Protection of the combustion chamber of gas boilers. Single-circuit wall-mounted gas boilers with a closed combustion chamber - rating

The desire of many apartment owners to achieve maximum autonomy and independence from city utilities is quite understandable. One of the main issues in this regard is creating your own heating system. This allows you to independently determine the start and end dates of your “local heating season", setting the desired temperature in the premises at any time of the year, without freezing if the cold in the fall came too early or the arrival of spring was too long, and without suffering from the heat if the situation is diametrically opposite. And from the point of view of payment for services, it turns out to be much more profitable. Therefore, the installation of individual heating boilers is among landlordV an increasingly popular trend.

Well, if the owners plan to create their own autonomous heating system, then it would be quite reasonable, in parallel with this, to immediately resolve the issue of independent hot water supply. It is no secret that almost everywhere with the supply of hot water throughout the year various “surprises” occur, and in addition, prices for public utilities tend to constantly increase. Thus? own heating and hot water supply system means not only “technical”, but also, to a certain extent, financial independence.

Of course, the limited space conditions of apartments in multi-storey buildings limit the owners in the choice of boiler equipment. However, there is a way out - this is a double-circuit wall-mounted gas boiler, how to choose which will be discussed in this publication.

Operating principle of double-circuit boilers

Today, in cities, network gas remains the most inexpensive source of energy. If a multi-storey building is connected to a gas main, then for sure, despite certain administrative and technological difficulties in installing the appropriate equipment, such a heating and hot water supply system will become the most profitable. Paying bills only for actual spending "blue fuel", the owners receive in return both independent heating and an uninterrupted supply of hot water for household needs. Moreover both the timing of switching on and the heating temperature - it all depends on the desires of the apartment owners.

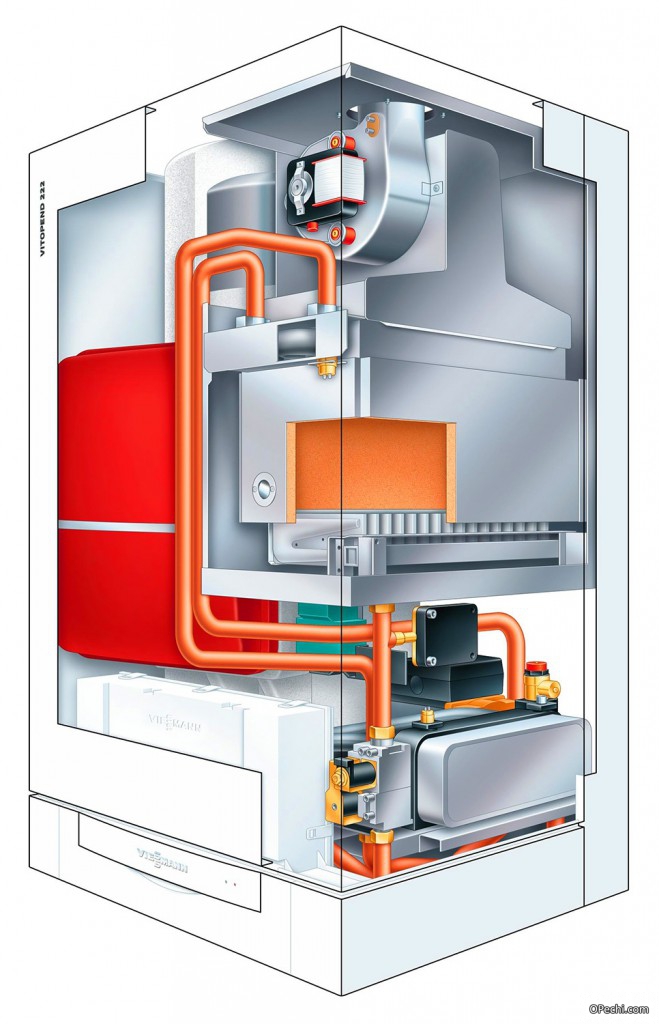

With a certain simplification of the connection principle double-circuit boiler can be schematically depicted as follows:

The boiler itself (item 1) is placed on the wall in the most convenient place, where there will be a connection to the gas main (item 2) and to the combustion product removal system.

Hot water circuit. A cold water supply pipe is connected to the boiler (item 3, blue arrows). Heated water is distributed (pos. 4, red arrows) according to a collector or corner circuit to points of consumption - in the bathtub (pos. 5), shower stall (pos. 6), kitchen sink (pos. 7), etc.

The heating circuit is closed. Circulation pump (most often it is structural unit the boiler itself) ensures the movement of the coolant through the supply pipes (item 8) and “return” (item 9). Depending on the specific features of the heating system, heating circuit conventional radiators (pos. 10), water heated floors (pos. 11), convectors of one type or another (pos. 12) can be connected. If desired, you can also install other devices here, for example, heated towel rails (item 13).

Thus, five pipes fit and connect to the wall-mounted double-circuit boiler:

- Gas main.

- Supply of the heating circuit with further distribution to priors or heat exchange systems.

- “Return” of the heating circuit.

- Cold water inlet

- The outlet of the heated water supply system for domestic needs with subsequent distribution to water intake points.

Inside the boiler itself, both circuits - heating and hot water supply - do not directly intersect, which makes it possible, if desired or necessary, to use a special coolant in the heating circuit.

By and large, this is the fundamental difference with single-circuit boilers, many of which have the ability to connect to a hot water supply system, but only through a boiler indirect heating.

Look at the diagram. Everything seems to be the same, but the points of consumption of hot domestic water are connected to an indirect heating boiler. And he, in turn, connects to the dedicated the boiler circuit along which the same coolant circulates as in the heating system.

