Polypropylene pipes for cold and hot water supply. How to choose polypropylene pipes for water supply

Excellent replacement metal pipes steel products made of polymer material: polypropylene pipes for water supply are especially common. They are made from random polypropylene copolymer. With the help of these pipes it is possible to install a water supply system for both cold and cold water. hot water, without thinking at all about the integrity of the pipeline. The pipe material is capable of withstanding pressures that are considered standard for main networks, temperatures up to 95 degrees Celsius with a constant flow and up to 110 with short-term temperature fluctuations.

When pipes freeze, they also remain safe and sound: this is due to their ability to expand along with the frozen medium in them and return to their original state after thawing. Polypropylene water pipes are also suitable for supplying water heated to high temperatures from double-circuit boilers or boilers.

Types of polypropylene pipes

Polypropylene pipes can be one of three types:

- PN10– pipes used for transportation cold water;

- PN20– they can be used for hot and cold water pipelines.

Pro tip:

Pipes of types PN10 and PN20 tend to increase their linear dimensions as the temperature rises. Therefore, their installation must be accompanied by a device various kinds compensators and sliding supports.

- Reinforced polypropylene pipes used in heating systems Oh. Their elongation when reaching a temperature of 60 degrees Celsius is significantly less than the elongation of similar pipes of previous types.

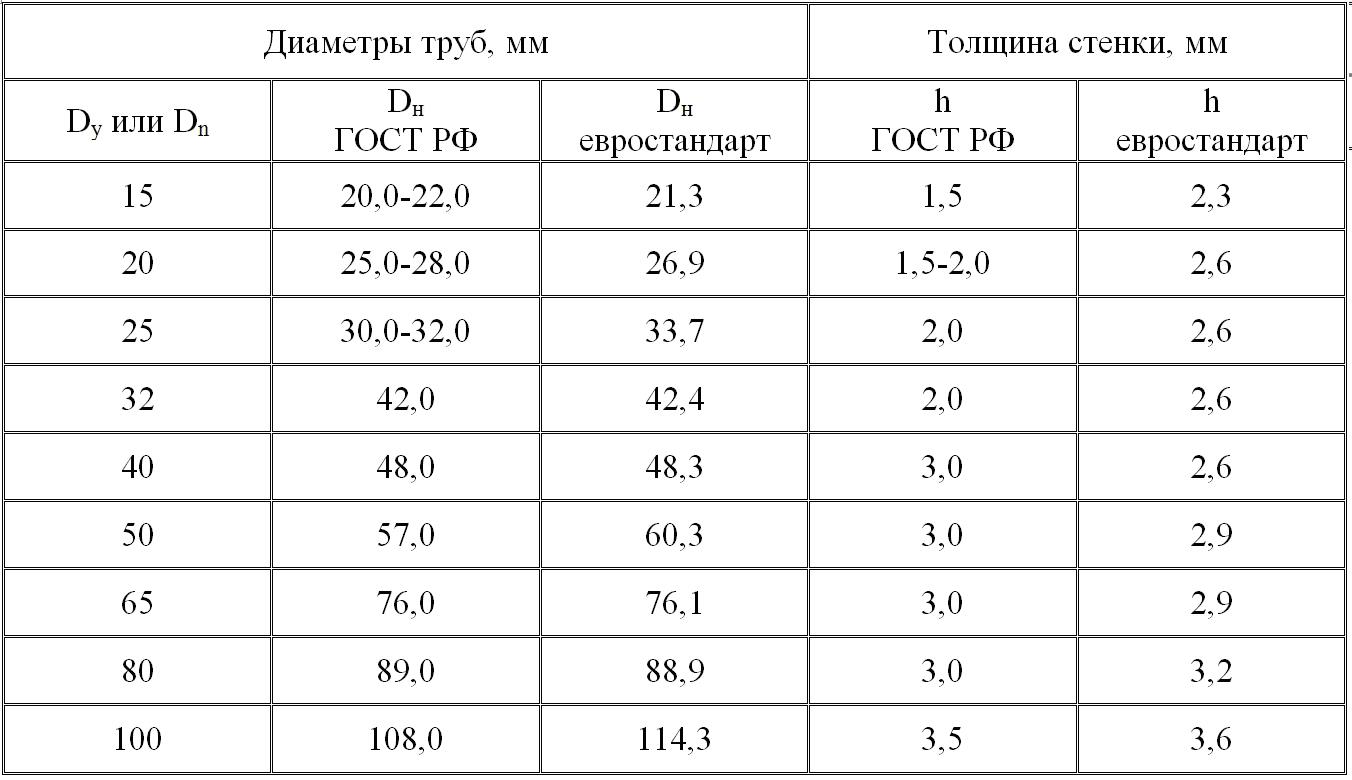

PP pipe diameters

When it comes to home plumbing, the most common diameters are 20, 25 and 32 millimeters. You need to choose them based on the diameters of the nozzles of your soldering iron. There are diameters of 40, 50, 63, 75, 90 millimeters, as well as the common 110 mm, but standard type soldering irons may not have such attachments.

Pro tip:

It is best to first purchase a soldering iron, and only then select suitable diameter heating or water pipes based on the diameters of the available nozzles.

How to install a water supply system

Installation of a water supply system from polypropylene pipes is carried out when all the necessary parameters have been calculated and the equipment for the work has been selected. The work is carried out in the following sequence:

- The old pipeline is being dismantled.

- Based on the diagram, pipe sections of the required length are cut.

- If polymer pipes are connected to steel pipes, connecting couplings are mounted at the ends of the steel pipes.

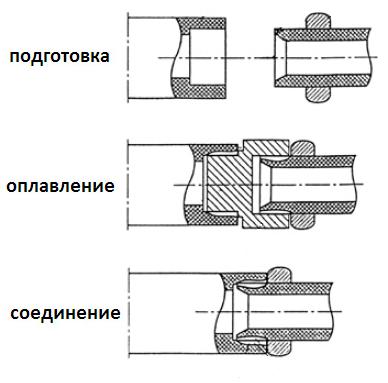

- Elements of fittings and pipes (couplings, tees) are welded using the polyfusion method.

