Homemade heating batteries

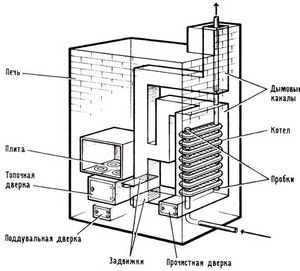

On this page, we will try to select the necessary assembly units for the desired apartment. The heating system of the mansion has some parts. The heating system includes, automatic deaerators, heating boiler, fastening system, circulation pumps, fittings, expansion tank, wires or pipes, radiators, thermostats, heat control mechanism. Each node has an important role to play. Therefore, the choice of parts of the structure is important to carry out correctly.

Homemade heating batteries

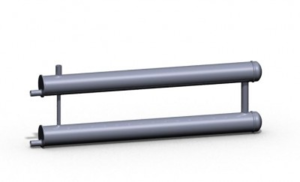

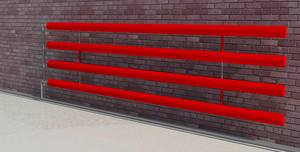

A heater consisting of smooth-walled pipes connected by welding to each other is called a register. Basically, pipes located horizontally are connected by vertical short bridges, through which the coolant also flows. The design of the registers underlies the creation of different types of heating radiators.

A heater consisting of smooth-walled pipes connected by welding to each other is called a register. Basically, pipes located horizontally are connected by vertical short bridges, through which the coolant also flows. The design of the registers underlies the creation of different types of heating radiators.

Heating registers are divided into three types:

- aluminum;

- cast iron;

- steel.

Aluminum registers are in great demand due to their low specific weight, good heat transfer, excellent corrosion resistance, long service life, lack of joints and welds.

Aluminum registers are in great demand due to their low specific weight, good heat transfer, excellent corrosion resistance, long service life, lack of joints and welds.

Aluminum pipes produced by monolithic casting. Aluminum registers are used in residential and administrative premises. The main disadvantage of aluminum devices is high price.

Cast iron registers differ ease of installation, because they have a flanged monolithic connection. During installation, a second flange is welded to the heating pipe, and then using bolts, a strong connection is made.

Steel registers are installed in the heating system by welding. Well-performed welding is guarantor of long-term service the entire heating system.

Stationary and mobile registers

To heat the coolant in stationary registers, heating boilers are needed. For heating the coolant in mobile registers, an electric heating element is used, operating from a network with a voltage of 220 V. This type of registers is used for workers' houses of builders, premises where finishing work is carried out.

Installation of registers in a room has a number of undeniable advantages before installing batteries in the heating system:

- long lifetime... pipes made of steel do not need repairs, at least 25 years;

- the heating system is distinguished by a high degree of reliability, the main requirement for ensuring such reliability is the high-quality performance of welds;

- an open heating system can be installed in rooms of a large area, the low resistance to the movement of the coolant provides a large diameter of the pipes used for the register.

Recently, registers have been installed much less frequently, choosing more alternative modern heating devices. TO disadvantages this type of device includes:

- not the most attractive appearance register, a thick steel pipe is laid along the wall throughout the room;

- small area of contact with air in the room leads to low heat transfer rate... zero use of convection;

- the supply of the heating system with registers is different high cost and the complexity of installation, steel pipes of large diameter in the construction market are quite expensive, the need to use welding during installation.

Let's look at the entire heating system as a whole. The role of the register can be played by supply pipes, a heated towel rail. When choosing a register model, you need to pay special attention to pipe diameter, of which it consists. Preference should be given to devices with a pipe diameter equal to 32 mm. For self-production of the register, it is not recommended to use pipes with a diameter exceeding 80 mm. To warm up the coolant in such large volumes, a too powerful boiler is needed, which is not always cost-effective.

Let's look at the entire heating system as a whole. The role of the register can be played by supply pipes, a heated towel rail. When choosing a register model, you need to pay special attention to pipe diameter, of which it consists. Preference should be given to devices with a pipe diameter equal to 32 mm. For self-production of the register, it is not recommended to use pipes with a diameter exceeding 80 mm. To warm up the coolant in such large volumes, a too powerful boiler is needed, which is not always cost-effective.

When installing an autonomous heating system in the house using registers, you need to do accurate calculation the number of devices and the preferred diameter of the pipes used. When calculating the required number of heating devices, take into account first of all wall thickness buildings, the number of window and door openings, the type of building material used to erect the building and many other factors.

When calculating pipe devices, only the heat transfer rate of a running meter of a pipe should be taken into account. For a room with a ceiling height not exceeding 3 m and an area of 20 sq. meters will be needed 20 m of steel pipe with a diameter of 60 mm. The calculation itself is simple, and the installation of a heating system with registers is no more difficult than installing radiators.

Establish registers when routing pipes to the bottom. This applies to both one-story and two-story buildings.

A heating system with registers in itself is not particularly difficult. The main requirement is to conduct welding works on the highest level. The complexity of the installation of the system can be minimized if all elements are pre-fabricated separately and correctly designed system diagram. Separately, you can assemble the pipeline and weld the register itself.

The finished components of the heating system can be interconnected using threaded connections. Basically, registers are installed, consisting of two horizontal pipes. If you plan to install a register under one wall (5 m) of a room with an area of 20 sq. meters, the size of the device, consisting of two pipes with a diameter of 60 mm, will be equal to the length of the wall.