Even if such a boiler has four water pipes at the outlet - two for heating circuits, and two for an indirect heating boiler, it will still not be considered double-circuit. It’s just that its internal design provides for rational redistribution of coolant flows with the necessary automation of this process. But the heat exchanger is used alone, and the composition of the liquid circulating in both circuits is no different.

A system using an indirect heating boiler has a number of significant advantages. In particular, it is possible to organize local closed recirculation of hot water - at any time, whenever the tap is opened, it will immediately flow hot water set temperature.

But there are also several negative aspects. Firstly, the cost of such a kit is always quite high. And second, but for small apartments Perhaps the most important thing is that installing a boiler and boiler will require a considerable area, which is not always possible.

It is in such conditions that a double-circuit wall-mounted boiler will help out. Its main advantages:

- Compactness - it does not take up much space, and at the same time, as a rule, does not disharmonize with the kitchen interior.

- Two problems are solved at once - heating the apartment and meeting the needs for hot water. The owners largely get rid of the “whims” of public utilities.

- Similar boilers correct installation and a thoughtful, balanced system autonomous heating very economical - this will certainly be immediately noticeable in the amount of monthly utility costs.

- The total cost of purchasing and installing a double-circuit boiler will be significantly lower than for a single-circuit boiler with an indirect heating boiler.

However, they are not deprived double-circuit boilers and significant disadvantages:

- These devices operate in only one mode at a time. For example, if it is necessary to heat domestic water, the boiler switches completely to water supply, temporarily turning off the heating circuit.

- As in the case of a gas water heater, there is a certain “inertia” - when opening the tap you will have to wait until the remaining water in the pipes flows out. cold water and until the boiler “accelerates” to the desired heating temperature.

- Many double-circuit boilers are very limited in heating volumes running water. So, taking a shower and washing dishes at the same time will either not always be possible or uncomfortable - when you close one tap, a temperature jump will inevitably occur in the other. True, many modern devices are equipped with an internal boiler, which eliminates this disadvantage.

- If in a single-circuit boiler purity of the coolant can be achieved, then in a double-circuit boiler Besides tap water is heated, which is not always and not always of the same quality. This gives a certain risk of overgrowing heat exchanger tubes, which You will have to either clean it regularly or replace it with new ones.

Which double-circuit wall-mounted boiler should I choose?

The boiler connection diagram shown above is very arbitrary, and in no way covers the variety of these devices. So in order to correctly determine the right model, it is necessary to take a closer look at the main selection criteria.

Boiler power and performance

- The boiler must fully cope with its main task - to ensure operation autonomous system heating. This means that one of the basic selection criteria is its thermal power.

Experts calculate the total amount of heat required by an apartment or house based on many factors - from the area and volume of the premises to the material of the walls, the degree of insulation of the building and the climate zone of residence. To independently determine the required boiler power, you can, with acceptable simplification, proceed from the standard of 10 m² of area of sealed premises per 1 kW. this rule will be valid with an average ceiling height of up to 2.5 - 3 m, and if the rules of proper thermal insulation are still followed in the house (apartment).

It is clear that the heating device should not operate at the peak of its capabilities, so it is better to provide a certain reserve, especially in the case where the insulation of a high-rise building still does not inspire complete confidence. Plus, the boiler needs additional power to heat water. In a word, it would not be a mistake to add another 30 ÷ 35% to the obtained value.

Most modern double-circuit boilers have a fairly wide power range. Technical documentation usually indicates its minimum and maximum values. For example, useful thermal power: 9.3 ÷ 14 kW.

- The second component of the problem is the performance of the device for heating water for domestic needs. If there is no boiler, then heating will be carried out according to a flow-through circuit, and the selection parameter depends on the number of water points that can operate simultaneously. It is clear that the more liters per minute the boiler can heat, the better.

Typically, the technical documentation of double-circuit boilers indicates several performance values, with different indicators of the temperature difference at the inlet and outlet. Usually they operate with the values Δt° = 25 and 35 degrees. This is not the temperature of the water at the outlet, but rather the increase in its value compared to the input. For example, in the summer the water in the water supply may be 15° WITH, and at Δt° = 25° 40° will flow into the taps, which is quite enough for taking a shower.

In principle, a productivity of about 10 ÷ 11 l/min at Δt° = is considered to be very good indicators 25 ° WITH, and 7 ÷ 8 l/min at Δt° = 35 °C.

All these considered characteristics will be valid only if the gas pressure in the main and water in the water supply correspond to the parameters specified by the manufacturer. You should also pay close attention to this.

Type and number of heat exchangers

According to the principle of heating water for domestic hot water, boilers can vary significantly. So, there are two main types of such devices - with a secondary heat exchanger and with a bithermic one. Each type has its own characteristics.

Main boiler heat exchanger, which is responsible for the most energy-intensive function, heating, and is always located above the gas burners. And water heating can take place in the same place, or with heat transfer from the heated coolant through an additional device - a secondary heat exchanger.

Double-circuit boilers with a secondary heat exchanger

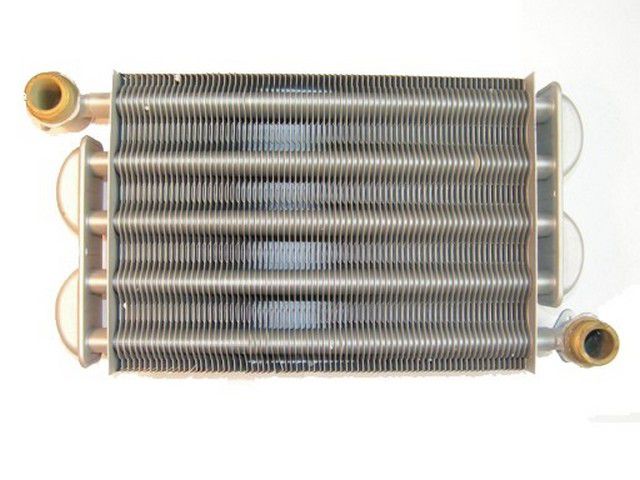

The primary heat exchanger itself is metal structure– a curved pipe, the turns of which are united by plate ribs to increase the heat exchange area from the hot combustion products to the circulating coolant. IN this option The boiler of such a heat exchanger has two pipes - inlet and outlet.

