Gas floor-standing boilers "Ross" of the "Lux" model range. Ross gas boiler: technical characteristics and installation

Floor-standing gas boilers Ross AOGV are designed for both heating and water heating for domestic needs, and are designed to work in open and closed systems heating.

They are equipped with a steel welded tubular heat exchanger made from seamless pipes and 3 mm thick sheet steel, which ensures long-lasting and reliable operation boiler

Fig.1. Type of boilers Ross

All welds are made using automatic welding machines. Specially designed turbulators are installed inside the heat exchanger pipes, which ensures the maximum possible heat transfer from gas combustion products to the coolant, rapid heating of the coolant and maximum efficiency - 93% of the AOGV boiler.

In the production of floor-standing boilers AOGV Ross, components from European manufacturers are used:

Gas automatics EVROSIT (Italy), MERTIK MAXITROL (Germany);

Expansion ELBI (Italy);

Circulation pumps WILO (Germany);

Burners Polidoro (Italy);

Heat exchangers IMAR and Giannoni (Italy),

Air vents, safety valves, thermostats, sensors, thermometers and pressure gauges Compini Corel, ICMA, T&G (Italy).

To maximize heat transfer from gas combustion products to the coolant, specially designed turbulators are installed inside the heat exchanger pipes. This ensures rapid heating of the coolant and achievement of maximum efficiency - 93% of the AOGV boiler.

The use of special plate burners provides uniform, and therefore higher quality, combustion of gas in the combustion chamber at various combustion modes and ensures effective heating of the entire surface of the heat exchanger.

Fig.2. Basic elements of floor gas boiler AOGV Ross

This model of the device is distinguished by a universal chimney with the ability to regulate the draft break (in models with a power of up to 40 kW, combustion products are discharged vertically or horizontally).

Models of Ross boilers with domestic water heating (DHW) use a copper water heater coil mounted in the main heat exchanger.

Selecting a room

The most optimal place for installing a Ross gas boiler in a residential building or apartment there is a separate special small room of appropriate volume with a window, window or transom, chimney duct, supply and exhaust ventilation.

For a device with a power of up to 30 kW, installation in the kitchen is possible. According to current regulations, installation in bathrooms is not permitted.

The device with a thermal power of up to 30 kW can be installed in rooms with a volume of at least 7.5 m3, not intended for permanent occupancy of people (in auxiliary premises), where the total duration of stay of people during the day does not exceed 4 hours.

The height of the room in which the boiler is installed must be at least 2.2 m. A device with a thermal power of 30 kW or more requires a separate special room with a volume of at least 13.5 m3.

The walls and floor of the room must be fire-resistant and must not be a source of dust. The best decision- This is covering walls and floors with ceramic tiles or coating with oil paint.

It is unacceptable to carry out work that produces dust while the device is in operation. This leads to the deposition of contaminants on the burners, in the heat exchanger channels, on the turbolizers and to the automatic shutdown of the boiler or to such a decrease in the amount of air required for normal combustion that soot appears, which interferes with normal operation.

When installing a Ross floor-standing boiler in kitchens and residential buildings, designed to operate on gas fuel with the removal of combustion products into chimneys, microconcentration control should be provided carbon monoxide(CO) and control of pre-explosive concentrations of natural gas by installing apartment (household) alarms.

These requirements do not apply to heating equipment with a sealed combustion chamber, in which combustion air is taken in and combustion products are removed through outer wall building.

Installation and installation of Ross boiler

The Ross AOGV floor-standing boiler is connected to the gas supply network through a gas filter. The tightness of the connection is checked using the soaping method. Prohibited use open flame to check the tightness of the gas circuit.

The device is installed on a fire-resistant base no closer than 0.5 m from combustible structures and no less than 0.1 m from non-combustible ones. Furniture and other flammable objects must not be placed closer than 0.5 m from the apparatus. The free space in front of the unit must be at least 1.25 m.

