The best long-burning wood-burning boilers. Long-burning pyrolysis boilers

Pyrolysis boilers long burning, owner reviews are quite positive. This is due to the fact that in Lately electricity and gas are becoming more expensive, and solid fuel(coal, peat, firewood) is becoming more and more accessible. Such units have high power and efficiency, and if you install more modern model, That automatic system, will reduce human intervention to a minimum. Another great convenience is that one load is enough for a day, that is, the owner does not need to constantly monitor the fuel level. You can only throw it in the evening or in the morning required amount firewood and enjoy the warmth. But, like any other technology, pyrolysis boilers In addition to their strengths, they also have their weaknesses, which you need to become familiar with before installing such a unit.

How does a pyrolysis boiler work?

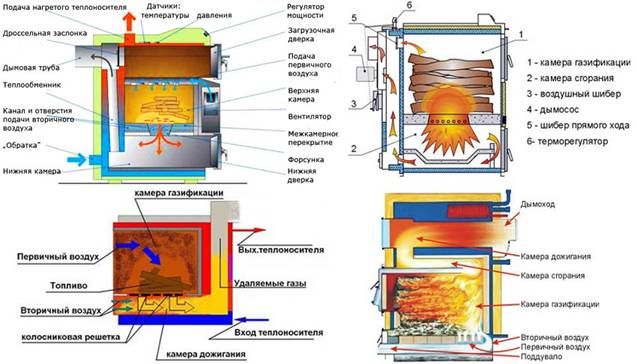

Long-burning pyrolysis devices represent a “laboratory” within which gas is extracted from solid fuel. This is what is used to heat the house. Pyrolysis is a physical and chemical process in which complex compounds decompose organic compounds into simple components in the form of a solid, liquid or gaseous state. For this to happen, it is necessary to provide high temperature and limited access of oxygen.

The design of the pyrolysis boiler has a two-chamber heating device, where in the upper part it is heated to 200-800 degrees, which contributes to the start of the exothermic reaction of solid fuel. There is no oxygen, which causes the material to slowly smolder. Having broken down into CO and CO2, the mixture passes to the lower part of the boiler, where the combustion temperature is already kept at around 1100-1200 degrees. The two chambers are connected by grates. The result is a selection large quantity heat (pyrolysis gas) intended for heating the house. The remaining fuel that does not burn is called coke or charcoal.

It is also worth noting that during the combustion of pyrolysis gas, it has to come into contact with a certain amount of active carbon at the outlet. This leads to the formation of a minimum amount of harmful impurities in the flue gases, which makes the operation of this installation safer. Thus, the flue gas mainly consists of water vapor and carbon dioxide.

It turns out that pyrolysis devices do not use the solid fuel itself, but the gas produced from it. Thanks to this technology, these boilers show an efficiency of 85-90%, since here the material is burned with virtually no residue. And at the very beginning of this action, the material is dried, that is, from the moment of ignition to the last spark, a “useful” process occurs. And this is not to mention the fact that gas combustion is much easier to control, especially if the device is equipped with automation.

As for the duration and quality of work, there are several fundamental points:

- weather conditions outside, in particular temperature;

- quality of thermal insulation in the house;

- what temperature do they want to have in the house;

- what fuel is used and what is its moisture content;

- how well the heating system was designed and who was involved in it.

If all conditions (except the first) were met in accordance with all requirements, then long-burning pyrolysis boilers, in comparison with their other solid fuel counterparts, show themselves to be much more efficient.

Suitable fuel

Pyrolysis boilers operate on almost any type of solid fuel. This can be firewood, coal (brown or black) or peat. Depending on what material is chosen, the boiler will need to be refilled so often. Since many users prefer to stock up on fuel in advance, it is a good idea to know what it should be.

The type of fuel material has the following combustion nuances:

- soft varieties of trees burn on average in 5 hours, while for hard trees this time is 1 hour longer;

- brown coal takes 8 hours to completely transform, and black coal takes 10.

Many people prefer wood, but it can be replaced with other organic fuels - wood waste, fuel pellets and briquettes, peat, coal, waste from Food Industry, which contain cellulose. Any fuel should have a moisture content of no more than 30%, or even better – 20%. Otherwise, there is a possibility that during the combustion process they will be released by-products burning and too much steam. And if the former are harmful to the health of the residents of the house, then the steam can damage the system, as it will lead to the formation of soot and tar. And this not only reduces heat transfer, but also disables system parts. In addition, steam causes a decrease not only in heating, but also in poor combustion, because it is almost impossible to make even an ordinary fire from wet wood.

Therefore, if it is not possible to buy ready-made fuel, then its preparation must be carried out correctly. Here you not only need to chop the firewood, but also dry it thoroughly and protect it from moisture. Only in this case can you be sure that in winter the pyrolysis boiler will heat the house properly.

Features of operation and startup of the system

The operation of a long-burning pyrolysis boiler has its own characteristics that distinguish these units from other solid fuel models. It was already mentioned above that the device has two chambers separated by gates. But few people know that before starting the entire system, it is necessary to preheat the loading tank (up to 500-800 degrees). Only in this case can you start loading fuel.

The operating diagram of the device is as follows:

- placing solid fuel in the duct;

- thermal distillation of the material;

- transfer of the resulting generator gas to the combustion furnace;

- heat exchanger recovers heat flue gases;

- control of air flow into the duct.

