Anaerobic gels for sealing threaded connections. Anaerobic gel sealants - a new word in plumbing and gas services

Connecting pipes to each other requires sealing. For this purpose, various types of sealants are used. Such compositions are widely used in production and in everyday life, due to their ease of use and quick drying. One of them is the SantekhMaster gel, which is suitable for sealing metal threaded and flange connections.

Description

Gel "SantechMaster" belongs to the category anaerobic compactors. The process takes place in the absence of oxygen. Chemical reaction begins when the thread is closed). At the same time, the gel does not expand or shrink. There is also no generation or absorption of heat. The polymer has good adhesion to metal. Due to this, the connection can withstand vibrations, temperature changes and pressure of 40 atmospheres. The product is non-allergenic and non-toxic. It does not have a pungent odor. Therefore, apply the gel in hard to reach places maybe with your finger. The composition includes a solvent - the time of contact with the skin should not be long.

Gels are used for room temperature. After drying, the assembled connection can work in quite difficult climatic conditions. The temperature range in this case is from minus 60 to plus 150 degrees. The speed of sealing depends on the rate of polymerization of surfaces. Some metals are more active in this reaction than others. This affects the strength of the connection.

Application area

SantekhMaster gel is suitable for sealing metal threaded or flange connections in areas such as:

- Water: drinking, cold and hot.

- Gas: natural, liquefied.

- The air is compressed.

- Antifreeze for heating.

Per connection water pipes with drinking water there is a special conclusion from sanitary services. Flange fasteners have advantages over threaded ones. They require less time to seal and require less force to close the surfaces. In this case, there is no need to crimp the connection evenly. Thanks to this, the gel can be used even on skewed flanges. At the same time, you cannot use the product in an environment of strong oxidizing agents (pure oxygen, chlorine, etc.).

Types of gels

There are three main types of seals, which differ in sealing time, size of connected pipes, and conditions of use. The funds have different colour: green, blue, red. Let's talk about each of them in more detail.

The green gel is used to connect pipes with a diameter of up to 40 mm (1.5 inches), due to its more liquid consistency. Suitable for those areas where the connection must have less force to loosen, for example, in hard-to-reach places. Hardening time is 20-30 minutes.

"SantechMaster" (blue gel) is used for pipes with threads up to 50 mm (2 inches). This is the most best option, which is used most often. It has average performance in terms of dismantling force and sealing speed (15-20 minutes).

In cases where it is necessary to speed up the process of starting the system as much as possible, use another product included in the line called “SantechMaster” - red gel. Its sealing time is only 5 minutes at room temperature. This composition is also suitable for working in low temperature conditions (from plus 5 degrees). In some cases it is necessary to preheat the connection. Suitable for pipes with threads up to 3 inches. Choose suitable remedy The information on the packaging will help.

Usage

Before use, SantekhMaster gel must be mixed. To do this, just shake the tube. It is convenient to apply the product to clean threads straight from the packaging. The gel is squeezed out of it in a uniform thick layer. Don't be afraid that it will start to spread or drip. The dense consistency of the composition protects against such problems.

Next, assemble the connection, twisting slightly so that the gel lies evenly. It is not necessary to tighten with a wrench. The gel will harden even in cases where only a couple of turns are twisted. At the same time, tightening it tightly will speed up the sealing process. Partial tightening is useful in cases where the connection must be in a certain position.

Sealing is considered completed correctly if the excess gel appears evenly. If there are none or they are distributed unevenly, the connection must be unscrewed and the application of the product repeated. Excess is removed with a brush. They can be used for the next connection.