Heating of water for domestic needs is carried out in a secondary heat exchanger, which is located below the combustion chamber and has no contact with the burner flame. Typically this element has a compact plate structure.

Secondary heat exchanger - more compact, plate type

There are already four pipes here, and inside there are two circuits for counter-flow of liquid. In one way, the heated coolant circulates, giving off heat, in the second, tap water receives it.

The operating principle of such a boiler is shown in more detail in the diagrams.

- The boiler is operating in heating mode.

Above gas burner(position 1) the primary heat exchanger is located (position 3). The combustion of gas supplied through the line (yellow arrow) leads to heating of the coolant in the circuit. The circulation pump (item 5) ensures the movement of liquid through the heating pipes. The three-way valve with a servo drive (item 7) is in a position in which the valves open the flow from the return of the heating circuit and at the same time close the entrance to the secondary heat exchanger.

As a result, circulation occurs “in a large circle”, through heating collectors and installed heating devices.

The diagram additionally shows the built-in expansion tank(pos. 8) and safety group - safety valve and automatic air vent(pos. 9).

- What happens when you open a hot water tap?

Through the pipes DHW circuit the flow of water begins. This causes the flow sensor turbine (position 6) to rotate. The signal from the sensor enters the automation unit, where a control pulse is generated to the three-way valve (item 7). The valve moves to the position in which the valve closes the inlet from return lines heating, but opens the entrance to the secondary heat exchanger. In this case, the pump does not turn off, ensuring the circulation of the heated coolant in a “small circle”.

During use hot water the circulation of coolant through the heating circuit is suspended.

In the event that this happens during a period when the heating is completely turned off, when the hot water tap is turned on, the flow sensor will transmit a signal to the control unit, which will start circulation pump, will open gas valve and will trigger the electronic igniter (item 2). The gas heaters (item 3) are ignited, and the circulation of the coolant begins through the secondary heat exchanger, transferring thermal energy to the water.

Advantages of boilers with a secondary heat exchanger:

- Double heat exchange eliminates the possibility of getting burned from overheated water. Under any circumstances, if the primary circuit temperature can reach 80° WITH, then in the secondary it will not rise above 60.

- For the same reason, and also because heating occurs exclusively during circulation in both circuits at the same time, the build-up of scale in the secondary heat exchanger is much less than in boilers with a bithermal heat exchanger.

- The primary heat exchanger tubes can be made thicker and are less at risk of clogging or fouling.

- Even a clogged primary heat exchanger can be washed and cleaned.

- This boiler is more repairable– each unit can be removed, cleaned or even replaced. Cost of each heat exchanger separately- not so high.

Disadvantages of boilers with secondary heat exchange in the DHW circuit

- The price of such equipment is higher than with a bithermal heat exchanger.

- Availability of an additional electromechanical valve ( three way valve) is an extra vulnerable point for breakdown.

Video: a short “lecture” on the construction of a wall-mounted double-circuit boiler

Boilers with bithermal heat exchanger

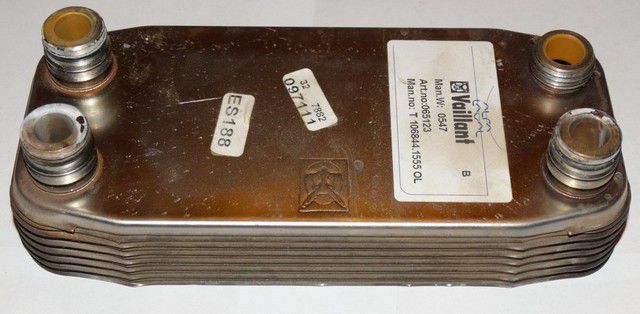

In these types of boilers, both heat exchange circuits are combined into one structural unit.

Bithermal heat exchanger - outside view...

Externally, the heat exchanger seems to be similar to the primary one, which was already mentioned above. But there are only four pipes - a pair each for heating and hot water supply.

![]()

... and he is in the cross-section

If you look at a cross-section of such a heat exchanger, you can see that the tubes have a cellular structure. Hot water circulation circulates through the central channel. External channels (in this case, four) are intended for circulation of the heating system coolant.

If only the heating is turned on, the circulation pump ensures the movement of the coolant, and the water in the central channel is motionless.

When you open the hot tap on the mixer, under the influence of the water supply pressure, water begins to move through the inlet pipe (item 1) towards the outlet pipe (item 2). The flow sensor through the control unit turns off the circulation pump of the heating system, and the movement of the coolant stops. The heat from the burners is taken over by the heated water. When the tap is turned off, the pump resumes operation, and the heating system becomes the main one.

Advantages of such a scheme:

- One heat exchanger takes up much less space. In addition, there is no three-way valve with a servo drive or additional piping. This makes the entire structure of the double-circuit boiler much lighter and more compact.

- Although a bithermal heat exchanger is sufficient complex from the point of view of the manufacturing technology of the part, its cost is still lower than two separate heat exchangers. This also affects the price of the boiler.

The disadvantages are very significant:

- In any mode, in one of the heat exchanger circuits the liquid is stationary, but is subject to heating. This leads to fairly rapid scale formation and overgrowing of the channels.

- The relatively narrow clearance of all channels also leads to the same consequences. Overgrowth of at least one of them leads to a decrease in boiler performance and the appearance of unpleasant noises.