If you follow this sequence of actions, then slow, oxygen-free combustion of the material will occur in the boiler. And this already leads to an increase in the efficiency of the release and combustion of pyrolysis gas, thanks to which a comfortable temperature will always be maintained in the house throughout the day.

Pros and cons

Like any other technology, pyrolysis boilers have their pros and cons. You should definitely familiarize yourself with them. Firstly, this will allow you to prepare your home for such a heating system, and secondly, it will save you from unnecessary financial costs, because such a unit is not very cheap.

If speak about strengths, then they are like this:

- These models are easy to maintain; even simple breakdowns can be fixed independently;

- if there is no main gas supply, then a pyrolysis boiler is the best alternative in cold weather;

- one load of fuel lasts up to 15 hours, despite the fact that other traditional solid fuel boilers require “refueling” every 5-8 hours;

- efficiency level reaches 85-90%;

- safe from an environmental point of view - during combustion, almost 100% of the material is recycled, and there are no toxic impurities in the flue gases;

- CO2 concentration is 2-3 times lower than in other solid fuel analogues;

- During operation, very little ash is formed, so the need for cleaning occurs much less frequently, and the system lasts much longer;

- The coolant heats up much faster, so you don’t have to wait long for comfort.

But for the sake of fairness, it is worth saying that pyrolysis boilers also have their drawbacks. Among them are:

- high price - the pyrolysis device costs 1.5-2 times higher than other boilers;

- pyrolysis boilers have one circuit, which is why it is not possible to heat water for domestic purposes (except for special configurations);

- the device runs on electricity, which means that if it goes out, the boiler will stop heating;

- the fuel must have a certain humidity (up to 20%) and if this requirement is violated, the boiler will not work;

- despite the development modern technologies, it was never possible to make pyrolysis models fully automatic - refueling is done only manually.

Although the disadvantages may seem significant enough to some to refuse such a purchase, in fact, they are much more effective than their analogues. Moreover, this has been proven by more than one study. But they completely burn fuel, which gives maximum heating efficiency and leads to minimal heat loss. Such moments completely compensate for all the disadvantages.

Nuances of choosing a pyrolysis boiler

Having become acquainted with the strong and weaknesses pyrolysis boilers, you can already think about purchasing such a unit. But this purchase will be rational if it is possible to always stock up on dry firewood.

When it is not possible to meet the requirements regarding fuel, it is recommended to pay attention to boilers that are combined. That is, they burn 80% of pyrolysis material and 20% of traditional material. You can also use other fuels with them, the humidity of which does not exceed 50% - wood waste, peat, coal, etc.

It is best to purchase a boiler with a loading chamber that can accommodate firewood up to 65 cm. The internal coating, which ideally should be made of high-quality ceramic concrete, is also important. This is what allows you to maintain optimal conditions inside the chamber. temperature regime, which ensures uniform combustion of fuel and protects the walls from burnout.

If you purchase a pyrolysis boiler with natural draft, then such a device must have an automatic adjustment system. In this case, the fan speed will be controlled by the controller, which, in turn, receives signals from temperature sensors and water pressure devices. When the indicators begin to exceed the norm, the controller will automatically adjust the air flow to each of the chambers, and may even shut it off altogether. The only thing that is required from the owner is to set the temperature mode on the boiler display.

Some modern manufacturers of pyrolysis boilers have improved their models, creating the ability to work with another water circuit. This addition makes it possible to provide hot water and you can enable it separately. This option is ensured by the fact that the coil with running water The hot water supply is located in the water jacket of the system. Therefore, while driving warm water, part of the heat goes to the second circuit, resulting in an average temperature. Such designs have additional protection that prevents water from boiling if the electricity suddenly goes out.

Pyrolysis boilers can heat not only the residential building itself, but also adjacent outbuildings where there is no plumbing. In this case, you need to pay attention to specially designed unit designs. In such models there is no water jacket on the body. It is replaced by an air heat exchanger. It is capable of heating a quadrature from 100 to 1000 square meters. m. Of course, boiler modification plays a decisive role. But any model has an air damper, which helps control combustion. This can be done manually or using a chain drive.

Finally, it’s worth saying about the chimney for such boilers. Since there is no mechanical stimulation of draft, the chimney must provide the proper draft force, otherwise all the smoke will go into the living rooms. For this purpose, a special fan must be provided in the design.

Depending on future operating conditions, a modification of the long-burning pyrolysis boiler is also selected. If a truly high-quality unit is selected, the fuel in it will burn for at least 8-10 hours, and it will require replacement no earlier than after 18-20 years.

Review of famous models

Among modern pyrolysis boilers, the companies BUDERUS, VIESSMANN and VIADRUS are especially popular and reliable. This is due to the fact that the quality fully corresponds to its price. Manufacturers take a responsible approach not only to the selection of materials, but to the assembly of devices itself. The boilers are fully automated, and this also applies to the ignition process itself.

Let's look at each manufacturer in more detail:

- Vitoligno 100-S from VIESSMANN – premium class (Germany). These units have a power rating from 25 to 80 kW, the efficiency level reaches 88%. The line of such models has a working pressure of no more than 3 Bar. The temperature of the supply pipe is 95 degrees, and the return pipe is 55 degrees. You can use logs up to 50 cm long. Vitoligno 100-S has automation, which consists of a controller and a set of sensors. There is a fan in the chimney duct, which provides draft as it serves as a smoke exhauster. The controller regulates the operation of not only the fan, but also circulation and network pumps, as well as three way valves boiler piping.