- Shut-off valves are installed.

- Channels are cut into the walls for laying pipes or holes for fastening are simply punched.

- Polypropylene pipes for water supply are finally installed.

Installation of polypropylene pipes

Features of the installation process

Polypropylene pipes with metal elements networks, such as faucets, steel pipes, filters or meters, are connected using fittings equipped with metal inserts. When installation takes place, threaded connections wind the fum tape, and when clamping, the tape edge should be directed towards the threaded clamp.

Pro tip:

Too much thick layer not needed, just make two turns. To avoid damaging the fitting and tearing the metal insert out of its body, do not over-tighten the threads.

In order to organize a bend, use corner fittings, or heat the pipe to 140 degrees using a hair dryer. It must be borne in mind that polypropylene ignites upon contact with fire, the ignition temperature is 350 degrees.

The expansion of polypropylene fluctuates depending on the temperature. Therefore, polypropylene pipes for hot water supply or heating provide a free distance of about a centimeter near tees or bends for thermal expansion.

A groove is made in the wall and, using tubular-type insulation, a gap is left around the pipe. Compound polyethylene pipes performed by soldering with couplings.

Polypropylene pipes used in heating or hot water supply have a metal braid inside. This manufacturing method makes it possible to reduce their thermal expansion by up to five times. Polypropylene pipes for cold water supply do not need heat compensators at all.

In principle, polypropylene pipes can easily withstand freezing, but shut-off valves and metal pipeline elements do not allow it. In this regard, you should not neglect seasonal drainage of water.

Soldering technology for polypropylene pipes

So, the soldering technology is as follows:

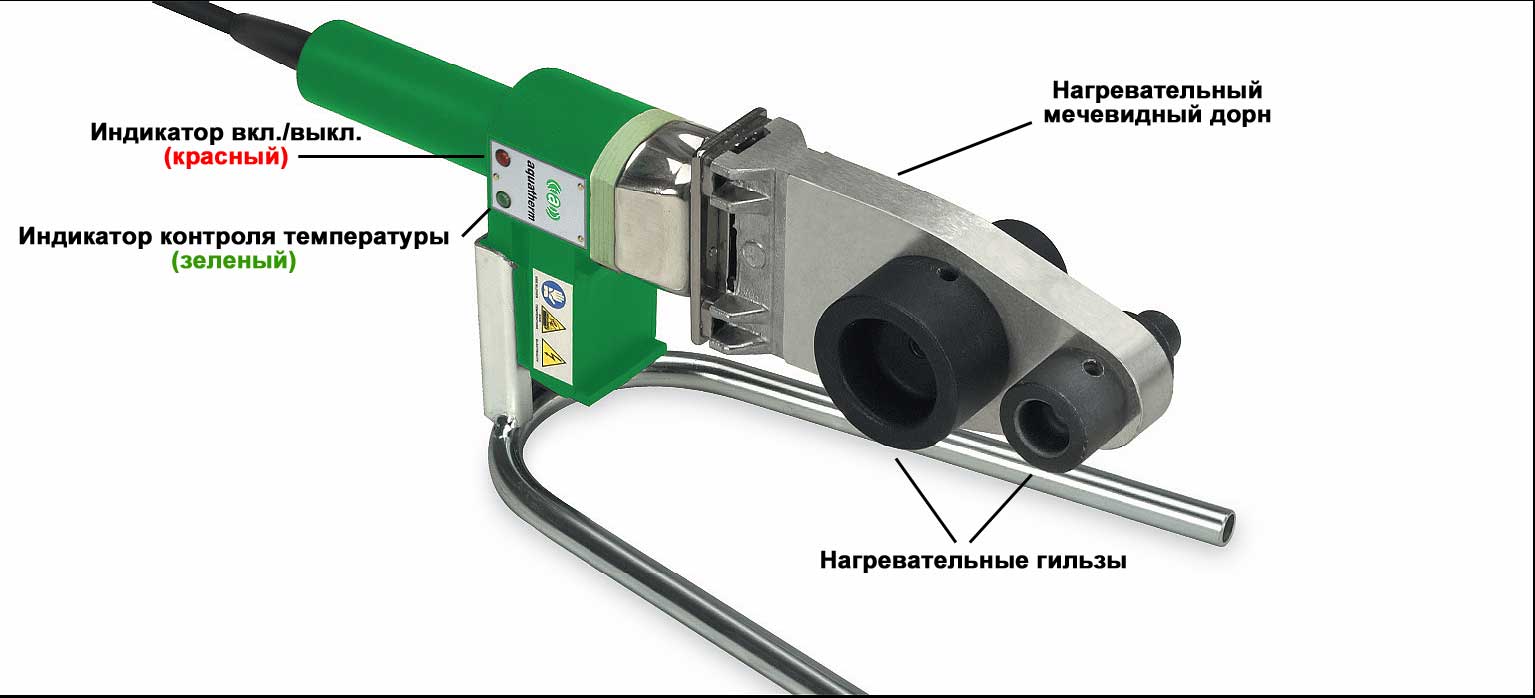

- Soldering begins by installing nozzles of the required diameter in the soldering iron. Position them based on your convenience, because the location of the heating nozzles does not matter. Cleaning the nozzles should only be done with a wooden scraper, as they are coated with a non-stick Teflon layer.

- We set the temperature on the soldering iron to 260 degrees. It will heat up to this temperature in 7 minutes and will then maintain it at the same level.

- Cut the pipe to the required length at a right angle. Then, simultaneously, both the pipe and the fittings must be put on the preheated nozzles.

- The larger the diameter of polypropylene water supply pipes, the longer the pipe will take to warm up. The pipe is placed in the nozzle and heated from the outside, the fitting is put on the steam nozzle and heated from the inside.