- While the hot water supply circuit is closed, the water continues to heat up and reaches the same temperatures as the heating fluid. When you open a tap, very hot water may initially flow, which can scald your skin. To minimize such a risk, they try to limit the overall heating temperature using hardware and software methods (not higher than 70 ÷ 75 ° WITH, although this is already too much). But such a reduction simultaneously entails a reduction in the possible thermal output of the boiler for the heating system.

- A bithermal heat exchanger is more difficult to manufacture, and the presence of a large number of joints greatly increases the likelihood of leaks. Cleaning such a structure from scale is much more difficult. Well, if a leak occurs (especially between the external and internal contour) such a heat exchanger is practically beyond repair and requires mandatory replacement. But its cost is much higher than both primary and secondary in other types of boilers.

Thus, in terms of these positions, a boiler with secondary heat exchange in the hot water supply circuit still looks preferable.

There is another innovative type of double-circuit boilers - with a condensation-type primary heat exchanger. They are designed with an eye to a fairly serious effect of saving gas consumption at the same or even higher thermal power levels.

The fact is that one of the combustion products natural gas is always water vapor. In ordinary boilers it is simply released into the atmosphere, and yet it thermal energy(temperature reaches 110 – 140 ° WITH) can additionally be used to heat the coolant.

A special heat exchanger device ensures steam condensation with heat release. Studies have shown that steam potentially stores up to 11% of the total heat generated by the boiler, and if their unreasonable losses are returned to heat exchange, then gas savings over the season can reach 30% of the usual consumption level.

Of course, for such energy-saving boilers- the future, and in many countries they have taken leading positions in popularity. The only thing that still holds them back from widespread use in our area is the very high price.

Type of combustion products exhaust system

Boilers are divided into two large subgroups - with open camera combustion and with closed. Accordingly, they are spilled into systems for supplying the air necessary for gas combustion and for removing combustion products into the atmosphere.

Chimney boilers with an open combustion chamber

An open combustion chamber assumes that air enters the burners naturally, from the room in which the boiler is located. Combustion products, also naturally rising up, are redirected to the pipe to which the chimney pipe is connected. In a word, the effect is used natural traction, based on the difference in density of cold and heated gases.

The advantages of such a boiler:

- The operation does not require a special fan. This means the absence of noise and lower power consumption of the boiler.

- The contraction does not have complex air injection and control elements (pneumatic relays), therefore, the overall reliability of the device is higher.

- A chimney assembled in accordance with all the rules solves the problem of condensation formation.

- Chimney boilers are cheaper than turbocharged boilers.

Flaws:

- Air enters the combustion chamber directly from the room. This means that the issues of constant supply ventilation should be considered. And this very often leads to excessive heat loss in the premises and the appearance of drafts.

- There are special, fairly strict rules for the design and installation of a chimney. This often leads to large-scale repair and construction work and serious expenses - otherwise you will not be able to obtain permission to install the boiler.

- Installing a chimney is not possible in principle in all buildings.

Flueless boilers with closed camera combustion.

Such boilers are often called turbocharged. The air for them is supplied from the street forcibly, using a special fan-turbine; accordingly, combustion products are also thrown out into the street by the created pressure.

The chamber itself is completely closed, and exhaust gases cannot enter the room.

The supply of air and the emission of combustion products can be carried out through two separate pipes, but the vast majority of modern boilers of this type provide for the installation of a coaxial system - a “pipe in a pipe”, which is discharged through the wall to the outside.

Inside external pipe with a diameter of, as a rule, 100 mm, a second one with a diameter of 60 mm is located coaxially. Through the space between the outer wall and the inner pipe, air is forcedly drawn in from the street. The internal channel serves for the exit of combustion products.

Advantages of such a system:

- There are practically no significant restrictions on its installation.

- There is no need to provide fresh ventilation in the room.

- The cost of such boilers is slightly higher, but it is fully justified by the absence of large-scale work on the design and construction of the chimney.

The disadvantages are the following:

- A significant temperature difference in the outer and inner pipes is accompanied by the formation of condensation. In severe frosts, this can lead to icing, impairing the permeability of the chimney and, accordingly, insufficient vacuum in the chamber for the automation to operate.

- Mandatory elements of the system are a pneumatic relay, a fan and a fan switch relay. All of them have a certain resource, and failure of any of them leads to failure of the boiler.

- The fan creates noise when operating. Moreover, this additional expense electricity.

Conclusion: a boiler with an open combustion chamber and a conventional chimney looks more reliable in operation. But turbocharged boilers are easier to install and have no special restrictions on the installation location.

Controls, automation, protection levels

The boiler must be fairly easy to use, have clear controls, be equipped with the necessary functions to optimize operation and several degrees of protection against emergency circumstances.

Presenters manufacturing companies They are constantly improving their models, thereby creating competition between brands, so new developments are constantly appearing. So, modern boilers can be equipped with the following options:

- Flame modulation in heating and water heating modes. The flame level is electronically regulated, ensuring smooth starts, which is especially important for models with instantaneous heating of DHW water. Automation independently selects the height of the flames depending on set temperature and specific current water flow.

In some models, the last 5 degrees to the set heating temperature of the heating system are gained at a reduced combustion intensity. This allows you to make the operation of the device smoother, reduce the number of starts, and therefore increase the service life of the equipment.

- Similar goals are pursued by a smooth electronic ignition system, when after the appearance of a minimum flame on the burners, it gradually grows to a given combustion intensity within 30 - 40 seconds.

When the boiler operates as a water heater, this option does not apply - what is important here, on the contrary, is the speed of heating the water to a given level.

- Weather-sensitive boiler automation. This innovation, when installing an external street sensor, allows the equipment to monitor the level of external temperature and make adjustments to maintain an optimal microclimate in the apartment.

More advanced equipment of this type also has an automatic self-adaptation function. Electronics not only compares graphs of changes in external and internal temperatures, but also conducts an analysis, making adjustments to the operation of the boiler, which leads to maximum comfort, and to significant gas savings.

