Installation of an expansion tank in an open heating system. Pressure in a closed heating expansion tank: instructions, principle of operation.

An expansion tank for heating systems is needed to prevent pressure surges due to sudden compression of water. Compression and expansion of the coolant occurs under the following conditions:

- when heated, the liquid expands (preferably a temperature of 20 to 90 degrees Celsius is required);

- as the temperature decreases, the liquid contracts, for example, the volume of the coolant at 90 degrees is much greater than that of water at a temperature of 10 degrees.

Purpose

The main task expansion tank consists of compensating part of the coolant due to an increase in its volume.

At forced circulation the pressure at the connection point between the tank and the system will be exactly equal to the standardized one.

If suddenly the pressure level changes at this point, it will turn out that the amount of coolant will increase. This contradicts the laws of physics and logic, since in a closed vessel there is nowhere for additional liquid to come from.

The expansion tank can be installed in any comfortable spot heating system.

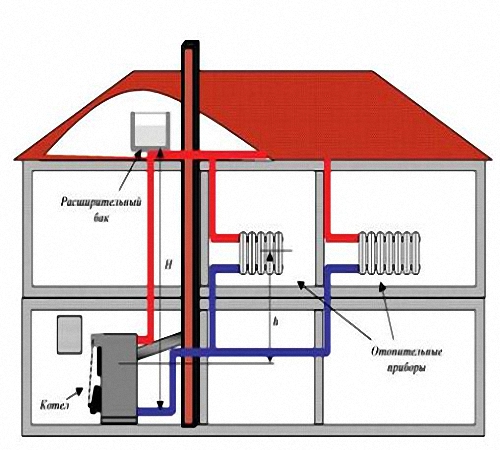

The design of an open heating system has a complex shape. Each node of such a system has a strict purpose, which is to quickly deliver hot liquid to the highest point of the pipeline. Moreover, after delivering the coolant, the system must pass it through all radiators and the boiler.

The expansion device (open) must be installed on top of the heating system.

Heating system

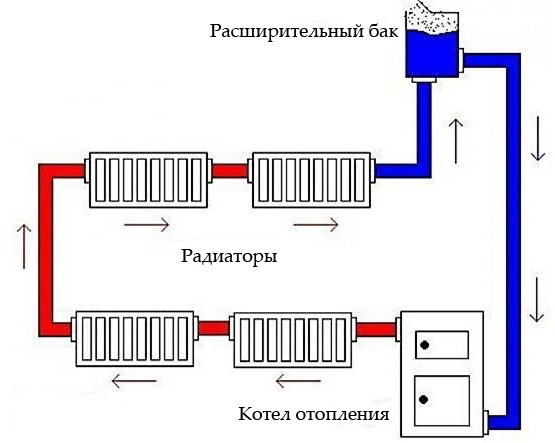

An example of a diagram for integrating an expansion tank into a heating system can be seen in the figure below.

Diagram of an expansion tank in a heating system

Diagram of an expansion tank in a heating system Blue lines indicate low-temperature coolant passing from the tank to the boiler. After passing through the boiler, the coolant heats up and begins its journey through the heating system (in this case, through radiators).

The red lines indicate the hot coolant, which originates from the boiler and goes through the radiators directly to the expansion tank. After complete passage According to the system, the coolant returns to the tank and begins its journey from the very beginning.

Due to these properties, when heated, excess coolant is formed in the heating system. To prevent excessive pressure from leading to an accident, it is necessary to use an expansion tank.

Expansion tanks are not devices with complex design. However, in order for the tank to last maximum term service, due attention must be paid to the instructions for installing and operating the device.

Types

There are two types of expansion tanks. Each of them has both disadvantages and advantages.

Open tank

An open-type expansion tank is a device of simple design that allows you to increase the amount of coolant in the system at any time. Introducing the coolant into the tank does not require excessive effort, since you can fill the liquid with an ordinary bucket.

Also, the device does not need additional components like:

- shut-off valves;

- covers;

- rubber membrane.