- BUDERUS – premium class (Germany). Such boilers also have a number of their advantages, in particular, their efficiency is 88-90%, despite the fact that their power varies between 20-40 kW. Operating pressure here is the same as in previous analogues - 3 Bar. The supply temperature is 95 degrees and the return temperature is 55 degrees. But in this boiler you can use logs 10 cm longer. Such boilers can be made of either cast iron or steel. Perhaps one of the most pleasant features of BUDERUS models is the aesthetic appearance, because not everyone has the opportunity to hide the cauldron out of sight.

- VIADRUS Nefaistos P1 – middle class (Czech Republic). You can use pellets for refueling. This is convenient because the boiler is loaded only once a week and no longer requires refueling. Although, to be fair, it should be said that the duration of the work largely depends on the volume of the bunker. The entire system is controlled automatically. For safer operation, the burners are equipped with a fire extinguishing system connected to water. VIADRUS products are in no way inferior in their technical characteristics to the Germans, but at the same time they cost an order of magnitude cheaper than their counterparts.

Of course, on modern market There are many different models, both domestic and foreign. When preparing to purchase, it is worth studying the general specifications pyrolysis boilers, and then, focusing on your finances, choose a specific model.

In places where interruptions in gas or electricity supply are possible, where fuel (wood, coal, etc.) is available, long-burning solid fuel boilers are taking root as the main or backup sources heat in heating systems. And long-burning pyrolysis boilers have proven themselves especially well. They are both effective and economical!

The topic of solid fuel boilers at one time lost its relevance, but is now quite confidently making its way into the heating sector. This is successfully helped by rising energy prices (gas, oil, electricity), as well as the greater popularization of individual construction of houses and cottages.

Let's look at their features...

Who are they?

The group of pyrolysis boilers for heating usually includes their solid fuel “brothers”, which consume mainly wood.

Important! Firewood in our country has the status of an easily accessible fuel. And, mind you, renewable. The main thing to remember is that forests not only need to be cut down, but also need to be planted...

High-tech supporters need not be nervous! This is not a leap into the past, but a smart integration of scientific technologies into human life. Studying a wood-fired pyrolysis boiler (even the simplest one) reveals the beginning of an impressive list of its advantages.

The benefits of pyrolysis in heating

The long-term search for energy-saving technologies has touched a little on organic chemistry. Scientists have noticed that in a high-temperature environment with limited access to oxygen, the combustion process of many organic solids is accompanied by a stable release of flammable gas, which in itself is suitable for further combustion. And when it burns, a large amount of heat is released.

In other words, when one fuel burns, a new (gaseous) fuel is formed. Wood is the leader in this process!

This process of generating flammable gas from solid organic substances during their smoldering was called pyrolysis, which determined the name of the pyrolysis heating boiler. They are also called gas generators or long-burning solid fuel boilers.

Due to the two-stage combustion of fuel (solid and newly formed gaseous), pyrolysis boilers produce more heat when burning the same volume of fuel than conventional solid fuel units. That is, their efficiency is much higher.

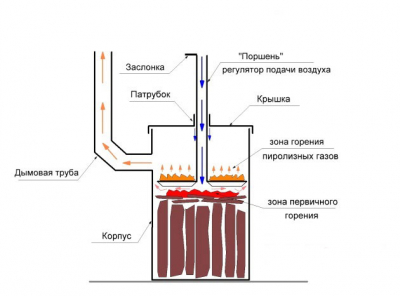

The main practical advantage of such boilers is their ability to operate for a long time (up to 25-30 hours) on one load of fuel. This is achieved by deliberately restricting the air supply to the combustion chamber.

And how does it work?

The difference between a pyrolysis boiler and a conventional solid fuel boiler is that it has two combustion chambers. It also has a separate compartment for waste from the combustion process.

The upper chamber (gasification) is intended for loading fuel. The primary decay of firewood occurs in it.

Due to the restriction of air access into the chamber, an exothermic reaction occurs in it. High temperatures from 200 to 800 °C lead to the formation of two flammable components: pyrolysis gas and charcoal.

The heat released at this stage is also spent on drying the wood and heating the air entering the combustion zone.

Next, the gas enters the middle chamber, where, in “steam” with air drawn into the chamber by a fan-exhaust fan at a high temperature of 1150-1200 O C, it ignites, releasing a significant amount of thermal energy and virtually complete combustion of the entire contents of the chamber.

The resulting ash, as well as soot, fall into the lower chamber, adapted for periodic cleaning, the frequency of which depends on the quality of the fuel and the intensity of use of the wood-burning boiler.

High temperature processes occurring in pyrolysis boiler long burning determine the requirements for the strength of the entire unit. Steel or cast iron are used. Cast iron is more “slow” (inertial), both when heating and when cooling, but it is also more durable. Steel improves dynamics when heated, but rapid cooling of a pyrolysis boiler is not always convenient. Cast iron has higher corrosion resistance, and steel surfaces are predominantly coated with ceramic materials, which protects the metal from “destructiveness” high temperatures. Various construction materials, the presence of automation, and the power of the unit determine its cost.