- Pump post-circulation. A useful feature that, when installed room thermostat, allows you to significantly reduce energy consumption. Once the required heating temperature has been reached in the heating system, the boiler turns off and the pump continues to operate for another three minutes. When it is necessary to resume operation, both the boiler and the pump are started simultaneously.

- Naturally, all modern electronically controlled boilers allow you to accurately set the temperature in both the heating circuit and the DHW. In addition, some models provide two switchable ranges in heating mode - for conventional radiators and for heated floors.

- The electronics allow programming of the boiler operation for a certain period of time, with the programs being stored in memory for reuse.

- Any gas equipment has several degrees of protection - in case of insufficient traction, in case of heater extinguishing, in the absence or insufficient water pressure in the circuits, etc. In addition, modern models are equipped with other safety functions. So, if the temperature in the circuits drops to +5 degrees, the boiler will start on its own to bring the heating level of the coolant and water to a safe value, in order to avoid freezing. In addition, some control systems also monitor the condition of the boiler elements. If the device has not been used for more than a day, the processor will will turn on pump or switch the position of the three-way valve back and forth. This allows you to avoid blocking or “sticking” of these units and extends their service life.

Control panels can have push-button, touch or electromechanical control, and are equipped with dial or digital indicators of temperature and pressure in the system.

Dimensions, “appearance”, manufacturing company

A mandatory evaluation criterion should be the dimensions of the boiler - they must correspond to the dimensions of the place where it is planned to be installed. This takes into account both the location of the gas main and the possibility of connecting to a chimney or installing a coaxial system. There are certain restrictions in these matters, for example, on the length coaxial pipe– this needs to be clarified in the product passport.

Perhaps, if the installation area allows, it makes sense to purchase a boiler with a built-in boiler - its dimensions are, of course, larger, but the ease of operation is incomparably higher - this has already been mentioned.

For many owners important criterion The choice is the design of the boiler. It is difficult to give advice here - the main thing is that the device does not spoil the interior. Most of the boilers have a matte white finish, which fits perfectly into any style.

No matter how much you like a particular model on sale, you should always give preference to reputable brands. Leading manufacturing companies provide a solid guarantee for their equipment, and since the boiler can be considered an expensive purchase, this fact is very important.

![]()

Very popular modern model"Baxi - Luna3"

Deserved authority and " untarnished reputation» used by European companies “Viessmann”, “Beretta”, “Baxi”, “Vaillant”, “Bosch”,. Protherm, Buderus, Ariston and other companies have proven themselves well. You can completely trust the products of Korean companies “Navien”, “Daewoo”, “Celtic”, “Kiturami” - in terms of equipment with modern electronics, they are sometimes superior to Europeans.

Video: wall-mounted double-circuit gas boilers Daewoo

You should be careful with Chinese technology, despite its relatively low price. Well, a brand “unknown to science” should be discarded immediately, no matter how attractive the model may seem.

When choosing between manufacturers, you should clarify whether there are service centers in the region, how difficult it will be to send equipment for maintenance or for replacement due to a complaint. Probably, you should not purchase a boiler from even the most popular manufacturer, if in a given area it is “exotic”, and the search for any trifling detail will be difficult.

So, in order to choose a really high-quality wall-mounted double-circuit boiler that is fully suitable in all respects, you should evaluate many criteria, understand the device, and carefully study technical documentation on the model you like, compare it specifications with the existing conditions of the planned operation. You should not chase the cheap - this purchase is made with the expectation of many years of service, and the stingy, as we know, pays twice.

Warmth is the most important component of comfort in a home. During construction, a lot of attention is paid to the heating system, because no matter how good the thermal insulation of the building envelope, without additional heating the house will still be very cold. The rating of gas wall-mounted single-circuit boilers will help you decide on the choice of the ideal heating mechanism. But before choosing such a heating mechanism, you need to determine its advantages over other models and make sure that it is necessary to install it.

Selecting a heating boiler

To ensure that the heating system does not cause trouble and does not waste a significant part of the budget, it is necessary to choose it carefully. To do this, you will have to understand the differences between heating equipment models. In all models, the coolant is heated not in a tank, but using the flow-through method. This ensures a continuous flow of hot material into the heating radiators and does not clutter up the space.

Fuel

The first thing that distinguishes heating systems from each other is the fuel required for their operation:

- Boilers that require solid fuel to operate. Typically, such equipment is installed in houses where there is no other heating method. Solid fuel has low efficiency. In addition, the operation of such a system will have to be constantly monitored and new fuel added to the firebox.

- Diesel and fuel oil. This large installations, intended for heating large space. They are not installed in apartments and private houses.

- Electric boilers. They are environmentally friendly, operate silently, and do not take up much space. It can be left without constant supervision. But in the event of a power outage, the house will be left without heating, which can be very inconvenient in winter.

- Gas. They are very economical to use and can work smoothly, even if the owners are away from home. Such equipment is environmentally friendly and does not pollute environment. Utility services very rarely turn off gas supplies; this happens only in emergency cases.

Depending on the communications provided to the house, each owner independently chooses the option that suits him. There is electricity even in the farthest corner of the planet. Gas is supplied to almost all gardening areas and villages.

Heating boiler installation method

Wall-mounted models are rightfully considered the ideal option for installation in a private home. Unlike their floor-standing counterparts, they take up much less space due to their small dimensions and installation on the wall. Thanks to this, the space under them can be used to store various things that do not require special conditions for this. Modern designers successfully make this irreplaceable element of comfort as invisible as possible and at the same time ergonomic. It can be hung in the kitchen, attic and bathroom.

