Heating radiators which are best for an apartment

No matter how high-quality batteries are in the apartment, sooner or later the moment comes when they have to be replaced with new devices. And immediately the problem is - which heating radiators are better for an apartment to choose? Another case when there is a desire to install new batteries is if there are old cast-iron "accordions" in the apartment for a long time, which do not want to fit into the interior created by the owners.

The modern market offers a wide range of models of radiators made of various materials and having a completely aesthetic appearance. Comparing the design of modern appliances with crude cast-iron batteries or ineffective and low-quality convectors that were previously installed in apartments, of course, I want to see such new items in my possessions.

Radiator selection criteria

It is necessary to approach the choice of modern radiators with all responsibility, since not all of their varieties are suitable for installation, for example, in a central heating system. Some types have characteristics that are designed for a clean coolant and a certain ultimate load, so they simply will not be able to withstand water shocks, which, alas, are not uncommon in our utilities. Other radiators, on the contrary, in an autonomous heating system will not show all their potential.

In addition to the selection of radiators according to performance indicators, it is necessary to correctly calculate the number of sections in the batteries for each separate room, otherwise the efficiency of their work will be very low, and the premises of the apartment will not be comfortable enough.

So, the effect of the installation of new heating devices will be expectedly high, if we take into account all their operational nuances and follow all the recommended technological installation rules.

Today, several different types of radiators are produced, differing in the material of manufacture and design:

- Cast iron batteries, both old and refurbished, with an elegant modern or retro design.

- Steel radiators - tubular and panel.

- Bimetallic heating devices made of two types of metal.

- Aluminum of various quality levels.

When choosing batteries for installation in an apartment, you need to consider the following criteria:

- The maximum pressure in the central heating system in the local heating system, and the possible limit for which the vending radiators are designed ..

- The maximum temperature and characteristics of the composition of the coolant in the system, as well as the endurance of radiators to these influences.

- The material of the device and its main physical characteristics.

- Battery design.

- Required radiator power - on the basis of this parameter, the number and size of sections required for efficient space heating is calculated. These calculations are made based on the recommendations of building codes and regulations, and can be carried out in various ways, which will be discussed in the article later.

To begin with, you can give a small table, which, albeit briefly, but rather informatively characterizes the main types of heating radiators. Well, then let's take a closer look at the basic types.

| Radiator types | Pressure limits: working (Pb), test pressure (Op), destruction (Pz), bar | Limitation chemical composition coolant by pH (hydrogen indicator) | Corrosive effects: oxygen (OK), stray currents (BT), electrolytic vapors (EP) | Section capacity at h = 500 mm; t = 70 ° С, W | Warranty, years | ||||

|---|---|---|---|---|---|---|---|---|---|

| RB | Op | Rz | OK | BT | Ep | ||||

| tubular or panel steel | 6 ÷ 10 | 15 | 18 ÷ 25 | 6.5 ÷ 9 | Yes | Yes | weak | 85 | 1 |

| cast iron type MS ÷ 140 | 10 ÷ 12 | 12 ÷ 15 | 20 ÷ 25 | 6.5 ÷ 9 | No | No | No | 160 | 10 |

| aluminum | 10 ÷ 15 | 15 ÷ 30 | 30 ÷ 50 | 7 ÷ 8 | No | Yes | Yes | 175 ÷ 199 | 3 ÷ 10 |

| bimetallic | 35 | 50 | 75 | 6.5 ÷ 9 | Yes | Yes | weak | 199 | 3 ÷ 10 |

| anodized aluminum | 15 ÷ 20 | 25 ÷ 75 | 100 | 6.5 ÷ 9 | No | No | No | 216,3 | 30 |

Types of heating batteries and their main characteristics

Cast iron radiators

Cast iron radiators are "long-livers", but they do not lose their relevance today, especially since they acquire an elegant appearance and improved characteristics. Batteries of domestic and foreign production are on sale, and there are certain differences between them - about them a little later.

- Batteries made of this material have not lost their demand, despite the fact that other, more modern heating devices have appeared, primarily due to the technical characteristics of cast iron. It is not subject to corrosion, radiators are not afraid of water hammer, as they have rather thick walls. Another advantage of cast iron over other materials from which radiators are made today is its high heat capacity, that is, the ability to maintain temperature for a long time, even when the external heating is turned off.