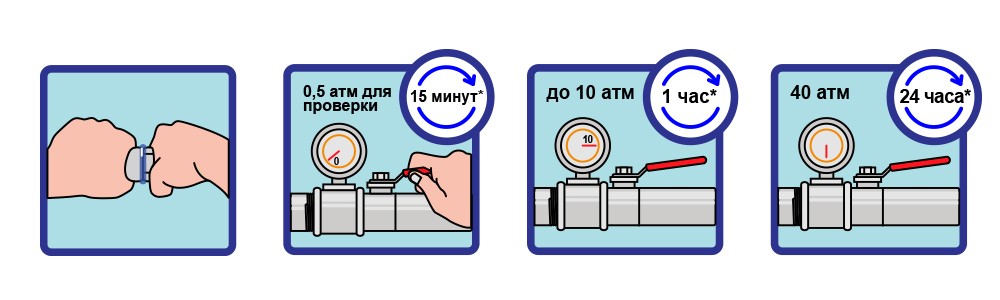

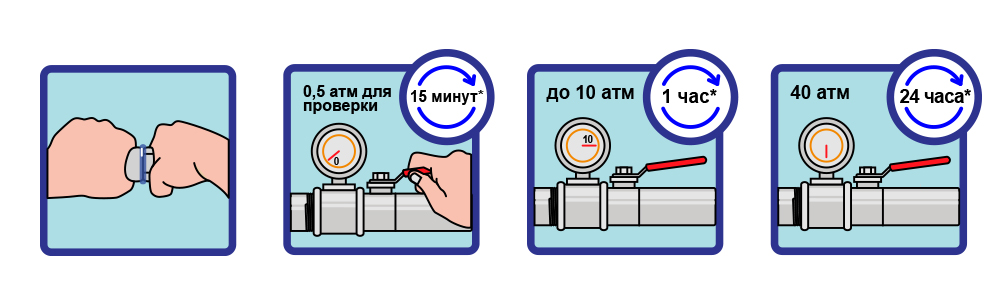

After a quarter of an hour, the sealing is checked by test pressure (within 0.5 atmospheres). If there is a leak, the pipe connection is immediately sorted out until the gel has completely hardened. If all is well, after 40 minutes they test it with a normal operating pressure of 10 atmospheres. After a day, pressure up to 40 atm is allowed.

Used in water supply, gas supply and heating networks. Have certificates for drinking water, natural and liquefied gas. Resistant to antifreeze, alcohol, gasoline, freon. Connections assembled using these seals operate under extreme conditions - they withstand vibrations, high temperatures and pressure up to 50 atmospheres.

The latest generation of gel-sealants came from the military industry and rocket science, and today they are actively used in household and industrial plumbing. The wide distribution of these compositions is due to the convenience of their use in everyday life and at work, as well as the unsurpassed speed of work.

The “smart” sealant composition polymerizes only inside the thread, where there is no oxygen. As a result, a solid polymer is formed that quickly seals the parts of the fitting and protects it from leaks.

Using modern gel-sealant “SantechMasterGel” or “StopMasterGel”, you are moving far forward in your practice. Atconventional sealingWith a strand of flax, corrosion appears on the threads and soon the connection leaks and may break. Linen is an organic fiber that absorbs moisture and can swell and rot. Anaerobic gels reliably seal threads, do not shrink or expand during hardening and use, have high adhesion to the thread surface and protect it from corrosion.

HOW ARE ANAEROBIC GELS USED?

Gel sealants are convenient to apply directly from a tube with a flat neck. You do not have to use additional devices to apply and distribute the gel. A fiberglass brush is also supplied with the gel; with its help, the gel squeezed out of the threaded joint is transferred to the next fitting. First, the brush must be burned and “fluffed” on a hard surface. This can be done again if the gel hardens on the fiber over time.

SO, YOUR ACTIONS:

1. Shake the tube of gel to mix the composition.

2. Then use the neck of the tube to evenly apply the gel to the threads in a thick layer. Due to its fairly dense consistency, the gel will not spread, will not drip from the thread and will not cause problems during application.

3. Assemble the joint by gently twisting both parts so that the gel is evenly distributed. Assembly is carried out manually - tightening with a wrench is not necessary. Tightening speeds up the sealing process, but the gel will polymerize even if you twist it just a few turns. This property is convenient for maintaining a certain position of a tap, meter or pressure gauge.