Possibility of combining heating and hot water supply

There is a difference in the number of circuits:

- The double-circuit version of the heating device ensures that the house is simultaneously supplied with uninterrupted supply of hot water to the taps and heating. This is very convenient, but it has one big drawback: such boilers cannot use anything other than water as a coolant. In addition, priority in this installation is given to heating the hot water liquid, which leads to downtime of the heating system when the hot water tap is opened. This is not critical if the heating process is interrupted for a short time, but over a long period of time the house can cool down a little.

- A single-circuit mechanism can only provide heating of the building. It is capable of heating and dispersing antifreeze through radiators and batteries.

Tip: The lack of a second circuit, and therefore hot water supply, can easily be solved by connecting a water heater. In this case, the heating begins to work uninterruptedly and the hot water supply system becomes completely autonomous and is always an available resource.

The combustion chamber

There are also open and closed combustion chambers:

- An open chamber implies the work of natural draft. Air to support combustion is taken from the premises, depriving it of a small part of oxygen. Combustion products, that is, smoke, are removed into the chimney also under the influence of natural draft. A similar design is borrowed from a conventional stove, but it has undergone some adaptation to modern world and new technologies.

- A closed chamber does not require a chimney; such boilers can be installed even in apartment buildings. Such chambers are equipped with a device that forcibly removes smoke. The smoke is also burned under the constant pressure of oxygen and releases additional heat, thereby increasing energy efficiency.

The best solution for heating a private home would be a single-circuit wall-mounted gas boiler with a closed combustion chamber. It satisfies all the requirements of home owners and is not difficult to use or install.

Selecting a boiler by comparing models

To ensure that the heating device is truly chosen correctly, you should compare models from different manufacturers. This method allows you to see the advantages and disadvantages different options. By making a rating of gas wall-mounted single-circuit boilers, you can identify the best option heating the space.

Comparison of Bosch heating boilers

This is a company engaged in the production household appliances for many years now. German quality quickly attracted the Russians and earned their respect. Gas boilers from this company are represented by many models different types. Their price category also differs. All this allows you to choose perfect option for every home.

WBN 6000-18 C RN S5700

Users rate this device as one of the best, noting its efficient and silent operation. Despite the double-circuit type of the boiler, it copes well with multitasking and equally effectively heats the house and ensures the availability of hot water.

WBN 6000-12 C RN S5700

He is able not to disturb the silence in the house and work quietly, but effectively. Users note the ease of installation and modest dimensions of this model. The shortcomings are considered minor and therefore no one mentions them.

WBN 6000-18 H RN S5700

Owners of this boiler note its compactness and energy efficiency, but such a boiler also has disadvantages. Sometimes the system gives an error; you can deal with this problem by flashing the equipment. This is a fairly simple measure, but it forces the owners to invite a specialist and endure some inconvenience.

WBN 6000-35 H RN S5700

Another heating system of compact dimensions. It is capable of providing heat to a medium-sized house even in severe frosts. Users note the ease of use and installation. This is due to a thoughtful and simple design, because what simpler mechanism- the less it breaks.

Comparison of technical characteristics of Chaffoteaux boilers

A French company founded more than a hundred years ago. Throughout this entire period, engineers have been developing and implementing new technologies in the production of household appliances. All products are checked repeatedly, and only flawlessly working copies reach customers.

ULTRA SYSTEM 25 CF

![]()

People who purchase this mechanism are pleased with the possibility of connecting an external boiler. This solves the problem of single-circuit boilers providing hot water supply. The mid-priced option works well and doesn't require any hassle to maintain.

ULTRA SYSTEM 30FF

![]()

Users love the anti-blocking pump system. It automatically starts working once a day and turns on the pump. It is equipped with other beneficial properties: temperature sensor, pressure sensor, etc. The owners especially like the Russified multifunctional display, which allows even the most technology-averse person to cope with the controls.

ULTRA SYSTEM 25 FF

![]()

This boiler model is distinguished by its ability to flawlessly maintain the required temperature of the liquid in the batteries. The controller almost never fails and copes well with the tasks assigned to it. This mid-range option is liked by all the people who buy it.

ULTRA SYSTEM 35FF

![]()

In this catching model, users note a dosed flame size, which allows them to regulate energy consumption and adjust the heating intensity of the building to their needs.

Comparison of technical characteristics of Vaillant boilers

The history of this company goes back almost one and a half hundred years, but in Russia they learned about this company relatively recently, only two decades ago. Engineers are concerned about the convenience of their customers and therefore are constantly engaged in installing and developing easy-to-use regulators. All control principles embedded in the products of this company are based on the so-called “intuitive control”. It is this that helps people who are not familiar with such a mechanism to accurately begin to use it correctly.

turboTEC plus VU / 5-5

Among the advantages of this boiler is the protection system. It helps people always set up and use correctly heating system without the risk of disabling a complex and expensive mechanism. Small size with good performance also earned respect among satisfied customers. It fits perfectly into the interior and is not noticeable.

turboTEC plus VU 242/5-5

According to buyers, this is one of the easiest gas boiler models to install. The sensors built into the system do not allow it to fail, so the heating in the house will be constant. Management and configuration are also very easy for many users. This is thanks to the wide and multifunctional display. Quite a powerful mechanism. It is suitable for private houses of a rather large area, but it is still better to consult with specialists.

turboTEC plus VU 282/5-5

In the event of a breakdown, this device is capable of diagnosing its faults independently. The technician called to fix the problem can simply make a diagnosis. That is why users note the speed of repair. Users praise the designers who thought through appearance. This specimen does not stand out in any interior.

turboTEC plus VU 202/5-5

Quite a powerful device. It is capable of heating a very large house. All functions of this heating system are regulated using safety mechanisms designed to prevent operational errors. This allows you to extend the life of the device and simplify its use. This option is ideal for use in spacious rooms, but the power regulator allows you to install it anywhere small house, but this is irrational.

Comparison of characteristics of the best models from different manufacturers

To see the full picture and make a rating of wall-mounted single-circuit gas boilers in terms of reliability and quality, it is necessary to compare boiler models with each other. For these purposes, you can choose boilers with the highest rating from each manufacturer.