Important! The installation of the register is carried out with a slope of at least 0,05% on the movement of the coolant.

In pipes with a large diameter, the coolant flows practically without resistance, and the register itself is installed as close as possible to the floor surface, which allows much improve room heating.

If you are a professional welder, it will not be difficult for you to make a register yourself. The design is simple, but well done welding... allows you to get a reliable device for heating the room.

If you are a professional welder, it will not be difficult for you to make a register yourself. The design is simple, but well done welding... allows you to get a reliable device for heating the room.

Installing a heating element in the manufactured structure and filling the pipes antifreeze or oil you will receive a homemade oil cooler. To heat the room, it is enough to plug the device into a power outlet. In this case, you do not need to do piping, buy and install a heating boiler, control devices, shut-off valves. You just need to assemble the register correctly to get the necessary for the premises heat transfer.

Why is it worth assembling the register yourself? First, factory registers have great price level. Secondly, the register construction is one of the simplest. If we compare the price of steel pipes consumed in register welding and the final price figure of the equipment itself, we see a threefold increase in cost.

For craftsmen to handle welding, making a register with their own hands will not present much difficulty. First selected the shape of the future equipment. Basically, these are pipes connected in parallel, but you can also make a register in the form of a coil.

Step-by-step instruction:

A heating system with registers will work much more efficiently if a circulation electric pump is installed near the boiler. In this case, the room will warm up much faster.

The video below demonstrates the process of making a heating register:

Source: http://teplo.guru/radiatory/stalnye/registr-otopleniya.html

Homemade heating batteries

Related articles:

Heating household devices manufactured at branded enterprises are effective and safe in everyday use, have a modern or retro design, but their purchase is not always justified in everyday life.

For example, for heating industrial and utility rooms, a home-made heating battery would be a better option, which, of course, is aesthetically inferior to expensive radiators painted with powder enamel, but warms no worse. According to the principle of functioning, "self-made" radiators do not differ from factory radiators, but it is not recommended to install them as a permanent source of heating for living quarters.

The heating register is a heating device consisting of a single pipe or several steel pipes connected into a single structure for the circulation of the heat carrier.

Practice and calculations have shown the feasibility of using smooth-walled steel pipes with diameters from 32 mm to 219 mm in order to provide the required area of the register heat exchange surface. At the same time, for the purpose of a compact layout in a heated room, the registers are made sectional or in the form of a coil. The use of steel pipes is motivated by the simplicity of their assembly using welding and ensuring the tightness of the welded seams. For the manufacture of heating registers, it is not at all necessary to look for new pipes of scarce assortments. You can use the scraps of pipes left after construction and installation work at the enterprise, or find something suitable in the warehouses of Vtorchermet.

The use of smooth-walled pipes predetermined two types of self-made registers for space heating:

- sectional, consisting of pipes muffled at the ends, connected by steel pipes of a smaller diameter;

- serpentine, that is, S-shaped.

When connecting pipes to the register structure, it is recommended to adhere to the distance between the outer surfaces 5 cm larger than the diameter from which the register is welded. This reduces mutual radiation and increases heat transfer.

The design of the sectional register represents one or several pipes horizontally located, in which the movement of the coolant begins from the upper pipe along its entire length, then flows through the connecting pipe at the other end to the next one.

The nozzles at the inlet and outlet are made threaded, but most often they are welded. They try to weld transition pipes as close to the edge as possible. Additional bridges provide structural rigidity. The most demanded for sectional registers are steel pipes with diameters from 76 to 159 mm. Welded seams must remain tight at a pressure of at least 13 atm.

It is important! By piling up the register pipes horizontally one above the other, it is impossible to achieve a linear increase in the thermal power of a home-made battery. The air flow that rises already heated by the lower pipes is less able to receive heat from the hot coolant, that is, the coolant will give up less heat.

Unlike rectilinear registers, in which large-diameter pipes are connected by smaller branch pipes, the coil can be represented as a solid pipe, in which the connecting arcs have the same diameter as the horizontal ones. The S-shape is more efficient because the entire pipe surface is involved in heat exchange.

Unlike rectilinear registers, in which large-diameter pipes are connected by smaller branch pipes, the coil can be represented as a solid pipe, in which the connecting arcs have the same diameter as the horizontal ones. The S-shape is more efficient because the entire pipe surface is involved in heat exchange.

Due to the absence of intermediate pipe constrictions and sections with a change in the direction of the coolant, there is a low hydraulic resistance in the coil.

In the case of making a heating battery with your own hands, you should not recklessly rush to any cheap pipe. Unambiguously, profile pipes, which will necessarily flow along the technological welded seam, will not work. Pipes for registers must be well welded, therefore St45 steel is not desirable.

In the case of making a heating battery with your own hands, you should not recklessly rush to any cheap pipe. Unambiguously, profile pipes, which will necessarily flow along the technological welded seam, will not work. Pipes for registers must be well welded, therefore St45 steel is not desirable.

Homemade radiators made of stainless steel, which are functionally heated towel rails in bathrooms, are very popular in everyday life. Craftsmen do an excellent job of polishing stainless steel, bending it on primitive pipe benders and creating openwork coil structures. The sluggishness of the factory services does not allow keeping up with savvy folk craftsmen, therefore the lion's share of household stainless steel batteries is handicraft.