- After the parts have warmed up, they are removed, inserted into each other and fixed in this position for a couple of minutes. The fixation time must be maintained without turning or shifting.

If the pipes are not fixed correctly, they must be cut off and soldered again. Otherwise, the technology for connecting them is unlikely to cause any difficulties. It is worth noting that the technology is slightly different.

For DHW needs? Does the installation of a polypropylene hot water supply have any special features? Today we will try to find answers to these questions.

Advantages

The main advantage of polypropylene over other pipes is its very affordable price. Here are a few specific examples from the price list of the Leroy Merlin online store:

- Unreinforced pipe PN 20 domestic production, designed for hot water supply needs, with a diameter of 20 mm will cost only 23 rubles per linear meter;

- A fiber-reinforced pipe of the same diameter costs 40 rubles per meter, and one reinforced with aluminum foil costs 57 rubles;

- A coupling for connecting 20 mm pipes will delight the buyer with a price tag of only 2.8 rubles, a tee of the same size costs 5 rubles 70 kopecks.

Please note: the closest competitor in terms of pipe prices is metal-plastic. With the same outer diameter as polypropylene, it is only slightly more expensive than an aluminum-reinforced hot water pipe. However, fittings for metal-plastic (compression and for crimping with a sleeve) are 10-15 times more expensive than polypropylene ones, which on the scale of a water supply creates a more than noticeable difference in price.

Fittings for polypropylene pipelines are structurally simple and therefore extremely cheap

However, low cost would not have played a decisive role if not for other properties of polypropylene:

- Pipes are durable. In hot water they last at least 25 years, in cold water - even from 50. Compare their resource, for example, with the service life of black steel in water supply (15 years);

- The smooth inner surface of polypropylene pipes does not become overgrown with deposits. Therefore, the throughput of the water pipeline does not decrease and its hydraulic resistance does not increase over time;

For comparison: when designing steel water pipelines, it is necessary to take into account the increase in the roughness coefficient during operation, deliberately overestimating their diameter.

- Welded connections with fittings are maintenance-free. They are stronger than a solid pipe and can be installed in ties and grooves;

- The appearance of the pipeline is preserved for decades. It does not need to be periodically painted or cleaned of rust;

- Polypropylene is a dielectric, which eliminates electric shock when, for example, neighbors try to save electricity by grounding electrical appliances to the water supply;

- It has low thermal conductivity. This means that the hot water in the pipes will cool more slowly, and the risers and cold water supply lines will not become covered with condensation in the summer heat.

Areas of use

Is it always possible to use polypropylene pipes for hot water supply?

Prohibited

Here standard specifications polypropylene pipe intended for domestic hot water needs.

- Working pressure - up to 20-25 atmospheres;

- Operating temperature - up to 95 degrees with the possibility of a short-term increase to 120°C.

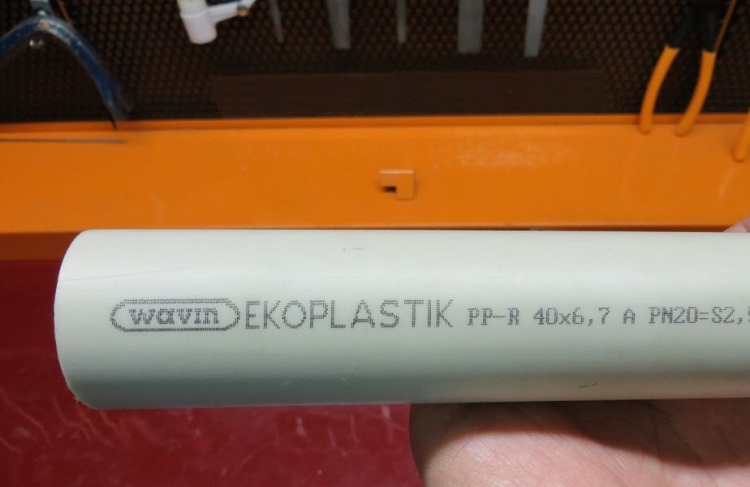

The characteristics of the pipe are usually indicated in its marking

There is a caveat: the given operating pressure values are valid for a temperature of +20°C. At a maximum of 90 degrees it drops to 8-9 kgf/cm2. The pipe service life of 25-30 years also remains relevant only within a strictly defined range of operating temperatures - up to +70°C.

Formally, the given characteristics fit into the typical parameters of both autonomous and centralized hot water supply (the latter is characterized by a water temperature of 60-75 degrees at a pressure of 3-7 atmospheres).

However, everything is smooth only as long as the DHW system apartment building works normally. Here are some of the most common force majeure situations:

- DHW operation from the elevator unit supply during the peak of cold weather. The supply temperature, according to the temperature schedule of the heating main, can reach 150 degrees. When the supply temperature exceeds 80 degrees, the hot water supply must switch to the return water supply, however, the forgetfulness of plumbers can play a bad joke on the owner of the polypropylene water supply;

![]()

- During testing of heating mains and heating systems for temperature, hot water must be turned off. However, a faulty valve or human factor again, they can lead to water superheated to 150°C flowing into the pipes;

- Finally, the fall of the valve cheeks or the rapid filling of the hot water circuit can lead to water hammer - an instant increase in pressure at the front of the incompressible fluid flow to 30 atmospheres or more. Water hammer lasts a fraction of a second, but this time is often enough to destroy a water supply system.

Conclusion: it is dangerous to use polypropylene for central hot water supply with water supplied directly from the heating main through the elevator tie-in (the so-called open system heat supply).

Allowed

Polypropylene can be unconditionally used in:

- (with hot water preparation in boilers and instantaneous water heaters). The water pressure in them is always equal to the pressure in the cold water system and falls within the range of 1.5 - 5 kgf/cm (up to 6-7 atmospheres if there is a powerful pump in the house), and the temperature is limited by the thermostat of the heating device;

- Centralized hot water supply systems in houses with closed circuit heat supply (without taking water from heating mains). In them, hot water is heated due to heat exchange with the coolant, while DHW circuits and heating is not provided. Accordingly, water hammer and temperature surges in the heating main will not have any effect on the operating parameters of the internal water supply system.

