. The most expensive are condensing boilers - their average price is about 70-80 thousand rubles with an equipment power of 24 kW.

The most favorable prices for gas boilers can be found through Yandex.Market - do not forget to indicate that you are interested in double-circuit samples.