For comparison, let's take the following heating boilers: turboTEC plus VU / 5-5 from Vaillant, ULTRA SYSTEM 25 CF from Chaffoteaux and WBN 6000-18 C RN S5700 from Bosch.

|

Boiler model name |

turboTEC plus VU / 5-5 |

ULTRA SYSTEM 25 CF |

WBN 6000-18 C RN S5700 |

|

Maximum power (kW) |

|||

|

Minimum power, (kW) |

|||

|

Efficiency (%) |

|||

|

Natural gas consumption, (m 3 /hour) |

|||

|

Consumption liquefied gas(kg/h) |

|||

|

Nominal natural gas pressure (mbar) |

|||

|

Permissible liquefied gas pressure (mbar) |

|||

|

Coolant, minimum temperature © |

|||

|

Temperature maximum |

|||

|

Flame modulation |

|||

|

Autodiagnostics |

|||

|

Safety of use (auto-lock) |

|||

|

Pump blockage protection |

|||

|

Price (rubles) |

As you can see from this table, cheaper models do not have some necessary functions; you can, of course, do without them, but with these additional options, using the device becomes much easier. Each owner must decide for himself whether he needs these additional functions. Budget models also cannot boast of low gas consumption; they waste this valuable resource in large quantities. Safety and ability to heat rooms remain virtually unchanged for all models, which allows us to conclude: Nothing will change in the design of the thermal boiler, but additional functions may differ greatly in the fall.

Each manufacturer is responsible for the quality of the product produced and therefore the boilers work well, but budget models will take longer to install and configure, and during operation they will require more careful care than expensive models.

| Brand and model name | Grade | Boiler type | Power Minimum/Maximum (kW) | Natural gas consumption (m 3 /hour) / liquefied gas (kg/hour) | Additional functions | Cost of the device (rubles) |

| Bosch, WBN 6000-18 C RN S5700 | 5 | Dual-circuit | 5,40/18,00 | 2,1/1,5 | 25 100 | |

| Bosch, WBN 6000-12 C RN S5700 | 4 | Dual-circuit | 5,40/12,00 | 2,1/1,5 | Panel modulation, pump blocking protection, | 24 00 |

| Bosch, 6000-18 H RN S5700 | 4 | Single-circuit | 5,40/18,00 | 2,1/1,5 | Panel modulation, pump blocking protection, | 25 600 |

| Bosch, 6000-35H RN S5700 | 3 | Single-circuit | 12,20/37,40 | 3,90/2,70 | Panel modulation, pump blocking protection, | 37 547 |

| Vaillant, turboTEC plus VU / 5-5 | 5 | Single-circuit | 11,20/6,10 | 1,46/4,10 | Weight 44 kg | 65 250 |

| Vaillant, turboTEC plus VU 242/5-5 | 4 | Single-circuit | 8,00/24,00 | 2,80/0,96 | Weight 41 kg | 49 400 |

| Vaillant, turboTEC plus VU 202/5-5 | 4 | Single-circuit | 6,10/19,70 | 2,40/0,89 | Weight 40 kg | 45 600 |

| Vaillant, turboTEC plus VU 282/5-5 | 4 | Single-circuit | 9,40/28,90 | 3,20/1,08 | Weight 42 kg | 54 100 |

| Chaffoteaux, ULTRA SYSTEM 25 CF | 4 | Single-circuit | 11,00/25,00 | 3,65/2,72 | 35 500 | |

| Chaffoteaux, ULTRA SYSTEM 30 FF | 4 | Single-circuit | 14,40/30,00 | 2,73/2,03 | Wide tank, circulation pump | 40 900 |

| Chaffoteaux, ULTRA SYSTEM 25 FF | 4 | Single-circuit | 11,00/25,00 | 3,17/2,37 | Wide tank, circulation pump | 39 000 |

| Chaffoteaux, ULTRA SYSTEM 35 FF | 5 | Single-circuit | 15,00/30,00 | 2,86/2,13 | Wide tank, circulation pump | 43 200 |

Thus, it is impossible to find the ideal heating boiler, because such equipment is selected individually depending on the area of the room, its features and the needs of the customer. The conditions in which the mechanism will be operated are also very important; for a small heating system it is not necessary to allocate an entire room.

Despite the importance the right choice, the most important thing in the design of a heating system is the installation process. This should be done exclusively by professionals; only they will be able to comply with all standards for installing heating equipment.

In the process of comparing heating boiler models, it was found that their price depends not only on the technical characteristics, but also on the brand that produces these products. Price is not always the deciding factor; sometimes you can get a decent device at a lower cost. So, you should pay attention first of all to the integrity of the manufacturer, and not to the cost and number of functions.

Which model of single-circuit wall-mounted gas boilers with a closed combustion chamber did you like best?

Indoor comfort in winter time is largely determined by the quality of the heating system. Therefore, for example, wall or floor standing boilers you need to choose as responsibly as possible. They must comply with current operating conditions, owner requirements, etc. This is the only way to achieve efficient work heating equipment.

Based on the number of circuits, there are two types of boilers:

1. Single-circuit. Provide space heating.

2. Double-circuit. The second circuit is used to heat water.

wall-mounted gas boiler

wall-mounted gas boiler Such devices with chimneys can be floor or wall mounted. Both of them can operate on different fuels: gas, electricity, etc.

These devices are distinguished by their performance, productivity, efficiency and technical parameters. Many consumers install floor-standing gas models in their homes. They are more productive, convenient to use, and can provide heating for industrial facilities. The difference between wall-mounted and floor-mounted single-circuit models is also in price.

Single-circuit or double-circuit boiler?

Gas boilers

Floor-standing gas heating devices have good technical characteristics and low hydraulic resistance.