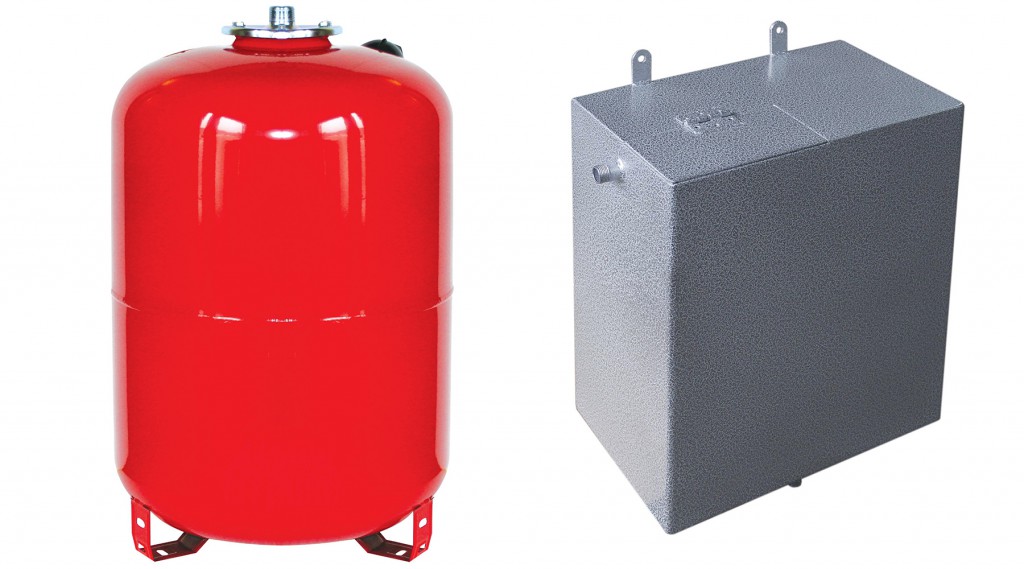

Open type expansion tank

Open type expansion tank If necessary, the design of the device has the ability to install a water intake valve for automatic or semi-automatic filling coolant liquid. Installing a faucet is not mandatory, that is, it completely depends on personal preference.

Some time ago, open expansion tanks were in use, controlling the volume of coolant during its natural circulation. However, such a system did not justify itself due to the following reasons:

- complex installation of the top point of the structure;

- poor protection against corrosion;

- low pressure level.

Closed tank

Closed tanks, also known as “diaphragms,” are used in heating systems where a circulation pump is responsible for moving the coolant. This type of tank, by generally accepted standards, has a red outer shell.

Closed type expansion tank

Closed type expansion tank The inside of the tank is a sealed container with a membrane made of technical rubber.

In addition to red closed tanks, there are also blue ones. Their main purpose is to provide hot water supply. These tanks use special food-grade rubber. Devices that use such rubber have a longer service life than tanks with a membrane made of technical rubber.

Device

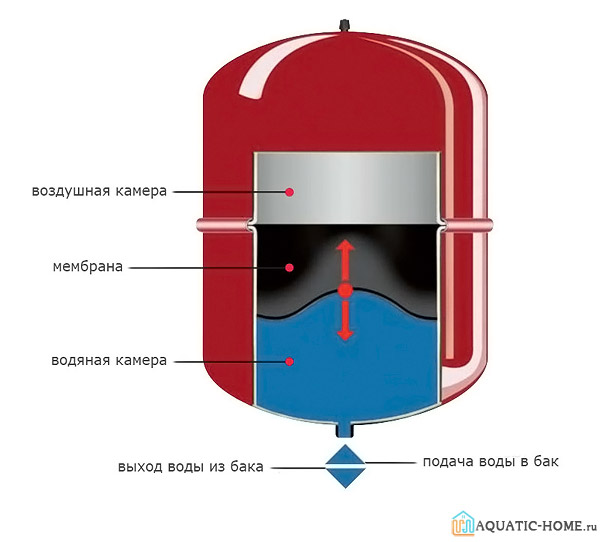

The inside of the closed expansion tank is arranged as follows:

- the internal space of the tank is separated by a special diaphragm or membrane that looks like a cylinder;

- the upper part of the space is filled with air or gas;

- the lower part is filled with coolant, or rather its excess.

Sectional design of a closed expansion tank

Sectional design of a closed expansion tank As the temperature of the coolant increases, its volume also increases. The resulting excess coolant is stored in the tank, reducing the “upper” space.

When the temperature of the liquid decreases, the coolant decreases in volume. Because of this, the excess coolant remaining in the tank returns to the heating system.

In a closed tank, you can install either a special replaceable membrane (flanged) or a non-replaceable one. A non-replaceable membrane has a significant cost advantage.

The membrane installed inside the unit is firmly fixed around the entire perimeter. Initially she clings to inside tank (on the liquid side) due to the fact that almost the entire expansion tank is filled with gas or air. When a certain amount of coolant enters the device, the air (gas) pressure increases significantly, which causes the diaphragm to move.

When the system is first started, there is some possibility of a membrane rupture, which occurs due to a sharp increase in internal pressure. During further launches, the pressure will normalize on its own, which reduces the likelihood of diaphragm rupture to a minimum.

In order to prevent rupture of the membrane, it is necessary to control the pressure using a pressure gauge (mainly a large-volume system). Thanks to the pressure gauge, when the emergency pressure is reached, the safety valve automatically opens, causing excess pressure to disappear.

The following advantages of a replaceable expansion tank for heating can be highlighted:

- the product can be either vertical or horizontal, depending on the needs of the buyer;

- an expansion tank with a non-replaceable membrane has a more significant limitation of the pressure level;

- if the diaphragm is damaged, it can be replaced without any problems (that’s what the flange is for).

