The best pyrolysis boiler. Long-burning pyrolysis boilers

Economical and efficient heating- the dream of every homeowner. Happy are those who have the opportunity to connect gas boilers, the rest have to choose between solid fuel boilers and electric ones. Solid fuel ones are good because heating is relatively inexpensive. Their disadvantage is that they require constant presence in order to supply fuel. But the latest developments are boilers long burning pyrolysis type - have become more convenient in this regard.

One load of fuel can heat the system from 8 to 24 hours (depending on the fuel and temperature environment). In the interval between stacking firewood, it doubles, and you can check it once a month - such fuel can be supplied automatically as needed.

They have disadvantages. Not without it. Two main ones: the equipment is expensive and very often volatile (requires guaranteed power supply). The price pays off during operation: with one stack of firewood the house will take twice as long to warm up, and with one stack of firewood it can take up to a day. In addition, there are boilers that burn everything: even construction waste and old tires. Anything that can burn.

Operating principle

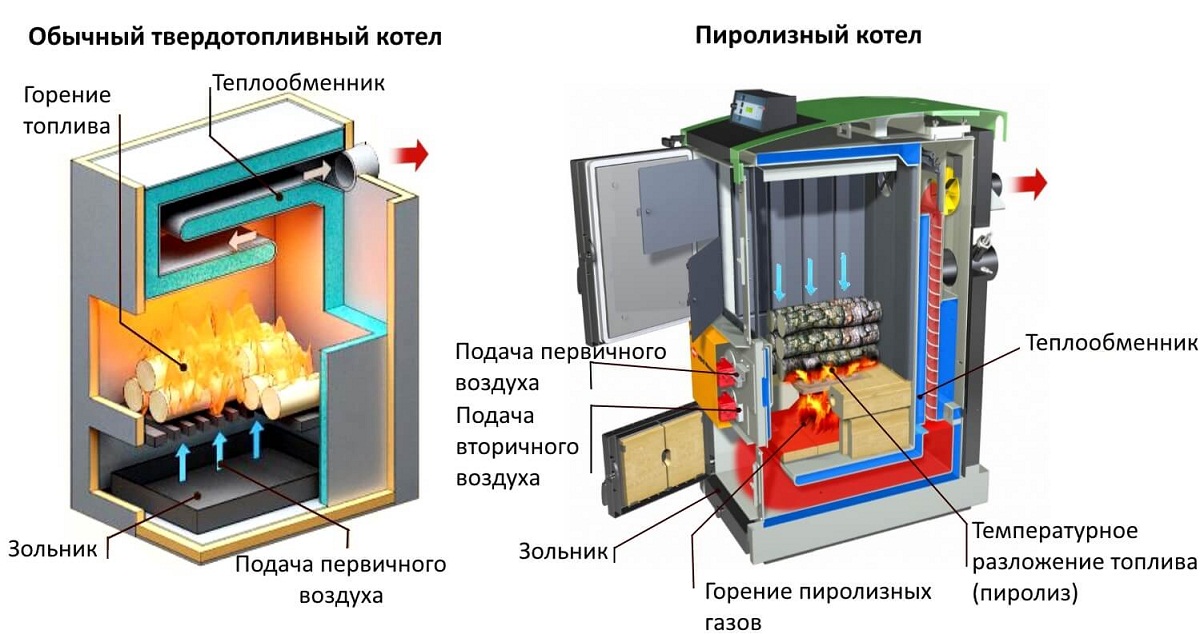

How is it that this doesn’t large quantity fuel produces so much energy? The thing is that most of the heat in conventional boilers (they are called direct combustion boilers) literally “flies” into the chimney.

If you heat with wood or coal, you know that it is impossible to touch the pipe - the temperature there is 300 o C and can be 400 o C. And in some cases (in bathhouses, for example) even higher.

In pyrolysis colas, the air leaves the firebox at a temperature of 130-160 o C. This is achieved due to the fact that not only the energy released by the firewood is used, but also the gas that they emit during smoldering is burned (a special mode is created for this).

The work is based on the fact that carbon-containing fuel (coal, firewood, pellets) when burned with a lack of oxygen, decomposes into a large amount of gases and combustible substances. Due to the fact that during the process of smoldering from wood or other carbon-containing fuel, a large amount of flammable gases is released, such devices are also called gas generator boilers. For example, wood as a result of pyrolysis is converted into:

- solid residue - which itself is a high-calorie fuel;

- methyl alcohol;

- acetone;

- various resins;

- acetic acid.

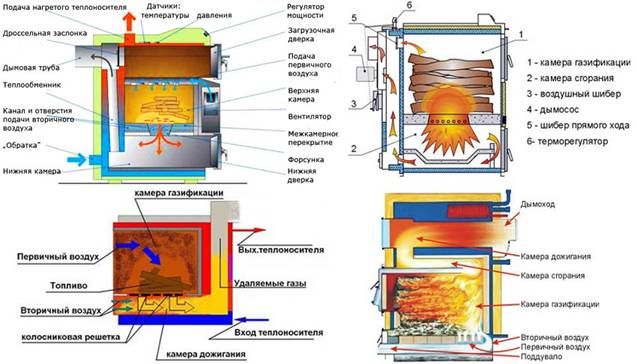

All these substances burn and release a large amount of energy. Pyrolysis boilers because they have two cameras:

- Fuel is placed in the combustion chamber and ignited to achieve the desired temperature.

- The gases released during fuel combustion are removed to the pyrolysis chamber (afterburning chamber). They already have high temperature, mix with the air pumped into it and ignite.

Air is supplied to both chambers separately; its quantity regulates the intensity of combustion and the power of the boiler at this stage. This is the only combustion technology that allows you to automate the burning of wood or coal.

Advantages and disadvantages

The release of gases during combustion in conditions of lack of oxygen occurs very actively. Because for efficient work In such equipment, automation is important, which will control the process: limit the supply of oxygen after the firewood has flared up and regulate the process in both chambers. This is the main disadvantage of the stake: it needs guaranteed power to work (for the automation to work).

There is another positive point: pyrolysis gases interact with carbon during combustion. As a result of these reactions, at the outlet of the boiler, the smoke consists mainly of carbon dioxide and water vapor with a small amount of other impurities. If firewood is used, CO emissions into the atmosphere are three times less than when using traditional technology. When working with coal, the situation is even more rosy - emissions are reduced by a factor of five.

