Which is better, single-circuit with a boiler or double-circuit? Choose a single-circuit or double-circuit gas boiler, the best double-circuit gas heating boilers. Double-circuit gas boiler.

- Classification of gas boilers

- About the advantages of condensing boilers

In the absence of centralized heat and hot water supply (DHW), heating a private home and providing it hot water are achieved using heating boilers operating on fuels available in the area of residence.

In addition, there was not enough hot water to prepare, so they asked the installer to recommend one with better performance in both aspects. Both boilers are waterproof, have high modulation and are able to regulate the drive temperature depending on the heat demand. The latter is important in a condensing boiler connected to radiators operating at high temperature to take advantage of the improved performance provided by this technology.

This high percentage would translate into high seasonal yields, which would be equivalent to fuel savings compared to a boiler that does not condense. But it helps me understand that the data is not misleading. The fuel used in this home is propane supplied by a well-known marketing company.

DHW can be provided using a separate (autonomous) heating device operating on gas, but in the presence of a centralized gas supply, a suitable source providing both heating and hot water supply is gas boilers. It is to these devices that such definitions as double-circuit or single-circuit are applied, the popularity rating of which is growing every year.

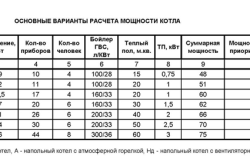

Economic table with actual consumption data

Let's see in the following table how much they could save by changing the boiler. In short, with a high efficiency boiler we would save €245 per year and we would write off in 11 years, while condensing would save €480 per year and we would write off in less than 7 years. It seems clear that a condensing boiler is more cost effective, as we suggested at the beginning of the post.

The results obtained are as follows. Since the demand for heating is greater, the savings achieved with boilers with higher outputs are therefore greater. Something that makes sense a priori: the more you spend on heating, the more savings you will get by replacing your old boiler with a better performance one.

Classification of gas boilers

Gas boilers are mainly classified as follows:

- floor or wall;

- traditional and condensing;

- single-circuit and double-circuit;

- with an open combustion chamber or closed type.

A floor-standing boiler, double-circuit or single-circuit, can be selected to any power. That is, in this regard their rating is very high. They are more durable (20-30 years) than wall-mounted ones (10-12 years), since they use the most durable and solid materials, including cast iron. The absence of power restrictions allows them to be used for indirect heating DHW boilers large volume. Durability is another advantage of this type of device, which increases its rating.

There is also a drawback: it is necessary to provide a separate room in the house for their installation, since it will not be possible to install them in the kitchen.

From the two tables presented it is clear that with this installation, changing the boiler to a high-efficiency boiler will mean a saving of 4% of the total cost over 10 years, approximately 400 euros. If you replace the condensate, we will save 15%. This is already almost € 000, which is important. And not only would it thank your pocket, we would all appreciate it.

Other posts on this topic that may interest you

Therefore, in the future, when you want to replace the boiler with condensate, you will solve this unpleasant problem.

- Edit Atekir.

- Source 2: "The Essential Guide to Condensing Boilers."

A wall-mounted boiler, double-circuit or single-circuit, unlike a floor-standing one, can be installed in the kitchen or in another room.

Choosing the right boiler allows you to save on heating your home.

It is easy to install in the attic, which is very convenient. Wall boilers compact, significantly cheaper, and easy to install. Although this positive quality interesting for the master. In order not to have to redo everything, carry out the installation yourself gas equipment not worth it.

How does a gas condensing boiler work?

Condensing boilers achieve much higher efficiency, thereby reducing heating costs and pollutant emissions. Our condensing boilers are suitable for both water heating and space heating. Energy efficiency of up to 98% Significant reduction in soot and particle production during combustion thanks to condensation technology Reduction of consumption by up to 30% compared to previous generations of boilers Reduced investment Possibility of system expansion with the addition of e.g. solar panels, heat pump, Deposit or control. In a gas condensing boiler, water is heated by combustion of heat, as in conventional boilers.

These devices are very diverse in appearance, which allows you to select them in accordance with the design of the room. It is these qualities that allow their rating to grow.

The power that a wall-mounted double-circuit or single-circuit boiler can have does not exceed 50 kW, which is significant drawback, since to heat a room with an area exceeding 300 m², one boiler will not be enough.