Comparison

Comparing the open and closed type of device, we can say that the latter has clear advantages, justified by the following factors:

- a closed tank has minimal heat loss, while an open tank requires additional insulation;

- service life is significantly longer;

- due to tightness closed tank the coolant cannot evaporate in the air;

- the closed type has less weight and size;

- a closed expansion tank can be installed in a system with high pressure, and an open one - only in systems with low pressure;

- a closed tank does not need to be installed on top of the heating system, which means there is no need to spend money on additional pipes;

- the closed type device guarantees absolute protection tank and heating system from corrosion due to lack of air.

External comparison of closed and open expansion tank

External comparison of closed and open expansion tank In order to carry out necessary calculations, you can do one of the following:

- You can resort to the services of specialized design companies that employ highly qualified specialists. Wizards use for calculations software, originally created for these purposes.

- Maybe self-creation drawings. However, in this case it is necessary to pay attention Special attention all the little things and exercise caution.

- There are also online calculators to perform calculations. When using them, it is recommended to pay special attention to the results and double-check them.

- Calculations can be made based on your own observations. This option is the most inaccurate, but quite acceptable at the stage of economic justification.

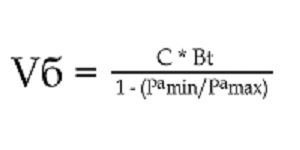

In the figure below you can see the most accurate formula for calculating the tank volume:

Formula for calculating tank volume

Formula for calculating tank volume where C is the total volume of coolant in the heating system (in liters);

Pa (min) – initial pressure in the tank (in bars);

Pa (max) – maximum pressure level in the tank (in bars).

To calculate the total volume, it is necessary to take into account all connected devices (boiler, heated floors, etc.).

Installation

There is no point in considering the process of installing an open type tank into a heating system. Unlike membrane tank, open type does not require much attention during calculations and installation work.

In order to get started, you need to prepare the following tools:

- gas key;

- stepped key;

- adjustable wrench;

- plastic pipes.

During installation, the tightness of each connection should be carefully checked. If you make an error with the tightness, the device will leak, which will eventually lead to an emergency.

The following instructions must be observed during installation:

- the calculations must be suitable for the heating system, which should be double-checked before installation work;

- during installation, the room temperature should be higher than 0 degrees Celsius;

- a tank with a volume of more than 30 liters must be installed on special legs;

- the tank must be installed up to the branch point;

- where the tank is installed, a colossal load is possible, so you should make sure that the place is load-bearing;

- at the coolant inlet to the tank it is necessary to install check valve or pump;

- A pressure gauge must be mounted on the outlet pipes.

To correctly install the membrane tank, you must follow the previously given instructions. It should also be noted that for knowledgeable person this matter will not require special effort and time, which cannot be said about a beginner.

The integration diagram of a closed expansion tank into the heating system can be viewed in the figure below.

Diagram of inserting an expansion membrane tank into a heating system

Diagram of inserting an expansion membrane tank into a heating system - A cut must be made on the return pipe (1) and on the section of the tube between the circulation pump (3) and the boiler (2).

- A triple splitter (4) is installed into the cut made.

- Installation work may vary slightly depending on the type of material.

- A ball valve (7) is attached to the lower tube of the expansion tank (6). The ball valve will allow you to stop the coolant supply if necessary.

- In case of repair, it is recommended to install a connection with “American” (a type of union nut) between the tap and the tank pipe.

- After ball valve it is necessary to install the pipe (9) up to the tee. It should be noted here that the shape, length, etc. doesn't matter.

Before installing the tank, you need to prepare the device:

- all fastenings must be free;

- an adapter must be sealed onto the threaded outlet (for sealing it is best to use a specialized paste, such as Unipack);

- after installing the adapter, a tap (7) is attached to the outlet;

- if the tank has everything necessary equipment to secure the tank, you can proceed with installation according to the above diagram;

- in the event that there are no devices, they need to be made (for this, the supply of the tank must contain a corresponding diagram, in the absence of which you can use a clamp).

After this work has been completed, the installation can be considered complete. An expansion tank for heating systems requires sufficient attention both at the selection stage and during operation. For maximum benefit It is important to calculate all aspects of the system to the smallest detail and follow all safety regulations.

If there is no opportunity or insufficient knowledge to self-installation unit into the heating system, it is recommended to contact a specialist.

Video about the tank

More detailed information I will share a video about the expansion tank below.

To avoid any problems with the heating system and not worry about performance, it is recommended to purchase closed expansion tanks. You should also take into account the compatibility of the system and device design.

If for some reason a closed tank cannot be installed in the heating system, you can purchase an open one. It is also recommended to do this if the system is initially open.

In contact with

One of the mandatory elements of engineering systems in a private house is an expansion tank for closed-type heating - the installation and selection of such equipment or its analogues for open systems must be made in full accordance with technical characteristics object and operating conditions. Only compliance with this condition will ensure durability, correct operation and safety of individual heating.