- It is also positive that cast-iron batteries will function perfectly not only in an autonomous system with a high-quality coolant and controlled pressure, but also in a central heating system. True, you should immediately make a reservation about that. That it is undesirable to install them in autonomous systems working with electric boilers - operation may turn out to be too expensive in terms of high energy consumption.

- Cast iron radiators may well be installed in an open-type autonomous heating system, in which the coolant is inevitably saturated with oxygen. This is not a problem for cast iron - the material is not subject to oxygen corrosion.

- Thick walls of cast-iron heating devices not only keep the coolant temperature longer, but also increase the resistance of the batteries to abrasive wear.

- If the old batteries had one standard size ruler, and for proper heating of the room it was necessary to select a radiator by exclusively varying the number of sections, today devices with different power parameters are being produced. This expands the possibilities for the complex selection of the necessary radiators, both in terms of the required power and in the design of the premises.

- In order to install the old cast-iron batteries, it was necessary to drive the brackets into the wall, and therefore damage its finish. Modern batteries are produced both in a hinged version and in a floor-standing version, with reliable legs. The latter are simply installed on the floor near the walls, and connected to the heating circuits.

- Many modern models of cast-iron radiators do not have to be painted periodically, as it was necessary with old battery options. They go on sale ready for installation, and already have a treated and painted surface, which does not need to be refreshed with a layer of paint annually. To care for these devices, you only need a damp soft cloth, which can be brushed off or wiped off dust. You can also notice that the absolutely smooth surfaces of modern batteries are fundamentally different from the rough sections of the old model, so dust practically does not collect on them.

- Some cast-iron models of batteries are produced in very original styles of design, which allows them to fit into any interior, no matter how modern or even retro-looking. It is possible to choose heating devices in such a way that they will also become a decorative element of the room's design, complementing and transforming it.

The main disadvantage of all cast iron radiators is their heavy weight. If you plan to hang them on the brackets, the latter must be securely fixed in the wall - and not every partition is even able to withstand such a load. In addition, to lift and hang such a battery, you will definitely need an assistant.

Cast iron radiators of domestic and foreign manufacturers

On the Russian market, you can find both domestic and imported cast iron radiators. European countries - Germany, Italy, Czech Republic, Spain and others - represent their products in a fairly large assortment. These products differ significantly from Russian ones in some characteristics:

- Unlike traditional domestic MS-140 or MS-90, foreign products have smoother, well-processed external surfaces, and the original retro versions are decorated with molding in the form of floral embossed ornaments.

- Imported products have a higher heat output with small dimensions. So, for example, with the same heat transfer, the volume of filling the section of the domestic battery with the coolant is 1.3 liters, and of the Czech production - only 0.8 liters. Therefore, this option will be more compact and neat.

- Foreign products have perfectly smooth internal cavities, which contributes to normal circulation of the coolant, without high hydraulic resistance, and prevents the formation of deposits of dirt and scale on the walls of the channels.

- Domestic batteries are sold with primed surfaces and require painting, while imported batteries are immediately ready for installation.

![]()

- The disadvantage of foreign products is their very high cost, which is several times higher than the price of Russian-made batteries.

For the sake of fairness, it must be said that the production of more modern cast-iron batteries is gradually getting better in our country. In addition, excellent cast-iron radiators of European quality are also produced in neighboring Belarus at the Minsk Heating Equipment Plant.

Output: for the conditions of an apartment, cast-iron radiators are quite applicable, especially when connected to a central heating system, of course, taking into account their characteristic shortcomings.

Steel radiators

Modern steel radiators differ in both their construction and design. They are usually made in the form of panels or pipes arranged together, therefore such heating devices are called tubular or panel. To understand their design and characteristics, you need to consider each of the types of batteries separately.

Panel steel radiators

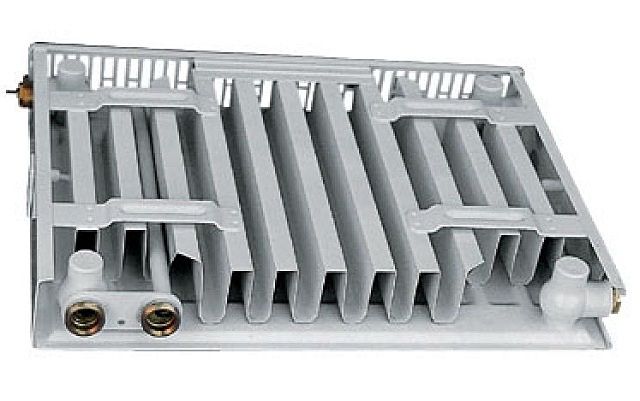

Panel radiators consist of two steel sheets, which are formed into the desired shape by means of stamping. Then the workpieces are welded into a hollow panel and, if necessary, equipped with special convector elements - in order to create a vertical directional movement of the heated air, thereby forming a kind of thermal curtain from the cold coming from the window.