The afterburning of gases and microparticles contained in it is also good because there is practically nothing to be deposited on the walls of the chimney: little soot is formed. And one more bonus: there is little ash left. Less ash and soot - less cleaning required. This is also nice.

Direct combustion boilers have an efficiency of about 60-65%. Pyrolysis – 80-90%. This is a noticeable difference.

But the benefits aren't over yet. The power of a conventional boiler can be adjusted quite arbitrarily. All possibilities are to open/close doors, vents and dampers. Moreover, you need to do this with your hands and rely on experience and intuition. The pyrolysis process can be adjusted over a wide range: you can leave 30% of the power, or you can “overclock” it to 100%. And the process is regulated by automation, which focuses on the specified parameters. Result: fuel savings of 40%.

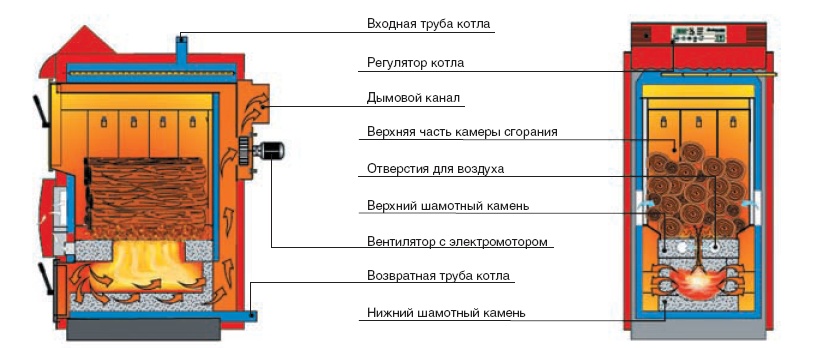

Structurally, colas can be made in different ways: in some models the afterburner chamber is located under the primary one, in others – on top. There are models in which it is located behind the primary firebox. In some units, air is not supplied from below the firewood through the grate, but is “blown in” from above, slowing down the combustion process. These are all variations of the same technology. But they also have their pros and cons. Let's look at some of them in more detail.

Features of Blago

These boilers were developed by engineer Yuri Blagodarov. Their main advantage is that they have non-volatile models. They do not use artificial air injection; the boiler operates on natural draft.

The thoughtful arrangement of fuel bunkers, afterburning chambers and the use of a catalyst (bath stone) made it possible to decompose not only simple carbons, but also complex ones. Due to this, the number of types of fuel has expanded significantly, and the efficiency of its distillation has also increased.

Another one distinguishing feature these boilers – the possibility of using raw firewood without loss of power. Blago boilers of industrial capacity can operate on wood with 55% humidity, low-power units successfully cope with 35% humidity.

The design is constantly being improved. IN Lately production of equipment for burning used tires has been launched, there is specialized equipment coal-fired.

Conventional long-burning pyrolysis boilers “Blago” use firewood, sawdust, wood chips, scraps and their mixture with coal chips. When using firewood, in principle, you don’t have to split it—even small logs of wood burn well.

As a result, the boilers are truly omnivorous: they work on old tires, rubber, leather, polyethylene, not to mention traditional types solid fuel.

Large Blago pyrolysis boilers have several fuel chambers (at least two). If necessary (slight frosts outside), you can put fuel in only one. The efficiency (81-92%) of the boiler does not change due to this, only the power becomes lower. For example, a 50kW boiler can be used at 12kW. Moreover, during the system acceleration period it will produce 25 kW, and the rest of the time - 12-15 kW. There are small models (from 15 kW) with one fuel loading chamber.

Blago long-burning pyrolysis boilers are produced with a power from 12 kW to 58 kW. More powerful units are made to order with matching input and output parameters. For units from 1 MW can be developed automatic line fuel supply (this is data from the message of the author of the project).

What does the manufacturer guarantee besides “omnivorousness”? Firstly, the amount of fuel required is smaller - it is needed by 20-30% compared to other boilers of the same operating principle. Secondly, long burning - fuel is added every 12-18 hours. Thirdly, high safety: the loading door and combustion valve are combined, which prevents accidental ignition during fuel loading; automatic adjustment of the plug is provided to prevent gases from escaping if installation rules are violated. Fourth, ease of use: automated control, no smoke when loading fuel, automatic cleaning of fuel channels.

Now about the shortcomings that are pointed out on the forums:

- The equipment is expensive.

Yes, not cheap. But everyone is sold a package of documentation for self-production.

| Model | Power | Square | Maximum system volume | Dimensions, mm | Fuel | Coolant | Price |

| BLAGO-TT 15 | 15 kW | 150 m2 | 0.83 m 3 | 1200*530*970 | Firewood, wood waste | 48 t.r. | |

| BLAGO-TT 20 | 20 kW | 200 m 2 | 0.60 m 3 | 1200*530*1140 | Firewood, wood waste | Water, non-freezing liquid for heating systems | 60 t.r. |

| BLAGO-TT 20 | 25 kW | 250 m 2 | 0.75 m 3 | 1540*725*950 | Firewood, wood waste | Water, non-freezing liquid for heating systems | 75 t.r. |

| BLAGO-TT 30 | 30 kW | 300 m 2 | 0.84 m 3 | 1540*725*110 | Firewood, wood waste | Water, non-freezing liquid for heating systems | 90 t.r. |

| BLAGO-T2 Т-BH-40 | 40 kW | 400 m 2 | 120 l | 2300*1100*1100 | Firewood, wood waste | Water, non-freezing liquid for heating systems | 120 t.r. |

| BLAGO-T2 Т-BH-50 | 50 kW | 500 m 2 | 168 l | 2300*1100*1300 | Firewood, wood waste | Water, non-freezing liquid for heating systems | 150t.r.. |

| BLAGO-T2Т-BC-40 (built-in heat exchanger) | 40 kW | 400 m 2 | 1805*1100*1100 | Firewood, wood waste | Water, non-freezing liquid for heating systems | 120t.r. | |

| BLAGO-T2Т-BC-48(built-in heat exchanger) | 48 kW | 480 m2 | 1805*1100*1300 | Firewood, wood waste | Water, non-freezing liquid for heating systems | 144t.r. |

- The disadvantage is the rapid cooling of the boiler when fuel is added late.

- The boiler is difficult to pyrolyze.

But the last two drawbacks are the result of little experience working with this boiler and the incorrect position when lighting the ash pan. Some consumers do not like the excessive discharge of the heat exchanger walls, which makes it difficult to load fuel (models TTS and TTU).