The resulting combustion products are usually forced out by the chimney. Thus, the energy contained in these gases is lost. However, condensation technology uses these gases, which consist mainly of hot water vapor. Extracts heat from flue gases and places it in the heating circuit.

The condensing boiler cools the steam in a specially designed heat exchanger. The energy thus obtained is used to preheat the water from heating. The water, already hot, passes into the primary heat exchanger, where it is heated to the final selected temperature. During this process, it is necessary to remove small amounts of water from the condensate.

A traditional single-circuit or double-circuit boiler has a significantly lower efficiency than a condensing boiler. An increase in efficiency in a condensing boiler is achieved by using the heat contained in water vapor as part of the combustion products. It should be noted that the condensing boiler costs more than usual, but these costs pay off within 2-4 years, and the faster, the greater the boiler power, that is, the more gas is needed to heat the room. In Russia, the rating of these boilers is not very high.

Difference between upper and lower heating value

The acidity of this water is so low that it can be discharged into the sewer without the need for treatment. When we talk about 98% efficiency for condensing boilers, this value refers to the “higher heating value”. Typically, the industry refers to the "lower heating value" when calculating the efficiency of its equipment. Lower heating value is the heat that can be produced by combustion without condensation. The net heating value refers to only a portion of the total energy of the fuel.

The functionality of boilers is determined by the number of circuits. So, in order to use a single-circuit boiler for domestic hot water, you need to purchase a separate container - an indirect heating boiler.

Double-circuit boilers independently provide both heating and hot water.

Return to contents

About combustion chambers of thermal apparatus

In contrast, higher heating value includes the heat contained in the exhaust gases and water vapor, which can be used by condensation. When calculating available energy, the higher heating value takes this additional heat into account. Boiler output, also called standard output, can reach 100% in ideal conditions, if calculated on the basis of a higher calorific value.

Condensing boilers require modifications to the chimney

When installing a condensing boiler on an existing chimney A plastic tube may need to be installed. But since this pipe has a smaller diameter than the chimney, this pipe can easily be placed in existing chimneys.

The most selected heating system

When looking for the most suitable heating system, there is no standard solution. It's not easy to find the best one for your needs. This can help you choose a heating system. This is how much steam the boiler produces while being able to be supplied.Image 1. The chimney works only if there is a fan, which provides it with artificial air exchange.

Combustion chambers are of open and closed type.

Into the camera open type the air (more precisely, oxygen) necessary to maintain combustion comes from the room, and combustion products are removed from it through the chimney. This process occurs naturally due to draft in the chimney.

- Kg of steam or ton of steam per hour.

- Kilo couple per square meter heating surfaces.

This is the ratio between useful heat and the total caloric content of the fuel burned. = Steam mass flow, fuel mass flow. Currently, large steam generators consist of a combination of components to create a complex device, especially when intended for combustion solid fuels which include superheaters, economizers, air preheaters, soot collectors, mechanical ash extractors, and others. Smaller units designed to produce heated steam in small and medium-sized industries will make do with almost all of the components listed above.

Therefore, in the room where the boiler is installed, it is necessary to ensure natural ventilation ensuring a continuous supply of air sufficient for combustion. Failure to comply with this requirement can lead to a lack of oxygen in the room and even carbon monoxide poisoning.

Therefore, to ensure safe operation It is advisable to install such a boiler in a separate room (boiler room) equipped in accordance with safety requirements.

Thus, the classic boiler components are listed below, with the caveat that not all components below are necessarily part of all steam generators. Ashtray A place where they deposit ash and/or possibly residual fuel that passes through the fire support without completing its combustion. The volume in which all combustible substances must be extinguished before reaching the combustion products and penetrate through the heat absorption beam by convection. This chamber sometimes confuses itself with its own oven, other times it separates completely.

The combustion chamber may be formed by the most refractory bricks, or by coated or fully irradiated tubes. This corresponds to a closed pressure vessel with pipes containing water inside it, which turns into steam after receiving heat.

Basic requirements for ventilation and chimney.

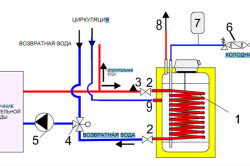

Image 2. Connection diagram for a double-circuit heating boiler.

- For the chimney, two holes must be provided in the wall: one (upper) for the exhaust pipe, and the second, at least 25 cm below, for cleaning it.