For normal operation The following devices, which are not included in the delivery package, must be installed in front of the device:

Water and gas purification filters;

Water softening device;

Voltage stabilizer (for volatile devices);

Device uninterrupted power supply(for areas where long-term power outages are possible) (for volatile devices).

All installed devices must be in good working order and function normally.

Connecting the Ross boiler to the chimney

Installation of a Ross AOGV boiler is permitted only if there is a chimney to discharge combustion products into it. The quality and efficiency of the device depends on what material and how the chimney is made. The cross-section of the chimney duct must be no less than the cross-section of the smoke outlet pipe.

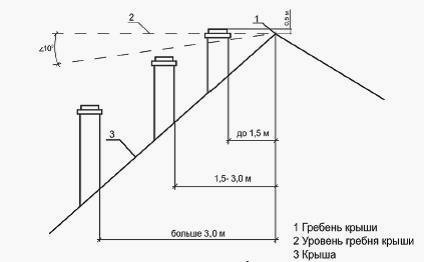

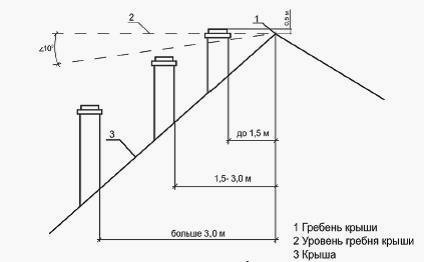

The height of the chimney above the roof is set depending on the distance to the roof ridge (Figure 3). If there are higher parts of buildings or trees near the chimney, then it should be installed above the boundary of the “wind pressure zone”.

The chimney channel must be strictly vertical, smooth, even, without turns or narrowings, dense, without cracks. The connection point of the device to the chimney pipe must be sealed.

Due to the fact that modern economical boilers Ross with high efficiency have low temperature weekend flue gases and operate in automatic intermittent (periodic) mode with a constant temperature difference, the chimney does not warm up well and aggressive condensation can form in it, which leads to low-temperature corrosion (erosion) of the chimney.

At insufficient thermal insulation chimney, in order to protect it from the harmful effects of condensation and destruction, you can use special inserts made of stainless acid-resistant steel or use special double-walled heat-insulated chimneys made of corrosion-resistant steel to remove combustion products.

Fig.3. Chimney placement

The chimney must ensure the removal of combustion products in all weather conditions. Before turning on the device and during its operation, it is necessary to check the presence of traction.

With normal draft, the match flame will be drawn into the combustion chamber and go out. To maintain economical and uninterrupted operation gas floor-standing boiler AOGV Ross, it is necessary to systematically clean the chimney and gas ducts of the device from soot and blockages.

During the initial inspection and cleaning of chimneys and ventilation ducts The following must be checked: compliance of materials, absence of blockages, density, serviceability and correct location of the head relative to the roof and structures located nearby, the presence of normal traction.

IN winter period At least once a month, home owners must inspect the chimney head to prevent freezing and blockage.

In a boiler with forced draft and closed camera Combustion air is supplied and exhausted by a fan through a coaxial chimney.

Coaxial chimney often called “pipe in pipe”. By inner tube In such a chimney, combustion products are removed to the street using a fan, and combustion air enters through the outside.

The single-circuit gas boiler Ross AOGV-16 is intended for heating premises equipped with water heating systems with water that has undergone water treatment. It is used for continuous operation.

The double-circuit unit additionally allows for heating water for household needs.

The operating principle of the boiler device is based on heating the coolant (water) located in the heat exchanger due to the combustion of gas in the combustion chamber of the device.

The AOGV-16 device runs on natural gas GOST 5542-87 with a pressure of 1274+100 Pa and automatically maintains the temperature set on the automation unit.

Fig.8. Construction of the Ross AOGV-16 gas boiler

The Ross-16 boiler consists of the following parts (Figure 8), described below.

