A simple diagram for connecting a solid fuel boiler. How to connect a solid fuel boiler - Instructions

Any modern solid fuel boiler is characterized by high efficiency, and therefore can be used to maintain temperature regime indoors at the required level, and save on energy consumption. However, only the correct piping will allow you to achieve maximum heat transfer from the heating circuit in the house and achieve the efficiency of the heating system as a whole. solid fuel boiler heating. The strapping pattern may be different. The choice is based on the financial capabilities of the owner of the house or apartment, and the geometry of the premises itself.

What is the correct heating scheme with a solid fuel boiler?

This is how heaters using wood, coal, briquettes or pellets are connected.

The heating circuit of a private house with a solid fuel boiler is a combination of heating elements, additional devices to the boiler and heating circuit, structural units of the wiring itself, which together form the house heating system with its operating characteristics. Full heating system includes a boiler, heating elements (radiators, pipes, heated towel rails, etc.), control and safety devices, an expansion tank, etc. A correctly executed circuit is a heating circuit that complies with modern state standards and norms.

List of main state standards, according to which solid fuel heating boilers are installed in a private house:

- state building codes and the General Regulations on Residential Buildings 2005;

- state standard on devices operating on solid fuel from 1995;

- state standard, which describes heating elements with a capacity of 100 kW (1993);

- building regulations on heating and air conditioning systems for residential buildings (1991);

- construction standards on motor ship networks.

Anyone who intends to connect solid fuel boilers to the heating system on our own It is imperative that you familiarize yourself with the above documents and adhere to the standards specified in them during the work.

The ideal option is to rely on specialists. They not only know everything necessary requirements for successful installation of the system, but also have relevant experience in this matter. They will do everything in the best possible way.

Basic wiring diagrams for a solid fuel boiler

The drawing according to which the heating will be made depends on the number of circuits itself heating element, geometry and area of the room where the circuit will be located, the presence of additional and auxiliary devices.

Heating with solid fuel boiler, circuit diagram:

- open with gravity circulation;

- closed with natural circulation;

- closed with forced circulation;

- collector type.

Regardless of which connection diagram for a solid fuel heating boiler is chosen, the circuit must be organized correctly. The temperature delta of water at the inlet and outlet of the system should not exceed +20 degrees. Otherwise there will be side effects. Condensation forms on the heat exchanger, which leads to corrosion of the latter.

Open circuit with gravitational coolant circulation"> Open circuit with gravitational coolant circulation

This is the easiest way to tie, which you can do yourself. In this case, the movement of coolant through the system occurs due to the difference in density of cold and hot water. The heated coolant flows upward, since its density is low. As it cools, the density of the liquid increases, and therefore the coolant sinks down.

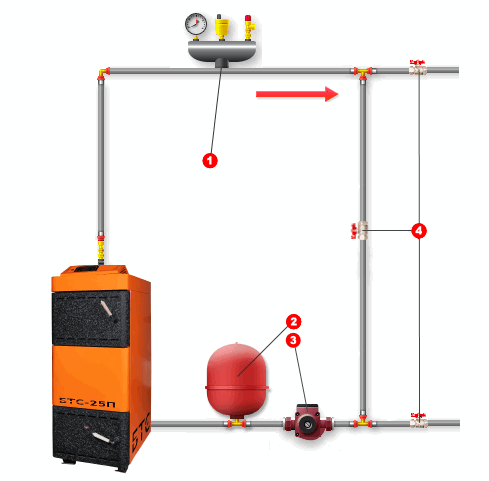

Gravity circuit with open expansion tank.

This installation scheme for a solid fuel heating boiler requires compliance with a number of rules. So, for complete circulation of the coolant in the system, the heating equipment must be installed below the level of the radiators by at least 0.5 m, and the expansion tank must be located at the highest point of the circuit. To reduce the hydraulic resistance of the system, choose pipes with a diameter of up to 50 mm (for distribution pipes to radiators, a pipe diameter of up to 25 mm is sufficient). A large number of locking devices and fittings significantly impair the circulation of the coolant, and therefore their number should be kept to a minimum.