Czech Atmos

The Czech company Atmos produces more than 200 models of heating boilers that burn wood, diesel fuel, briquettes. There is equipment that runs on several types of fuel; gas boilers are made to order.

Long-burning pyrolysis boilers Atmos are produced both for heating small rooms power from 15 kW (90-180 m2), and for production premises up to 1000 m2 and more.

They consist of two chambers located one above the other: at the top is a fuel chamber, at the bottom is a gas afterburning chamber. Cameras (one or both) may have ceramic finish, which increases the efficiency of heat use - it is not dissipated through the walls, but is used to heat the coolant. The fuel bunker has big sizes, you can even put quite large whole logs there. This reduces the power, but increases the combustion duration (can be used in warm weather when high temperatures in the system are not needed).

Atmos produces pyrolysis boilers using different fuels:

- on wood - marked Atmos DC;

- coal-wood - Atmos C and Atmos AC;

- pyrolysis boilers Atmos DC 24 RS, DC 30 RS;

- Atmos pellet boilers

The boiler marking also contains the prefixes GS, GSE and S. The first two types have an all-ceramic finish on both fireboxes, resulting in higher efficiency and a significantly lower percentage of carbon dioxide emissions into the atmosphere. Despite the fact that the cost of such devices is almost 50% higher, practically only equipment of this type is sold in Europe. In our country lion's share sales account for less efficient, but cheaper boilers marked S without ceramic coating firebox

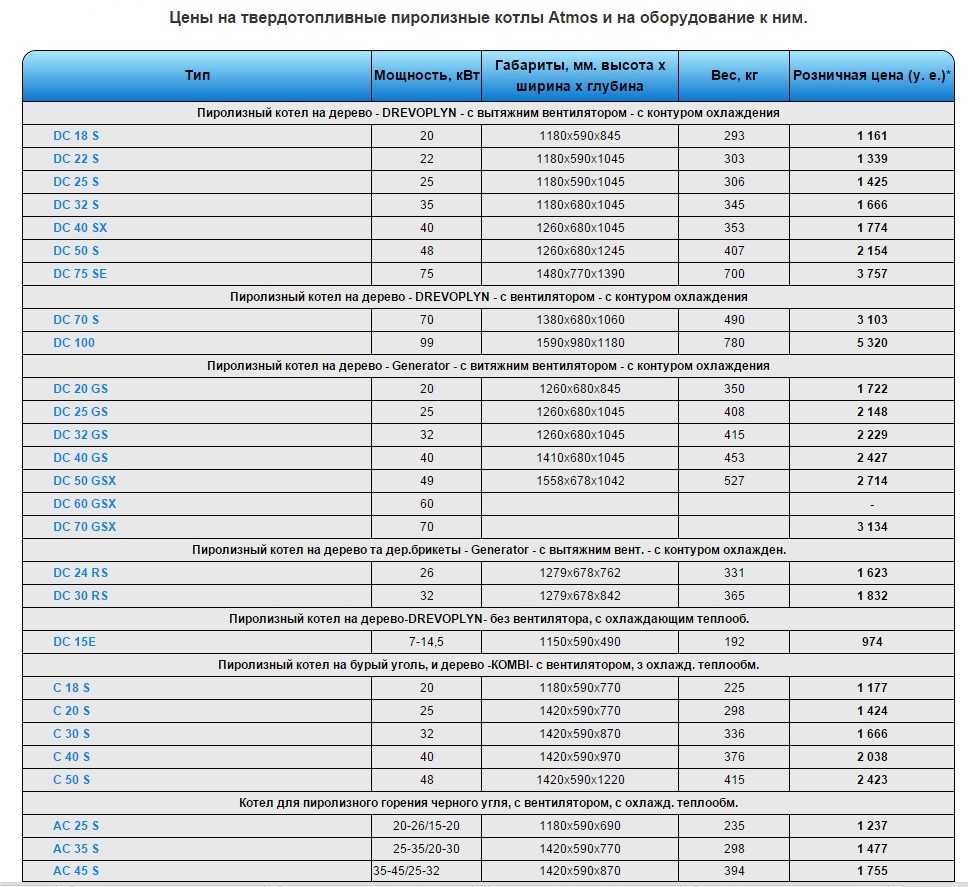

Long-burning pyrolysis boilers Atmos: prices and specifications(click on the picture to enlarge it)

German quality "Bosch"

Boilers from German from Bosch Can be used as primary or backup heating equipment. What distinguishes them is great opportunity power regulation (by changing the operating mode of the smoke exhauster, you change the power of the heating unit). Boiler efficiency is 78-85%, the volume of water in the system is 76-124 liters.

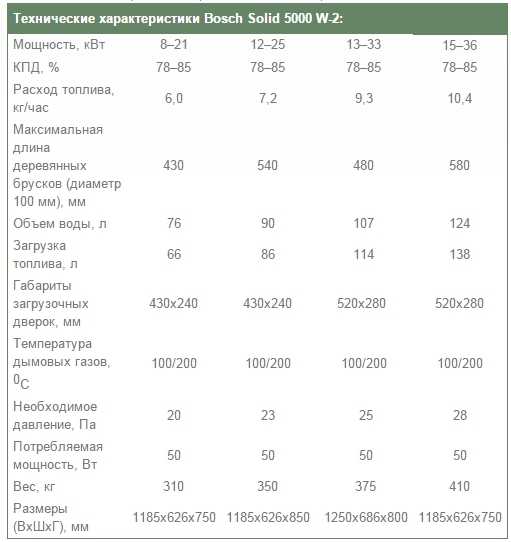

Technical characteristics of the long-burning pyrolysis boiler Bosch Solid 5000 W-2

Boilers operate only on wood with a moisture content of up to 25%; you can use briquettes from wood materials. The design is similar to their Czech counterparts: on top there is a fuel loading and gasification bunker, and on the bottom there is a gas afterburning chamber. Between them there is a ceramic burner. The cost of such boilers starts from 2000 euros.

Another video material that explains the principle of operation of solid fuel pyrolysis boilers

The air temperature directly affects how comfortable your room will be. And it, in turn, depends on how well it will work heating device. If you choose this unit wisely, you will be able to enjoy the warmth without thinking about what the weather is like outside the window. But today the range of boilers is so impressive that an inexperienced person can simply get confused. In this range are also pyrolysis boilers, which are simple, efficient and modern. Pay attention to them.

Long-burning solid fuel boilers: design and principle of operation

A pyrolysis boiler can be classified as one of those devices that perform their work using solid fuel. The device heats the coolant, which in turn distributes it throughout the room.