Set of advantages and disadvantages

Modern technologies that use pyrolysis boilers have allowed them to acquire a number of advantages:

- Efficiency of up to 85% is explained by the operating features of the boiler, which ensures complete combustion of fuel;

- complete combustion of fuel ensures minimization of waste;

- the slow combustion process allows you to add a new portion of fuel twice, and in some designs, with economical use, even once a day;

- the boiler design provides the ability to automatically dynamically control the power of the heating system within the range of 30-100%, by regulating the rate of air flow into the lower combustion chamber;

- the environmental friendliness of this boiler design is ensured by the virtually complete combustion of both solid and the resulting gaseous fuel mass, which ensures low emissions (about 3 times less) of carbon dioxide into the atmosphere;

Wood-burning pyrolysis boilers also have disadvantages. These are also worth mentioning:

- the most insignificant is the need for constant power supply to the unit. But due to the fact that modern heating systems are predominantly forced circulation coolant, then electricity will be required to ensure the operation of the circulation pump.

- “single-circuit” pyrolysis units, which is also easily compensated by the installation storage boiler For DHW systems, which naturally leads to additional costs;

- quite high price, which is also compensated by economical fuel consumption;

- the need, although rare, is still “manual” loading of fuel. New pyrolysis boilers using wood pellets, which can be automatically reloaded from fuel bunker or warehouse.

- “demanding” on the quality of wood fuel, especially its moisture content, to ensure highly efficient operation.

And in conclusion about the global...

As we can see, energy-saving technologies have firmly taken root in the long-burning pyrolysis boiler, realizing their current global goals:

- minimizing fuel consumption;

- increasing the heat transfer of fuel during combustion;

- reducing the concentration of morbid substances in combustion products.

By installing a boiler of this type in your home, you will not only optimize your time spent on its maintenance, but also make your contribution to the conservation of nature.

Heating houses with solid fuel boilers is quite common in small settlements where there is still no gas. In most cases, the most common firewood or fuel briquettes are used as fuel.

The disadvantage of such boilers is that they force many approaches to add new portions of fuel. Long-burning pyrolysis boilers are devoid of not only this drawback, but also some others - we’ll talk about this as part of our review.

Features of pyrolysis boilers

Traditional wood-burning boilers are annoying because they require constant monitoring. That is, every 2-3 hours you need to add more and more fuel to them, otherwise the pipes in the house will become cold. It’s especially difficult at night, when instead of restful sleep, household members get a headache in the form of cooling heating. On the one hand, sleeping cool is good for your health. On the other hand, greeting the morning with your teeth chattering desperately is not very pleasant.

Classic boilers for heating a home have another important drawback - low efficiency. The fuel in them burns very quickly, most of the heat simply evaporates into the atmosphere. Along with it, combustion products containing flammable gases fly into the air. They can be used to obtain additional portions of heat - this is what happens in long-term combustion pyrolysis boilers.

As you already understand, solid fuel pyrolysis heating boilers are free from both of the above disadvantages. They are equipped with spacious fireboxes, burning solid fuel according to a slightly different principle. Here are their main features:

The operating principle of a solid fuel pyrolysis boiler is very simple. This drawing, although it does not cover all the nuances, conveys the essence of the technology in full.

- Large firebox volume – up to several tens of liters. Thanks to this, the frequency of approaches to laying fuel is reduced several times;

- Pyrolysis combustion principle - allows you to get much more thermal energy from the same amount of firewood;

- Quite large in size - in fact there are two fireboxes. In one, wood burns slowly, and in the second, combustion products released from the wood are burned;

- Low combustion temperature – reduces the thermal load on the metal.

Long-burning pyrolysis boilers are somewhat more complicated than their traditional counterparts, but they provide significant fuel savings.

It should be understood that due to complex design, often containing elements of automation, pyrolysis boilers have a high price. Therefore, the initial cost of purchasing them may seem large. But in the future they will definitely justify themselves.

Operating principle

Now we will try to understand how a long-burning pyrolysis boiler works and how it works. The principle of operation is very simple and at the same time complex. Pyrolysis is discussed in a school physics course - when heated in a confined space, wood releases flammable gases that can be set on fire to produce heat. In fact, there is no direct combustion of wood in such an experiment.

In long-burning pyrolysis boilers, wood still burns, but with limited air supply. You could say it's a slow burn. Having flared up, the tree begins to release flammable gases, which burn in the afterburner. In total, we get two sources of heat - burning wood and burning wood gas. The effect of such staged combustion is felt in the form of fuel savings of up to 40%.

Wood gas in long-term combustion pyrolysis boilers is formed as a result of slow smoldering of fuel. At the same time, the equipment heats the air, which, together with wood gas, is supplied to the afterburning chamber. There the mixture ignites and burns, producing a large amount of heat. At the same time, the amount of harmful emissions, compared to traditional boilers, is extremely small.

Thus, a pyrolysis boiler is a direct saving of fuel, since a larger amount of heat can be released from the same portion of firewood. Instead of 10 cubic meters of firewood per winter period it may take only 6-7 cubic meters. At the same time, users will not need to add new portions of firewood to the insatiable firebox every 2-3 hours.

Long-burning pyrolysis boilers are available in several modifications:

Despite the low combustion rate of the fuel, the emitted porylization gases are capable of inflating the flame to a similar bright white-yellow color.

- Non-volatile - they operate on natural draft and are controlled mechanically;

- Energy-dependent - here pyrolysis occurs using forced draft. Due to this, combustion efficiency increases;

- With different locations of the afterburning chamber - it can be located above or below the combustion chamber. Modifications with a sequential arrangement of cameras are also available for sale.