- The room must be equipped ventilation grille, mounted in a wall or in front door. Lattice in external wall should have an area of 8 cm 2 per 1 kW of boiler power, and if the air flow is provided from interior spaces, then at the rate of 30 cm 2 / kW.

- The premises must necessarily have a connection with the general ventilation system building.

- The chimney must be completely isolated from the boiler room.

- The cross-sectional area of the chimney should in no case be smaller than its outlet from the boiler.

- The chimney should rise above the ridge of the roof.

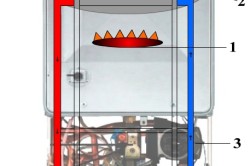

The closed chamber is connected to a chimney of a special design, consisting of two pipes inserted into one another (coaxial type). By inner tube combustion products are removed outside, and through the outer pipe Fresh air enters the combustion chamber. Image 1 shows the design of such a chimney. This design only works if there is a fan that provides artificial air exchange, that is, the system becomes dependent on electricity. This is its significant drawback. But there is also an advantage: as a result of heating the air with the heat of combustion products, the efficiency of the boiler increases, and the temperature of the exhaust gases decreases. Because the increase in efficiency is possible only due to more efficient combustion of fuel, then such a boiler pollutes the environment less.

Responsible for increasing temperature saturated steam, formed in the boiler. All steam passing through this device is overheated. Where the temperature of the feed water is raised, using the residual sensitive heat of the combustion gases before they are eliminated by the flue.

Also known as an air preheater, its function is to heat combustion air and then introduce it into the furnace by utilizing the reasonable heat of combustion gases. These are the intermediate or final parts of the circulation of flue gases in the chimney. These channels can be made of brick or steel sheets, depending on the temperature of the gases circulating in them.

Return to contents

Single-circuit gas boiler: modes of use

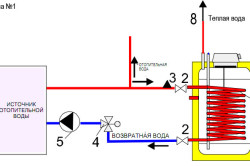

Image 3. Diagram of the mode in which the boiler heat exchanger is connected to the boiler through valves.

The single-circuit version of the heat source is intended for heating the room, but it provides the possibility of connecting a boiler that has its own heat exchanger. By periodically passing the coolant through the boiler heat exchanger, the sanitary water is heated to set temperature. This use case is shown in Image 2.

This is the part that circulates the hot combustion gases through the entire system using the so-called pulling effect. However, although the draft is promoted by the exhaust fan, its function is reduced by directing combustion gases into the atmosphere. In this case, the circulation is called induced. Gas circulation may also be provided by a combustion blower fan with sufficient pressure to overcome any loss of charge in the circuit. In this example, the run is considered forced.

Based on a more complex block, Fig. 1 allows you to identify the classic components and operating principle of the installation. The operating principle of a complex log-burning kiln installation. There are several ways to classify boilers. For example, they can be attributed to the following aspects.

If the boiler is intended only for heating the room, then instead of shut-off valves (2) plugs are installed at these outlets. Circulation pump(5) continuously running. Three-way valve(4) is in a position where return water from the heating system circulates through it. The operation of the boiler (ignition of the burner) is controlled by an external temperature sensor located in the room: when the temperature in the room drops to a predetermined level, a control signal is sent to ignite the burner.

Regarding water gas Place. . Note: All types above are with 1, 2 or 3 passes. Blade, curtain or wall with water. Regarding the energy used for heating. . Production of soda or black liquor. In this work we will wait for a classification regarding the relative location of water gases and, in addition, electric boilers.

This was the first type of boiler. It is also called a fire stack, chimney stack, or pyrotubular pipe, due to the hot gases from combustion that circulate inside the pipes in one or more passages, drawing water out of them. This is the simplest type of boiler. Subsequently, with some improvements, it was renamed the Scotch Cauldron.

Image 3 shows the mode in which the boiler heat exchanger (1) is connected to the boiler through valves (2). In this mode, control of its operation is transferred to a temperature sensor located inside the boiler. At the same time, this sensor sends a command to switch the valve (4) to a position in which return water from the boiler heat exchanger flows through it, and the coolant circulation in the heating system stops.

According to the diagram, we note that the flamotubular boiler is nothing more than an outer cylinder containing water and an inner cylinder meant for the furnace. Its stretching or discharge is normal. Higher production capacities and pressures determine the use of water-water boilers.