Heating diagram for a private house with a solid fuel boiler open type with natural circulation has a significant advantage in its simplicity and low cost. However, here it is impossible to control the coolant temperature at the boiler outlet, which generally reduces the efficiency of the circuit. Through oxygen enters the coolant. It leads to corrosion of the heating circuit itself and the boiler heat exchanger. Such heating with a solid fuel boiler, the circuit in particular, can be considered as a budget option for a house that is visited from time to time.

Closed heating system with natural circulation"> Closed heating system with natural circulation

If you need an inexpensive but high-quality piping for a solid fuel heating boiler, the diagram indicated above is best option. A closed gravity system works due to the difference in density between hot and cold water. Due to its simplicity, the circuit is inexpensive to install and subsequently maintain, and is durable. The closed safety tank prevents free oxygen from entering inside. As a result, pipes, radiators and the boiler heat exchanger are less susceptible to corrosion.

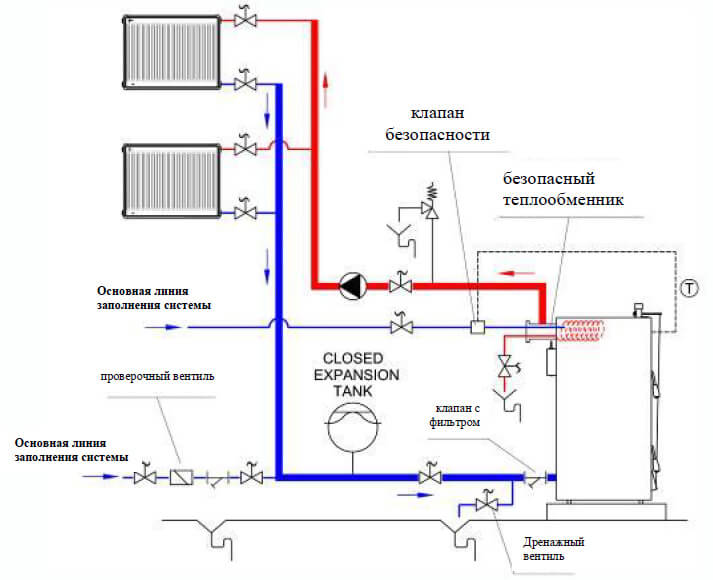

Gravity circuit with sealed expansion tank.

In addition to the main heating element (boiler), expansion tank, membrane tank, there is “ ", which makes home heating efficient and safe with a solid fuel boiler. The circuit is complemented by a pressure gauge (pressure control inside the circuit) and a safety valve (pressure is released through it).

Disadvantages: it is impossible to control the temperature of the coolant at the outlet, the heating efficiency as a whole decreases, since the coolant moves naturally.

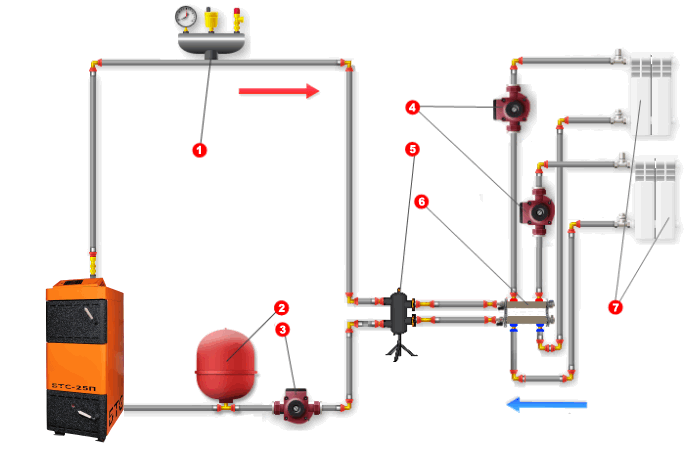

Closed system plus circulation pump"> Closed system plus circulation pump

Such an installation of solid fuel heating boilers in a private home is considered energy efficient and cost-effective. Here the efficiency of the circuit increases due to the high heat transfer of the coolant. The volume of water in the system decreases, which reduces energy consumption for heating it. IN closed system with forced circulation there is no need to install pipes large diameter, since hydraulic resistance to the coolant helps overcome the circulation pump. Important The coolant itself does not evaporate. After all, a sealed membrane tank. The closed piping of a solid fuel heating boiler prevents the formation of corrosion inside the system, which extends its service life.

A circuit in which the coolant does not come into contact with air.