Heat exchanger (1) is an all-welded cylindrical body, in the lower part of which there is a combustion chamber (6).

Pipes through which combustion products pass are welded inside the heat exchanger body. Turbulators (7) are installed in the pipes, increasing the efficiency of heat transfer from combustion products to the coolant (water).

A gas automation unit (2) is installed in the lower part of the front wall of the heat exchanger. The pipes (11) are used to connect the heat exchanger to the heating system.

A glass (9) is welded into the upper part of the heat exchanger for installing a gas valve thermocylinder, and a ring (8) for installing a thermometer (10).

The heat exchanger is installed on the frame (5). In double-circuit models, a tubular heat exchanger for the hot water supply circuit, made of a copper tube or stainless corrugated hose, is additionally mounted inside the heating circuit heat exchanger.

To connect the hot water supply circuit, pipes (25) are used.

Block gas automation(2) consists of a gas manifold (12) mounted on a bracket. The plate burners are mounted on the same bracket.

The gas manifold (12) is connected to a multifunctional gas valve (14), which regulates the gas supply to the Ross-16 boiler depending on the required operating conditions.

The gas manifold has an outlet in which nozzles (15) are installed. The gas supply from the gas pipeline to the gas valve (14) is carried out using an adapter (16).

Each time the apparatus (boiler) is turned on, the burners (13) are ignited by the constantly burning flame of the pilot burner (17).

Multifunctional gas valve(14) ensures that the apparatus (boiler) is turned on and the set operating mode is maintained together with the thermocouple (18), draft sensor (20), pilot burner (17) and piezoelectric element (19).

To access the gas valve, you must open the front door of the appliance.

The piezoelectric element (19) is placed directly on the gas valve (14).

The multifunctional gas valve allows you to:

Turn off both the main and ignition burners - the control knob is in the “dot” position;

Light the pilot burner;

Put the device (boiler) into operation.

Fig.9. Electrical circuit diagram of the Ross AOGV-16 boiler

A1 - Ignition burner

A2 - Gas valve EURO SIT 630

SK1 - Draft sensor – thermostat TK24-03-3-60°±3%

XS1, XS2 - Automotive terminal clamp

When the piezoelectric element button (19) is pressed, a spark is generated to ignite the pilot burner (17).

The combustion product collector (3) ends with a neck for connection to the chimney. A draft sensor (20) is installed on the combustion products collector (3).

To clean the heat exchanger, remove the casing cover of the Ross AOGV-16 boiler, then remove the combustion product collector (3).

The outer casing (4) consists of side walls firmly fixed to the frame, an opening front door and a removable top cover. To control the water heating temperature in the heat exchanger, a thermometer (10) is installed on the front panel.

The bed (5) is formed by two support brackets. The heat exchanger and casing are fixed to the frame. The frame has holes for threading handrails (22 mm in diameter) for moving and transporting the device.

An integral part of the frame is a reflector made of sheet steel (21), which significantly reduces thermal effect heat exchanger on the floor.

Ross AOGV floor-standing gas boilers are designed for both heating and water heating for domestic needs, and are designed to work in open and closed heating systems.

They are equipped with a steel welded tubular heat exchanger made of seamless pipes and 3 mm thick sheet steel, which ensures long-term and reliable operation of the boiler.

Fig.1. Type of boilers Ross

All welds are made using automatic welding machines. Specially designed turbulators are installed inside the heat exchanger pipes, which ensures the maximum possible heat transfer from gas combustion products to the coolant, rapid heating of the coolant and maximum efficiency - 93% of the AOGV boiler.

In the production of floor-standing boilers AOGV Ross, components from European manufacturers are used:

Gas automatics EVROSIT (Italy), MERTIK MAXITROL (Germany);

Expansion ELBI (Italy);

Circulation pumps WILO (Germany);

Burners Polidoro (Italy);

Heat exchangers IMAR and Giannoni (Italy),

Air vents, safety valves, thermostats, sensors, thermometers and pressure gauges Compini Corel, ICMA, T&G (Italy).