The main purpose of the expansion tank is to level out the expansion of the coolant (water) when the temperature changes, thereby avoiding the occurrence of water hammer, squeezing out gaskets and destruction of pipelines, etc. The volume of the tank is calculated individually based on the system parameters. The operating principle and design of the models differ for different types of systems.

Designs of various systems and their features

Open heating systems

Open heating systems usually do not have circulation pump and are equipped with leaking tanks (with lids or completely open). The expansion tank in such a system is a reservoir into which water is added as needed. The design of such a tank is simpler, and the cost is much lower compared to closed models.

You can buy an expansion tank for open-type heating, or you can make it yourself, which, with certain skills and the availability of materials and equipment, is not so difficult

At the same time, such a device has a number of disadvantages:

- Due to the lack of tightness of the system and frequent opening of the lid, significant amounts of oxygen penetrate into the system with air. Its presence provokes the formation of rust on the walls metal elements(radiators and pipes).

- The leakage of the system also contributes to the evaporation of the coolant, which becomes more intense as the temperature rises. Thus, adding water to the expansion system is required quite often.

- In order for an open system to work effectively, the expander must be installed as high as possible (not lower than the highest point of the wiring). This is not always convenient, and such installation requires more time and effort.

- The need for thermal insulation to reduce heat loss, especially if the tank is located in an unheated room.

Note: An additional function of an open type expansion tank is also to remove air from the system.

Closed systems

The amount of water in a closed heating system is constant. The coolant circulates through the piping using a special pump. A closed-type heating expansion tank is a reservoir divided into two chambers by a flexible membrane. While one of them receives water from the system, expanding when heated, the air in the second is compressed.

Expansion tank for closed system heating, the price of which is higher due to a more complex device, at the same time more practical and easy to use. Ensuring the integrity of the system is preserved and does not cause corrosion, it quickly pays for the money spent on the purchase. In this case, air removal from a closed type system cannot be performed using an expander. For this purpose special valves are used.

Expansion tank for closed heating systems with various types membranes

Expansion tank for closed heating systems with various types membranes The advantages of closed type expanders are:

- compactness,

- minimal heat loss without the need to provide thermal insulation,

- no contact of the coolant with air, which eliminates the possibility of evaporation and reduces the risk of corrosion,

- wide choice of installation location (almost anywhere),

- high permissible pressure.

Expander maintenance

When using an expansion tank for heating, the following recommendations should be followed:

- Inspect the system twice a year, checking for mechanical damage and rust in the container - for all types.

- Check the pressure every six months - for closed systems.

- Periodic check of the membrane condition - for closed systems.

- When not in use, empty the reservoir and dry it - for all types.

- Comply with the manufacturer's requirements regarding acceptable values pressure and temperature.

- Use only branded components for repairs - mainly for closed tanks.

- It is preferable to use inert gas for the closed expander chamber.

Calculation of expansion tank volume

Regardless of the type of system (open or closed), it is generally accepted that the expansion tank should increase the total volume of the entire system by 10%, that is, if the pipelines and radiators contain 300 liters of water, the volume of the system with the tank should be 330 liters, that is, an expander of 30 liters is required.

It is important to consider that the need for a ten percent increase is valid only for heating using water as a coolant. If glycol liquid is used for these purposes, the volume of the tank increases by 50% of the calculated value for the water tank. This difference is due to different meanings expansion coefficient of water and glycol.

Many users find it difficult to calculate the total volume of coolant in the system. It can be produced in different ways.

- The most precise method there will be a calculation of the expansion tank for heating with measurement of the geometric parameters of all elements of the system (piping and radiators). After this, the volume of each of them is calculated separately, and the results obtained are summarized. Calculations will require some time, but carrying out such work is fully justified by the accuracy of the result and the ability to choose optimally suitable model expander.

- More in a simple way is to track the water consumption on the meter when filling the heating system. However, this method can only be applied to open systems.

- Another option is to take the heater power as the initial parameter. According to the standards, for every kilowatt of boiler power there are 15 liters of liquid. The method is applicable in cases where you are absolutely sure of the accuracy of the calculations for choosing a heater.

Installation work

Strict adherence to installation rules when equipping an open or closed heating system with an expander will ensure the safety and efficiency of the equipment.

Installation of an open type expansion tank

It has already been said above that the expansion tank for an open system is mounted at the highest point. This requirement is due to two factors:

- The coolant rises into the expander and drains it back into the heating system by gravity, because there is usually no circulation pump in such systems.

- This arrangement of the expansion tank allows it to be effectively carried out additional function– air removal. Bubbles always rise to the top.

A feature of installing the expander in open system is that there is no need to equip the tank with shut-off valves. As a rule, the tank is supplied with only two pipes, through one of which the coolant enters the container, and through the other it returns to the system. Even the presence of a lid on the tank is not essential, although its absence can lead to an increase in the loss of water volume from evaporation, as well as the entry of debris and dust into the system.