They decided to take advantage of this loss to reduce the cost of fuel, which at the time was coal. The problem was solved by increasing the heating surface of the water by placing sufficient quantity pipes and supply hot gases through the pipes into the passages and then by exhaust into the chimney. Thus, the yield was increased, although this type of boiler did not have an efficiency of more than 60%.

Return to contents

Double-circuit gas boiler: operating modes

Image 4. Room heating work: A – heating supply line, B – inlet cold water, C – hot water outlet, D – heating return line, 1 – heat exchanger, 2 – shut-off screws, 3 – three way valve.

This type is originally intended for heating the room and heating sanitary water. Structurally, they differ in the number of heat exchangers.

In one embodiment, the boiler has one heat exchanger, through which either the heating system coolant or sanitary water can be pumped. The work of heating a room is shown in image 4, and in DHW mode in image 5. These diagrams indicate the heating supply and return lines (A and D, respectively), the cold inlet and the hot outlet DHW water(C and B respectively).

The heat exchanger in this scheme is called biothermal. Plumbing water circulates through its inner pipe, and heating system coolant circulates through its outer pipe. The pump constantly pumps the coolant, but during the selection of sanitary water by any consumer, the main circuit is disconnected from the heating system, and the coolant circulates only inside the boiler, heating the sanitary water.

In another embodiment, the device has two heat exchangers, primary and secondary. This option is shown in Figure 6. The primary heat exchanger (5) can be connected via a three-way valve (3) to the heating system (inlet D, outlet A) or to the secondary heat exchanger (4), which contains DHW circuit(input C output B).

Image 5. Work on heating a room in DHW mode: A – heating supply line, B – cold water inlet, C – hot water outlet, D – heating return line, 1 – heat exchanger, 2 – shut-off screws, 3 – three-way valve, 4 – secondary heat exchanger.

What is the advantage of two heat exchangers?

If in the first option hard water initially circulated in the main circuit, then throughout the entire system, including external pipes bimetallic heat exchanger, scale will form, but it will not increase over time.

Hard sanitary water, flowing through the internal pipes of the heat exchanger, will eventually render the hot water supply out of working order. To replace the heat exchanger, you will either have to turn off the heating system or stop using hot water until the end. heating season when it will be possible to turn off the gas and begin repairs.

If there are two heat exchangers, replace DHW heat exchanger possible without interrupting the heating of the room, that is, having two nights of heat transfer is better than one.

Having analyzed design features floor and wall-mounted double-circuit and single-circuit boilers, you can decide for arranging your own home.

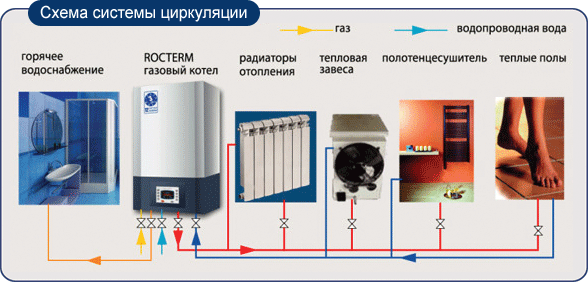

A double-circuit heating boiler allows you to effectively solve two of the most important problems for the owner of a country home: heating and water heating. Today, many different models of this equipment are produced, differing from each other not only in parameters and price, but also in the principle of the device.

This small educational program will help guide anyone who is thinking about buying such a boiler, but does not yet know how to choose it.

The difference between a double-circuit boiler and a single-circuit boiler

Heating boilers with one circuit are intended only for heating the coolant circulating in the heating system. For heating tap water the owner of such a boiler has to buy and install another unit - geyser or boiler. Comfort in this case is quite expensive: firstly, purchasing a separate gas water heater and heating boiler requires significant costs; secondly, two installations take up a lot of space. In this case, it is necessary to build two chimneys for each unit separately, since if they are connected to one smoke removal channel, the “exhaust” of one of the devices can block the hood from the other, causing fuel combustion products to enter the room. Maintaining two separate devices is also more difficult.

The figure shows a diagram of the design of a single-circuit boiler.

IN dual-circuit models instantaneous water heater and heating boiler are assembled into one unit. Thus, the homeowner solves two problems at once by buying just one device, compact and relatively inexpensive. Accordingly, the piping, maintenance and installation of the chimney is simplified.