Reinforcement

It is executed:

| Image | Reinforcement type |

|

|

Aluminum foil glued between two layers of polypropylene. |

|

|

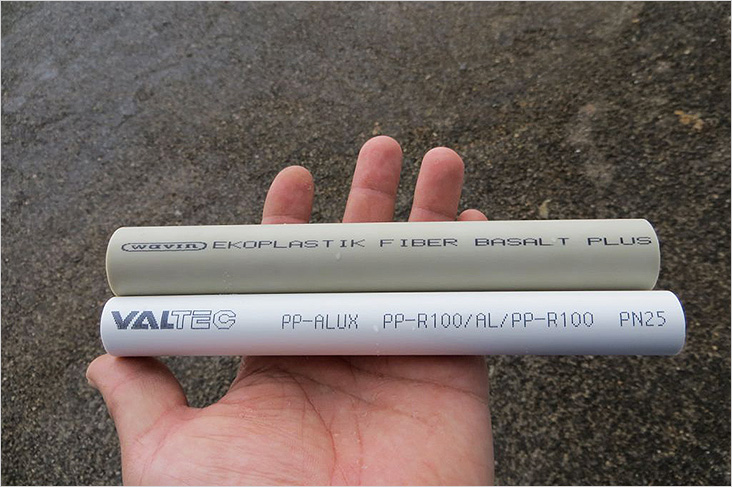

Fiber (chopped mineral fiber) included in the middle layer of polymer in the pipe structure |

Useful: three layers of fiber-reinforced pipe are formed on one extruder and reliably fused to each other due to the production technology itself. In the production of pipes with aluminum reinforcement, the quality of the product greatly depends on the quality of the glue used and adherence to the technology.

It is believed that the task of reinforcement is to ensure maximum tensile strength of the pipe. And indeed, the maximum operating pressure 25 atmospheres typical for reinforced pipes; however, the functions of the reinforcing layer do not end there.

One of the features of polypropylene is that it is extremely high coefficient elongation when heated. When submitting to polypropylene water supply with room temperature water heated to 70 degrees, each linear meter will lengthen by 6.5 mm (versus, for example, 0.5 mm for a steel pipeline).

Reinforcement significantly reduces dimensional change when heated:

- Fiber reduces elongation to 3.1 mm;

- Aluminum foil is even more effective: with it, polypropylene pipes reinforced for hot water supply elongate by only 1.5 mm/m when heated to 50°C.

Plumbing assembly

The method of installing polypropylene pipes is low-temperature soldering. The surfaces of the pipe and fitting are melted upon contact with the Teflon nozzle of the soldering iron and are aligned with each other. Thanks to molecular diffusion, the plastic of the parts is fused into a single whole, and after cooling, the connection is ready for operational loads.

How to solder

How long does it take to heat the pipe and fitting with a soldering iron? Comprehensive instructions are contained in the appendix to SNIP 2.04.01-85, which describes correct installation polypropylene.

| Outer diameter of water supply, mm | Heating, sec | Connection time, sec |

| 16 | 5 | 4 |

| 20 | ||

| 25 | 7 | |

| 32 | 8 | 6 |

| 40 | 12 | |

| 50 | 18 |

Do-it-yourself plumbing soldering has several subtleties.

- When combining a pipe and fitting with a soldering iron nozzle and when connecting parts to each other, they must not be rotated around the longitudinal axis. When turning, waves will remain on the surface of the plastic, which will reduce the quality of the connection, leaving cavities inside the fitting;

- Soldering can begin no less than five minutes after turning on the soldering iron;

- The connection can be subjected to operational loads only after complete cooling (2 minutes for diameters 16-25 mm and 4 minutes for diameters 32-50 mm);

- Polypropylene hot water supply pipes reinforced with aluminum need to be stripped before welding with a fitting. A shaver or trimmer (these tools differ only in the position of the knives) removes the outer or inner layer foil, allowing welding to combine the fitting with the inner polymer shell of the pipe.

Polypropylene for last years has become probably the most popular material for installing water supply systems in city apartments and private houses. Its combination of durability with reasonable cost has made it a hit among plumbing installers. But do you know everything about this material?

Characteristics

Temperature

- The temperature at which polypropylene becomes plastic is approximately 140 degrees Celsius. However, manufacturers limit the maximum operating temperature of pipes to 95 and even 90C.

The fact is that the strength of plastic drops noticeably when heated even before the phase transition begins. The temperature limit allows the pipes to withstand the normal pressure in the water supply systems.

In addition, manufacturers are quite reasonably afraid of lawsuits: if, with the declared temperature conditions up to 110 degrees, the tightness of the pipeline will be compromised at, say, 108C, the company will have difficulty clearing its reputation. The lower the declared temperature, the greater the actual safety margin.

![]()

Pressure

- The marking of pipes indicates the pressure that they can withstand at a temperature of +20C.

I have already mentioned that when heated, the strength of the polymer decreases. If at room temperature a pipe marked PN20 can withstand a pressure of 20 kgf/cm2 without destruction, then when heated to its maximum +90, the maximum operating pressure will drop to 7 - 8 atmospheres.

PN20 in the marking is the maximum operating pressure at room temperature.

By the way, this is why I strongly advise against using PP pipes for distributing hot water in houses with a centralized hot water supply from an elevator unit. Why?

Arguments are at your service:

- The standard pressure on the hot water supply when supplied from the supply line is up to 8 kgf/cm2 at temperatures up to 90 degrees, which in itself is already dangerously close to the critical values for pipes. With a further increase in the supply temperature, in accordance with the temperature schedule, the DHW must switch to return. In theory.