4. You will notice excess that protrudes from the threaded joint as it is tightened. Evenly squeezed out excess indicates that the gel was applied correctly and its quantity is sufficient for a reliable and durable connection. Conversely, if there is no excess or it is squeezed out unevenly, unwind the connection, add gel and assemble again.

5. Remove excess with a brush and transfer it to the next thread.

6. After a few minutes, the so-called manual fixation will occur. This means that you will not be able to unscrew the connection by hand. After 15 minutes after manual fixing, check the connection for leaks with a small test pressure. If it appears, recheck the connection until the composition hardens. If there is no leak, then after another 40 minutes the nominal operating pressure of up to 10 atmospheres can be supplied. After 24 hours, pressure up to 40 atmospheres can be supplied.

Gel polymerization time depends on joint diameter, material and temperature environment. In 80% of cases, the waiting time is much less than recommended according to the instructions.

Just 6 steps and a sealed connection for a wide variety of household systems ready.

Make sure the threads are clean before applying the gel. The sealant gel contains solvents that degrease threads and remove light dirt. But for best result You should wipe the thread with a rag or rag. If there is rust and to remove it, wipe it down wire brush. If there is heavy oil contamination, degrease.

WHAT IS IMPORTANT TO KNOW ABOUT GEL SEALANTS?

There are three types of them: SantekhMasterGel Blue, SantekhMasterGel Green and StopMasterGel Red Ultrafast.

Available in volumes of 15 and 60 grams. They differ in the polymerization time, the diameter of the pipes for which they are intended, the temperature for installation and the force when dismantling the connection.

The composition of the gel is non-toxic and non-allergenic. It does not have a pungent odor that irritates the receptors or mucous membranes. The gel can be applied by hand in the most difficult to reach places. However, due to solvents, prolonged contact with skin is not advisable.

- The operating temperature of connections assembled using gel sealants is from -60 to +150 °C.

- We guarantee that the sealant in a gel-like state retains its properties for at least 3 years from the date of production when used proper storage: in a closed tube, away from sources sunlight and warmth. The performance of the composition is maintained beyond the warranty period as long as the gel has a liquid consistency.

The consumption of the gel, taking into account the “waste-free” nature, that is, the use of surplus, is very economical. In case of economical application, a 15 gram tube is enough for 30 fittings, and a 60 gram tube is enough for 100 fittings (1/2, 3/4 inch in diameter).

Do you want to achieve professional results?

Do you value your reputation?

Are you used to working only perfectly?

Choose anaerobic gel sealants SantekhMasterGel and StopMasterGel!

AREAS OF USE:

- natural gas

- liquefied gas

- cold and hot water

- drinking water

- compressed air

* Attention! SanTechMasterGel is not used for sealing plastic threads!

Anaerobic gel-sealants “SantehMasterGel” and “StopMasterGel” own production Region Spetstechno companies are innovative polymer materials for sealing threaded and flanged metal connections.

Used in water supply, gas supply and heating networks. They have certificates for drinking water, natural and liquefied gas. Resistant to antifreeze, alcohol, gasoline, freon. Connections assembled using these seals operate under extreme conditions - they can withstand vibrations, high temperatures and pressures of up to 50 atmospheres.

What is anaerobic gel?

Anaerobic sealant gels, or, as they are often called, the latest generation of anaerobic sealant adhesives for sealing threaded connections came from the military industry and rocket science, and today are actively used in household and industrial plumbing. These sealants are also suitable for gas pipes, which confirms their sealing of threaded connections of many gas pipelines. The wide distribution of these compositions is due to the convenience of their use in everyday life and at work, as well as the unsurpassed speed of work.

The “smart” sealant composition polymerizes only inside the thread, where there is no oxygen. The result is a solid polymer that quickly seals the parts of the fitting and protects it from leaks - which is especially important for sealing gas connections.