Installation of a closed tank

Installing an expansion tank for heating in closed systems is somewhat more complicated, since it is a completely sealed device. Unlike open expanders, which users often make on their own, such units are created only in the factory, so you will have to buy an expansion tank for the heating system if you have this type.

There are several rules by following which you can install a heating expansion tank correctly.

You can learn about what to look for when purchasing in a separate article.

Criterias of choice storage water heaters given . Often in private homes they are preferred.

What water filters will be useful in country house we talked about in this article

- It should be remembered that installing an expansion tank in a heating system involves selecting, purchasing and installing a model with a red body. Models painted blue are designed for cold water supply. Structurally, the expanders do not differ from each other, but the red ones are designed for prolonged high-temperature exposure.

- Despite the generally accepted practice of using a circulation pump only for closed systems, the presence of a pumping unit does not change the state of the system. That is, if for heating with open tank install a circulation pump, it will not become closed. It’s just that in open systems there is most often no need for such units.

- The boiling of the coolant in the heating system has nothing to do with the operation of the expander. Most likely, you should reconsider the slope of horizontal pipelines and the diameters of the pipes used.

- It is not recommended to install the expander in close proximity to the pump due to possible pressure drop.

- During installation, only special heat-resistant sealants should be used.

- When installing the expander, take into account the need for its maintenance and possible repairs and ensure free access to the unit.

- Some boiler models are already equipped with expansion tanks and then there is no need to purchase one additionally.

The use of an expansion tank is necessary in every closed heating system, and even in some systems connected to central heating. The process of installing an expansion tank is quite complicated, but if you carefully study the instructions, doing it yourself, without involving specialists, is quite possible.

Operating principle of the expansion tank

The expansion tank is a metal tank that is connected to the heating system. The main function of this device is to eliminate the increase in pressure in the pipeline due to expansion of the coolant.

Expansion tanks come in two types: open and closed. The operating principle of each of these tanks differs from each other.

The open expansion tank has a metal lid that opens to add coolant to the system.

A closed expansion tank consists of a metal container that does not have any openings other than the connection to the system. The container is separated by an internal membrane made of rubber. When the pressure increases, the rubber bends and the coolant enters the tank; when the pressure decreases or the coolant leaks, the rubber presses on half of the tank in which the gas is located and the coolant enters the system. Thus, the expansion tank is a pressure regulator that prevents high voltage surges in the system. If you do not use an expansion tank, the heating system will not function properly, and taps, pipes and the boiler will quickly fail.

Expansion tanks are used in private system heating, and in some cases in a system connected to central heating.

Types of expansion tanks for heating

Expansion tanks are divided into:

- open,

- closed.

An open expansion tank has a number of disadvantages, so it is rarely used, mainly in cases where the system is not connected to a pump and water circulates freely.

Disadvantages of an open expansion tank:

- due to frequent opening of the lid, contact between components of the oxygen heating system occurs, which causes rust to form on the walls of pipes and radiators;

- when the water temperature rises, the liquid evaporates, so you should periodically add coolant to the system;

- an open expansion tank is installed at the highest point compared to the heating system, so installing such a device takes a lot of time.

The only advantage of an open expansion tank is its low cost compared to a closed one.

A closed expansion tank is called a membrane tank; depending on the type of membrane, there are:

- expansion tanks of replaceable type,

- non-replaceable expansion tanks.

Replaceable expansion tanks require replacing the membrane if damaged. To replace the membrane, simply unscrew the flange.

Non-replaceable expansion tanks mean replacing the entire tank if the membrane is damaged. Such tanks are more resistant to pressure changes, and the membrane fits perfectly and hermetically to the outer wall of the container.

Expansion tanks come in two forms:

- balloon,

- flat.

The balloon shape resembles a large container in which a membrane or lid is located, depending on the type of tank.

Flat expansion tanks have a flattened shape and a membrane in the form of a diaphragm. The advantage of flat expansion tanks is that they take up little space and are easy to install.

Calculation of expansion tank for heating

The size and volume of the expansion tank is affected by:

- system type;

- system capacity;

- maximum permissible pressure;

- installation location of the expansion tank.

The easiest way to determine the volume of the expansion tank is to find out the capacity of the heating system and divide this amount on 10%. For example, if the heating system contains 400 liters of coolant, then the volume of the expansion tank will be 40 liters if the coolant is water. If glycol fluid is used as a coolant, then another 50% must be added to this amount.

Please note that 3% of the coolant in the closed expansion tank goes to compensate for possible leaks. In any case, the volume of the tank obtained as a result of the calculation should be slightly increased.

To obtain an accurate calculation in large or complex heating systems, it is better to trust specialists or use an online calculator.

The correct design of the expansion tank is indicated by the failure of the safety valve.

Installation of an expansion tank for open heating

The open expansion tank is where water comes into contact with oxygen. An open container is used when water moves freely through the system without using a pump or when the system is connected to central heating.

Since air comes into contact with water, the entire heating system is designed at a slope so that excess oxygen is forced out of the radiators.