Disadvantages include energy dependence (when the electricity is turned off, the circulation pump stops working) and expensive installation, such as connecting a solid fuel boiler to a heating system closed type Only a specialist can do it right, and you have to pay for his services.

A characteristic feature of the closed type piping is the circulation pump. It forces the coolant to move through the system, thereby increasing the heat transfer of heating pipes and radiators. The operation of the pump is controlled by a temperature sensor. The pump is always installed on a pipe through which the cooled coolant returns to the boiler. In this case, the service life of the equipment is significantly extended. Installation of a solid fuel boiler and a heating system with forced circulation of coolant is carried out in houses and apartments that are constantly used.

Collector circuit"> Collector circuit

It is difficult for an untrained person to make a manifold connection for a solid fuel heating boiler on his own, and therefore the services of a specialist are necessary here. However this method heating a home is considered energy efficient. The explanation is simple: each radiator or any other device for transferring heat from the coolant to the air in the room is connected to the circuit individually through a collector. The latter device plays the role of a kind of coolant distributor and has the form of a large-diameter pipe, from which there are outlets to each battery in the house.

Collector wiring very convenient and practical.

Don’t know how to install a collector heating system on a solid fuel boiler? The scheme is quite complicated for a person without the appropriate education and experience. That is why the services of a specialist are simply necessary here.

The advantage of collector wiring is that it can be used to control the temperature of each radiator in the house. After all, the batteries are connected individually. This is convenient if one of the heating devices breaks down. To replace it, you do not need to completely turn off the heating in the house. On the other hand, if one of the rooms in the house is not used, it can not be heated at all, cutting off the flow of coolant. to each battery is performed under a rough floor screed, which improves the aesthetic characteristics of the interior and additionally heats the floor. Collector system allows you to create several circuits in the house with different temperature conditions, since you can connect a solid fuel heating boiler using a hydraulic arrow.

Selecting a connection diagram for a solid fuel heating device

When organizing a heating system at home, it is not enough to have a drawing of a solid fuel heating boiler in front of you. In this case, you need to decide on the type of heating circuit for the house. To solve the problem, experts today offer several options. These are open and closed wiring with forced and natural circulation. The open contour is suitable for a summer house or holiday home. Forced circulation will help maintain the air temperature at the desired level in normal, residential buildings, while allowing significant savings on energy consumption. Collector wiring is new type heating the house, allowing you to create in every separate room your temperature regime. However, if you don’t know how to connect a solid fuel heating boiler to the collector circuit, trust the work only to specialists, because the wiring itself is difficult to perform.

If you have questions about how to install a solid fuel heating boiler, the video below will help you understand some aspects of the job.

Connect the equipment correctly of this type to the heating system is possible only taking into account its features. That is why we will consider below several typical engineering solutions, we note those details that should be paid attention to Special attention. We will separately study devices that perform protective functions in the event of emergency situations. This information will be useful in order to implement the corresponding project with your own hands and ensure high level safety during future operation.

Connecting a solid fuel boiler to an open gravity system

Here, when heated, the coolant rises up through the pipes. Next it goes to radiators, where it is cooled. During this process, its mass and density increase. Under the influence of gravitational forces, it falls down to the boiler, in the heat exchanger of which reheating occurs. Afterwards this cycle repeats.

No heating required in this system forced circulation liquids. It works fully without special pumps. This increases its autonomy, increases reliability, and reduces noise levels.

But there are also some restrictions that must be taken into account in order to produce everything necessary work do it yourself correctly:

- Under the influence of natural forces, the coolant will not move too quickly. Thus, heating of the premises cannot be done quickly.

- The same factor limits the permissible length of highways. In the horizontal direction it should not be higher than 25-30 meters. During installation, it is necessary to create a slope of the pipes in the direction of movement of the coolant of at least 0.5%.

- The boiler is installed 50 cm lower than the radiators. At the stage of creating working drawings, the number of turns, regulators, and other devices that impede the free movement of liquid should be minimized.

- The expansion tank is mounted at the highest point of the pipeline. In addition to excess liquid, gases formed in the system accumulate in it. When they create excess pressure, the valve is activated and they are released into the surrounding space. It is imperative to ensure that in the room where the tank is installed all year round there was a positive temperature.