But this installation has a number of differences that set it apart from traditional boilers. The first thing you need to pay attention to is its design and principle of operation.

The work of a pyrolysis boiler is to process wood, this process is called pyrolysis. It releases a mixture of gases from solid organic matter under the influence of high temperature and the absence of oxygen. As a result of this process, the fuel decomposes into a dry residue, as well as gas or coke.

Such a process can only be carried out in the presence of high temperature, which is at least 1000 degrees. In addition, a reaction occurs and a large amount of heat is released, the fuel dries, and the air that enters the combustion zone heats up. The gas released from the fuel reacts with oxygen and begins to burn, releasing heat.

The peculiarity of this process is that the gas interacts with carbon, and, consequently, carcinogenic substances are reduced to a minimum.

Long-burning pyrolysis boilers: fuel

In principle, pyrolysis boilers can operate on any type of solid fuel. More precisely, it is firewood, peat, coal or wood. Firewood in this case is the most economical option.

The size of the firewood is determined according to the parameters of the firebox. Basically, firewood is used for the pyrolysis device, the size of which is about 40 cm and the diameter is 200 mm. In the case of briquettes, their size should be approximately 30 by 3 cm.

It is also necessary to take into account that such a system is very demanding on humidity. If it is elevated, a large amount of steam will be released, which affects the heat and creates soot. In order for the device to operate optimally, the fuel moisture content should not be higher than 45%, the ideal is 20%.

Experts have found through research that when using fuel with a moisture content of 20%, about 4 kW of heat will be released per hour. At the same time, the fuel, whose humidity was above 50%, generated several times less heat.

It is for this reason that you need to pay attention Special attention humidity of the material.

Along with firewood and briquettes, you can use any wood waste and sawdust for heating. Their volume should not exceed a third of the required volume of fuel.

How do pyrolysis heating boilers differ from other installations?

Those who purchased this equipment note that they received a large number of benefits.

The main ones include:

- Increased efficiency of the device, since the fuel burns almost completely;

- It is possible to regulate the temperature in a heated room, this allows you to use fuel with great savings;

- Reduced level of harmful substances in gases, since they are released several times less compared to conventional equipment;

- Fuel needs to be loaded several times a day; if the boiler is operating in economy mode, then once will be enough;

- Semi-automatic control allows using a remote control to reduce or increase the air supply from 30 to 100%;

- Combustion of products is minimal and cleaning of equipment is simple.

Of course, the device also has some disadvantages, which should also be mentioned. The first disadvantage is that all automated models operate solely on electricity. The second is that the boiler costs several times more than standard combustion devices.

But the savings that are made during the operation of the boiler pay for all costs over time. Well, the last drawback is that most often pyrolysis-type boilers are made as single-circuit ones, so they can only be used for a heating system. If you also want to get water heating, you will have to spend extra money.

Rating of long-burning pyrolysis boilers

The world leaders in the production of pyrolysis boilers are German companies. They are designed for lower emissions of toxic substances into the atmosphere and show the highest possible efficiency. Some of the models are able to work for a day without adding fuel.

The secret of such work lies in the fact that the design has been improved, and its firebox is equipped with the latest technology. The operation and its efficiency are fully controlled by automation, this helps to achieve a uniform thermal index and at the same time reduce financial costs.

From Russian made We can highlight the company from Kostroma TeploGarant, which produces Burzhuy-K models.

They are highly practical and can work with any type of solid fuel.

A distinctive feature of these devices is that they work effectively with fuel whose humidity is high. This indicator gives this manufacturer a great advantage over its competitors.

Czech solid fuel boilers for long burning

Czech boilers are among the most popular. For example, the company Dakon produces boilers that are identical to analogues from Germany or Russia, and as a result, their efficiency is no different. Among successful models, we can highlight the design, which is controlled by a remote control; it is with it that not only temperature control is carried out, but also all the main adjustments. This model has the longest service life among class equipment. In addition, this device is capable of operating only at a third of the power, when it is not yet warm, but no longer cold.

Models with interesting and practical parameters can be found from Czech manufacturers from the company OROP.

The main feature of these boilers is their complete independence from energy. In addition, their design feature allows you to work not only on wood fuel, but also on coal.

In order to control the work process, dampers are used; they can be either open or closed. The efficiency of a boiler from such a manufacturer is approximately 89%, which in principle can be considered a good indicator. Boilers of this brand are considered to be best example, not only because it is non-volatile, but also the gas atom is released less. Also among the models of this manufacturer you can find types of low-power and top-acting boilers.

What is a pyrolysis boiler (video)

Pyrolysis boilers are becoming more and more popular every year. They can be called the most practical option that runs on solid fuel. Although price policy of such boilers is quite high, the efficiency shows excellent results, and the cost of fuel is affordable for everyone. Thanks to the wide variety of models, you can choose the boiler that suits your structure.

When restoring or building a small house in the village, many often think about alternative uses stove heating. The question becomes relevant not only of achieving maximum comfort, but also rational, economical spending natural resources. Today, the best alternative to solid fuel boilers are long-burning pyrolysis boilers. The question immediately arises: why such heating equipment, and what does “pyrolysis” have to do with boilers?

Solid fuel boilers with pyrolysis combustion are otherwise called gas generator boilers. The main advantages of such boilers are the ability to control operating power and high efficiency, which can reach 85%.

A distinctive feature of solid fuel boilers with pyrolysis combustion is that they burn not only wood, but also wood gas released under the influence of high temperature. With such combustion, very little ash remains and virtually no soot. Pyrolysis combustion provides a high temperature in the firebox bunker, as a result of which not only wood gas is released, but also its further passage through the nozzle. The gas burns with a clean, beautiful flame of white or yellowish color.

The disadvantages of pyrolysis boilers include their higher price compared to traditional solid fuel boilers, as well as the need for electrical power. Any type of wood, wood briquettes and wood waste, the moisture content of which does not exceed 20%, can be used as fuel for gas generator boilers.

An undeniable advantage of pyrolysis boilers is the ability to operate throughout the day with a single supply of fuel. Of course, the duration of work with one bookmark is determined by a number of factors:

- Outside air temperature

- Set room temperature level

- Fuel moisture

- Degree of building insulation

- Correspondence building regulations heating system

In any case, pyrolysis boilers are much more efficient than traditional ones solid fuel boilers. The question immediately arises, on what is such a statement based?