Expansion tank installation location: the highest point in relation to the heating system. The installation height of the expansion tank must exceed the installation height of the heating system.

Expansion tank installation diagram:

An additional expansion tank is installed if it is impossible to mount the heating system at an angle. The installation level of the main and additional expansion tanks must be the same.

The open expansion tank includes pipes:

- expansion,

- signal,

- circulation,

- overflow.

Using an expansion pipe, the tank is connected to the heating system.

In most cases, an open expansion tank is mounted near the boiler and connected to the water supply system using a signal pipe that monitors the coolant level.

The overflow pipe connects the tank to the sewer; when the tank overflows, the liquid is automatically drained into the sewer.

The circulation pipe ensures the supply of coolant if the expansion tank is located in an unheated room.

![]()

Installation of a closed expansion tank

Before studying the rules for installing a closed expansion tank, let’s consider the advantages of this device over an open expansion tank:

- minimal heat loss;

- do not need isolation;

- work at high pressure surges;

- installation anywhere, without reference to the highest point;

- closed type devices are more compact and easier to install;

- no rust formation on the internal walls of the heating system;

- ease of maintenance.

Tools for work:

- adjustable wrench;

- wrench for installing plastic pipes;

- step key.

The preparatory stage includes:

- disconnecting the boiler from electricity, gas or water supply;

- turning off the tap responsible for coolant circulation;

- draining the coolant from the heating section on which the expansion tank is installed.

Instructions for installing the expansion tank:

1. Install a shut-off and drain valve on the supply pipe to shut off and drain the water.

2. Connect the expansion tank to the system using screws or flanges. If the heating system pipes are polypropylene, you need to use a soldering apparatus, couplings, angles and fittings.

3. A fitting called “American” will help you easily remove the tank for replacement or repair in the future. Before installing the fitting onto the expansion tank, wrap linen tape around the threads and apply sealing paste.

4. When the water has been drained from the system, cut the pipe with special scissors and install a tee.

5. Install the safety valve and pressure gauge.

6. Before starting the system, clean the coarse filter.

7. Before connecting the expansion tank to the system, you need to create operating pressure. To do this, use a pump.

8. When the expansion tank is connected to the network, turn on all coolant supply taps and turn on the boiler.

1. Install the expansion tank so that the coolant flows from the top.

2. In the absence of data on the exact volume of the heating system, the capacity of the expansion tank is calculated based on the boiler power: 15 liters of liquid are calculated for 1 kW of power.

3. Before purchasing and installing an expansion tank, inspect the heating boiler. Many modern boilers have a hidden expansion tank, which is located in the middle of the boiler.

4. Do not install a closed expansion tank near the circulation pump, due to the occurrence of large differences pressure.

5. Installation of a vacuum expansion tank is carried out only at positive temperatures.

6. Installation of a closed type membrane expansion tank is carried out on the supply side cold water to the boiler.

7. As a sealant, use only those sealants that are resistant to high temperature, otherwise leakage is inevitable.

8. When determining the location and installation of the expansion tank, you should think about the further approach or maintenance of the device. Do not install the expansion tank in hard-to-reach places.

9. When installing the expansion tank, follow safety rules and generally accepted instructions.

10. Be sure to read the manufacturer's instructions for installing the expansion tank.

11. Be sure to install a safety valve, which sometimes comes with the tank; if there is no valve, buy it separately.

Maintenance of the expansion tank for heating

1. Once every 6-7 months, the expansion tank should be inspected for mechanical damage or rust. If they are present, you need to fix the problem.

2. In closed expansion tanks, the pressure should be checked once every six months.

3. In devices with a replaceable membrane, the membrane must be periodically checked for integrity or damage.

4. If the expansion tank is not used for a long time, store the tank in a dry place, making sure to drain all water and dry the device.

6. It is best to use an inert gas such as nitrogen to fill the air chamber.

7. Proper work expansion tank depends on the pressure and temperature of the heating system.

8. If the pressure drops sharply, there is a risk of damage to the membrane. To replace the membrane you need to perform a number of steps:

- disconnect the expansion tank from the system;

- relieve pressure in the tank using the valve located at the top of the tank;

- remove the flange located at the point where the tank is connected to the system;

- remove the membrane and drain excess water;

- insert the membrane and install the flange;

- attach the tank, having previously set the desired pressure.

1.

2.

3.

Today, you can install a heat supply system in a private house in as soon as possible. The main thing that is needed for this is sufficient financial capabilities of the property owner and then the planned will be implemented, since the domestic building materials market offers a wide choice heating equipment and components.

One of the main points of creating a system is the installation of an expansion tank in the heating system. The performance of the heating network of a private home largely depends on it.

Types of expansion tanks

The place where the expansion tank of the heating system, such as in the photo, should be installed is determined based on the type of structure, which can be:- open;

- closed.

In a closed type heating structure they use expansion device, the installation and further operation of which have their own characteristics and differences. The tank is made in the form of a sealed capsule having two chambers, separated from each other by a rubber membrane. That’s why the product is also called .