However, if for any reason the mechanic fails to transfer the hot water supply to the house to the return pipeline of the elevator unit, the temperature of the hot water can reach 120 - 130 degrees during the peak of cold weather. From the thermal power plant the water comes even hotter - up to 150 C, but some of the heat is lost during transportation to the apartment.

What will happen at this temperature and operating pressure of 6 - 8 kgf/cm2 with any polymer pipes is not difficult to guess. IN best case scenario they will rapidly degrade and instead of 50 years they will last 3-4 years; in the worst case, the riser will burst and the apartment with all your things will be flooded with dirty boiling water;

- Once a year, the heating main is tested for density: the pressure in it increases to 12 - 25 atmospheres. During this time, housing and communal services workers must close the inlet valves of the elevator units and open the discharges into them. In theory. Should I explain further?

- Another type of test is temperature. During testing, the supply is heated to the maximum according to the temperature schedule of +150 degrees; Water does not boil only due to increased pressure. The hot water supply must be turned off during testing. In theory. I think the dear reader himself understands that in real world the human factor has not been canceled;

- Finally, don’t forget about water hammer. If, after turning off the hot water, an unqualified mechanic fast opens the hot water supply valve, water will begin to rapidly fill the drainage tank (horizontal water supply) and risers. If there are open taps in the circuit, air will be forced out through them. At the moment when practically incompressible water fills everything DHW system, the pressure at the flow front will briefly increase to 25 - 30 atmospheres (inertia has not gone away!). Guess whether the PP pipe can withstand such a load?

What about in private houses? No restrictions. Modern boilers and boilers allow you to maintain a stable and safe water temperature; Water hammers are also impossible with minimal adequacy of the home owner.

Reinforcement

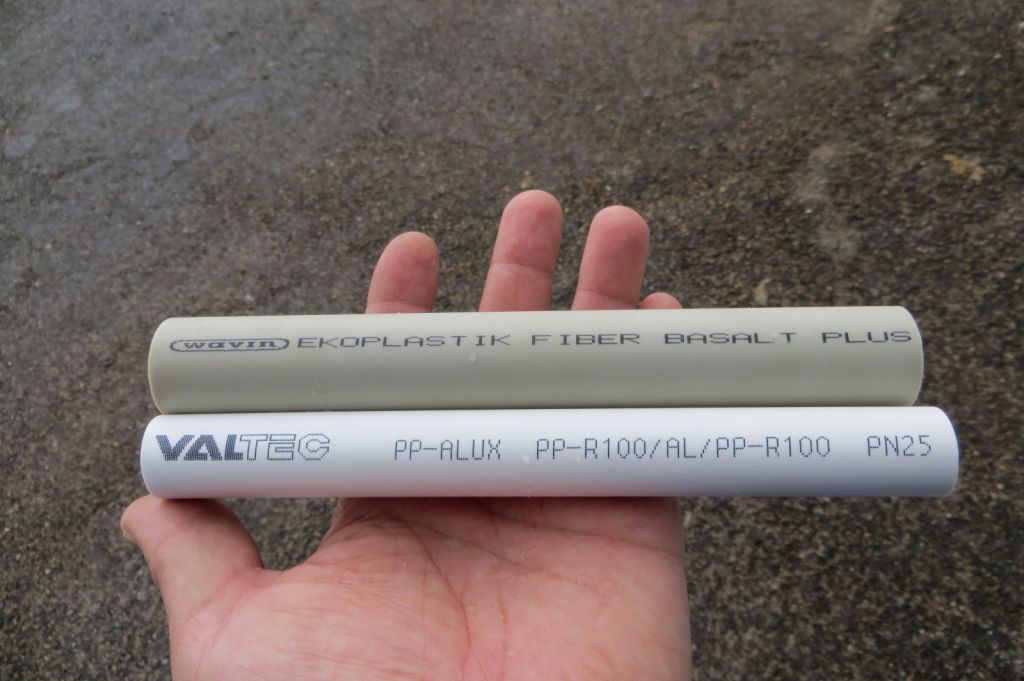

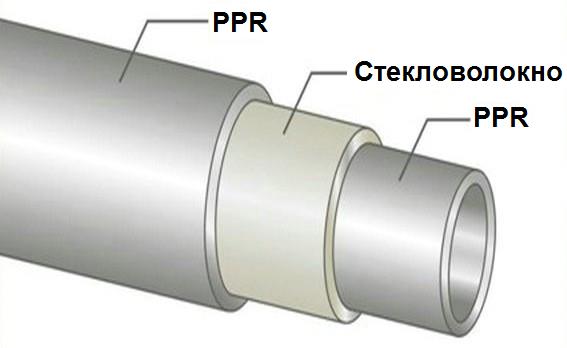

- Two different materials are used to reinforce polypropylene - aluminum and chopped fiberglass.

Aluminum foil approximately 0.5 millimeters thick is glued between two layers of polypropylene. It can be located either in the middle of the wall thickness or closer to its outer side.

The technology for the production of fiber-reinforced pipes is noticeably different: all layers of the pipe (including those consisting of polymer mixed with fiber) are forced through an extruder simultaneously and welded into a single whole. As a result, the strength of the connection between the layers of the pipe practically does not differ from the strength of each layer.

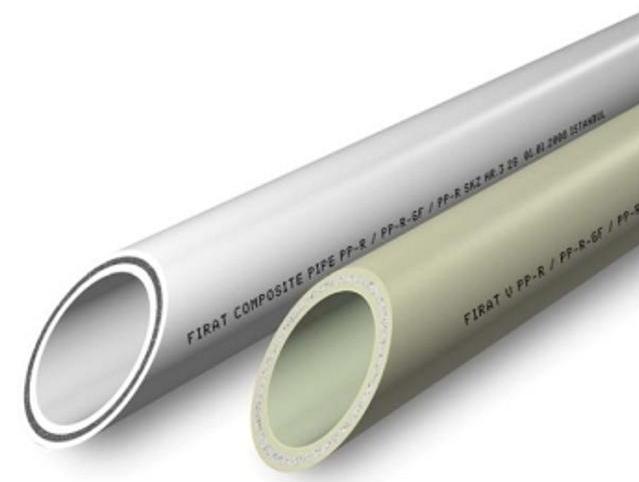

The pipe is reinforced with fiber on top and aluminum on the bottom.