First of all, when burning wood, especially if it is over-moistened, it is not possible to achieve a high temperature, which is quite possible when burning wood gas. In addition, much less secondary air is required for gas combustion, which results in a higher temperature and increased fuel combustion efficiency. The ability to automate the process is similar to the automation of liquid fuel and gas boilers, making it much easier to control the combustion process of pyrolysis gas.

How does it work

The principle of operation of a gas generator boiler is based on dry distillation of fuel (or pyrolysis combustion), the meaning of which is that when there is a deficiency of oxygen under conditions of exposure to high temperatures, dry wood splits and the volatile part is released. It is this volatile part that is called pyrolysis gas, and the solid residue is called coke or charcoal.

Pyrolysis of wood occurs in a wide temperature range from 200 to 800 degrees. The process is exothermic in nature, that is, it proceeds with the release of heat, as a result of which there is an improvement in drying the fuel and its heating, and also heats the air that enters the burner action area.

Thermal energy is obtained as a result of the combustion of pyrolysis gas released at high temperatures, which is mixed with oxygen in the air. It should be noted that during the combustion process, pyrolysis gas comes into contact with active carbon, due to which there are practically no harmful impurities in the flue gases at the exit from the boiler.

In general, we can say that the main components of the flue gas output are water vapor and carbon dioxide. At the same time, emissions of carbon dioxide into the atmosphere are three times less than when operating similar boilers burning coal or wood.

During pyrolysis combustion, a minimum of ash and soot is formed, which reduces the cost of operating equipment, which are associated with more rare cleanings.

Something about fuel

To ensure long-term operation of the pyrolysis boiler and its operation with maximum power The most dried wood should be used as fuel.

For example, 1 kg of wood with a moisture content of 15-25% has a calorific value of about 4 kW/hour, the same amount of fuel with a moisture content of 25-40% is 3 kW/hour. If the wood moisture content exceeds 50%, then 1 kg of wood will have a calorific value of less than 2 kW/hour.

Obviously, the amount of energy released is largely determined by the moisture content of the wood. Excess moisture causes low heating, poor combustion, and smoke. Regular use of “wet” firewood as fuel significantly reduces the service life of not only the chimney, but also the boiler itself. The boiler power can be reduced by half, at the same time, the amount of consumption of low-quality fuel can have a similar indicator only in the direction of increase.

The operation diagram of a pyrolysis boiler can be simplified by the following procedure:

- Loading firewood or wood waste into the pre-flow

- Thermal sublimation of fuel

- Supply of generator gas to the furnace for combustion

- Utilization of heat from flue gases using a heat exchanger

- Control of air supply to the pre-flow required for the pyrolysis process

Price

From the material presented above, it becomes obvious that the pyrolysis boiler is a modern and effective solution issue of heating system design. Despite the many obvious positive aspects of using pyrolysis boilers, many are still stopped by their high price.

The price of the most primitive domestic gas generator boiler is more than a thousand dollars, and the cost of imported analogues is even higher. So it turns out that the main task of the designers is to make such efficient equipment more accessible.

You can do it yourself

If you don’t have the funds to buy a pyrolysis boiler, then this is not a reason to refuse such equipment. You can order the boiler to be manufactured by specialists, which may cost a little less, or you can try to make such a boiler yourself. True, for this you will have to get drawings, and, unfortunately, there are not so many of them on the Internet.

Blago boiler

Inventor Blagodarov Yu.P. speaks very flatteringly about his brainchild - the Blago boiler, giving a lot of arguments in favor of his invention.

Blago pyrolysis boilers differ from their standard counterparts in the following characteristics:

- Increased loading chamber size

- Increased size of the camera doorway

- Ability to work with both a smoke exhauster and natural traction

- No direct draft gate

- No manual adjustment

- Availability of plate gas-tube heat exchanger

- Heating of air supplied to the combustion chamber

- Convenient and easy to clean

- Higher efficiency

- High-quality steel was used to make the boiler

- The lining is made using high-quality fireclay

- No smoke when reloading fuel

- Excellent price-quality-technical parameters ratio

The Blago pyrolysis boiler is not only adapted to weather conditions and the needs of our consumers, but can also confidently compete with imported analogues, often surpassing them in many technical, physical and economic parameters.

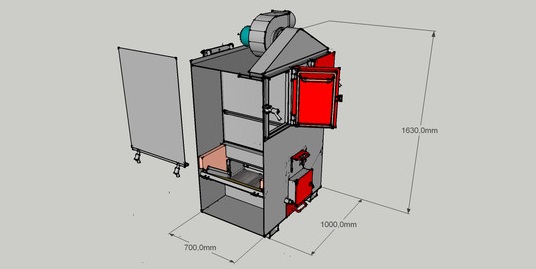

View of the finished Blago boiler

The Blago pyrolysis boiler is very similar to its Polish prototype IRLEH, the only difference is the improved quality of afterburning of pyrolysis gases, which is realized through the supply of heated air.

Blago boiler size for houses from 100 to 200 sq.m.

By combining the ignition valve with the loading door, as well as the installation of an additional swing door, it was possible to significantly increase the fire safety of the equipment, which is due to the impossibility of pyrolysis gases escaping and self-igniting outside the boiler. Thanks to this, you don’t have to worry about the operator’s inattention; even if he doesn’t open the kindling chamber before opening the loading door, pyrolysis gases will still not be able to enter the room. This is due to the fact that when the loading door is open, the hinged door will play the role of a fuse, which will prevent the gas from spreading into the room and direct it towards the chimney.

System fire safety The device is designed in such a way as to prevent any emergency situation that may arise due to the fault of the operator. You can put logs from half a meter in length into the combustion chamber, and the duration of the boiler operation on one load can reach 10 hours.

Boiler "Teplolov"

Another type of hot-water-air heating boilers are “Teplolov” type boilers. These are quite simple and reliable devices that are designed for organizing heat supply to buildings. for various purposes. You can use waste lump wood, pressed briquettes and wooden logs as fuel. In this case, the length of the logs should be in the range of 0.38-1.0 m, their diameter should be no less than 0.1 m and no more than 0.25 m.

The minimum acceptable size of briquettes is 3/30 cm. Small wood waste, including sawdust, can be burned along with logs, but their quantity should not exceed a third of the volume of the loading chamber.

The large loading door and increased chamber volume reduce labor costs for chopping wood. Wood whose moisture content does not exceed 30% can be used as fuel.