The installation of a closed expansion tank is allowed anywhere in the heating network, with the exception of inserting a container after the circulation pump in the immediate vicinity of it. Otherwise, pressure surges throughout the system are possible.

The operating principle of a closed tank is simple. After the coolant has heated up and increased in volume, its excess fills the empty space in membrane device. As a result, the pressure in the system continues to remain at an acceptable level (read: "").

Features of installation of expansion tanks

Installation of an expansion tank in a heating system is carried out taking into account some points:- installation of the device is allowed in a room where the temperature does not fall below zero;

- easy access should be provided air valve to, if necessary, regulate the pressure in the air part of the tank;

- when the installation of the device is completed, there must be access to the shut-off equipment, drain tap and nameplate;

- it is impossible to allow the application of a static load to the membrane tank (pressure from pipes and other devices);

- if the reducer is located after the water meter, this measure will allow maintaining a constant initial pressure in the membrane tank. When the safety valve is activated, the pressure must not exceed the maximum permissible operating pressure level in the tank (read: " ");

- fastening is carried out in such a way that the safety valve is located up to the flow fittings in the direction of flow of the coolant.

A heating scheme with an expansion tank always provides that it is installed only on the side from which cold water is supplied to the heating boiler. Installation of the device at the exit is prohibited.

Mistakes made when installing an expansion tank

Many property owners try to carry out many of the work on arranging the heating system themselves, including installing an expansion tank with their own hands. At first glance it seems that there are problems with similar work will not arise, but in reality it has certain difficulties, which is well known to specialists.The most common mistakes made when installing an expansion tank in a heating network occur for a number of reasons:

- absence complete set necessary tools or their poor quality. When performing work, they often use wrenches - universal (gas) and adjustable.

In addition to them, a special wrench is also required, which is necessary when installing a metal-plastic pipeline, and a stepped wrench for detachable connections; - use for compacting materials that are not intended for these purposes. For example, instead of high-quality sealant, they use cheap products for windows made of polyvinyl chloride, which are intended for another temperature regime. The first time after application, the connections look attractive, but after commissioning the heating structure, this type of sealant cannot withstand the load and high operating temperatures. It’s good if a leak is discovered as a result, but often the consequences are more serious;

- The installation of the expansion tank in the heating system was carried out in hard to reach place and the approach is practically impossible;

- The volume that the expansion tank should have was calculated incorrectly, or the device was purchased at random.

It should be noted that the installation and fastening of the heating expansion tank must be carried out in accordance with accepted standards and rules ensuring safe operation. Before installation, you must correctly determine the installation location of the device.

After completing the installation of the expansion membrane tank on your own, everything seems to look great, and the inaccuracies made during this process are invisible. Disadvantages will become obvious after starting heating season and the main thing is that this will happen at the most inopportune moment. For example, it’s frosty outside, but heating system out of order.

Watch a video on installing an expansion tank in a heating system:

In order to avoid problems in the future, you need to familiarize yourself with the recommendations from the manufacturer for installing such an element of the heating supply system as an expansion tank. This information will help you avoid extra expenses: temporary, physical and financial.

In order to compensate for the 3% increase in coolant volume during heating to 70 degrees, an expansion tank is used for closed-type heating in the corresponding heating systems. You can visually distinguish the RB from the hydraulic accumulator (HA) of cold water supply systems by the red color of the body (HA tanks are blue).

Expansion tank for a closed heating system

In open (atmospheric) heating circuits, the expansion problem is solved in the following way:

- a container is mounted at the highest point of the circuit (usually an attic or attic);

- the excess volume of liquid flows under excess pressure into this container (tank);

- After cooling, the water flows back into the system under the influence of gravity + atmospheric pressure.

Open type expansion tank

The main disadvantage is the evaporation of water, the need for regular addition, and airing of the system. The hermetically sealed system is completely devoid of these disadvantages. closed system heating To compensate for the expansion of the coolant, an expansion tank for heating of a closed type is used here; contact with the atmosphere is excluded.

Closed device in the system

The design and principle of operation of the tank

Membrane sealed tanks are much more convenient to use than open vessels. For cold water supply systems, the industry produces hydraulic accumulators (HA) of blue color, stabilizing the pressure inside them. In heating circuits, a red expansion tank is used for heating of a closed type (RB), which eliminates “airing” of the circuit and is necessary to drain the water that has increased in volume during heating.

Design

Membrane tanks have a similar design, differing in details:

- HA - a rubber bulb is placed inside the hydraulic accumulator, repeating the contours of the internal chamber;

- RB - an expansion tank for closed-type heating is divided in half by a rubber partition (elastic material is usually rolled into a seam connection between the two halves of the body).

In 90% of cases, the RB has a cylindrical shape, however, there are modifications in the form of tablets for small volumes of coolant. When water is heated, the liquid expands and excess volume enters the tank.