Different models of double-circuit boilers (floor-mounted and wall-mounted) may differ significantly from each other, but the heating of water and coolant in them is carried out according to the same scheme. If there is no hot water flow, the coolant is heated gas burner, circulates in the primary circuit connected to the heating system. As soon as the user opens the hot water tap, the boiler automation switches the valves so that the coolant is redirected to the second circuit. This circuit is connected to the heat exchanger built into the boiler instantaneous water heater, through which it is fed tap water. Thus, working environment- coolant - used alternately for heating and hot water supply. This leads to one of the disadvantages of a double-circuit boiler: significant consumption of hot water negatively affects the efficiency of the heating system.

Double-circuit gas boilers can be equipped with a storage tank for hot water - a boiler. Such devices consume more fuel and are larger in volume, but they can simultaneously serve several points of water consumption, unless, of course, hot water is constantly consumed in them. When the water supply in the tank is exhausted, the user will not have to wait for a new portion to be heated, as is the case with household electric boilers. The boiler will automatically switch to instantaneous water heater mode.

What are the types of double-circuit boilers?

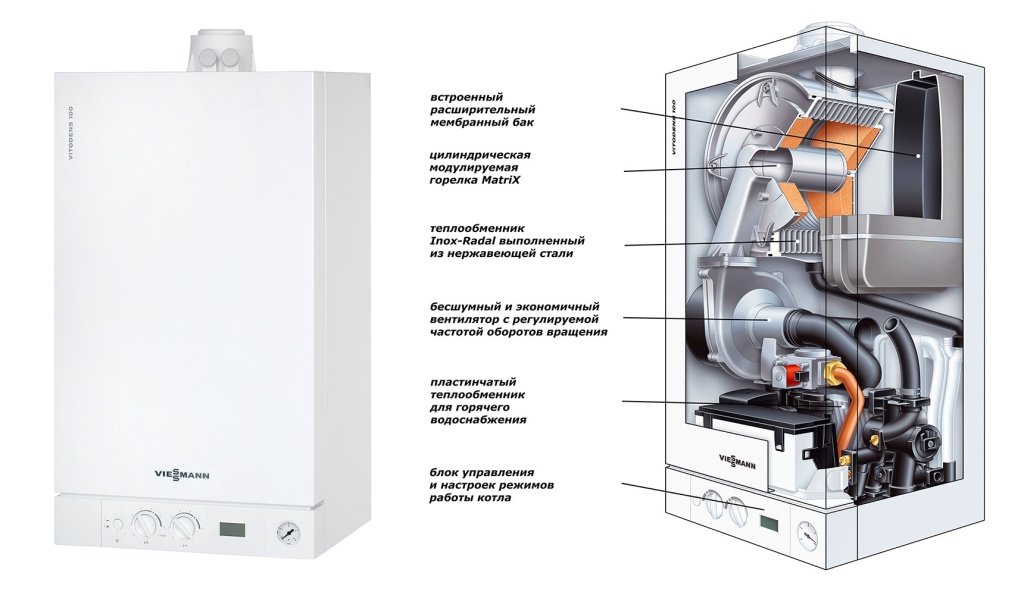

Advantages of the boiler model from Viessmann.

Modern models of double-circuit gas boilers may differ in the following features.

The smoke removal system can be convection or condensation. In the first case, the products of fuel combustion, including water vapor, from the combustion chamber enter directly into the chimney, from where they are released into the atmosphere due to convection or, as they also call it, natural draft.

In condensing-type boilers, there is a heat exchanger between the combustion chamber and the chimney, which is connected to the heating circuit. This scheme allows you to absorb additional thermal energy, most of which is formed by the condensation of water vapor.

The advantages of convection boilers include: simplicity of design, low price (gases are removed in dry form, so there is no need to use expensive corrosion-resistant materials), convective draft in the chimney allows you to do without a fan.

Disadvantages: relatively low efficiency: a significant part of the thermal energy literally flies out into the chimney.

All the disadvantages of condensing systems - high cost, complexity of the device, the presence of an electricity-dependent fan - are more than compensated by the main advantage: due to steam condensation, the efficiency of the boiler almost doubles.

Coolant circulation in the system.