Using the modern gel-sealant “SantehMasterGel” or, you are moving far forward in your practice. With conventional sealing with flax strands, corrosion appears on the threads and soon the connection leaks and may collapse, which is unacceptable for gas connections, as well as in water supply and heating systems. - organic fiber, absorbs moisture, can swell and rot. Anaerobic gels reliably seal threads, do not shrink or expand during hardening and use, have high adhesion to the thread surface and protect it from corrosion. Therefore, it is better to use gels for sealing gas connections and water supply and heating systems. Anaerobic adhesive sealants are perfect, for example, for heating radiators and other plumbing fixtures in the house, as well as for gas equipment.

How are anaerobic gels used?

Thread adhesive is convenient to apply directly from a tube with a flat neck. You do not have to use additional devices to apply and distribute the gel. A fiberglass brush is also supplied with the gel; with its help, the gel squeezed out of the threaded joint is transferred to the next fitting. This is very convenient, especially if you use glue for several plumbing threaded connections. First, the brush must be burned and “fluffed” on a hard surface. This can be done again if the gel hardens on the fiber over time.

So, your actions:

1. Shake the tube of gel to mix the composition.

2. Then use the neck of the tube to evenly apply adhesive-sealant onto the plumbing or other threads in a thick layer. Due to its fairly dense consistency, the gel will not spread, will not drip from the thread and will not cause problems during application, which will allow you to easily seal gas connections and water supply and heating systems.

3. Assemble the joint by gently twisting both parts so that the gel is evenly distributed. Assembly is carried out manually - tightening with a wrench is not necessary. Tightening speeds up the sealing process, but the gel will polymerize even if you twist it just a few turns. This property is convenient for maintaining a certain position of a tap, meter or pressure gauge.

4. You will notice excess that protrudes from the threaded joint as it is tightened. Evenly squeezed out excess indicates that the gel was applied correctly and its quantity is sufficient for a reliable and durable connection. Conversely, if there is no excess or it is squeezed out unevenly, unwind the connection, add gel and assemble again.

5. Remove excess with a brush and transfer it to the next thread.

6. After a few minutes, the so-called manual fixation will occur. This means that you will not be able to unscrew the connection by hand. After 15 minutes after manual fixing, check the connection for leaks with a small test pressure. If it appears, recheck the connection until the composition hardens. If there is no leak, then after another 40 minutes the nominal operating pressure of up to 10 atmospheres can be supplied. After 24 hours, pressure up to 40 atmospheres can be supplied.

The gel polymerization time depends on the connection diameter, material and ambient temperature. In 80% of cases, the waiting time is much less than recommended according to the instructions.

Just 6 steps and a sealed connection for a wide variety of household systems is ready.

Make sure the threads are clean before applying the gel. The sealant gel contains solvents that degrease threads and remove light dirt. But for better results, wipe the threads with a rag or rag. If there is rust and to remove it, wipe it with a wire brush. If there is heavy oil contamination, degrease.

Application with gas

As mentioned earlier, anaerobic gel sealants came to us from the space industry and began to be widely used in both the domestic and industrial spheres. Along with plumbing, anaerobic sealants are widely used to seal gas pipe connections. Often gas pipe connections require a seal on the threads to avoid gas leaks, which in turn can lead to unpleasant consequences. Various masters out of habit, they use proven gas sealants for a long time, but few people know about the unreliability of some of them. Sealants for gas pipes must be selected with extreme care; not only the reliability of the system depends on the reliability of the gas connection, but also human lives. Therefore, maximum attention should be paid to sealing gas pipe connections.

Flax or fum tape are not suitable for gas. Especially fum tape, which absolutely cannot be used as a sealant for gas connections due to the impossibility of predicting its reliability. One of the most popular modern sealants for gas pipes are anaerobic gel sealants, which reliably seal gas connections and minimize the risk of leaks.

Plumbermaster Gels are often used in this area. Strict adherence to instructions and precautions allows you to reliably seal gas connections without fear of consequences.

Sealing gas pipe connections involves sealing the gas connection to for a long time. Plumbermaster Gels in this case are a good alternative to expensive analogues - European sealants. Our gels are not subject to decomposition, are resistant to vibrations, and have all the necessary permits for use with gas, including.

What is important to know about gel sealants?