Connecting solid fuel heating boilers to a closed system

In this case, the recommendations listed above will be useful, but a different tank, a closed type, is used. A flexible membrane is installed inside it, changing its shape as the pressure in the pipeline increases and decreases. The size of this container is selected to be more than 10% of the amount of coolant that a particular heating system can accommodate. This tank is mounted at the bottom of the trim. As a rule, it is installed in the same room with the boiler, in the return line.

In a closed system, it is necessary to install special control and safety products:

- A pressure gauge is used to visually check pressure.

- Emergency valve. It opens automatically if the pressure in the system rises above the nominal level.

- An air valve is necessary to remove the formed gases.

If the listed components are not included in the boiler’s standard configuration, they must be purchased separately. They are installed in the output line.

Connecting solid fuel boilers to other heating systems and their components

- Forced circulation. It uses a pump that turns on/off depending on the readings of a temperature sensor built into the return line. This blower is built into the line between the membrane-type expansion tank and the boiler. This closed heating system does not have the disadvantages of its gravity counterpart. But in this case, it is necessary to ensure an uninterrupted supply of electricity. To reduce the risk of accidents, it is recommended to install electronic surge protection units. Having an autonomous gasoline or diesel generator will be useful.

- Collectors. Such nodes are often used in different systems heating. They are distributors (one input - several outputs). You can connect different groups of radiators, heated floors, and heated towel rails to them. This will allow users to make necessary adjustments to individual devices. The connection diagram for a solid fuel boiler does not differ from the version that uses a forced circulation system with a special pump. It should be noted that in this option the number of pipes will increase, their installation will be more difficult.

- Boiler for heating water. You can build it with your own hands parallel to the lines with radiators. In order for this device to operate economically, a valve must be installed in front of its heat exchanger at the inlet. It is adjusted in such a way that the coolant supply stops when the required temperature inside the tank is reached.

- Connection thermal battery will increase the efficiency of a solid fuel boiler. This container, equipped with good insulation, accumulates heated coolant. It is dosed into the heating system using a pump and valves. The operation of this second circuit is controlled automatically using the readings of temperature sensors.

Protective systems

As noted above, it is possible to correctly connect solid fuel heating boilers only with the mandatory installation of protective devices:

- The safety valve is inserted into the outlet line and connected to the drain. It is triggered if a certain pressure level in the pipeline is exceeded.

- Overheating protection is provided by connecting a special heat exchanger. If the automation detects an excess of temperature, the cold water supply valve opens. Such a block is installed on the output line.

- Similar protection can be created in a system with a boiler indirect heating. It is used as an additional emergency circuit when the temperature in the main line rises above the established critical level. You will need to install a check valve and adjust the automation equipment accordingly.

- To reduce the likelihood of corrosion pockets, you can eliminate conditions that promote the formation of condensation inside the boiler. To do this, it is necessary that the coolant temperatures at the inlet and outlet differ by no more than 20°C. This result will be obtained if we set mixing valve thermostatic type into the return line. It is connected at the same time to the supply line, mixes taken from it hot water to obtain the desired temperature proportions.

There are many different schemes for connecting a solid fuel boiler for heating systems. It all depends on the system and its type, and of course the boiler, the most important thing in all this is the selection of the right technical system installation, for a specific connection. Of course, the project can be ordered from licensed organizations that have a lot of experience and education, but finances do not always allow this, so many people draw boiler connection diagrams on their own. First of all, the efficiency of a solid fuel boiler depends on correct connection. Installation of a heating system for a wood-burning boiler differs from installation of an electric or gas boiler. What is the difference? The fact is that the operating temperature of a wood boiler is 60 - 90 degrees, and this temperature is almost impossible to accurately regulate, because everything solid fuel boilers These are inert boilers. Few people know all the intricacies of the operation of such a boiler, and they make the mistake of using these boilers at temperatures below 55 degrees, this temperature is the dew point, which will lead to the appearance of condensation that will flow out of the boiler.

At low temperatures, a lot of soot is formed in the chimney and heat exchanger, which will lead to difficulty in maintenance and to a decrease in efficiency. To avoid all these problems, you need to install a buffer tank, also called a heat accumulator. If everything is calculated correctly, then the heat will be transferred with maximum efficiency to the buffer tank, which will serve as a thermos, and the heating system itself will extract heat as needed. With this connection, the solid fuel boiler will produce maximum efficiency, will never overheat, it can be used with maximum efficiency, while fuel will be saved, that is, firewood, there will be less need to burn soot, and there will also be minimal condensation.