The coloring of such a battery occurs after all the elements are assembled into a common structure. The paint is applied using a special technology that ensures the strength and durability of the coating.

In order for the steel batteries to last as long as possible, the protective paint coat must be applied evenly. Therefore, when purchasing this type of device, special attention should be paid to the coating, since steel sheets can be corroded on damaged, unpainted areas.

Panel batteries are designed for a heat carrier with a temperature of up to 85 ÷ 95 degrees, as well as for the standard pressure created in the centralized heating system.

The number of panels and heat exchange convector "accordions" can be different

This type of heating device usually has its own classification, which is based on the number of panels and convection heat exchangers in the finished assembly. An example is given in the table:

Panel radiators can differ quite strongly not only in the number of panels, that is, in the depth of the structure, but also in other dimensions. Their length can be from 400 to 3000 mm, and their height usually varies from 200 to 900 mm.

In addition, panel batteries are produced with bottom or side connection. The choice for this parameter is made depending on how the piping of the heating circuit is located.

Panel heating radiators have their advantages and disadvantages, which you should definitely familiarize yourself with before deciding to purchase

The positive aspects of panel radiators include the following:

- Relative ease of installation of devices in the heating circuit. The radiator has a one-piece design and does not need to be assembled from separate sections.

- Panel radiators tend to warm up quickly. A sufficiently large area of the panel itself and the fins of the heat exchangers-convectors contributes to effective heat transfer, so the room heats up quickly enough.

- The compact size and aesthetic appearance make it possible to fit such a radiator into almost any interior.

- To fill an autonomous system with panel radiators installed in it, a fairly small amount of coolant is required.

Panel radiators have their own significant disadvantages, which include the following:

- They are reliable at normal pressure in the central heating system, but they are not designed for powerful water shocks, which often occur when the system is filled with coolant before the start of the heating season. Panels may simply not be able to withstand such a test. Therefore, if they are chosen for installation in an apartment, it is necessary to use a special device - a reducer to protect against excessive intra-system pressure, which will smooth out the load on the panel, taking a blow on itself.

- The inner surfaces of the panel often do not have an anti-corrosion coating, although they are in direct contact with the coolant, and the durability of their use will depend on its quality. As you know, in a central heating system, the coolant is very often not of high quality, and can contain very active impurities that contribute to metal corrosion. Therefore, as a rule, a panel-type radiator cannot be operated in such conditions for a long time, since unprotected steel surfaces are unstable to an aggressive environment.

Based on the above considerations, it follows output that the installation of panel steel radiators in an apartment with a central heating system is undesirable.

Tubular steel batteries

Unlike panel radiators, tubular radiators consist of several sections, but "tightly" fastened together by welding. Therefore, they also do not need to be assembled, since they are purchased ready-made, representing a complete structure from a certain number of sections. Therefore, in order for heating to be effective, it is necessary, before purchasing such radiators, to calculate the required total power required for a specific area, and from these considerations, select the optimal model.

Batteries of this type are designed for an in-system pressure of 8 ÷ 10 atmospheres, so it would be useful to install a reducer, since water hammer when filling the central system with a coolant can lead to emergency situations.

Steel radiators have a wall thickness of only 1 ÷ 1.5 mm, so the coolant quickly heats them up, and the metal begins to transfer heat to the room. However, it should be noted that thin walls are also the weak side of such batteries, since they are easily susceptible to mechanical damage.

Tubular structures are more resistant to an aggressive environment of low-quality heat carrier than panel structures, since they usually have an internal protective coating made of polymer materials. Therefore, they are less exposed to corrosive effects and, accordingly, with normal other parameters of the system, they can serve longer.

Tubular radiators can have very different, sometimes even "unexpected" dimensions. So, their height ranges from 200 to 2500 mm, their depth ranges from 100 to 250 mm, and their width can vary widely depending on the need for total thermal power.

Tubular radiators are produced in a wide variety of design solutions, they can be wall-mounted and floor-mounted. Moreover, they are installed both near a wall or window, and even in the middle of the room. For installation in the center of the room, radiators with a height equal to the height of the ceiling are used, taking into account the support legs. This option is used when the room needs not only to be heated, but also to be divided into separate zones.