There are many modifications, but in general the device and principle of operation are almost no different.

Energy-dependent long-burning pyrolysis boilers are good because they often contain automation, which can control the power of the equipment and the intensity of combustion, focusing on the temperature of the coolant or the temperature in the rooms.

Long-term combustion in pyrolysis boilers is ensured by two factors at once. The first factor is the low burning/smoldering rate of wood. The second factor is the large volume of the combustion chamber. For example, there are pyrolysis boilers on sale with a firebox volume of 50 liters or even more. It is not surprising that the frequency of approaches to load fuel is reduced to 1-2 times a day.

Advantages and disadvantages

Pyrolysis boilers have a number of advantages over their traditional counterparts. But they also have some disadvantages. Let's discuss all their pros and cons:

- Profitability - it varies from 10 to 40%, depending on the model, combustion intensity and air temperature outside the window;

- Long burning – you can add fuel only 1-2 times a day. For example, morning and evening. The house will be warm at any time of the day;

- Environmentally friendly - firewood burns almost completely, with minimal release of combustion products;

- Almost complete extraction of heat into the heating system - the temperature of the exhaust gases is lower here than in traditional boilers;

- In long-burning pyrolysis boilers, they are often implemented various mechanisms power control - they work by adjusting the intensity of fuel smoldering and gas supply to the afterburner chamber.

There are also disadvantages:

Due to its impressive dimensions, you will have to find a lot of free space to place the boiler. The basement and attic are the most promising options.

- Expensive - user reviews say that long-burning pyrolysis boilers are very convenient, economical and practical. But the initial costs of purchasing them are extremely high (most true for powerful energy-dependent models);

- Energy dependence - such units are more efficient, but require connection to the electrical network (the total electricity consumption is low, but in its absence, work will be difficult or completely impossible);

- Large dimensions - long-burning pyrolysis boilers are noticeably larger than any other solid fuel units.

The disadvantages are not the most serious, some of them can be neglected. But you have to come to terms with the high cost.

Fuel used

We have already said that long-burning pyrolysis boilers operate on wood. This is a fairly common and inexpensive type of fuel. In some cases, firewood can be obtained completely free of charge. But these boilers can operate on many other types of solid fuel. For example, in some stores we can buy a pellet pyrolysis boiler. It operates on fuel pellets on the same principle as the units described above.

The main advantages of pellet models are automated fuel supply (implemented in some units) and low ash content of the fuel.

You can also purchase a coal-fired pyrolysis boiler. It will delight you with long burning and high efficiency. Coal boilers work on the same principle of operation, producing flammable gas from coal. Due to the powerful calorific value, the frequency of approaches for adding fuel is lower than when using long-burning wood-burning pyrolysis boilers.

Popular models

Popov's pyrolysis boiler is simple non-volatile unit, made of steel. The design turned out to be so successful that many craftsmen copy it when assembling heating equipment with your own hands. The presented boiler is omnivorous; it can burn almost any solid fuel. And the impressive firebox of gigantic volume allows you to count on almost 24 hours continuous burning. In this case, the fuel burns almost completely, forming a minimum of components harmful to nature.

One of the advantages of this pyrolysis boiler is the ability to add logs custom size(up to 75 cm in low-power models, up to 240 cm in the most productive units), which ensures long-lasting combustion. Maximum power equipment is 1000 kW, the minimum is only 25 kW. Depending on the selected operating mode, the efficiency of the device varies from 75 to 95%.

Geyser boilers

Equipment from the manufacturer of the same name is presented in two lines - household and industrial. Long-burning Geyser household pyrolysis boilers have a power of 10 to 50 kW. They can operate on any solid fuel, characterized by a high efficiency index. The firebox volume of the smallest model is 40 liters. The equipment is non-volatile and is characterized by extreme ease of operation and unpretentiousness.

Buderus boilers

Long-burning solid fuel pyrolysis boiler Buderus Logano G221-20 from the famous trademark Buderus is an excellent purchase for heating your home. Its power is 20 kW, thanks to which it can heat rooms up to 200 square meters. m. The control here is mechanical; connection to a source of electricity is not required. The heat exchanger here is made of cast iron - this affects the cost of the model, but makes it durable and resistant to corrosion. True, the efficiency of the heating unit is only 78%.

Its closest analogue is the more advanced long-burning pyrolysis boiler Buderus Logano S171-22 W. It has a high efficiency of 87%. The use of forced draft is responsible for this - inside we will find a small fan. Another difference is the steel heat exchanger. This does not add reliability, but it does make the equipment more affordable. Average consumption fuel is about 6 kg/hour.

Boilers Bastion

Long-burning Basting pyrolysis solid fuel boilers of the M-KST series are non-volatile equipment that runs on wood and other types of solid fuel. The line has been in production for 3 years and is characterized by a low number of negative reviews. The youngest model has a power of 12 kW, the oldest – 50 kW. The boilers are equipped with powerful cast iron heat exchangers, the minimum firebox volume is 40 liters. Among the advantages - reliable design and affordable price.

Video

Long-burning pyrolysis boilers are excellent for heating a residential building. First of all, it should be noted their versatility. Today there are models with different designs. Their characteristics and dimensions are very different.