How to install a boiler safely, reliably and get maximum comfort.

In order to comfortably use a solid fuel boiler, and also to keep the house warm, the boiler needs to be loaded several times a day, at least twice, of course, all this directly depends on the correct selection of the boiler power and the use of a buffer tank. When choosing a boiler, you need to take into account the height of the ceiling, the thickness of the walls, whether the house is insulated or not, the presence of heated floors and the temperature zone.

Systems using a solid fuel boiler and a buffer tank are not cheap, but at the same time, they are in great demand in European countries. This gives the advantage of independence and efficiency over other heat sources such as electricity or gas.

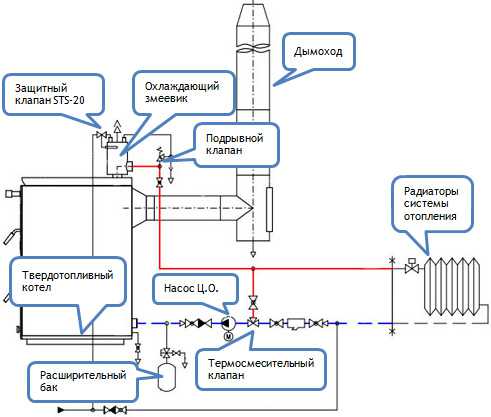

The connection diagrams for a solid fuel boiler, which are presented on our website, are suitable for almost every home, and it is they that most manufacturers recommend using when connecting a wood-burning boiler to a heating system. Thermo-mixing valve, adds cold water to hot, which prevents cold water from entering the boiler body, this protects the boiler from thermal shock and corrosion; when using such a valve, your boiler will work for a very long time. The change in water volume will be compensated by the expansion tank, and the boiler safety group, also called the “burst valve,” will operate at the moment of excess pressure. The STS-20 valve will supply cold water to the cooling coil from the water supply system at the moment when the temperature in the boiler body reaches 95 degrees, with this scheme the boiler will operate as safely and economically as possible. Another important element in the operation of solid fuel boilers, this correct installation chimney. If the chimney is installed incorrectly, many troubles may arise that will lead to a decrease in efficiency, the formation of tar and condensate in the boiler body and smoke in the house or boiler room.

Connection diagrams for a solid fuel boiler in a place with a gas or electric boiler:

What kind of boiler room should there be for a solid fuel boiler?

Based on the requirements of regulatory documents, “How to connect a solid fuel boiler,” all boilers over 30 kW must be installed in a separate room.

If the boiler is less than 30 kW, it can be installed in a house or basement; for convenience, you can store fuel for it in one room, but not less than 1 m from the boiler. Before deciding where the boiler will be installed, you need to prepare the base for its installation, it must be made of non-combustible materials, everything in the boiler room must have a fire resistance limit of 0.75 hours. The boiler must be installed so that it can be accessed from all sides, There should be a distance of at least 1 meter from the front of the boiler to the wall, which will ensure trouble-free maintenance of the boiler and its loading with firewood.

Ventilation in the room must be supplied, minimum diameter ventilation duct 14 cm, and it should be located under the ceiling of the room, preferably above the boiler.

If the boiler is connected to the sewer, then, before discharging water into sewer system, it is necessary to install a floor drain; if for some reason it is impossible to connect the drain, you need to make a container or well in which the water will be cooled before being discharged into the sewer; you also need to install a pump in this well to pump out the water.

Video instructions for installing a solid fuel boiler:

Solid fuel boilers are gaining popularity again today. Cause increased interest to this type heating equipment consists of several aspects at once. Greater power and autonomy of solid fuel mechanisms, compared with gas and electricity, provide ample opportunities to the consumer for equipment in the home autonomous system heating. Installation of a solid fuel boiler is especially important for residents of those areas where there is no centralized gas supply. In terms of choosing a heating device and heating system, the fact that for installation on solid fuel does not require obtaining official permission from the supervisory and control authorities is captivating.

The installation of the heating boiler is carried out taking into account the design data. Further working system heating is subject to registration by the Ministry of Emergency Situations authorities responsible for stove heating and safety of objects heated by solid fuels. Schematically, the installation and connection of solid fuel heating units is as follows.