Heat Elongation

- Polypropylene pipes for water supply have the highest coefficient of elongation when heated among all materials used in the installation of water supply systems.

If you heat a pipe without reinforcement from 20 to 70 degrees, each meter of it will become 6 - 7.5 millimeters longer. That is why reinforced pipes are preferred for hot water supply.

I'll give you some interesting numbers:

- Fiber reinforcement reduces the elongation of the pipe when heated by 50 degrees to 3.1 mm per meter;

- Aluminum foil reduces this value to 1.5 mm/m;

- When heated by 50 degrees, a steel pipe elongates by only 0.5 mm per linear meter.

- Installationrisers and hot water supply connections must be carried out taking into account the fact thatlengthpipes will expand when heated.

For this purpose, compensators are installed on risers - ring or U-shaped bends. The riser is fixed with clamps that do not prevent the lengthening pipe from sliding into them.

The eyeliners are also fixed movably; It is better to leave bends at the points where plumbing fixtures are connected without fixing them at all.

When laying liners in grooves, a gap of 0.5 - 1 cm wide is always left at the ends of the grooves, allowing the pipe to lengthen.

Is it necessary to equip polypropylene pipes for cold water supply with expansion joints?

To answer this question, let's do a simple calculation.

In winter, the temperature of cold water is slightly above freezing point and is approximately +5C. In summer, at the peak of the heat, it can increase to +25C. The temperature delta will be 20 degrees.

Elongation when heated at such a temperature delta is approximately 2.5 mm per linear meter; with a riser length between the ceilings of 2.5 meters, its straight section will lengthen by 6.25 mm. This is not much, but it is quite enough for the pipe to noticeably bend or go “wave”.

The conclusion is obvious: it is advisable to install compensators on both cold and hot water.

Choice

- If you are attractedpricepipes from a little-known manufacturer, it is better to take a closer look at products with fiber reinforcement.

The reason is quite obvious: during their production, technological violations have less impact on the quality of the product. In the case of aluminum reinforcement, incorrect technology for gluing layers or poor-quality glue can lead to the fact that the pipe begins to delaminate after a year or two of operation.

- Please note that, unlike steel pipes, polypropylene pipes are marked with an outer diameter.

Steel water and gas pipe is marked with a so-called nominal bore, which indicates the possibility of connection to a pipe thread of the appropriate size and is approximately equal to the internal diameter. So, a DN 25 pipe has an internal diameter approximately equal to 25 millimeters.

But a 25 mm polypropylene pipe with a wall thickness of 4.2 mm (as, for example, Ekoplastik PPR S 2.5 / PN 20 / SDR 6) will have an internal diameter of only 25 - (4.5 * 2) = 16 millimeters. Its capacity relative to steel will be only (16/25)^2=0.4096, or 41%.

The conclusion is obvious: the diameters of polypropylene pipes installed to replace steel pipes must be at least one step larger.

Polypropylene, however, has important advantage before steel. It maintains a constant internal diameter, since it does not become overgrown with rust and deposits, and the internal walls remain perfectly smooth throughout the entire period of operation of the pipeline.

Compound

- The most common way in which polypropylene pipes for water supply are connected is socket welding using a low-temperature soldering iron.

The instructions for assembling the connection with your own hands are not complicated:

- Soldering iron with fixed on it heating element using a nozzle of the appropriate size is heated to operating temperature. On an instrument with a thermostat, you need to set it to 240 degrees;

- The outer chamfer is removed from the pipe. The internal chamfer has already been removed by their manufacturer;

- The pipe is inserted into the soldering iron nozzle, and the socket of the fitting is put on it from the opposite side of the heating element;

- After the surfaces have melted, the pipe and fitting are combined in a smooth forward motion. You cannot rotate the pipe while inserting it into the fitting - the melted surfaces will move in waves, which will sharply reduce the strength of the connection. The fitting and pipe are fixed motionless while the plastic melt sets, after which you can move on to the next connection.

The time it takes a soldering iron to heat the parts to the melting temperature quite predictably depends on their diameter:

Soldering pipes has one more subtlety. If they are reinforced with aluminum, then the reinforcing layer must be completely removed from the welding field.

The fact is that aluminum foil is gradually destroyed by water and the electrochemical processes that occur in it. Destruction of the foil layer will lead to delamination of the pipe and a critical drop in its strength. However, it is enough to remove the foil from under the fitting and the problem is solved.

For this purpose, use one of two tools:

- A shaver uses a pair of knives to remove the outer reinforcing layer;

- The trimmer cuts out the first few millimeters of reinforcement placed in the middle of the wall thickness.

Both tools come in either hand-held or drill or hammer attachment form.

- With polypropylene, both shut-off valve elements with socket fittings for welding and conventional threaded taps and valves can be used.

They are installed through adapters from polypropylene to pipe threads. Thread sealing is carried out sanitary flax with any impregnation quick-drying paint or silicone sealant; Instead of flax, you can just as successfully use a polymer thread with Tangit Unilok silicone or its analogues.

In my opinion, installing shut-off valves on threads with American threads is much more practical. It will allow you to replace the faucet, if necessary, without cutting it out along with a piece of water supply.

Conclusion

I hope that I was able to replenish the knowledge of the respected reader in the field of installation of water supply systems. As usual, Additional materials can be learned by watching the video in this article. I would appreciate your comments and additions. Good luck, comrades!

Currently, polypropylene pipes for cold and hot water supply have become widely popular in home wiring.