The type of construction of Teplolov boilers, as well as the principle of fuel combustion, has some differences from standard solid fuel boilers. The operation of the equipment is based on the principle of thermal decomposition of fuel. During the process in the loading chamber, against the background of oxygen deficiency and high temperature, pyrolysis gas is released, the combustion and heat transfer of which are similar to the operation of the Blago pyrolysis boiler presented above. Coefficient useful action and carbon dioxide emissions are also close to those of Blago boilers.

Design of the Teplolov boiler

The Teplolov boiler consists of two chambers located one above the other. In the upper chamber, which is fuel bunker, fuel is loaded, and here it burns with the release of natural gas.

It is thanks to gasification that in the first chamber the wood is dried and the air is heated, which is then sent to the combustion chamber. In the lower chamber, pyrolysis gas is burned, and ash also accumulates here. The chambers are connected to each other by a special gasifying nozzle. The boiler power is adjusted by dosing the secondary air injection.

The positive characteristics of Teplolov pyrolysis boilers include fairly precise adjustment, which is not often implemented in standard solid fuel boilers. A sensitive thermostat makes it possible to accurately set the temperature of the coolant. Heating the air entering the combustion zone makes the operation of the boiler more economical, and pyrolysis combustion minimizes the amount of waste and increases the service life of the equipment. The boiler power can reach 40-50 kW, and the operating time on one load is determined by the quality of the fuel and can reach 12 hours.

Both water (water heated floors or traditional mounted radiators) and air can be used as a coolant. The latter option looks more promising, as it allows you to warm up the room more quickly. Another positive point can be considered the absence of the need to deliver coolant and reduced costs for ensuring the tightness of pipes.

A coolant leak will not cause any damage; the system can be stopped and resumed at any time. This aspect is quite relevant for owners country houses and dachas, where people do not live permanently, because the air in the pipes cannot freeze, which often happens with water, and destroy the heating system.

The coolant movement is based on natural circulation– hot air rises through the pipes, and the influx of cold air occurs by gravity.

A finished Teplolov boiler costs about 1,400 euros. If you have drawings that you can purchase from the creators of these boilers and independent execution work, this figure can be halved.

December 29, 2013  Alexei

Alexei

Comfort in the home is always associated with the air temperature in the room. And it is directly dependent on the quality of the heating equipment and its operation.

Only right choice boiler will allow you not to freeze in your own home. However, their range is so large that you can’t help but think, which model to choose?

Most often they use gas appliances, but what to do if there is no mains near the house? In this case, you need to pay attention to. They run on wood and can heat even large industrial spaces.

Solid fuel or not

What is a pyrolysis heating device, and what is the principle of its operation? Let's look at the main points. A pyrolysis boiler, or also called a gas generator boiler, is a type of solid fuel heating equipment.

The principle of its operation is based on the combustion of gas, which is released under the influence of high temperature on wood with a lack of oxygen. To obtain it, a device was created consisting of two chambers - a pyrolysis boiler. The lower part is intended for loading firewood, the upper part is necessary for burning gas.

But to obtain it, certain conditions must be created, such as:

- Having a very high temperature

- Almost complete absence of oxygen

Such parameters can be achieved only if the lower firebox is completely sealed, as well as if there is a special boiler design vacuum pump, pumping air out of the chamber after laying firewood. All gases, including pyrolysis gas, are volatile, which means that it easily rises through the nozzle into the chamber where it is burned, which leads to heating of the heat exchanger. Such a device belongs to long-burning systems.

Such parameters can be achieved only if the lower firebox is completely sealed, as well as if there is a special boiler design vacuum pump, pumping air out of the chamber after laying firewood. All gases, including pyrolysis gas, are volatile, which means that it easily rises through the nozzle into the chamber where it is burned, which leads to heating of the heat exchanger. Such a device belongs to long-burning systems.

What to look for when choosing

Pyrolysis boilers, like other models of heating equipment, are divided into:

Pyrolysis boilers, like other models of heating equipment, are divided into:

- Dual-circuit

The former are chosen only as heating systems, while the latter are capable of providing hot water for household needs.

There is also a difference in power. It can reach 2000 kW. But, regardless of the differences, the operating principle of all hydrolysis devices is exactly the same.

Therefore, when choosing, pay attention to:

- Power

- Exterior design

- Number of circuits

There is another factor - cost. Of course, the operation of the boiler does not depend on it, but the filling of your wallet is very significant. This means that you should take it into account when choosing.

Which manufacturer to choose

To understand the features of various models, we will conduct them comparative analysis and find out which one will be the most optimal to answer the question - which is the best pyrolysis boiler to choose for your home?

To understand the features of various models, we will conduct them comparative analysis and find out which one will be the most optimal to answer the question - which is the best pyrolysis boiler to choose for your home?

Undoubtedly, German companies are considered leaders in the production of heating devices. They were able to create models of pyrolysis boilers with high efficiency and the lowest emissions harmful substances in atmosphere. Long-burning devices from Viessmann or Buderus can operate on one burner for 24 hours.

The manufacturer was able to achieve such results thanks to the improvement of the boiler furnace. The presence of automation systems allows you to regulate the activity of its work. The result of this is a reduction in fuel costs and ensuring uniform thermal conditions in the room.

The next most popular are heating devices from the Czech manufacturer Dakon. Structurally, they differ little from German products.

The next most popular are heating devices from the Czech manufacturer Dakon. Structurally, they differ little from German products.

The same steel body of the combustion chamber, welded from metal with a thickness of at least 5 mm, and several ceramic blocks. Behind the structure is a manifold with an exhaust fan, and in front are the doors of the loading chamber.

The main achievement of the manufacturer was the appearance of the control panel.

The boiler operation process is also no different from other models. The same principle of gas supply using a fan and high efficiency, the ability to control operation regulation using automation. However, this company also has its own new products - this is its pyrolysis boiler in a cast iron body.

The model is produced under the Daman Pyro brand and is considered the most durable in this class of equipment. In addition, the device is capable of operating at half power in the off-season. The disadvantage of the model is its energy dependence, since the fan runs on electricity.

The model is produced under the Daman Pyro brand and is considered the most durable in this class of equipment. In addition, the device is capable of operating at half power in the off-season. The disadvantage of the model is its energy dependence, since the fan runs on electricity.

Another model worthy of choice is pyrolysis boilers of the OPOP brand from a Czech manufacturer. Their characteristic feature is energy independence, as well as the ability to use not only wood, but also coal as fuel.

In the model of this manufacturer, gases enter the combustion chamber through the burner. In it, under the influence of secondary air, the process of combustion occurs. The power of the device is regulated in the process of opening the air intake dampers. The efficiency of this boiler is also quite high and amounts to 89%.