Having assessed all the obvious advantages individual heating using fossil fuels or wood waste, the pros and cons of solid fuel appliances, you can safely start installing heating equipment in a private home. The only thing that is of interest in this situation is how to connect a home solid fuel boiler to other devices and to the heating system itself

Let's consider the features and nuances of connecting equipment of all types.

On this moment In everyday life, quite a variety of schemes are used for connecting solid fuel boilers to an individual heating system. In each individual case, the type of boiler and what fuel is supplied are taken into account. heating device and what is its power. The main tasks and requirements that are set for heating devices are space heating, operation DHW systems, the required level of comfort and operating conditions.

How to connect a solid fuel boiler to the system, if already at the development and planning stage there was a desire to establish interaction between the solid fuel boiler and electrical appliance. When it comes to directly installing the unit and connecting it to all elements of the entire heating complex, a lot of questions arise.

A correctly drawn up thermal diagram is the key to successful installation and connection of equipment. A smart decision would be to order the development of the project from a specialized institution. If you decide to do everything yourself, you will need certain technical knowledge, skills and the participation of professionals. The reason to turn to the services of specialists is that the connection diagram of a solid fuel boiler is significantly different from the gas boiler we are all used to autonomous heating And heating circuit on electricity.

Moreover, the subsequent operation of the entire heating system and the profitability of individual heating depend on how correctly the solid fuel heating device is connected.

Important! It should be remembered when working with solid fuel units that the operating temperature of the boiler varies in the range of 60-90 0 C, no less and no more. Painstaking and careful adjustment of the heating temperature is required to reach operating mode due to the inertia of boiler equipment of this type.

Eg: you are using a heating device in operating mode at a temperature below the permissible limits. The temperature of the coolant in the return circuit is below 55 0 C (dew point) leads to the formation of an excessive amount of condensate, which begins to flow out of the boiler. Firstly, on the walls of the firebox a large quantities soot that settles on the heat exchanger and accumulates on the walls of the chimney, reducing its cross-section. As a result, precious efficiency indicators of the heating device are lost, and difficulties arise with its maintenance. Secondly, the boiler room takes on an untidy appearance.

The installation of the boiler is preceded by work related to connecting the heating equipment to the pipeline system. , despite the complex and expensive equipment, it should be simple and understandable. To connect the product, the heating configuration must meet the following minimum requirements:

- there must be a large and small circuit through which water circulates;

- the pipeline must have good permeability;

- installation of the pipeline must be carried out in accordance with the parameters specified on the specification.

Ventilation plays an important role in home heating. The device must be connected to a ventilation system, the installation of which is carried out strictly in accordance with existing standards and standards. Properly equipped exhaust hood and ventilation not only facilitate the operation of the boiler, but also guarantee the safe operation of a complex unit in a residential building.

Traditional connection diagram for solid fuel boilers

The basis of almost any autonomous heating system used today is the connection of a heat accumulator to a solid fuel boiler. It is this connection that is the key to the safety of the entire heating complex. Pre-made thermal calculations allow the smooth supply of coolant to a special container that performs storage functions. If necessary, while the main mechanism is cooling, the heating system takes coolant of the required temperature from the heat accumulator.

A heater with a heat accumulator can operate in a constant operating mode, maintaining the highest possible efficiency, while saving precious fuel.

For reference: At the design stage, you can calculate the volume of the storage tank, taking into account the power of the device. Such calculations are important, first of all, to calculate the number of times the boiler is loaded with fuel to heat a living space for two or three days.

Often it is with the help expansion tank the coolant temperature is adjusted in heating circuit. Below is a diagram of connecting a heat accumulator to a solid fuel boiler and the place of the heat accumulator throughout unified system heating a private house.

The expansion tank is a mandatory element of the entire system, on which hot water supply is based. The hot water supply circuit is placed in a heat accumulator, where the heated coolant gives off its heat running water, circulating through DHW circuit. Without an expansion tank it is impossible to install a heated floor connection. Boilers long burning together with a heat accumulator, they are ideal for arranging heating systems of the “warm floors” type. Due to the expansion tank, the required temperature of the coolant is created, which then enters the pipeline laid on the floor. Heating "warm floor" in this form has maximum efficiency.