These devices are simple to maintain and do not require the owner to exert much physical effort. Additionally, it should be noted that pyrolysis boilers are economical. The wood in them can be used with a moisture content of up to 50%.

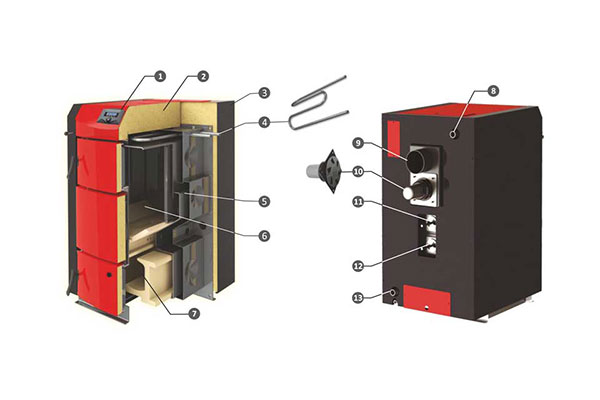

Boiler design with controller

A distinctive feature of this type (the diagram of a long-burning pyrolysis boiler is shown below) can be safely called a volumetric chamber, which is designed for fuel combustion. It closes with a metal door. In some cases it is installed with a window. In such a situation, you can observe the combustion process and, if necessary, add firewood to form pyrolysis gas.

There is an entrance next to the camera that connects the device to the home's plumbing system. A special air supply mechanism is hidden behind the side panel of the boiler. With its help you can regulate traction. The unit damper is installed under the air drive. The control unit is located at the top of the structure, and the heat exchanger is located under the casing and is reliably protected. The device is equipped with a fan for exhaust. It should also be noted the pipe, which is necessary to remove excess pyrolysis gases. The design of the device itself can be equipped with wheels, which are needed to transport the boiler.

Models with fuses

Long-burning pyrolysis boilers of this kind usually have a double combustion chamber. In this case, the device is equipped with a special sensor that monitors traction. The fuse is directly mounted on the side panel of the device. To supply air there is a special network that connects to the tee. The external contour of the boiler has a protective casing. With plumbing system this type devices are connected through special connectors, which are located at the bottom of the structure. The main frame of the boiler supports the ash pan.

How to make long-burning pyrolysis boilers?

The drawings will help you make this device yourself. Although this is quite difficult and requires some experience. In order to build homemade long-burning pyrolysis boilers, you will first need to look for a combustion chamber. As a rule, they are made of steel. The actual design of the device can be cast iron. In this case, additional supports will need to be welded. An ash pan should be installed under the boiler chamber. At the same time, it must be fenced with a net. The air damper is usually made small. In this case, it will be easier to regulate the traction.

A drive system must be installed to supply air. It consists of two plates that are connected to each other. The boiler heat exchanger should be installed last. The door, like the combustion chamber, should be made of steel. In this case, it will be able to withstand high thermal loads. A fan is installed next to the firebox. As a result, part of the pyrolysis gases will be removed from the boiler.

Consumer reviews about Bosch boilers

The Bosch company is quite famous, and its products are different good quality. The average boiler power is 80 kW. This is quite enough to heat a residential building with a total area of up to 900 square meters. m. Heat exchangers in many models are made of cast iron. The thickness of the metal is quite large. Firewood no longer than 40 cm is used as fuel for boilers. Loading in all models is provided by the manufacturer manually. The combustion chamber depends on the modification of the device.

The consumer has the opportunity to choose any size for his convenience. On average, chambers are produced with a total volume of up to 400 liters. All models have mechanical controls. To control traction, a lever is installed on the top panel. In autonomous mode, the boilers can operate for about 7 hours. For connection to the water supply, the device has two 70 mm connectors. According to the owners, it is possible to load large firewood. The boiler models are quite simple to maintain. In order to clean the ash, you just need to open the door and take out the drawer. This should be done at least once a week.

Features of Atmos models

For large cottages, these long-burning pyrolysis boilers are ideal. They differ primarily in their design. The actual thickness of the metal is insignificant, but there are additional stops. No special tools are required to install the boiler. To connect the device to the water supply system, there are standard threaded connectors. Among the shortcomings, rather poor management should be noted. In some cases, the draft control may become stuck. As a result, you will not be able to control the air flow. There are also certain problems with the ash pan in early models. It is quite difficult to pull out, and the doors sometimes do not close well.

On average, the boiler can operate for about 5 hours on one load of wood. Some models are equipped with an auto shut-off system. Consumers were also pleased with the high-quality cooling heat exchangers. DC series models are best suited for heating a home. According to experts, Atmos DC100 is the best long-burning pyrolysis boiler of this company.

What do they say about Teplodar boilers?

Russian long-burning pyrolysis boilers from the Teplodar company are distinguished by their productivity. Coefficient useful action in some cases it reaches 90%. The average power of the units fluctuates around 14 kW. This makes it possible to heat rooms with a total area of no more than 140 square meters. m. Reviews indicate that the models are quite simple to maintain. To connect the device to the water supply system, pipes are provided at the bottom of the structure. Many models have mechanical controls.

Among the shortcomings, consumers note bad doors. In this case, this makes loading the camera much more difficult. At the same time, firewood is only suitable for sizes up to 30 cm. You can choose a suitable boiler based on its dimensions. The auto shut-off system is not installed on all models. The frames in many modifications are durable, but the wheels for transportation are of poor quality. As a result, the oven may become unstable.