Among other products, they stand out for their durability, low friction, strength of connections, decorativeness and low price. They replaced steel ones in our apartments. Indeed, it is quite difficult to say whether it is advisable to install a steel pipe instead of a plastic one.

Along with this, polypropylene pipes have different designs, different diameters and even, different materials manufacturing, as their markings may indicate.

General characteristics of polypropylene pipes for water supply

These products for water supply are usually made white. By design, they can be reinforced or non-reinforced. All pp pipes have a significant temperature coefficient of expansion, which distinguishes them.

At the same time, reinforced ones have a temperature coefficient of expansion that is several times lower than that of non-reinforced ones, therefore non-reinforced ones are used for cold water supply, while reinforced ones are considered universal.

Polypropylene pipes are considered durable and are predicted to last for decades. They are not afraid of corrosion, stray currents, and have a significant mechanical strength and are neutral to many aggressive environments. They are connected to other elements of the pipeline.

The connection turns out to be monolithic and is almost the same in strength as the pipe itself. To transition to pipes made of other materials, composite fittings (from two or more materials) are made.

In the event of a fire, polypropylene can cause you a number of unpleasant moments. But nothing in our life is perfect.

Products can be reinforced with fiberglass, solid aluminum or perforated aluminum. The reinforcing layer is located between two layers of polypropylene, that is, it is a pipe with a triple structure. In addition, regarding aluminum there is such a nuance, where exactly the reinforcing layer goes, in the middle, or closer to the edge.

This is important during installation, since the installation of polypropylene pipes with an aluminum reinforcing layer requires the removal of aluminum at the joint. However, the removal method will be different.

As for products with fiberglass, they do not require any additional preliminary preparation except that the cut must be perpendicular.

Since polypropylene pipes have different design features, then they are marked accordingly. Let us give examples of it, showing which one is reinforced and with what:

- PPR 20mm “Aquatechnic” PN 16 – no reinforcement;

- PPR 20mm (PPR-GF-PPR) SDR6/PN25 – with fiberglass;

- VALTEC PP-FIBER PN20 with fiberglass.

Using this example, we will look at what kind of markings we have. It is clear that they contain the name of the manufacturer “Akvatechnik” or “Valtek”.

PPR marking denotes the type of polypropylene, there are only 3-4 of them, and this designation indicates the strength characteristics of the material and the purpose of the pipe, which is discussed below. PP means polypropylene, without specification. The numbers following them indicate the internal diameter in millimeters.

That is, the pipe is reinforced, in this case with fiberglass. The word “Fiber” in the PP-FIBER marking also speaks about fiberglass reinforcement.

Markings are quite common PN, it talks about the pressure for which the pipe is designed. If this marking is followed by the number 20, then it is designed for a pressure of 2 MPa; if 16, then it is designed for 1.6 MPa; if 25, then by 2.5 MPa and so on by analogy.

Marking by material of manufacture and purpose

According to their intended purpose, polypropylene pipes are conventionally divided into the following types:

- intended for ventilation and cold water supply, are marked PPH;

- intended for cold and hot water supply – PPB;

- intended for heating systems, in other words, universal, are marked PPR.

There is also the PPRC marking, which also indicates versatility.

In addition, some sources claim that pipes marked PN25 will be universal, and PN16 are suitable for hot and cold water supply, PN10 are suitable only for cold water supply.

Installation of cold and hot water supply

Polypropylene, unlike steel, has a fairly large expansion coefficient, so during operation, even within small apartment, it can lengthen and shorten by several millimeters in length. It is clear that the installation of such a system should not be rigid.

If polypropylene pipes are mounted on top of the wall, then the fasteners are placed quite rarely, or they make it possible to move it along the axis. In addition, there may be a bend in the pipeline. A specially made compensator in the form of a loop is also sold.

In cases where cold and hot water supply is installed inside the wall, in a groove, during work, you need to think about how access to the main line will be achieved in the event of an emergency.

It is also necessary to organize empty space around the pipeline for thermal expansion, and the diameter of the groove should be somewhere around 70% larger diameter pipeline. And to fix the pipeline, soft inserts are inserted in some places.

For the same purpose of combating the elongation and movement of the heating riser, in the ceilings it is necessary to install a coupling around the pipe and fill the gap with soft material.

As you can see, installation of cold and hot water supply is not so simple. However, in most of our apartments, even new buildings, you don’t have to think about these little things.

Polypropylene in heating

Polypropylene gives more reliable connection, rather than metal-plastic, however, it almost does not bend and has fairly good thermal insulation, so it is not used in a heated floor system.

But polypropylene is quite suitable for use in risers and heating distribution. Of course, heat transfer to an apartment compared to steel pipe yours will decrease, but let's hope for the quality of your batteries.

Storage and operation of polypropylene pipes for cold and hot water supply

These products are durable and are not afraid of aggressive environments, are not afraid of corrosion, but due to temperature changes, the pipeline can expand (at the same time it can come into contact with external environment– rest against a beam or other fasteners) and bend, which affects its durability. That is why the rules for its installation were discussed above.

Market polymer materials is growing every day. A significant sector of the total volume of products presented is occupied by pipeline systems. The range of their applications is very wide. Having studied the types of polypropylene pipes for water supply, the properties of the material, implement in the future right choice it will be much easier.

Characteristics of polypropylene pipes

When planning the installation of a water supply system, close attention should be paid to the properties of the material used. What are the main characteristics of polypropylene pipes? Among the advantages, the following features are noted:

- Not exposed to corrosive processes. This helps maintain the quality of the product for a long time.

- Resistance to biochemical aggressive environment.

- Reliability during operation winter frosts. There are no breaks in the elements of polypropylene pipes made of plastic.

- High quality insulation noise and vibration. The movement of water in polypropylene pipes is almost invisible to others.

- When used in hot water supply, heat savings range from 10-20% relative to the operation of metal products.

- Installation does not require significant financial costs, and the connections are highly reliable.