For calculations: The volume of the heat accumulator is taken at the rate of 25-30 liters. capacitive volume per 1 kW of boiler power.

Connection diagrams for solid fuel boilers together with an expansion storage tank represent a complex of complex and expensive equipment. Despite the high cost of such heating schemes, the investment and your efforts will pay off soon.

Other connection diagrams for a solid fuel heater

We connect the device to the main line with admixture

The design of the heating system in this case includes the following elements:

- heating equipment safety group (thermostatic valve, safety valve);

- expansion tank (heat accumulator);

- a circulation pump that supplies coolant to the entire system;

- shut-off valves.

This scheme is different in that it has an additional mixing circuit and taps, with the help of which you can easily volume the coolant in the mixing circuit. This type of connection allows you to keep heating radiators with comfortable temperature, despite the fact that the heating boiler is operating in optimal mode.

Eg: V pyrolysis boiler water temperature is 70-80 0 C, heating system for living rooms gives the coolant temperature to the batteries no more than 65 0 C.

Connecting a solid fuel unit with a hydraulic boom

This type of connection is used in situations where the heating system has more than one circuit. Hydraulic distributor or hydraulic arrow performs the function of a fuse, excluding hydraulic influence circulation pumps installed on each circuit. The hydraulic arrow simultaneously acts as a sludge catcher and degasses the entire heating complex.

The connection diagram for a solid fuel boiler with a hydraulic boom in a house consists of the following elements:

- control devices;

- expansion tank;

- two circulation pumps independent from each other;

- hydraulic boom;

- heating radiators;

- distribution combs (dirt collectors).

Connecting a solid fuel boiler with an electric or gas boiler

The heating system can include a whole set of heating devices, the task of which is to complement each other if necessary. Coal or wood fired boilers are used as the main source of the heating unit, while electric or gas unit perform auxiliary functions.

Connecting an electric boiler to a solid fuel boiler is carried out in order to combine all the main units into a single automated system heating.

On a note: electric boilers usually duplicate the work of traditional wood-fired boilers. When the combustion in the furnace of the main boiler weakens, this happens especially often at night, the electric heating device starts up.

The electric heating device also serves as a trigger for the solid fuel boiler.

The connection is made through a buffer tank, which plays the role of a hydraulic separator and a heat accumulator. The attenuation of the flame in the boiler furnace leads to the fact that the temperature of the coolant in the expansion tank begins to drop, therefore, the electric heating is automatically turned on. When the main boiler resumes operation, the reverse process occurs. The heated coolant flows back to the sensor and the electric heater turns off. What kind of device should work is decided by automation.

An approximate diagram is shown in the figure below

The system is viable and highly efficient, however, such a set of heating devices has a very high cost. Basically, a similar scheme is used for heating large residential buildings.

How to connect your unit to ventilation and chimney

Connecting a solid fuel boiler to a chimney is one of the key tasks, the solution of which determines the subsequent functionality of not only the heating device, but also the entire heating system. Your home, in which you want to have a comfortable microclimate and coziness, must be protected from harmful combustion products.

For those who want to make a chimney with their own hands, there are some practical tips.

- the chimney pipe must have a diameter no less than the cross-section of the outlet pipe;

- when the chimney has rectangular shape, and the boiler outlet pipe is made round shape, it is necessary to compare them according to the flow area.

- the length of the chimney from the first bend should not exceed two pipe diameters. Chimney should have a minimum number of turns and bends.

- for better draft, the horizontal section of the chimney in relation to the heating boiler is located at an angle of 45 0 (an inclination angle towards the boiler of 30 and 15 degrees is allowed).

In the latter case, compliance with the angle of inclination is not necessary if the heating boiler is equipped with a blower.

In the video you can get the necessary information on how to install the chimney of a solid fuel boiler.

Conclusion

Installation of a solid fuel boiler involves a complex and painstaking process. Many factors depend on which connection scheme you choose. The efficiency of autonomous heating will appear immediately after the solid fuel boiler is put into operation. Turning on the boiler will clearly show whether the heating unit is connected correctly and how all other system elements and devices function. During the first start-up, you can identify technical shortcomings and mistakes, which can be eliminated to optimize all processes. A normally operating mechanism will ensure the system required quantity coolant for heated floors. A correctly calculated expansion tank capacity guarantees you sufficient quantity water for hot water supply.