– There are three types of them: SantekhMasterGel Blue, and StopMasterGel Red Ultrafast.

– Available in volumes of 15 and 60 grams. They differ in the polymerization time, the diameter of the pipes for which they are intended, the temperature for installation and the force when dismantling the connection.

– The composition of the gel is non-toxic and non-allergenic. It does not have a pungent odor that irritates the receptors or mucous membranes. The adhesive sealant can be applied by hand in the most difficult to reach places for both plumbing and other threads. However, due to solvents, prolonged contact with skin is not advisable.

– The operating temperature of connections assembled using gel sealants is from -60 to +150 °C.

– We guarantee that the sealant in a gel state retains its properties for at least 3 years from the date of production if it is stored correctly: in a closed tube, away from sources of sunlight and heat. The performance of the composition is maintained beyond the warranty period as long as the gel has a liquid consistency.

The consumption of the gel, taking into account the “waste-free” nature, that is, the use of surplus, is very economical. In case of economical application, a 15 gram tube will be enough for 30 fittings, and a 60 gram tube will be enough for 100 fittings (1/2, 3/4 inch in diameter).

Do you want to achieve professional results?

Do you value your reputation?

Are you used to working only perfectly?

Choose SantekhMasterGel and StopMasterGel, which you can right now!

Anaerobic sealant for threaded and flanged metal connections. Forms a high strength seal that is resistant to different environments: water, antifreeze, natural and liquefied gas, alcohol, gasoline, etc. Withstands pressure of 40 bar or more, temperature changes, mechanical stress, and shaking. Dismantling with standard tools.

| Name | Max. diameter connections |

price, rub. | |

| Anaerobic sealant "SantechMasterGel", green, tube | 1,5" | 435 | |

| Anaerobic sealant "SantechMasterGel", blue, tube | 2" | 435 |

Anaerobic sealants polymerize in the thread gap at room temperature in the absence of atmospheric oxygen. Contact with metal threads is critical. SantekhMasterGels can also be applied to slightly oily surfaces. They have adhesion to metal and form a high-strength seal that can withstand significant pressures, temperature changes, mechanical stress, and is resistant to various types media (water, natural gas, acetone, alcohol, freon, gasoline, motor oil, antifreeze, brake and transmission fluid).

Characteristics

- Maximum connection diameter: 1.5", 2";

- Can be sealed: 60 1" connections;

- Minimum installation temperature: 0°C.

Advantages

Anaerobic gel sealants are 2nd generation polymers that do not have the disadvantages inherent in 1st generation polymers (fum tape, for example). Their use makes it possible to obtain a vibration- and shock-resistant connection that can withstand high pressure environment, temperature changes.

The service life of such a connection is very high, since the resulting plastic is able to retain its properties in the threaded gap for decades. The key to tightness is not only and not so much the thread relief, which prevents the resulting plastic from being squeezed out, but the adhesion to the metal that this polymer has. The thread metal itself remains reliably protected from corrosion throughout its entire service life. Moreover, the connection itself can always be disassembled with a standard wrench for a diameter of up to 1-1.5 inches.

- Extremely easy to use, requiring no skills;

- Easy to assemble due to the lubricating properties of the composition;

- Thread sealing occurs regardless of the twisting force;

- The seal maintains tightness at high pressures up to the point of pipe rupture (withstands 50 atmospheres or more).

- The best economic efficiency of the price-reliability combination;

- Does not harden on exposed surfaces. Excess product can be easily removed from external surfaces with a rag, followed by internal rinsing. Thanks to this, there is no risk of clogging narrow passages and filters;

- Chemical resistance to oils, antifreeze, alcohols, freons, gasoline and other technical media;

- They do not swell (there is no risk of fittings breaking) and do not shrink (there is no need to tighten the assembly). Equally easy to seal both small and large (up to 4 inches inclusive) diameters;

- Anaerobic sealants reliably seal flange connections without the use of additional gaskets (metal-to-metal);

- Anaerobic sealants most reliably protect threaded connections from corrosion.