It should be noted that installing such a model on a conventional heating circuit will be unjustified. The connection diagram for a double-circuit condensing-type boiler is no different from the traditional one, but in order for such a unit to function with maximum efficiency, the coolant entering the heat exchanger of the smoke removal system must be cold. If the temperature difference between the coolant and the steam is insufficient, the latter will not condense. And since a working environment circulates in the heating circuit with a lower temperature than in conventional systems, temperature, it has to be equipped with larger, and therefore more expensive, radiators.

Fuel combustion chambers in gas boilers can be open or closed. Convection units are equipped with chambers of both types, condensation units are equipped with only closed ones.

What is an “open firebox”? This is a combustion chamber that uses oxygen from the air in the room in which the boiler is located. Closed - completely isolated from environment. In such systems, coaxial type chimneys are used or, more simply, a pipe in a pipe. Products of fuel combustion are removed through the inner pipe, and suction clean air carried out externally. Smoke from a closed chamber, regardless of whether the smoke removal system has a heat exchanger (condensing boilers) or not (convection boilers), is removed only forcibly by means of an electric fan. Therefore, such boilers are called turbocharged.

The advantages of boilers with an open firebox: low cost (the difference in price is quite significant), energy independence (this means electrical energy).

Principle of operation heating system using a double-circuit boiler.

Disadvantages: due to the lack of oxygen in the room, where it becomes difficult to breathe, there is a danger of combustion products entering the room in the event of a draft failure, only a vertical chimney is required.

Taking into account the disadvantages of boilers with open combustion chambers, they are usually installed in separate room.

Advantages and disadvantages of turbocharged boilers

Double-circuit turbocharged boilers are characterized in exactly the opposite way. Their advantages:

- can be installed in any room;

- absolutely safe;

- smoke can be discharged in any direction.

- high price;

- cannot work without electricity.

Model of a turbocharged gas boiler.

Gas heating boilers are floor-mounted and wall-mounted. Most buyers imagine what a wall-mounted boiler is: such boilers can often be seen in city apartments that have heating system and DHW. Units of this type are compact in size and light in weight, but are limited in power and performance. hot water. Floor-standing boilers have to be installed in a more spacious or even separate room, but these units have great power and, accordingly, DHW productivity. A floor-standing boiler has another important advantage: since its weight, unlike a wall-mounted one, is not limited in any way, manufacturers equip it with a cast-iron heat exchanger, which is of higher quality and more reliable than steel.

In addition to all of the above, floor standing boilers may differ by burner type. The cheapest are atmospheric burners, but they cannot boast of high efficiency, have relatively low power and are too noisy. Expensive forced-air burners do not have all these disadvantages.

How to choose a double-circuit boiler?

The main parameters by which a double-circuit boiler model is selected are power and hot water performance. Let's consider each of the characteristics in detail.

Determination of required power

Boiler components.

For precise definition power sufficient for efficient work heating circuit, it is necessary to perform a thermal calculation. His technique is quite complex, so only a heating engineer with certain experience and knowledge can cope with such a task. special knowledge. Thermal calculation takes into account many factors (area window openings, thermal permeability of walls, heat transfer from radiators, etc.) and allows you to select the optimal boiler model without overpaying for extra kilowatts. But on initial stage you can do without it. The required power is approximately estimated based on empirical data: on average, a heating system consumes about 100 W of energy per 1 sq. m of heated area. If one or more rooms border on unheated rooms, this figure can be increased to 150 W.

Determining the required hot water flow

We remind you: if you plan to consume intensive hot water, it makes no sense to install a double-circuit boiler, since heating in this case will be purely symbolic. Ensure the supply of hot water for normal household needs simultaneously with heating double-circuit boiler quite capable.

To determine the required hot water consumption, you simply need to sum up the water consumption at all points connected to the boiler. On average, from a regular water tap with a system pressure of 2 - 3 atm, from 4 to 6 liters of water flows out in one minute. During a shower - 10 - 12 liters. If the scheme involves connecting more than three points to the water supply system, you can take the total flow rate of not all, but only a few of them.