To maximize heat transfer from gas combustion products to the coolant, specially designed turbulators are installed inside the heat exchanger pipes. This ensures rapid heating of the coolant and achievement of maximum efficiency - 93% of the AOGV boiler.

The use of special plate burners provides uniform, and therefore higher quality, combustion of gas in the combustion chamber at various combustion modes and ensures effective heating of the entire surface of the heat exchanger.

Fig.2. The main elements of the floor-standing gas boiler AOGV Ross

This model of the device is distinguished by a universal chimney with the ability to regulate the draft break (in models with a power of up to 40 kW, combustion products are discharged vertically or horizontally). Models of Ross boilers with domestic water heating (DHW) use a copper water heater coil mounted in the main heat exchanger.

Selecting a room

The most optimal place to install a Ross gas boiler in a residential building or apartment is a separate, special small room of appropriate volume with a window, window or transom, chimney duct, supply and exhaust ventilation.

For a device with a power of up to 30 kW, installation in the kitchen is possible. According to current regulations, installation in bathrooms is not permitted.

The device with a thermal power of up to 30 kW can be installed in rooms with a volume of at least 7.5 m3, not intended for permanent occupancy of people (in auxiliary rooms), where the total duration of people's stay during the day does not exceed 4 hours.

The height of the room in which the boiler is installed must be at least 2.2 m. A device with a thermal power of 30 kW or more requires a separate special room with a volume of at least 13.5 m3.

The walls and floor of the room must be fire-resistant and must not be a source of dust. The best solution is to cover the walls and floor with ceramic tiles or coat them with oil paint.

It is unacceptable to carry out work that produces dust while the device is in operation. This leads to the deposition of contaminants on the burners, in the heat exchanger channels, on the turbolizers and to the automatic shutdown of the boiler or to such a decrease in the amount of air required for normal combustion that soot appears, which interferes with normal operation.

When installing a Ross floor-standing boiler in kitchens and premises of residential buildings, designed to operate on gas fuel with combustion products discharged into chimneys, it is necessary to provide for monitoring micro-concentrations of carbon monoxide (CO) and monitoring pre-explosive concentrations of natural gas by installing apartment (household) alarms.

These requirements do not apply to heating equipment with a sealed combustion chamber, in which combustion air is taken in and combustion products are removed through the outer wall of the building.

Installation and installation of Ross boiler

The Ross AOGV floor-standing boiler is connected to the gas supply network through a gas filter. The tightness of the connection is checked using the soaping method. It is prohibited to use an open flame to check the tightness of the gas circuit.

The device is installed on a fire-resistant base no closer than 0.5 m from combustible structures and no less than 0.1 m from non-combustible ones. Furniture and other flammable objects must not be placed closer than 0.5 m from the apparatus. The free space in front of the unit must be at least 1.25 m.

For normal operation, the following devices, which are not included in the delivery package, must be installed in front of the device:

Water and gas purification filters;

Water softening device;

Voltage stabilizer (for volatile devices);

Uninterruptible power supply device (for areas where long-term power outages are possible) (for volatile devices).

All installed devices must be in good working order and function normally.

Connecting a Ross boiler to a chimney

Installation of a Ross AOGV boiler is permitted only if there is a chimney to discharge combustion products into it. The quality and efficiency of the device depends on what material and how the chimney is made. The cross-section of the chimney duct must be no less than the cross-section of the smoke outlet pipe.

The height of the chimney above the roof is set depending on the distance to the roof ridge (Figure 3). If there are higher parts of buildings or trees near the chimney, then it should be installed above the boundary of the “wind pressure zone”.

The chimney channel must be strictly vertical, smooth, even, without turns or narrowings, dense, without cracks. The connection point of the device to the chimney pipe must be sealed.