- Some battery designs are equipped with wood panels installed on top, and, in fact, are a bench designed for different needs, depending on the location of the heater. For example, if it is installed in the hallway, it can be used as a shoe stool, since it will be convenient to sit on it. In the evening, shoes can be placed on a wooden surface to dry.

Since tubular batteries are produced in different colors and in various, even sometimes unexpected design delights, they can be matched to any interior design.

The disadvantages of batteries with a tubular design include only two main points, but quite serious ones that negatively affect the efficiency and safety of the apartment heating system:

- A sufficiently low heat transfer, leading to an increase in energy costs if the batteries are installed in an autonomous heating system. The structure heats up quickly, but it also tends to cool down quickly, so the heating boiler will work almost constantly, with short interruptions. Conclusion - it is unprofitable to install them in the autonomous heating system of a private house.

- The elements of the radiator are connected by welding, the seams of which will become a weak point in the event of water hammer. Therefore, it is also undesirable to install them in an apartment circuit connected to a central heating system. If they are nevertheless chosen because of a suitable design, then it is necessary to install a reducer that will take the load from a sharp pressure drop on itself.

Conclusion from the above : Tubular steel batteries, despite their visual appeal, are far from ideal. Installing such radiators in an autonomous system will lead to unnecessary energy costs, and in the central heating system - to an increased risk of emergencies.

Aluminum radiators

Aluminum radiators have an aesthetic appearance, but it must be said right away that, in terms of their technical characteristics, they are not very well suited for installation in a central heating system.

For autonomous heating systems, the best choice is high-quality aluminum radiators

For homeowners with autonomous heating, aluminum radiators are very popular due to their elegant appearance and high heat transfer. In an autonomous system with a stable pressure and a high-quality coolant, aluminum heating devices can last from 15 to 25 years - these are the terms that manufacturers usually indicate in the technical passport as the minimum.

Radiators are designed for in-system pressure up to 15 atmospheres and a coolant temperature of 80 ÷ 90 degrees. They have excellent power (heat transfer), reaching 200 ÷ 210 W, and the volume of each of the battery sections is only 450 ml with a weight of 1 ÷ 1.5 kg. The sections are fastened using a threaded coupling.

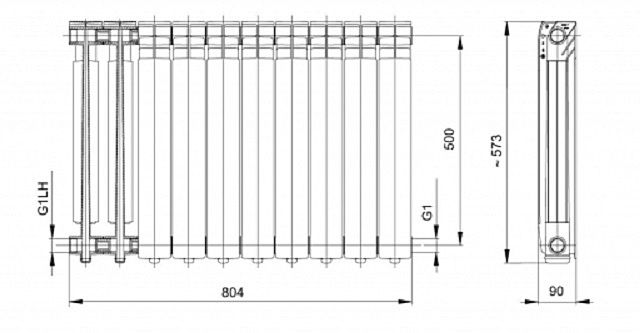

Aluminum batteries can vary in size. So, the standard for the distance between the lower and upper axis of the radiator can be 500, 350 and 200 mm. If desired, you can find or order devices with a non-standard distance of 700 millimeters or more.

The schematic drawing shows a center-to-center connection of 500 mm with a total battery height of 573 mm.

This type of battery is made from an alloy of aluminum and silicon additives that give the metal additional strength, but in two different ways - extrusion and casting.

When using casting technology for the manufacture of parts, each section of the battery is cast separately by filling a special form with the prepared alloy. This manufacturing technique guarantees tightness of each section.

- Batteries produced by casting technology are designed for heating system pressures up to 16 atmospheres. During factory tests (pressure testing), the coolant is usually supplied under a higher load, which reaches 25 atmospheres, which indicates that the manufacturer provides consumers with an additional margin of safety for their products. Cast heatsinks come in a variety of shapes, but generally have a smooth outer surface for better heat dissipation.

- The second, manufacturing method, using extrusion technology, consists in forming sections by forcing the melt through special nozzles that define the configuration of the products. As a rule, the so-called secondary aluminum, a scrap recycled product, acts as a raw material here. The quality of the metal is certainly worse, since the composition of the alloy is not so balanced, the presence of impurities is not excluded. Such aluminum turns out to be more brittle, more susceptible to oxygen corrosion.