Expert opinions on Protech products

Long-burning pyrolysis boilers of this brand are famous for their powerful ventilation systems. In this case, gases will never enter the room. There is enough fuel for the device to for a long time. Control units are installed in different modifications and differ in their characteristics. If we consider the boilers of the first series, then they are characterized by standard designs. In this case, the damper can only be adjusted in two positions.

Thus, controlling the air flow and adjusting the temperature in a residential building is quite problematic. If we consider the boilers of the second series, then completely different blocks are used. First of all, they are distinguished by their versatility. Additionally, you can make fine adjustments to the device damper. As a result, traction adjusts quite quickly.

Consumer reviews of Dakon models

Long-burning pyrolysis boilers of this brand are distinguished by their economical fuel consumption. They are also absolutely environmentally friendly and do not harm human health. The loading chambers in many models are quite voluminous. Due to this, you can stack firewood with greater comfort. Their efficiency reaches 80%. Among the shortcomings, reviews note only poor contours. In general, they are made of a thin sheet of metal and have poor temperature control.

There are a wide variety of exhaust fans installed, and they depend on the power of the unit. Ash pans are quite convenient to install, but in some models they are small in volume. As a result, the owner has to remove the ash very often. Boilers cope well with large pieces of wood. These devices can work without electricity, but when paired with other heating devices they operate more efficiently. When the fuel in the chamber runs out, the device will turn off automatically. It will be difficult for consumers to select a compact model of this brand. The manufacturer mainly produces powerful units for large rooms.

Overview of Viadrus boilers

Viadrus is famous all over the world for its quality. The characteristics of the products of this brand are similar to the Teplodar models. Heat exchangers are made exclusively from refractory steel. The air flow is adjusted mechanically. The average power of devices fluctuates around 25 kW. The bunker is designed for a volume of up to 90 kg. The heat transfer efficiency of the device is 90%. Among the features, we can highlight interesting models that have hob. All this allows the owner to prepare various dishes without consuming any electricity.

Fuel tanks in all models are of the front type. The boilers are capable of operating on shavings and wood chips. On average, the heating area is 120 square meters. m. On one load of fuel the unit can last about 7 hours. As a result, we can say that long-burning pyrolysis boilers (solid fuel) of this brand are most suitable for dachas and small cottages.

- Diagram and structure of a pyrolysis combustion boiler

- Operating principle of a pyrolysis heating device

- Advantages and disadvantages of pyrolysis boilers

- Installation and installation of pyrolysis type boilers

Every owner of a private home, when choosing a solid fuel heating boiler, undoubtedly wants to do the best choice. One of the main criteria that all buyers, without exception, pay attention to is efficiency. Among the variety of devices presented on Russian market, there is one variety that uses a special method of burning it - long-burning pyrolysis boilers. Let's try to figure out how such a boiler works and how it is designed, and also consider its main pros and cons.

Diagram and structure of a pyrolysis combustion boiler

The essence of pyrolysis can be explained using the example of a long-burning wood-burning boiler. Under the influence of high temperatures in the firebox (about 450 degrees Celsius), wood decomposes into solid and gaseous components. Subsequently, each of these components is burned separately. Heating devices of this type are also called gas generators, and the method itself is called the dry distillation method. Thanks to this technology, better efficiency is achieved and less wood consumption than when using classic way, but the price of the device increases significantly.

The main types of fuel for long-burning boilers using the pyrolysis method are: wood, coal, peat, sawdust, pellets. The main fuel requirements are as follows:

limited dimensions

The dimensions of the bookmark should not be larger than the dimensions of the firebox. In the case of using wood logs, their length is usually limited to 40cm and diameter to 20cm.

low humidity

To obtain high efficiency, as well as to extend the service life of the boiler, it is necessary that the humidity of the fuel used in it does not exceed 20%.

According to the type of fuel used, all types of pyrolysis boilers can be divided into:

wood burning

Structurally, designed to work on wood. It is with this fuel that they provide the best efficiency. The most famous model of this type is

coal

The main type of fuel is brown coal or coke.

pellet

Such boilers operate on pellets - pressed fuel granules from wood processing waste.

combined (or universal)

Can work on any of the above listed types fuel. The efficiency of universal long-burning boilers is usually worse than those designed for a specific type of fuel.

Photo 2: Construction of a wood-fired pyrolysis boiler

Photo 2: Construction of a wood-fired pyrolysis boiler Depending on how many contours the structure contains, the following are distinguished:

single-circuit

The hot water boiler contains one circuit, which is used to heat the house.

double-circuit

The design provides an additional circuit to provide hot water supply.

Below is a diagram of a pyrolysis boiler, looking at which we will analyze its structure. A long-burning domestic heating boiler usually consists of the following main elements:

Photo 3: Design diagram of a pyrolysis boiler

Photo 3: Design diagram of a pyrolysis boiler Control device

The automatic boiler control unit is designed to set various boiler operating modes. This device allows you to control various parameters operation of the heating device.

Frame

The outer frame is made of steel and coated with special heat-resistant and wear-resistant paint. The use of special paints in heating boilers dictated by their operating conditions and temperature conditions.

Thermal insulation

To reduce heat loss from the pyrolysis boiler, it is thermally insulated. Mullite-silica boards, asbestos, diatomaceous earth, and lime are used as materials for thermal insulation.