Due to the fact that modern economical Ross boilers with high efficiency have a low temperature of the exhaust flue gases and operate in an automatic intermittent (periodic) mode with a constant temperature difference, the chimney does not warm up well and aggressive condensate can form in it, which leads to low-temperature corrosion ( erosion) of the chimney.

If the thermal insulation of the chimney is insufficient, in order to protect it from the harmful effects of condensation and destruction, you can use special inserts made of stainless acid-resistant steel or use special double-walled thermally insulated chimneys made of corrosion-resistant steel to remove combustion products.

Fig.3. Chimney placement

The chimney must ensure the removal of combustion products in all weather conditions. Before turning on the device and during its operation, it is necessary to check the presence of traction.

With normal draft, the match flame will be drawn into the combustion chamber and go out. To maintain economical and uninterrupted operation of the AOGV Ross gas floor-standing boiler, it is necessary to systematically clean the chimney and gas ducts of the device from soot and blockages.

During the initial inspection and cleaning of chimneys and ventilation ducts, the following must be checked: compliance of materials, absence of blockages, density, serviceability and correct location of the head relative to the roof and structures located nearby, the presence of normal draft.

In winter, at least once a month, home owners must inspect the chimney head to prevent it from freezing and blocking.

In a forced draft boiler with a closed combustion chamber, air is supplied and exhausted by a fan through a coaxial chimney.

The Ross company has a wide dealer network in Ukraine, Russia and Kazakhstan. Gas boilers are one of the priority areas company, therefore is given Special attention technical parameters and innovation in this area.

Specifications

Ross wall-mounted gas boilers are presented in several variations: with open or open combustion chambers closed types, single or double circuit and different power levels. They have a light weight (43-46 kg) and compact dimensions of 380 * 400 * 785 m. A special feature of Ross is the use of Italian parts during assembly, namely: Giannoni copper heat exchanger, burner, Polidoro ignition and flame control electrodes, SIT automatics. There is a device for protecting the heat exchanger from scale and an automatic air vent. The boiler is equipped with a German Wilo pump or Grundfos and a 7-liter expansion tank. Has protection against jamming and freezing. It is possible to connect an indoor or outdoor temperature controller. Efficiency level – 92%.

Specifications:

- Power: 18 and 24 kW.

- Heated area: 180-240 m2.

- Water consumption: 10-13 l/min.

- Gas consumption: 2.1-2.8 m3/h.

The Ross company also produces models of wall-mounted boilers together with Italian company G-20 of the same modifications as regular ones. A special feature of these models is the presence safety valve, additional heat exchanger (for double-circuit variations), expansion tank Zilmet for the accumulation of excess water. The control unit performs constant testing of the boiler operation and self-diagnosis. They are presented with dimensions of 340*400*750 m and a weight of 45-49 kg. They have a lower level of efficiency (90%), but greater power. Main characteristics:

- Power: 24, 28, 32 kW.

- Heated area: 240-320 m2.

- Water consumption: 13.6-18.4 l/min.

The extensive model range of the Ross series of floor-standing boilers allows you to choose the appropriate AOGV boiler

Ross floor-standing gas boilers are presented in the following classes:

- Premium (with steel heat exchanger). The cylindrical heat exchanger made of boiler steel allows for greater heat transfer and uniform distribution of water pressure. Equipped with a vertical chimney 1.5 m high. Can work for liquefied gas. Available in models from 8 to 21 kW, single- or double-circuit, which differ in the following parameters: heated area 80-200 m2, flow rate natural gas 0.93-2.3 m3/h, liquefied 0.68-1.7 kg/h, water consumption for dual-circuit models 3.5-5.5 l/min, efficiency 93%.