Note: A single-circuit boiler is capable of heating up to 400 m2.

It is made of cast iron with good insulating qualities, fire-resistant burners, equipped with the possibility of pre-mixing, a closed chamber and an equipped chimney for the removal of combustion products.

Important characteristic floor-standing models - the ability to circulate coolant without using pumping equipment. This increases the efficiency of the devices. The design includes protective elements that eliminate the need to limit temperature conditions. Through the use of modern automated control systems, high combustion productivity and heating efficiency are ensured, as well as safe removal of combustion products through.

floor-standing

floor-standing Single-circuit gas boilers are used only for space heating; they cannot provide hot water. Such devices are built in two versions:

- Economical type of heating. In addition to heating device A instantaneous water heater is installed. Provided minimum consumption gas when two devices are operating.

- Optimal heating type. In this case, the heat exchanger is installed in. Provides increased hot water consumption. It is important to coordinate the power of the two devices. If the gas boiler has less power than the boiler, the normal level of hot water consumption will be difficult to ensure. Then an electric water heater can be used.

Double-circuit gas boilers include the following components:

- heat exchanger;

- burner;

- pump;

- expansion tank;

- chimney - this is what the ventilation system is sometimes called.

The tank is connected to the heating and water supply system. Job heating device carried out with priority for hot water supply. When the tap opens, the heating heat exchanger is switched off. Only the hot water supply circuit is heated, and the water is heated in flow mode.

Note: If the water consumption is high, it is recommended to use a single-circuit boiler with a built-in boiler, otherwise hot water will be provided, and the house will be poorly heated.

Prices for devices vary. Some domestic models have increased weight and increased dimensions, inconvenient chimneys. Therefore, they may require a separate chimney to remove gas combustion products.

About connecting a gas boiler

Operating principle

The operating principle of floor-standing devices with a closed and open combustion chamber is quite simple. When burning, the gas gives off heat to a heat exchanger located inside the structure. Liquid passes through it, is heated and supplied to the heating system. For proper functioning, a high-quality heat exchanger is required:

1. Cast iron elements are durable, since the material is resistant to burning and is not subject to corrosion. As a result, the structure can function for more than 50 years. But there is one drawback - fragility, which means that a sharp temperature change or strong mechanical stress can cause damage to the case.

2. The steel heat exchanger is characterized by increased mechanical strength to allow it to effectively resist damage. The element has less weight than a cast iron body. However, there is also a minus - susceptibility to corrosion, which causes fairly rapid burnout during heating. The operational period is about 5–15 years.

3. Copper elements are now used quite rarely.

Features of Thermomax floor-standing boilers

equipment requirements

To ensure the most efficient operation, the following requirements must be met:

- Maximum power and endurance. Boiler performance is determined by power. The higher it is, the more comfortable conditions accommodation. It is better to use single-circuit wall or floor models with a closed or open chamber, focused specifically on heating, and not heating water.

- Maximum heat at low cost. Thanks to the availability automated system control and automatic ignition ensure efficient combustion of gas, which creates optimal ratio mixture ingredients in the combustion chamber.

- Heating of any room. Wall models have limited use. Single-circuit floor-mounted boilers can provide heating not only for small areas, but also for huge industrial premises.

- Full compliance with safety criteria. Otherwise, the operation of single-circuit boilers can turn into a dangerous undertaking.

Advantages

A single-circuit floor-standing boiler with a chimney has the following advantages:

- High performance. Single-circuit floor models, like wall-mounted boilers, models use technological techniques in combustion chambers.

- Heat transfer efficiency. Single-circuit wall-mounted or floor-mounted boilers effectively transfer heat from a closed or open combustion chamber to the heating system.

- The automated control system of single-circuit models ensures economical fuel consumption.

- Single-circuit devices make it possible to organize heating of large areas. Additional chimneys may need to be installed.

- Large functionality: several temperature modes (you can equip a heated floor), a standby mode and auto-on when the gas supply is restored, application modern means monitoring.

- For control temperature regime V single-circuit boilers Sensors and coaxial cables for electronic control can be used.

- Hassle-free and long work, ease of maintenance with a closed or open combustion chamber.

- A single-circuit boiler provides low level noise.

- Minimum selection of combustion products through the chimney.

- Availability. Prices for single-circuit models allow you to acquire such devices. Moreover, these can be wall or floor models with a closed or open chamber and chimney.

The single-circuit boiler is equipped with a cast iron heat exchanger, which ensures good thermal insulation. And the burners make it possible for the device to operate on liquefied or natural gas.

Both double-circuit and single-circuit boilers require installation in separate room, installation of the chimney. Installation wall options easier to perform than floor-mounted ones. Also, a single-circuit boiler is characterized by energy dependence. All this makes the device popular in the market.

Many owners of apartments and small houses prefer to buy a wall-mounted gas boiler. We offer models from such well-known brands as: Viessmann, Bosch, Baxi, Protherm, Vaillant. The products of the presented manufacturers are in demand on the world market and in Russia.

Characteristics and capabilities of wall-mounted gas boilers

Heating equipment running on gas does not require a place to store fuel, because it comes from central communications in the required quantity and almost without stopping. Moreover, gas is superior in thermal output to other types of fuel, and the operation of gas boilers is easier to automate. That is why the presented models are so in demand on the heating equipment market.

We offer following types wall-mounted gas boilers:

- single- and double-circuit;

- with open and closed combustion chambers;

- With various types automatic control.

The Hydrotop online store is a leader in its market segment. Each buyer is guaranteed to be able to buy a wall-mounted gas boiler, as well as optional equipment For competent organization heating and hot water systems in the house and apartment.

We offer affordable prices And high quality service. You just need to choose a boiler with optimal power, which varies from 10 to 100 kW. Wall-mounted gas boilers are reliable operation, profitability and high efficiency.