The finished sections are assembled into a common structure, which during operation cannot be increased by building up or reduced - a finished assembled battery comes from the factory, which is a finished product. Such radiators cannot be repaired either - this should be taken into account when planning a purchase. The conditions of high pressure in the system, poor-quality coolant, the likelihood of water hammer are clearly not for such radiators. True, the price for such heat exchange devices is significantly lower than for cast ones.

- Another type of radiators is produced from aluminum, but already having a high degree of purification of raw materials and with anodic oxidation of surfaces. They are often called that - anode. In the manufacture of the original alloy, aluminum changes its structure several times - this process is performed to achieve maximum material resistance to any type of corrosion. Therefore, such batteries are not afraid of the aggressive environment of any coolant.

The anode radiator sections are manufactured using injection molding technology and then assembled using threaded couplings and reliable seals. Such products can, if necessary, be disassembled, for example, to remove a damaged section, or built up to obtain the required total thermal power.

The inner surfaces of the batteries, made of anodized aluminum, are perfectly smooth, which contributes to the unimpeded circulation of the coolant. The working pressure of such radiators is much higher than that of ordinary aluminum ones, and can reach up to 20 ÷ 25 atmospheres.

Externally, anode batteries do not differ from ordinary aluminum ones, but their cost is much higher. Therefore, when purchasing this version of radiators, it is imperative to check the product passport, which is always attached to such high-quality products.

All aluminum batteries have common "pros" and "cons", which you also need to know if you decide to choose this type for installation in an apartment.

So, the advantages of aluminum radiators include the following qualities:

- High heat dissipation.

- Low weight, greatly simplifying the stages of transportation and installation work.

- A variety of sizes from which you can choose the one you want.

- Aesthetic appearance that allows you to "introduce" such radiators into the interior of any style.

- Relative operational safety. On impact, flat and smooth aluminum surfaces are more difficult to get injured than, for example, angular cast-iron batteries - this quality is especially important if small children live in the apartment.

- Aluminum batteries are excellent "friends" with thermostatic devices - this allows you to precisely regulate the temperature regime. This quality is especially important if an autonomous heating system is created in the apartment, since the thermoregulation devices of radiators contribute to saving on energy consumption.

The negative aspects of these heating devices are the following factors:

- High risk of gassing in the internal channels of the structure (applies to conventional, non-anodized aluminum batteries, cast or extrusion).

- Possible leakage at the connection of sections without the possibility of repair - for extrusion radiators made of secondary aluminum.

- Concentration of heat in the area of the ribs of the elements of the device.

Some of the potential problems with aluminum batteries can be circumvented. So, for example, in order to prevent gases from accumulating inside the structure, it is recommended to install a special air vent for each radiator.

General conclusion: If aluminum batteries will be installed in an apartment with an autonomous heating system, then any will do, based on the financial capabilities of the owners and taking into account all the listed disadvantages. If the apartment is connected to central heating systems, it is recommended to choose exclusively radiators made of anodized aluminum - it is more resistant to an aggressive environment, and to elevated temperatures, and to pressure drops in the system.

Bimetallic radiators

Bimetallic radiators are currently the most popular of all types of modern batteries, perhaps second only to traditional cast iron batteries.

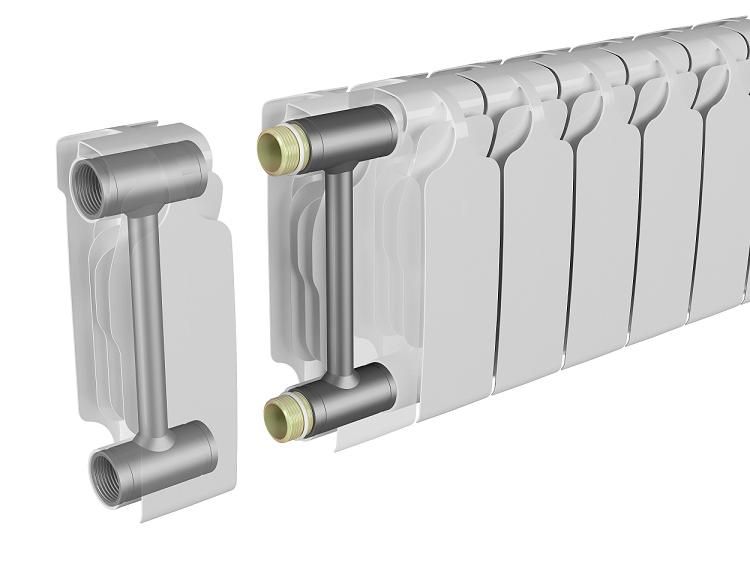

These heating devices are manufactured according to a combined principle - they are assembled from parts made of two different materials, which, in fact, is clear from the name. So, the outer part of the battery is made of aluminum, which has maximum heat transfer, and the inner channels for the circulation of the coolant are made of high-quality steel alloy that is not subject to corrosion. The aluminum outer surfaces have a protective enamel coating, which gives the radiators an aesthetic appearance.