- Luxury (with steel heat exchanger). These positions have the ability to connect a vertical or horizontal chimney, and can also operate on liquefied gas. The series is represented by equipment with a power of 7-96 kW, single- or double-circuit. Main characteristics: heated area 70-960 m2, natural gas consumption 0.8-10.8 m3/h, liquefied gas 0.7-8.4 kg/h, water consumption for double-circuit - 4-18 l/min, efficiency 93 %. In addition, there are models with direct ignition. They are equipped with a controller, which makes it possible to save gas consumption, configure control from room thermostat, connect a turbo attachment to organize the forced removal of combustion products. They are characterized by high power (50-96 kW) and have the following parameters: heated area 500-960 m2, natural gas consumption 5.8-10.8 m3/h, liquefied gas 4.4-8.4 kg/h, water consumption for dual-circuit - 9-18 l/min, efficiency 93%.

- Floor-standing with cast iron heat exchanger. A feature of this class is the use of Italian components during assembly: an Imar heat exchanger made of cast iron, a Polidoro or Bray burner, a burner unit, piezo ignition and thermocouples, SIT automation, an Elbi expansion tank (in low-power models). You can connect a vertical or horizontal chimney to them (for models with a power of 70 kW or more - only a vertical one). Can also operate on liquefied gas. Technical characteristics: power 16-96 kW, heated area 160-960 m2, natural gas consumption 1.8-10.8 m3/h, liquefied gas 1.4-8.1 kg/h, efficiency 93%.

Advantages and disadvantages

Ross gas boilers have both advantages and disadvantages. The advantages include the following:

Italian details.

- Automatically maintains heat at a given level.

- Corrosion resistance, impact resistance.

- The safety thermostat turns off the boiler in the event of an emergency.

- Possibility of creating a non-volatile heating system.

- Possibility of operation on liquefied gas (for floor-standing equipment).

Main disadvantages

1. Too wide assortment, which makes it difficult to make a choice.

2. High price for a domestic manufacturer.

Reviews

Consumer reviews of Ross gas boilers are not always clear

The reviews about Ross studied by our experts are very ambiguous. Some consumers note the quality and sufficient level of reliability, which is achieved through the use of Italian components during assembly. There are positive reviews from users who have been using Ross gas boilers for several seasons. The company's floor-standing equipment is more in demand, while wall-mounted equipment is not of interest to customers.

Some users note a discrepancy with the declared power. It is also believed that European standards are not adapted to our conditions, which affects the quality of their work. Indicate the uneconomical nature of boilers with a cast iron heat exchanger. There are comments regarding the service; there are cases of long waits for delivery of parts to replace broken ones. Many point out the somewhat inflated price for Ukrainian-made boilers.

Price

The price level for boilers depends on the power and class of equipment.

— Wall: 3600-5300 UAH.

— Wall-mounted (joint production with G-20): 6200-12200 UAH.

— Floor-standing Premium: 2700-3900 UAH.

— Floor-standing Lux: 3900-14200 UAH.

— Floor-standing with cast iron heat exchanger: 4800-19000 UAH.

In comparison with boilers with similar parameters, for example, Danko, which are also produced in Ukraine, Ross equipment has higher prices, but does not benefit from other characteristics.

Ross boiler installation and flashing, video

Installation and operating instructions

Installation and startup is carried out by a specialist with the appropriate license. He also instructs consumers and explains the principles of operation of the equipment.

Attention: You cannot fill the heating system with water that has not undergone water treatment. It must comply with the requirements of GOST 2874-82. The system pressure should not exceed 3 bar.

When operating the boiler, you need to remember a few basic rules:

1. You cannot turn on the boiler if the heating system is not filled or not completely filled, this will lead to equipment breakdown.

2. When the boiler is operating with expansion tank, it is necessary to control the water level in it. It should not fall below a quarter.

3. Do not close the taps on all heating radiators; this will stop the water circulation.

4. If there is no draft, the boiler cannot be lit.

5. If the automation is broken, the burner is clogged, etc., the boiler cannot be used.

6. In case of equipment shutdown, it is necessary to turn off the gas valve.

7. It is prohibited to repair or disassemble the boiler yourself. This can only be done by a specialist.