- There is practically no loss of pressure.

- A wide range of fittings allows installation of water supply of any configuration.

- Environmental safety of the material.

Subject to the purchase of high-quality polypropylene pipes and components for them, compliance technological processes during installation of water supply and correct operation, the service life of the products exceeds 50 years.

Product marking

The use of polypropylene pipes in various fields economic activity necessitates the need to familiarize yourself with their labeling for clear orientation in a wide range of products. Product classification includes several parameters. Based on the feedstock, polypropylene pipes are divided into four types:

- PRN pipes are based on homopolypropylene, they differ high strength. Scope of application: cold water supply, industrial pipelines, ventilation systems.

- The block copolymer is the starting material for pipes of the second type RRV. The scope of application is similar to the first type; in addition, they are used in underfloor heating systems.

- The abbreviation PPR indicates that it belongs to the most common third type. The use of random copolymer in the production of products ensures the possibility of operation in cold and hot water supply, during the installation of heated floors and water heating.

- The main feature of products marked PPs is that they are difficult to ignite and are characterized by stability when exposed to temperatures up to +95 o C.

Warning ! The maximum temperature for long-term exposure to polypropylene pipes of the third type for hot water supply is 70°C; exceeding the level is allowed for a short period of time.

Color range of products:

- white;

- gray;

- green;

- black.

The first three types have almost identical characteristics; black color indicates additional protection against ultraviolet radiation. Polypropylene pipes are single-layer and multi-layer. When reinforcing multilayer products, aluminum foil or fiberglass is used.

After the manufacturer, the first letters in the marking determine the material from which the pipe is made. The following numbers indicate the outer diameter of the pipe, the range is from 10 to 1200 mm, and minimum thickness walls. The PN symbol indicates the nominal pressure value; the optimal value for long-term operation in a water supply system varies between 10-25 bar.

Advice ! Remember the rule: the wall thickness of a polypropylene pipe should increase in proportion to the value of the nominal pressure.

In addition to basic information, the products indicate compliance with technical regulations, date of manufacture and other useful information.

Properties of reinforced pipes

Along with multiple advantages, the operation of polypropylene is associated with certain difficulties. What are they? The resistance of the material to high temperatures is very low: +140 o C is enough for softening, the guaranteed operating temperature without damage is +95 o C, depending on the source raw material, this figure may be even lower. With cumulative impact high temperature and pressure, the stability of polypropylene is significantly reduced than when each factor is influenced separately. This leads to deformation of polypropylene products. Reinforcement will help to avoid problems with hot water supply, creating a kind of frame that prevents the lengthening and expansion of the pipe. Currently, manufacturers offer two options for reinforcement - using aluminum or fiberglass.

Aluminum

Polypropylene pipe with aluminum reinforcement comes in two types. In the first case, a kind of frame performs the function of an outer shell, in the second it is located between layers of polypropylene. In this case, you can verify the presence of a protective frame by studying the cut of the product.

The essence of the design is the adhesive connection aluminum foil thickness 0.1-0.5 mm and polypropylene. The quality of the final product directly depends on the characteristics of the source materials. The desire to save money can lead to the purchase of low-quality products that can delaminate over time, which will significantly affect the strength of the water supply system.

Fiberglass

An alternative solution, one step above the previous option, is fiberglass. Although the pipe consists of three layers: polypropylene inside and outside, and fiberglass in the middle, overall it is a monolithic structure. This feature is formed during the manufacturing process by welding the middle layer with the outer and inner ones.

By gluing fiber fibers with polypropylene layers, it is ensured that pipes in the water supply system do not deform when heated. Determining fiberglass reinforcement when choosing polypropylene pipes is quite simple - three layers are clearly visible on the cross-section of the product, the middle of which is brightly colored. The color does not indicate any characteristics of the pipe; the manufacturer relies solely on his own preferences.

Features of material selection

When purchasing polypropylene pipes, they are guided by key material selection criteria:

- planned operating features;

- cold or hot water supply.

- White and gray polypropylene products are mainly intended for use in heating and water supply.

- Installation of the water supply system is carried out using shut-off valves and polypropylene fittings.

- To assemble the system you will need fittings with a bend angle of 45 and 90 o C, valves, plugs and couplings.

- The final installation process involves the use of special welding machine, called a pipe soldering iron.

It is very important to choose the correct diameter of the product for the water supply system. In a private house, the default diameter is 20 mm. During construction multi-storey building Each stage has its own size, determined on the basis of a refined calculation.

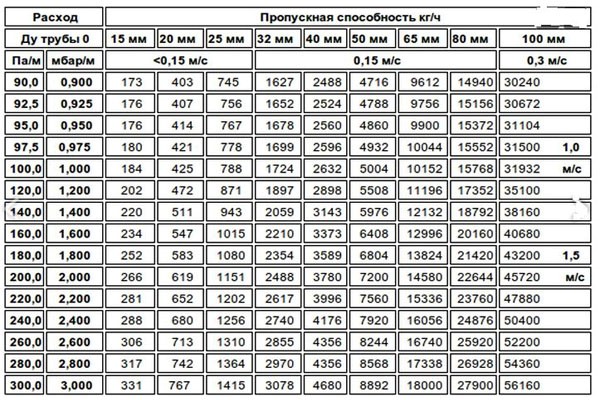

There are specially developed parameters for supplying the block, house, entrance and plant to the apartment. A priori, the size of polypropylene pipes increases in proportion to the increase in water consumption. For apartment buildings used in economic activities:

- risers of a 5-storey dwelling - diameter 25 mm;

- for risers of a house consisting of 9 or more floors, the diameter of polypropylene pipes is 32 mm;

- intra-apartment wiring is similar to private sector houses - 20 mm.

Table bandwidth depending on the pipe diameter is presented below:

When choosing polypropylene pipes for water supply, give preference to a product with fiberglass reinforcement. This optimal combination ease of use, quality and cost of the material.