Pyrolysis devices and Russian manufacturer, produced under the brand name Bourgeois. Their main feature is the ability to use even wet wood as fuel, which sets them apart from their foreign competitors.

The choice of brand of solid fuel heating equipment cannot be unambiguous, since although they all have the same operating principle and differ little in their constructive solution, but each model has its own cost.

And very often it is this that has a decisive influence on the choice of a good pyrolysis boiler. If we take it into account, then we should give first place to Russian products. It is this that has the lowest cost with good overall quality equipment.

What consumers say about it

Consumers have increasingly begun to choose solid fuel heating devices, but among them, of course, the best are pyrolysis boilers. And although the price for them is quite high and ranges from 90 to 300 thousand rubles depending on the manufacturer, there is still a demand. It is due to the low price of fuel, the fairly high efficiency of these boilers, as well as the possibility long work from one download.

To ensure the competitiveness of this equipment and choose the most best model, just look at the reviews. Those who have already installed such equipment write that the savings amount to quite a significant amount, especially considering the constant rise in prices for energy and gas. This means that such boilers have a chance to become leaders.

To ensure the competitiveness of this equipment and choose the most best model, just look at the reviews. Those who have already installed such equipment write that the savings amount to quite a significant amount, especially considering the constant rise in prices for energy and gas. This means that such boilers have a chance to become leaders.

Foreign or domestic

If we consider specific models, then it all depends on availability Money. And, as always, the best pyrolysis boiler for the home is German, although Czech equipment also has high quality. As for domestic models, they also have their advantages, for example the ability to use wet firewood. Therefore, you should choose based on your own requirements and capabilities.

Long-burning pyrolysis boilers, reviews from owners are quite positive. This is due to the fact that recently electricity and gas have become very expensive, and solid fuel (coal, peat, firewood) is becoming more and more affordable. Such units have high power and efficiency, and if you install more modern model, That automatic system, will reduce human intervention to a minimum. Another great convenience is that one load is enough for a day, that is, the owner does not need to constantly monitor the fuel level. You can only throw it in the evening or in the morning required amount firewood and enjoy the warmth. But, like any other equipment, pyrolysis boilers, in addition to their strengths, also have their weaknesses, which you need to become familiar with before installing such a unit.

How does a pyrolysis boiler work?

Long-burning pyrolysis devices represent a “laboratory” within which gas is extracted from solid fuel. This is what is used to heat the house. Pyrolysis is a physical and chemical process in which complex compounds decompose organic compounds into simple components in the form of a solid, liquid or gaseous state. For this to happen, it is necessary to provide high temperature and limited access of oxygen.

The design of the pyrolysis boiler has a two-chamber heating device, where in the upper part it is heated to 200-800 degrees, which contributes to the start of the exothermic reaction of solid fuel. There is no oxygen, which causes the material to slowly smolder. Having broken down into CO and CO2, the mixture passes to the lower part of the boiler, where the combustion temperature is already kept at around 1100-1200 degrees. The two chambers are connected by grates. As a result, a large amount of heat (pyrolysis gas) is released, intended for heating the house. The remaining fuel that does not burn is called coke or charcoal.

It is also worth noting that during the combustion of pyrolysis gas, it has to come into contact with a certain amount of active carbon at the outlet. This leads to the formation of a minimum amount of harmful impurities in the flue gases, which makes the operation of this installation safer. Thus, the flue gas mainly consists of water vapor and carbon dioxide.

It turns out that pyrolysis devices do not use the solid fuel itself, but the gas produced from it. Thanks to this technology, these boilers show an efficiency of 85-90%, since here the material is burned with virtually no residue. And at the very beginning of this action, the material is dried, that is, from the moment of ignition to the last spark, a “useful” process occurs. And this is not to mention the fact that gas combustion is much easier to control, especially if the device is equipped with automation.

As for the duration and quality of work, there are several fundamental points:

- weather conditions outside, in particular temperature;

- quality of thermal insulation in the house;

- what temperature do they want to have in the house;

- what fuel is used and what is its moisture content;

- how well the heating system was designed and who was involved in it.

If all conditions (except the first) were met in accordance with all requirements, then long-burning pyrolysis boilers, in comparison with their other solid fuel counterparts, show themselves to be much more efficient.

Suitable fuel

Pyrolysis boilers operate on almost any type of solid fuel. This can be firewood, coal (brown or black) or peat. Depending on what material is chosen, the boiler will need to be refilled so often. Since many users prefer to stock up on fuel in advance, it is a good idea to know what it should be.

The type of fuel material has the following combustion nuances:

- soft varieties of trees burn on average in 5 hours, while for hard trees this time is 1 hour longer;

- brown coal takes 8 hours to completely transform, and black coal takes 10.

Many people prefer wood, but it can also be replaced with other organic fuels - wood waste, fuel pellets and briquettes, peat, coal, waste from Food Industry, which contain cellulose. Any fuel should have a moisture content of no more than 30%, or even better – 20%. Otherwise, there is a possibility that during the combustion process they will be released by-products burning and too much steam. And if the former are harmful to the health of the residents of the house, then the steam can damage the system, as it will lead to the formation of soot and tar. And this not only reduces heat transfer, but also disables system parts. In addition, steam causes a decrease not only in heating, but also in poor combustion, because it is almost impossible to make even an ordinary fire from wet wood.

Therefore, if it is not possible to buy ready-made fuel, then its preparation must be carried out correctly. Here you not only need to chop the firewood, but also dry it thoroughly and protect it from moisture. Only in this case can you be sure that in winter the pyrolysis boiler will heat the house properly.

Features of operation and startup of the system

The operation of a long-burning pyrolysis boiler has its own characteristics that distinguish these units from other solid fuel models. It was already mentioned above that the device has two chambers separated by gates. But few people know that before starting the entire system, it is necessary to preheat the loading tank (up to 500-800 degrees). Only in this case can you start loading fuel.

The operating diagram of the device is as follows:

- placing solid fuel in the duct;

- thermal distillation of the material;

- transfer of the resulting generator gas to the combustion furnace;

- the heat exchanger utilizes the heat of flue gases;

- control of air flow into the duct.

If you follow this sequence of actions, then slow, oxygen-free combustion of the material will occur in the boiler. And this already leads to an increase in the efficiency of the release and combustion of pyrolysis gas, thanks to which a comfortable temperature will always be maintained in the house throughout the day.