The membrane material has a calculated elasticity; when the pressure decreases, it pushes out working fluid back to . Therefore, for tapping, it is enough to make a branch with a tee and mount it on the RB branch pipe.

Important! It is prohibited to install a red membrane tank immediately after the circulation pump.

Materials

HA uses food-grade rubber membranes, the shape of which completely eliminates contact of water with the walls of the metal casing. In RB the membrane is made of technical rubber, the inner surface of the tank is covered with anti-corrosion.

Thus, GA and RB are not interchangeable devices; they are intended for different operating conditions. If you install a blue tank in the heating circuit that is not designed for hot water, the service life of the system will be reduced. When installing a red tank in the cold water line, the water will no longer meet sanitary standards.

Tank parameters, calculation and selection criteria

The characteristics of the expansion tank for closed-type heating must satisfy the operational requirements. The easiest way to calculate the volume of RB is in the following way:

- fill the system with water;

- pour it into a calibrated container to calculate the volume of the coolant;

- multiply the resulting figure by a factor of 0.08.

Volume calculation

Thus, for a 100 liter heating circuit you will need a tank with a capacity of 8 liters. Another way to determine the volume of an expansion tank for closed-type heating is to calculate the heating power:

- To obtain 1 kW of thermal energy, about 15 liters are used in heating registers hot water;

- knowing what is needed for the cottage thermal power, you can calculate the total volume of coolant;

- after which, calculate the volume of RB with the specified coefficient.

Helpful information! The proportions used are 17 l/kW, radiators 10.5 l/kW, convectors 7 l/kW.

In professional calculations, the formula is used:

V = (V s x K)/D , Where

D – equipment efficiency;

TO – expansion coefficient;

V s – volume of the system.

In turn, efficiency is calculated using the formula:

D = (P 1 – P 2)/(P 1 + 1) , Where

P2 – charging pressure;

P 1 – maximum pressure.

For a one-story building, the charging pressure corresponds to 0.25 bar (2.5 m high, respectively), for two-story house will be 0.5 bar. Maximum pressure taken equal to the characteristics of the safety valve (2.5 bar). Therefore, the value of D will be 0.64 or 0.57 for a one- and two-story house, respectively.

For example, for a system with a power of 22 kW (200 m2) 330 liters of coolant will be required, the volume of the RB tank will be 330 x 0.04/0.64 = 20.6 l.

Attention! The volume should only be rounded up, choosing the closest value in the manufacturer’s line.

Do-it-yourself tank installation, nuances

To eliminate water hammer inside the system, an expansion tank is installed for home heating closed type, taking into account the requirements:

Tank with removable bracket

To ensure the maintainability of the equipment, a ball valve is screwed onto the RB branch pipe, which allows you to remove the tank without disassembling the entire system (for example, to replace the membrane). Without taking into account the nuances of the boiler room layout general scheme installation looks like:

- unpacking the expansion tank;

- installation of threaded fitting (“American”);

- installation of a ball valve;

- fastening the bracket with a band clamp (if the model does not have welded fasteners);

- wall or floor installation;

- releasing pressure from the system, draining the coolant;

- piping with a polymer (usually propylene), composite (metal-plastic) or steel pipe;

- pressure testing with working pressure;

- adjusting the pressure inside the air chamber (if necessary) using a car pump.

Helpful information! For sealing threaded connections in pressure DHW systems For heating, Unipack linen winding is used. FUM tape is not intended for this.

There are brackets with safety groups that make it easier to install the radio in the correct position.

The air nipple is usually protected by a decorative cap with a threaded connection. Some modifications of the RB are equipped with a bleed valve, which allows you to relieve excess pressure into the sewer.

The minimum coolant temperature is traditionally observed in the return line. After the water returns to the body inside the heating registers, it has almost room temperature. If the RB is mounted in this particular area, the effect of the aggressive environment on anti-corrosion coating will be minimal, the service life of the equipment will increase.

Pressure in expansion tank closed type heating is created after installation by a car pump. The main recommendations for this equipment are:

- upper coolant supply;

- installation at positive air temperatures;

- use of heat-resistant sealants.

Helpful information! In some boilers, the expansion tank of a closed-type heating system is built in by default. However, its volume may not be enough for specific operating conditions; calculation is still necessary.

Installing the RB in a hard-to-reach place will reduce the quality of equipment maintenance. Safety valve It is not always included in the package, so you will have to purchase it separately. Corrosion on the outside of the housing is not a reason to replace the equipment, but it is recommended to turn off the system, relieve pressure, treat defective areas anticorrosive

Replaceable membranes are controlled in accordance with the declared resource; the pressure inside the RB should be checked twice a year. The air chamber can be filled with inert gas, which will increase performance characteristics tank.

Thus, you can calculate the volume of the expansion tank and mount it inside a closed heating system on our own. It is enough to take into account the nuances given in this manual so as not to confuse the equipment with a hydraulic accumulator.

How to choose the right expansion tank (video)