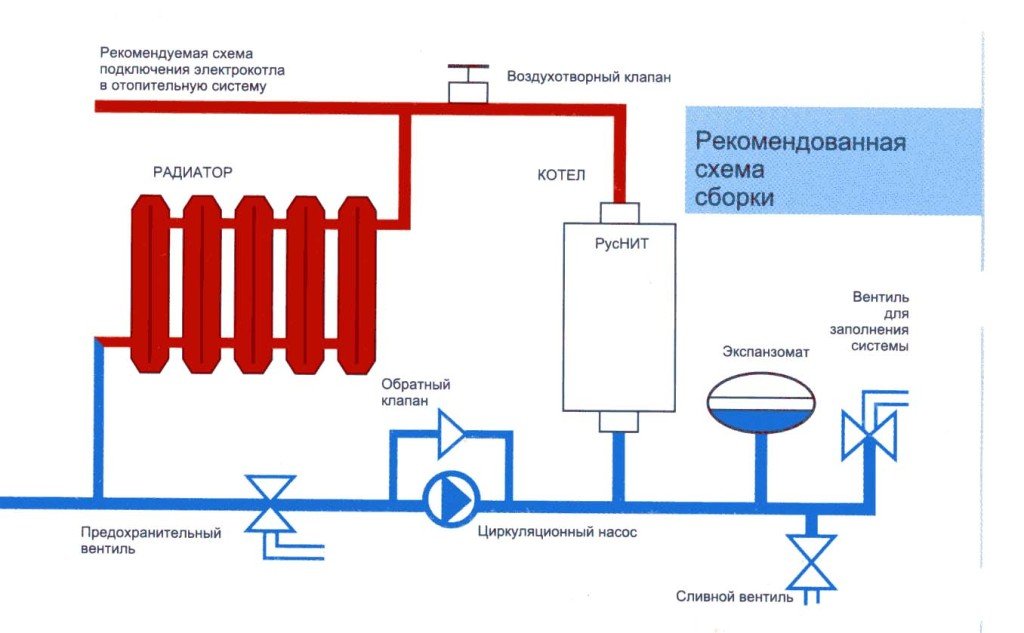

Assembly diagram of heating system components.

Please note: in the boiler passport, hot water performance is tied to the temperature difference before and after heating the water. Therefore, to choose optimal model you should know not only the flow of hot water in your home, but also the temperature of the cold water entering the boiler. Let's say we have two taps with a flow rate of 5 l/min of hot water, and the temperature of the water in the water supply before heating is 7 degrees. Therefore, we need a boiler that provides hot water output of 5 + 5 = 10 l/min at a temperature difference of 40 - 7 = 33 degrees (40ºС - comfortable temperature water for washing dishes, showering, etc.).

An approximate calculation will allow you to determine whether it is worth spending time studying wall-mounted boilers or whether it is better to immediately look at floor-standing boilers. Maximum limit on heated area for wall models is 200 sq. m, for hot water - 14 l/min. If the values you obtain exceed these indicators, only floor-standing boilers are suitable for you. In general, such units are more popular than their wall-mounted competitors. Buyers, even for small water consumption and heated area, prefer floor-standing boilers, since such models are equipped with more reliable and durable cast-iron heat exchangers. In addition, they are less picky about the quality of power supply.

Factors affecting the durability of boilers

Wall-mounted boilers, being more modern and complex, often fail at the slightest power surge. In this case, as a rule, the main board burns out, the replacement of which is very expensive. Another important point: floor-standing boilers are more suitable for working with low-quality water. The heat exchangers of wall-mounted boilers, which manufacturers strive to make as light and compact as possible, are a set of small-diameter tubes that clog very easily.

If tap water contains too much a large number of hardness salts, pay attention to floor-standing boilers with a boiler. Such units are not afraid of salt deposits and provide hot water supply even during peak hours, when the pressure in the water supply drops significantly or disappears altogether.

Buyers who frequently experience power outages should choose non-volatile double-circuit boilers. These, as a rule, are floor models With open camera combustion. Important At the same time, it has a burner ignition mechanism. The more convenient and economical electric ignition will be inappropriate in this case, since it is also not able to function without power supply. A model with manual or piezo ignition would be optimal. The burner in boilers of this type lights up from a constantly burning gas wick. The disadvantages of such systems are increased gas consumption and the inability of the boiler to automatically resume operation after a temporary drop in pressure in the gas supply system.

Double-circuit boiler - very complex equipment, and many features specific model may only appear during operation. Therefore, before purchasing this device, we recommend that you carefully study user reviews published on the Internet.