Pros and cons

Like any other technology, pyrolysis boilers have their pros and cons. You should definitely familiarize yourself with them. Firstly, this will allow you to prepare your home for such a heating system, and secondly, it will save you from unnecessary financial costs, because such a unit is not very cheap.

If speak about strengths, then they are like this:

- These models are easy to maintain; even simple breakdowns can be fixed independently;

- if there is no main gas supply, then a pyrolysis boiler is the best alternative in cold weather;

- one load of fuel lasts up to 15 hours, despite the fact that other traditional solid fuel boilers require “refueling” every 5-8 hours;

- efficiency level reaches 85-90%;

- safe from an environmental point of view - during combustion, almost 100% of the material is recycled, and there are no toxic impurities in the flue gases;

- CO2 concentration is 2-3 times lower than in other solid fuel analogues;

- During operation, very little ash is formed, so the need for cleaning occurs much less frequently, and the system lasts much longer;

- The coolant heats up much faster, so you don’t have to wait long for comfort.

But for the sake of fairness, it is worth saying that pyrolysis boilers also have their drawbacks. Among them are:

- high price - the pyrolysis device costs 1.5-2 times higher than other boilers;

- pyrolysis boilers have one circuit, which is why it is not possible to heat water for domestic purposes (except for special configurations);

- the device runs on electricity, which means that if it goes out, the boiler will stop heating;

- the fuel must have a certain humidity (up to 20%) and if this requirement is violated, the boiler will not work;

- Despite the development of modern technologies, it has not been possible to make pyrolysis models fully automatic - refueling must be done only manually.

Although the disadvantages may seem significant enough to some to refuse such a purchase, in fact, they are much more effective than their analogues. Moreover, this has been proven by more than one study. But they completely burn fuel, which gives maximum heating efficiency and leads to minimal heat loss. Such moments completely compensate for all the disadvantages.

Nuances of choosing a pyrolysis boiler

Having become acquainted with the strong and weaknesses pyrolysis boilers, you can already think about purchasing such a unit. But this purchase will be rational if it is possible to always stock up on dry firewood.

When it is not possible to meet the requirements regarding fuel, it is recommended to pay attention to boilers that are combined. That is, they burn 80% of pyrolysis material and 20% of traditional material. You can also use other fuels with them, the humidity of which does not exceed 50% - wood waste, peat, coal, etc.

It is best to purchase a boiler with a loading chamber that can accommodate firewood up to 65 cm. The internal coating, which ideally should be made of high-quality ceramic concrete, is also important. This is what allows you to maintain optimal conditions inside the chamber. temperature regime, which ensures uniform combustion of fuel and protects the walls from burnout.

If you purchase a pyrolysis boiler with natural draft, then such a device must have an automatic adjustment system. In this case, the fan speed will be controlled by the controller, which, in turn, receives signals from temperature sensors and water pressure devices. When the indicators begin to exceed the norm, the controller will automatically adjust the air flow to each of the chambers, and may even shut it off altogether. The only thing that is required from the owner is to set the temperature mode on the boiler display.

Some modern manufacturers of pyrolysis boilers have improved their models, creating the ability to work with another water circuit. This addition makes it possible to provide hot water and you can enable it separately. This option is ensured by the fact that the coil with running water The hot water supply is located in the water jacket of the system. Therefore, while driving warm water, part of the heat goes to the second circuit, resulting in an average temperature. Such designs have additional protection that prevents water from boiling if the electricity suddenly goes out.

Pyrolysis boilers can heat not only the residential building itself, but also adjacent outbuildings where there is no plumbing. In this case, you need to pay attention to specially designed unit designs. In such models there is no water jacket on the body. It is replaced by an air heat exchanger. It is capable of heating a quadrature from 100 to 1000 square meters. m. Of course, boiler modification plays a decisive role. But any model has an air damper, which helps control combustion. This can be done manually or using a chain drive.

Finally, it’s worth saying about the chimney for such boilers. Since there is no mechanical stimulation of draft, the chimney must provide the proper draft force, otherwise all the smoke will go into living rooms. For this purpose, a special fan must be provided in the design.

Depending on future operating conditions, a modification of the long-burning pyrolysis boiler is also selected. If a truly high-quality unit is selected, the fuel in it will burn for at least 8-10 hours, and it will require replacement no earlier than after 18-20 years.

Review of famous models

Among modern pyrolysis boilers, the companies BUDERUS, VIESSMANN and VIADRUS are especially popular and reliable. This is due to the fact that the quality fully corresponds to its price. Manufacturers take a responsible approach not only to the selection of materials, but to the assembly of devices itself. The boilers are fully automated, and this also applies to the ignition process itself.

Let's look at each manufacturer in more detail:

- Vitoligno 100-S from VIESSMANN – premium class (Germany). These units have a power rating from 25 to 80 kW, the efficiency level reaches 88%. The line of such models has a working pressure of no more than 3 Bar. The temperature of the supply pipe is 95 degrees, and the return pipe is 55 degrees. You can use logs up to 50 cm long. Vitoligno 100-S has automation, which consists of a controller and a set of sensors. There is a fan in the chimney duct, which provides draft as it serves as a smoke exhauster. The controller regulates the operation of not only the fan, but also circulation and network pumps, as well as three way valves boiler piping.

- BUDERUS – premium class (Germany). Such boilers also have a number of their advantages, in particular, their efficiency is 88-90%, despite the fact that their power varies between 20-40 kW. Operating pressure here is the same as in previous analogues - 3 Bar. The supply temperature is 95 degrees and the return temperature is 55 degrees. But in this boiler you can use logs 10 cm longer. Such boilers can be made of either cast iron or steel. Perhaps one of the most pleasant features of BUDERUS models is the aesthetic appearance, because not everyone has the opportunity to hide the cauldron out of sight.

- VIADRUS Nefaistos P1 – middle class (Czech Republic). You can use pellets for refueling. This is convenient because the boiler is loaded only once a week and no longer requires refueling. Although, to be fair, it should be said that the duration of the work largely depends on the volume of the bunker. The entire system is controlled automatically. For safer operation, the burners are equipped with a fire extinguishing system connected to water. VIADRUS products are in no way inferior in their technical characteristics to the Germans, but at the same time they cost an order of magnitude cheaper than their counterparts.

Of course, on modern market There are many different models, both domestic and foreign. When preparing to purchase, it is worth studying the general technical characteristics of pyrolysis boilers, and then, focusing on your finances, choose a specific model.