Bimetallic batteries are assembled from sections, which are fastened together with a threaded coupling using reliable seals.

The reliability and durability of these radiators is explained by the fact that aluminum, which perfectly conducts heat, does not come into contact with the coolant and serves as a kind of decorative "casing" for internal steel elements through which antifreeze or water circulates. The internal channels, made of stainless alloys, are very resistant to baric loads, due to which the radiators are able to withstand pressure in the system up to 35 ÷ 40 atmospheres.

The similar qualities of these batteries make it possible to fully use them for central heating circuits, that is, to install them in apartments of multi-storey buildings. They are also suitable for autonomous heating systems.

By the way, bimetallic batteries fully reveal all their advantages precisely at high pressure and temperature indicators inherent in central heating circuits. For autonomous systems, however, such expensive devices may still seem overkill.

With such high performance, long and warranty periods of use, bimetallic batteries are justifiably expensive, especially in comparison with steel or aluminum versions. This circumstance can be called, perhaps, the only drawback, but on the other hand, there are many advantages of such batteries:

- Bimetallic batteries have high thermal conductivity, therefore they quickly heat up and transfer heat to the room.

- Corrosion resistance significantly extends their trouble-free service life, which can be calculated for many decades.

- The neat appearance and compact design allow the radiators to fit into any interior style.

- This type of radiator has a hardened two-layer outer coating, so a lot of dust does not collect on their surface. It is easy to care for them, as it is enough to wipe them with a damp soft cloth.

- Radiators are relatively lightweight, so their installation is quite simple, and it can be done without the involvement of specialists.

It should be noted that bimetallic radiators in appearance are practically indistinguishable from aluminum, with a very noticeable difference in price. Therefore, you need to purchase them only in specialized stores, having carefully read the technical documentation and manufacturer's warranties.

Output: Bimetallic batteries can be safely called universal. They are fully suitable for installation in an apartment with a central heating system. Nothing prevents you from acquiring them for an autonomous system, but their specific advantages in such conditions may be unclaimed. It may be wiser to purchase more affordable high quality aluminum radiators.

Calculation of the number of sections or the total power of the radiators

Calculation using basic formulas

As mentioned above, the calculation of the number of radiators for a separate room can be done in two ways - by area or by the volume of the room.

- Area calculation

The calculation, therefore, is made according to the formula:

N = S × 100 / Pс,

where the symbols have the following meanings:

N- the number of radiator sections;

S- the area of the room in m²;

Pc- thermal power of one section of the radiator - this value can be found in the product passport.

- Volume calculation

A more accurate calculation can be carried out by calculating the volume of the heated room, since in this case the height of the room's ceilings is also taken into account. Calculation by volume assumes 41 W of heating system power per 1 m³ for a panel house, or 34 W for a brick one. The formula looks like this:

N = S ×h × 41 (34) / Pc

The designations in the formula are the same, with the only addition that h Is the height of the ceiling.

Of course, if you plan to purchase a non-separable radiator, which is a one-piece structure, then divide by the specific power of the section Pc - not necessary, that is, this part is simply excluded from the formula. The resulting value will show what total radiator power is needed for a given room.

However, these formulas will be valid only for standard average conditions. Therefore, when calculating a radiator by the area or volume of the room, it is important to take into account the correction factors, which are determined by the minimum winter temperature in the region of residence, the features of the location of the room, the quality of wall insulation, the number and type of windows, the presence of a door to the street or to the balcony. Moreover, even the location of the batteries and the diagram of their insertion into the heating circuit can be of considerable importance for calculating the thermal power.

There is probably no point in listing all the correction factors and presenting a rather cumbersome calculation formula in this article. It is better to invite the reader to use a convenient calculator, which already contains the main dependencies.

Calculator for calculating the required thermal power of heating radiators

For the calculation, it will be enough to indicate the requested data. The calculator will allow you to determine the number of sections of the selected type of radiator. If the calculation is made only to determine the total thermal power required for high-quality heating of the room (for example, to select non-separable models of steel or aluminum batteries), then the field with the requested specific rated power of one section is left blank.