Boiler boiler prevention device

This device allows you to keep the boiler temperature within the required limits. Boiler boiling is very dangerous and can lead to boiler failure and, in some cases, to an explosion.

Heat exchanger

The heat exchanger is a cast iron or steel container that is filled with coolant. In its upper and lower parts there are valves for connecting the supply and return lines of the heating system. During the combustion process, the coolant inside the heat exchanger heats up and circulates through the heating system.

Load chamber

The loading chamber (gasifying or combustion chamber) is a compartment into which solid fuel is loaded. After loading and igniting fuel, the supply of primary air decreases. The combustion process slows down and the fuel begins to slowly smolder, releasing pyrolysis gas. The temperature at which this procedure occurs is approximately 450C. The resulting gaseous mixture is forced into the next compartment, called the combustion chamber.

The combustion chamber

In the combustion chamber, a mixture of wood gas and secondary air is burned. This mixture is supplied forcibly from the gasification compartment. The combustion process takes place at a temperature of 1100C.

Flow connection

The supply pipe is used to supply hot water from the boiler to the heating system.

grate

The grate is a cast iron or steel grate located between the loading and combustion chambers. Gasification of solid fuel occurs on it, and through holes in it, pyrolysis gas is pumped into the combustion chamber located below.

Chimney pipe

The chimney is a channel for removing combustion gases. Length and section chimney should depend on the boiler power.

Chimney fan

Since most use top blast, it is necessary to use forced draft using a fan or smoke exhauster.

Primary air valve

Primary air is intended to preheat the fuel and begin the pyrolysis process.

Secondary air valve

Secondary air is necessary for afterburning pyrolysis gases in the combustion chamber.

Return line connection

Through the return pipe, the coolant from the heating system returns back to the heating device.

Operating principle of a pyrolysis heating device

So, how does a pyrolysis boiler work? Let's look at the step-by-step diagram of its operation using the example of a coal-fired pyrolysis boiler:

Stage 1:

Solid fuel, in our case coal, is loaded into the firebox. The boiler lights up and the door to the combustion chamber closes tightly. Since the supply of primary air is limited, the process of smoldering and the release of pyrolysis gas begins. The duration of combustion can be controlled by adjusting the supply of primary air.

Photo 4: How a coal pyrolysis combustion boiler works

Photo 4: How a coal pyrolysis combustion boiler works Stage 2:

A mixture of pyrolysis gas and primary air is forced into the combustion chamber through holes in the grate. Secondary air is also supplied there to ensure combustion intensity. The process of combustion of a mixture of pyrolysis gas and secondary air occurs at high temperatures. The resulting thermal energy heats the coolant inside the heat exchanger.

Photo 5: How the pyrolysis gas afterburning system works

Photo 5: How the pyrolysis gas afterburning system works Stage 3:

Through the flue, through forced draft with the help of a smoke exhauster, gaseous combustion products are released into the atmosphere. It should be especially noted that the exhaust gases generated as a result of pyrolysis combustion contain a minimal amount of harmful impurities. Most flue gases consist of water vapor and carbon dioxide.

As you can see, the operating principle of a pyrolysis boiler is somewhat more complicated than a traditional one. That is why their cost is usually 2 times higher. Before deciding which boiler to buy, pyrolysis or classic, let's look at the pros and cons of pyrolysis combustion boilers.

Return to contentsAdvantages and disadvantages of pyrolysis boilers

The use of pyrolysis technology has both advantages and disadvantages. The main advantages of long-burning pyrolysis boilers are:

Burning duration

Increased efficiency

When using pyrolysis combustion, solid fuel burns much better. To obtain the same amount of heat using pyrolysis, less fuel will be required than with traditional combustion.

High efficiency

The efficiency when using pyrolysis is much higher. The range of efficiency values for pyrolysis boilers is 85-92%.

Environmental friendliness

The composition of the gases at the outlet of a pyrolysis type boiler is almost completely free of harmful impurities. The main part of exhaust gases consists of water vapor and carbon dioxide.

Adjustable

The gas generation process is easy to adjust. Therefore, most often pyrolysis boilers are automatic. Adjusting the combustion intensity allows you to adapt to the needs of the heating system.

Photo 6: Automatic household gas generator boiler

Photo 6: Automatic household gas generator boiler In addition to the advantages we have discussed, they also have a number of disadvantages. Let's take a closer look at them:

Energy dependence

The design feature of the pyrolysis boiler is that the supply of primary and secondary air, as well as draft, is carried out forcibly using fans that require electricity. However, there are also energy-independent models with natural draft, but they are quite rare.

Requires low moisture content

The gas generation method is very sensitive to the moisture content in solid fuel. The drier the fuel used, the better. Recommended humidity no more than 20%

Full download required

With a small amount of fuel, pyrolysis boilers begin to burn unstably. Therefore, it is recommended not to load less than 30-50% of the manufacturer’s recommended rate.

Difficulty in automatic fuel supply

For wood-burning pyrolysis boilers, it is difficult to organize automatic fuel supply due to large sizes logs It is possible to make an automatic long-burning coal boiler only if the size of the coal fractions is uniform.

High price

The high cost of long-burning gas generator boilers is one of their most significant disadvantages. You can buy such a boiler at 1.5-2 times more expensive than devices of similar power, but using traditional way burning.

Read more about heating devices pyrolysis type, their advantages and disadvantages, see the video: