Heat-insulated floor water from gas double-circuit boiler. We supply a water heated floor from a gas boiler - an economical system

In the article we are going to discuss the sources of heat for low-temperature heating. Is the electric boiler suitable for underfloor heating? Is it difficult to connect a solid fuel boiler to a laid pipe?

We will try to find answers to these and some other questions.

Heated floor - it is convenient and practical. However, he, like any heating system, needs a source of heat.

What's the difference

First, let's define what is fundamentally different from radiator heating in terms of the choice of heat source.

The answer does not have long to search. Touch the radiator in winter. Excuse me, what did you say? And, it was heard ... And now imagine that the same temperature has a floor.

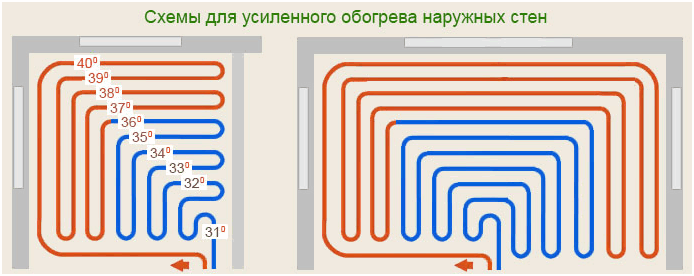

So, we formulate the temperature of the coolant should be limited to about 40 degrees.

Exceeding this value will make staying in the room extremely uncomfortable.

And now let's see how good in these conditions of operation are boilers using different sources of thermal energy.

Of course, we estimate not only the ability to maintain the desired temperature, but also a number of equally important parameters:

- Efficiency. It is clear that the cost of kilowatt-hours of heat should be reasonable.

- Convenience of operation. It is desirable that the boiler does not require constant attention of the owner.

- The complexity of installation and requirements for strapping.

Electricity

Efficiency

From this point of view electric boilers for floor heating - the worst possible solution. To produce a kilowatt-hour of heat, they need exactly one kilowatt-hour of electricity. And its price in most parts of the country is approaching 4 rubles.

Perform a simple calculation. Suppose that the average daily heat demand of a house is 10 kilowatts. In this case, the costs per day at a rate of 3.5 p / kWh will be 10x24x3.5 = 840 rubles. For heating - a lot too much, is not it?

To clarify: electric boiler for underfloor heating can be much cheaper if you have a double tariff counter installed.

Thermal inertia allows you to use the full power of the boiler only at night, when electricity is cheaper.

Convenience of operation

But from this point of view, the electric boiler completely rehabilitates itself: it does not require maintenance at all. It is enough to set the desired temperature of the coolant or, in the presence of a remote thermal sensor, air - and the device will continue to work in a completely autonomous mode. Programmable boilers are able to regulate the temperature within the daily or weekly schedule.

Installation

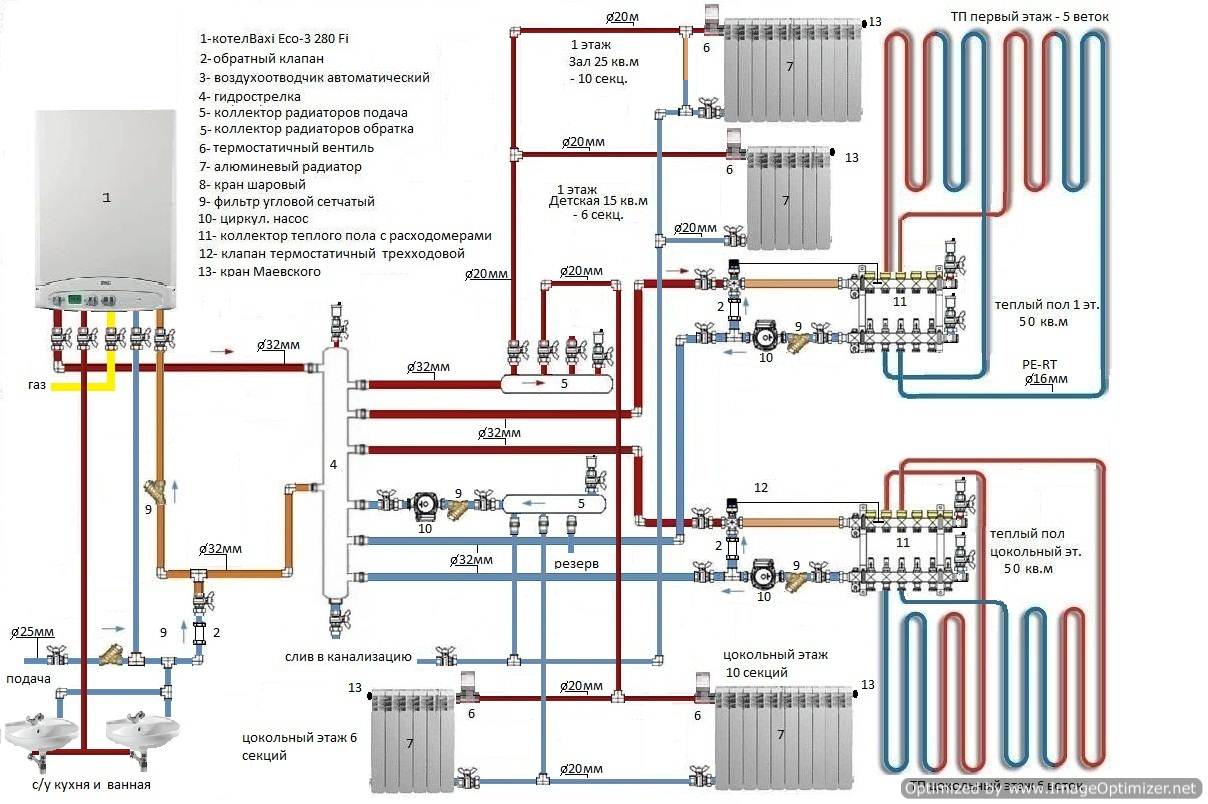

Heated floor and electric boiler mate without any problems. At all. The working temperature of the heat carrier in most models starts at 25 degrees, so no expensive strapping is required. All that is needed is a collector, even if several circuits are connected to the same boiler.

A nice bonus is the absence of the need to remove combustion products. Thanks to this feature, an electric heater can be mounted anywhere in the house, without being tied to ventilation ducts or external walls.

Gas

Efficiency

Warm floor from gas boiler This is, in contrast to electricity, the most economical heating option. The rational distribution of heat characteristic of low-temperature heating systems is superimposed on the minimum cost per kilowatt-hour of heat produced by burning natural gas.

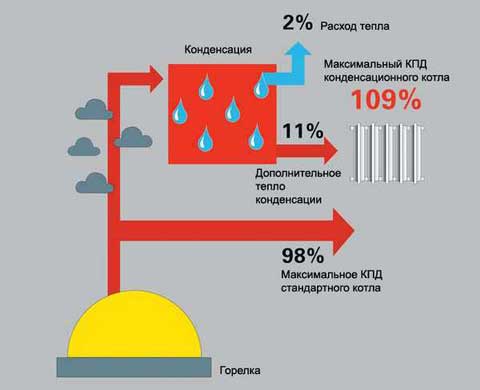

Useful: The efficiency of gas boilers varies from 60% for the oldest models produced in 70-80 years, to ... 110% for modern condensing boilers.

Of course, the efficiency above 100% is nothing more than a marketing trick: 100% takes the so-called lower calorific value, that is, the amount of energy released directly during the combustion of gas.

Additional energy is produced by condensation of combustion products.

Convenience of operation

Convenience and autonomy gas boilers for the warm floor is almost the same electric. Devices with electronic ignition are able to control the temperature on the thermostat, ignite and extinguish the burner, depending on the need for heat and forcibly remove the combustion products.

Piezo ignition boilers, however, can only automatically support set temperature coolant and turn off the gas supply when the pilot burner flame is lost. It is necessary to rekindle the flame manually. However, the limited functionality of this class of devices is compensated by their complete non-volatility.

In the photo - gas boiler with piezo ignition.

Installation

Condensation gas boilers for underfloor heating are almost ideal: their work requires a return temperature not higher than 40 degrees.

How to dispose of excess heat supply?

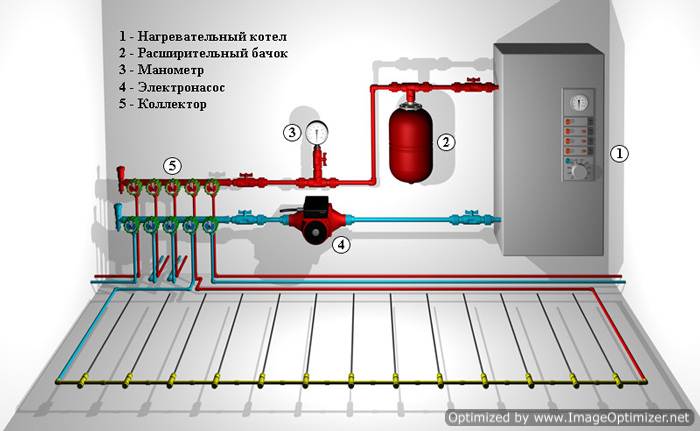

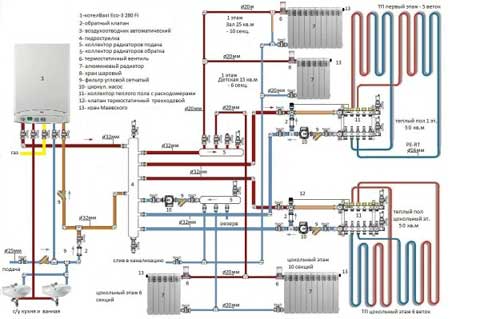

- A very popular solution is the use of a heated floor as a return pipe for a contour of classic convection heating with conventional aluminum radiators.

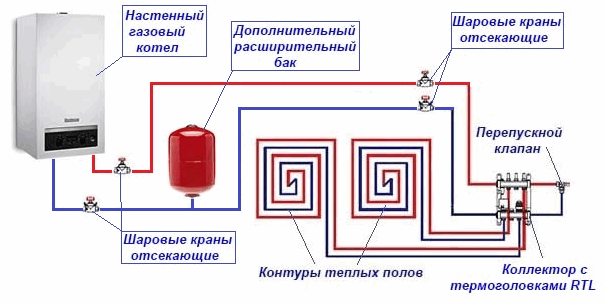

- In addition, the underfloor collector can be equipped with a mixing unit. Outwardly, it strongly resembles an elevator unit and uses the same work pattern - it mixes a part of the water from the return pipeline to the supply.

The traditional gas boiler, however, requires a sufficiently high supply temperature - at least 60 degrees. The limitation is due to the fact that at a lower return temperature, the combustion products will start to condense on the heat exchanger, which is undesirable.

They are quite aggressive, and the material of the heat exchanger, in contrast to the condensing boiler, is far less resistant to corrosion. Is it possible to solve this problem when installing heating with your own hands?

The instruction is quite simple, but will require additional costs.

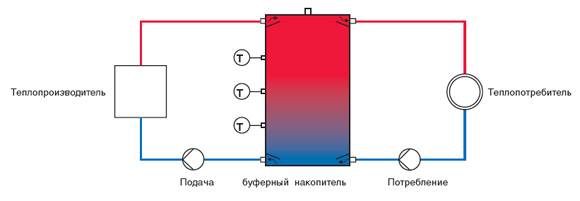

- A hydraulic needle is installed between the feed and return pipes. In its simplest form, it is a vertical tank with several taps at different levels.

- Since the water in the tank at a low circulation rate will inevitably become stratified by temperature, it is easy to select the flow for the heated floor from its lower, cooler part. The hotter water from the pipes located above will go to the boiler.

- Having established the simplest temperature control circuit that controls circulation pump in the contour of a warm floor, it is easy to get an arbitrary coolant temperature, almost not tied to the return flow in the boiler.

Solid fuel

Efficiency

From this point of view, the warm floor from the solid fuel boiler is inferior only to the trunk gas. Alas - in the 21st century it is still advantageous to drown with coal or firewood. Electricity, diesel and liquefied gas are much more expensive.

Convenience of operation

We put a fat minus.

List of problems solid fuel heating quite extensive:

- The frequency of kindling and, respectively, fuel loading - at least once a day.

- Ash must be removed manually.

- Fuel must be stored close to the boiler, and it must be protected from precipitation.

- The chimney needs periodic cleaning: the products of combustion will settle on its walls.

- Finally, in most designs, when thermal power is limited, the efficiency drops dramatically.

Horror, horror, horror. But sometimes you have to put up with it - the main gas is not everywhere.

Installation

It is clear that in this case the heated floor from the heating boiler is not directly powered. The coolant temperature will be too high, and the problem with uneven heating during the day does not add any enthusiasm.

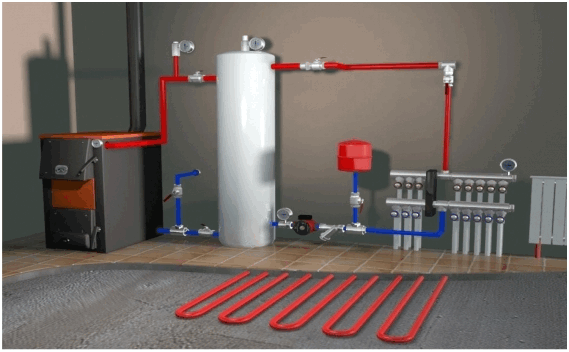

The solution can be a scheme similar to the one above: a heated floor is connected to the boiler through a massive tank, a heat accumulator. In fact, two independent circuits are formed with different coolant temperatures.

Please note: the bonus we get a constant temperature of the heating circuit.

The boiler at rated power heats the water in the tank, then the accumulated heat for a long time is given to the floor.

Schematic diagram of the use of capacity - heat accumulator.

Conclusion

It seems that the leader in the combination of efficiency and functionality is obvious. Condensation gas boiler - the optimal solution for low-temperature heating. As always, the video in this article will formulate the topic visually, thus more fully, see. Successes!

Warm water floor from a gas boiler is considered the most common type of individual heating scheme in the private sector, as well as in many apartment buildings. The heating system develops systematically and more and more often a warm floor from a gas boiler is added to the classical radiator scheme, and sometimes it completely replaces the radiators. Further in the article we will look at how to connect a heated floor to the boiler, as well as how hot floors are realized in practice.

In most cases, the implementation of thermal floors connected to a gas boiler makes it possible to refuse the use of radiators, which is a big plus on the aesthetic side. The pipes installed in the screed are also completely protected from any kind of mechanical damage. And with this method of heating the air is heated in the most appropriate way. But the most frequent example in practice is the implemented heating and warm floor from one gas-fired boiler. As a result, we get a good warm water floor from the gas boiler.

When selecting a gas boiler, it is necessary to take into account the area of the room that needs to be heated. After all, an accurately selected boiler for a warm floor will save you from the need to further make additional connection of heating elements to achieve a comfortable temperature.

Thermal floor from the gas boiler

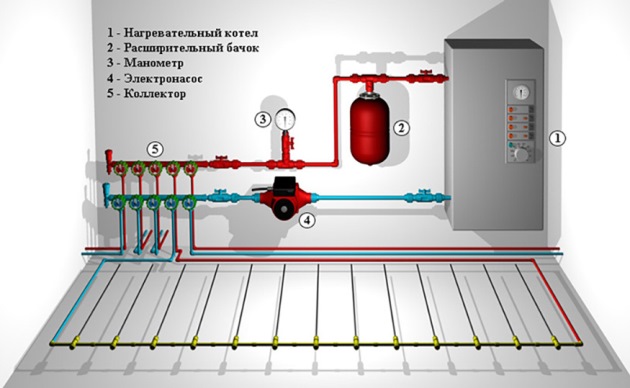

One of the best combinations of implementation are heated floors gas. In the presence of a stable source of electricity choose wall gas boiler. Its advantages are: having your own pump to ensure stable circulation hot water, expansion tank, filter and protective valves. With this combination, the scheme of connecting thermal floors to the boiler is extremely simple.

The heater connects to the comb of the distribution type directly directly by the pipes, but it is necessary to take into account the following important nuances:

- At the ends of the heat generator it is necessary to install shut-off valves;

- The built-in expansion tank must have such a volume that is enough for the needs of the heating scheme. Therefore, carry out the necessary calculation of the volume of fluid in the pipes and compare this value with the capacity of the tank. In case the volume share expansion tank less than one tenth of the total water in the pipes, then installation is necessary additional tank on the return line.

- In the event that if the expansion tank is not provided with an expansion tank, then it must be mounted on the return pipe closer to the boiler.

The nuances of the warm floor without radiators

- To warm the entire room, the warm floor from the boiler will need to be heated to thirty degrees Celsius, which is not very pleasant for people's feet.

- Batteries react quickly enough to changes in temperature, and the thermal floor will take much longer to heat the room. This “slowness” is caused by a significant mass of the screed, which must be initially heated.

- The efficiency of warm floors from a gas boiler with a minimum of combustion is quite low, due to the need to maintain a low temperature coolant. The approximate efficiency drop is 20%, which is an extremely unpleasant moment. In the case of transferring the boiler to the optimum mode of operation, at which the set temperature will be at least 65 degrees, the burner will switch to the multiple cut-off mode, due to the fact that there is no need for a significant amount of heat carrier for the floor heating scheme. And this, in turn, is an abnormal mode of operation of the unit and can cause a speedy failure of the boiler.

The only way to properly operate a gas boiler with a floor heating scheme without using radiators is to use a buffer-type tank.

Heat flooring scheme

The important point is to perform the correct contour. After all, for each room should be designed its own contour. The length of the pipe in the circuit can not be arbitrarily long, it has its limitations. The maximum effective area that can be heated by a single circuit is forty squares.

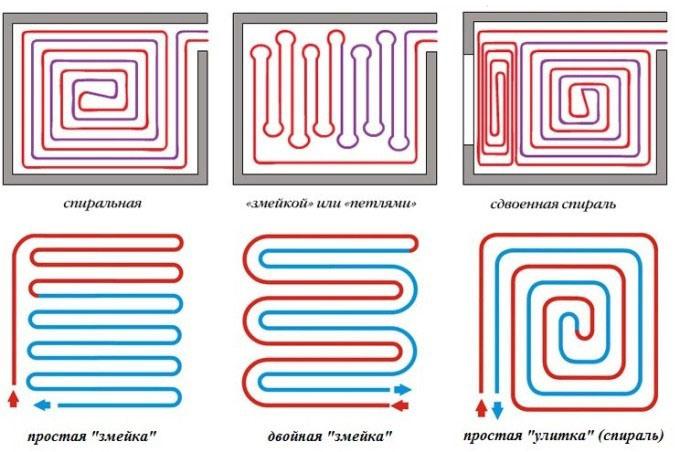

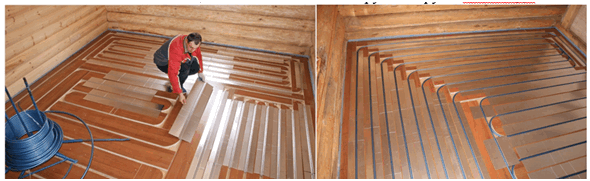

The pipe installation scheme is chosen depending on the room dimensions: in a small room, the snake method is more often used, but in rooms with a large area the laying method is used - a spiral. The distance between each turn can be as small as 15 cm and reaches a maximum of 30 cm.

The installation of one circuit is performed strictly by a single pipe of integral order, it is unacceptable to use any connecting elements.

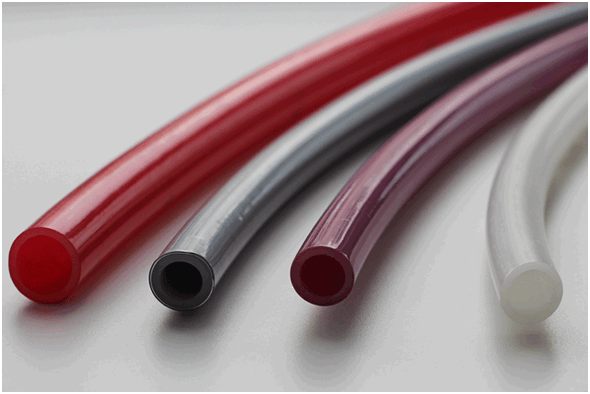

Metal-plastic pipes are used for laying, they are best suited for this type of floor.

Connection to collectors

The collector is an integral part of the thermal floor scheme, without which its implementation is simply impossible. They are used by at least two in the system: the supplying collector and the so-called reverse. A special order mechanism is mounted on the regulator of the supply manifold, which allows adjustment of the entire system in the machine and in manual mode. The main purpose of the reverse type manifold is to adjust the flow of the coolant and stabilize the pressure throughout the circuit.

System check

The first launch of the thermal floor system is carried out in order to check the operability of the entire circuit as a whole and check all joints for tightness. All circuits are filled with coolant, air is vented and all valves and taps are checked for functioning.

After the connection of control devices is carried out, a pressure check is repeated. The pressure is created one and a half times more than nominal.

After studying this material, you learned the answer to the question of how to connect a heated floor to the gas boiler circuit and found out what subtleties exist, as well as what problems may arise during the implementation of repairs in the house.

Warm water floors in their own homes - the modern reality of a promising future! The climate in a private house, regardless of the season will be warm!

Nowadays, the construction sector is experiencing a period of active development in various areas: new projects help create conditions in a private house that are comfortable for all family members.

Weather conditions in our country often present surprises in the form of snow in the summer, for example, and even winters are harsh. With the onset of autumn, the temperature regime in the house or apartment changes: it becomes cool in the room. To change the seasons did not affect the heat in a private house, you can provide housing with an additional source of heat. To do this, you do not need to buy different fans and heaters - all this is a tribute to the past, the twenty-first century offers a new generation of heating systems - a built-in warm water floor.

The project has gained popularity among consumers for whom the warmth and comfort of the hearth is an important problem that needs to be addressed. The design is a fairly simple mechanism, due to which you can perform the installation on the principle of "do it yourself."

Warm water floors connected to the gas boiler - a simple solution for additional heating of the room.

The mechanism of the project

The floor is warm water - there is nothing like an autonomous heating system for housing.

The design is a network of pipelines that are built into the base of the floor. Hot water flows through them, it serves as a source of heat. The pipes are located under the flooring. The pipes from the polymer is hot water, its flow is from the boiler (gas).

The floor gradually heats up, due to which the air is heated throughout the room. The system is thought out: a uniform heating of the room is ensured.

It is important to consider that the project of warm water floors is recommended to be installed only in private housing, since installation of a structure in an apartment puts a risk of leakage due to damage to the pipeline.

This design does not require screed preparation. The basis of the project are the boards from the old flooring. Special attention should be paid to the absence of gaps and gaps between these boards, if any - it is recommended to replace the floor covering.

Pros of the project warm floor

- Affordable price.

- Autonomy of the system.

- The principle of uniform heating of the room is active.

- The microclimate in the room is optimal: the humidity is comfortable for living.

- Refusal of additional heating devices, such as a fan and heater.

- Lack of damp in the room.

- The design operates regardless of the problems with the supply of electricity.

- Easy installation.

Minuses

- It is not recommended to install warm water floors in an apartment building.

- The complexity and time-consuming installation in such a structure.

- Possible leaks due to damage to the pipeline in the apartment.

The qualities that the project should have

- Durability and reliability.

- Uniform heating of the room.

- Waterproofing.

- No additional devices for heating the room.

- Aesthetic look.

- Long service life.

Required materials for the floor of the gas boiler

- Plasticizer.

- Sand.

- Crushed stone

- Cement.

- Profile.

- Pipes made of metal.

- A gas boiler.

- Hydro barrier

- Foil.

- Cranes and fittings.

Installation "do it yourself". Boiler

To start the installation of the system with your own hands, you should purchase a high-quality boiler.

In order not to be mistaken in the choice of the boiler you need to consider some aspects:

- ease of use; affordable price; ability to work with

- low temperature mode.

Autonomy of work

Exist different boilers for a heated floor system, however, gas boilers are gaining popularity, due to the fact that with enough power, they work without interruption. Automated control allows you to easily control the mode of heat supply in the house.

Affordable price

Today, gas is a more profitable raw material for the selected project. So, when installing a warm water floor from a boiler, the charge for electricity will be lower as compared to analogues.

Compatible with system

Different boilers are suitable for heating systems, familiar to consumers. The temperature of such devices from sixty to ninety degrees.

Note that a warm water floor system needs lower temperatures (from 35-50º). In such a situation, it is impossible to do without a collector unit, with the help of which the necessary degree of water heating will be ensured.

Floor

To install the floor with their own hands to prepare a solid base. It is placed on the screed. The base may be a screed of concrete. The screed must be made level, otherwise the water circulation may be disturbed and the floor heating system will fail in the form of a leak.

Screed

Over the rubble install lighthouses. For the solution, it is recommended to purchase cement of the brand that corresponds to the planned work. Lighthouses should be positioned so that the distance between them is ten centimeters less than the rule. Pour the screed solution. Let the solution dry well. As a rule, it will take a week. Professionals recommend a drying time for a screed of twenty one days.

Pipe installation

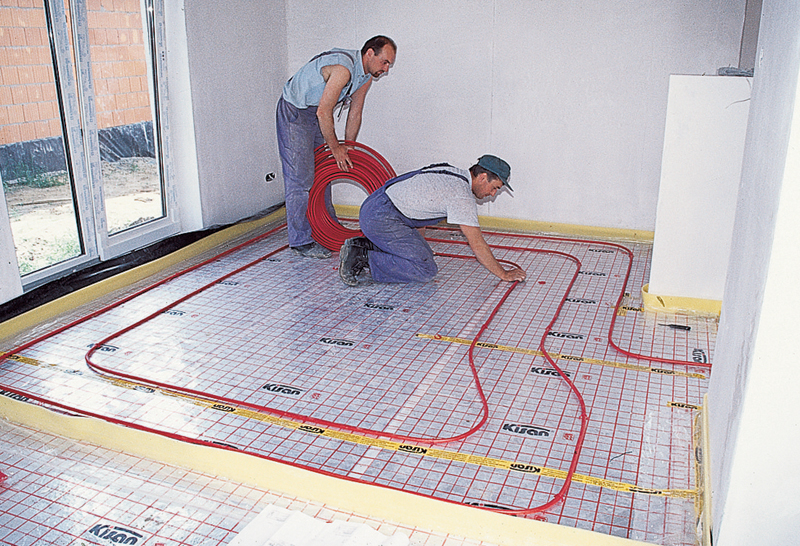

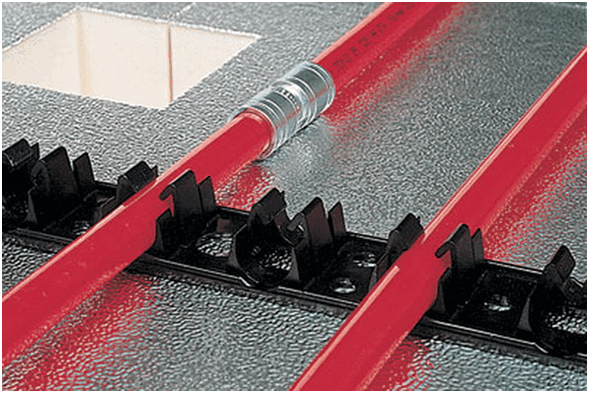

Above the dried screed, you need to lay a hydro-barrier. Wrap the edges of the film on the wall by ten centimeters. You can start laying sheets of foam. For residential premises, such sheets will be the twenty-fifth density. The standard size of this material is one hundred to fifty. A convenient element are the grooves for joining on the edge of the sheets. The material of the building element is very malleable, if there is a need to change the size, it is enough to use a stationery knife.

Laying of the pipeline from polyethylene

Laying of the pipeline from polyethylene Then you need to put a heat reflector. This will require a foil.

For installation of the pipe will need brackets made of plastic.

Pipe laying methods

- Spiral

- Snake

Spiral: uniform heating of the room. Parallel arrangement of water supply and return flow. For structural strength, it is desirable to mount frequently. This method will ensure uniform distribution of heat around the perimeter of the room due to the fact that the direction of the pipeline goes from the tie-in to the center, then back to the collector. There are no special requirements, except for one: more often to use fasteners.

Snake: the promotion of the coolant occurs on the principle of "snake": from one side to the other. Moreover, on its way the water cools, so the contour near the inset is the warmest.

Note that the warm water floor with their own hands - the design is quite simple. After choosing the method of laying pipes, it is important to mark them up. The contours should be no further and no closer than twenty-five centimeters from each other. In this way, optimal heating of the room will be achieved.

To ensure the fixation of the pipe bends, put a spring on it.

Then gradually insert the pipe into the brackets until the process is complete.

Connecting the system "warm floor"

Before you engage in connecting a heated floor to the system is to prepare the distribution node. So that with its appearance the geometry of the room is not broken - to build it into the wall. So, in the wall you need to make a niche in which to place a special box equipped with a door. Put the outputs (three) and two combs into it. The supply pipe will join it to the side, and at the exit there will be three pipe connection channels. For outflow you need to place another comb below. Taps should be installed in front of the pipes at the outlet.

The temperature mode in the house is available to correct automatically: special gates will help with this, with which you can set the required temperature to the system.

Upper screed

After working with pipes go to the upper screed. Put beacons on cement mortar, - give time to dry (twenty-four hours).

- After the work done, it is advisable not to include the boiler in full force.

- To optimize the temperature in the house with a floor heating system you need to choose the right flooring.

- Do not use carpet in the bedroom or in the nursery.

Exploitation

- The project must be connected in the autumn.

- The warm floor from the boiler in the house is easy to install with your own hands: do not deviate from the process technology.

Warm floor from the gas boiler - a guarantee of health and joy of loved ones!

Approved by an expert

Preferring autonomous heating methods, homeowners want to solve the problem of heating an apartment or house once and for all. Independent heating provides not only optimal temperature conditions in residential premises, but also provides significant cost savings in the family budget. What kind autonomous heating give preference to you. To get started, let's take a look at the main existing options for home heating, based on the energy they consume:

- Electrical devices.

- Solid fuel devices.

- Units on liquid fuel.

- Devices on gas.

Each of these groups is divided into subgroups according to the method of installation, the coolant used, the application, etc. But to this list of devices used as the main means of heating housing, you need to add the systems involved in the heating process as additional devices that increase comfort temperature conditions in the room. Such systems include so-called underfloor heating, electric and water.

Of particular interest in this regard is the water heated floor, operating from a gas boiler - an autonomous generator of hot water. The system is relatively new, but well-studied, superior in efficiency to devices such as, for example, heated fans.

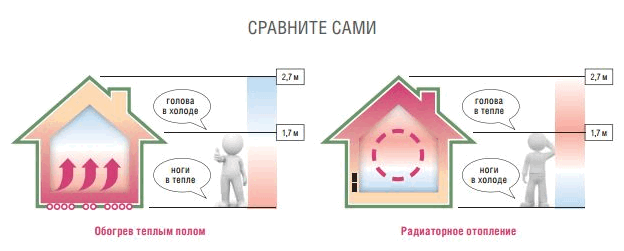

The idea of a warm floor in a residential area is not new. A man has long paid attention to the laws of physics operating around us - the warm air in the room always accumulates above, above the ceiling. The cooled air, on the contrary, goes down, making the floor the coldest place in the room, eating precious kilocalories with its large area.

Artificially heated to a certain temperature, the floor becomes a powerful source of heat in the room. Due to the large area of heating, the air warms up evenly and rises upwards, filling all the internal space. The process of air exchange provides the necessary temperature in the room, and minimizes the difference between its values at the floor level and under the ceiling. In rooms equipped with warm floors, there are practically no zones with cool air.

Gas boilers used today for home autonomous heating, are fully capable of ensuring the normal operation of a warm water floor. To achieve effective improvement of comfort in this situation, it is possible under certain conditions - accurate thermal and hydraulic calculations, competent installation of a system of warm floors.

Concept

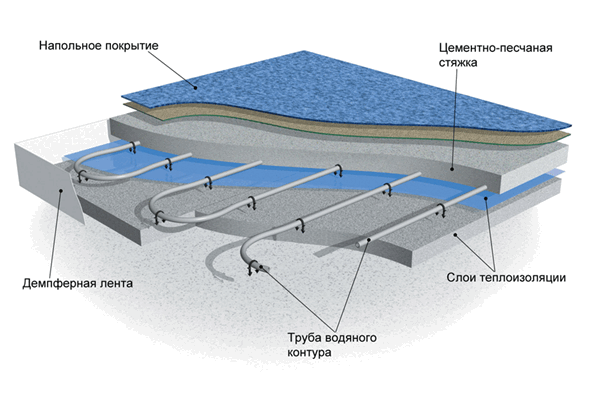

It is possible to provide floor heating by laying in the pipeline space between the floor and the floor covering, in which the heat carrier heated by the gas boiler will circulate. Water acts as a heat carrier (ordinary or with special additives against freezing) - a traditional liquid used for stand-alone boiler equipment.

The heat exchanger in this case is the pipeline laid under the floor covering. The effect is achieved due to the large heat transfer area. The amount of heat entering the interior space is sufficient for the horizontal and vertical distribution of the warm air mass.

Important! The principal difference of this system from other types of heating systems is low coolant temperature. For a warm water floor, it is sufficient to heat the coolant to a temperature of 30-50 ° C.

Components of the "warm water floor"

The main structural elements of such a system are:

- a gas boiler;

- pressure pump;

- stop valves and fittings;

- the main pipeline for distributing coolant to the residential premises;

- floor mini-pipe for laying on the surface of the subfloor;

- collector;

- automatic system and adjustment of operating modes.

A gas boiler

For a private house of a large area where it is planned to increase the comfort of the temperature regime in a large number of rooms, the best choice would be a floor-standing double-circuit gas boiler in an autonomous version. Such units have great power, they are capable of simultaneously solving several tasks at once - heating of residential premises and provision of hot water supply.

On a note: for gas heating equipment in the floor version it is necessary to equip the appropriate room with a chimney and ventilation. The room allocated for the boiler room (boiler capacity up to 30 kW) must have an area of at least 4 square meters and a minimum volume of 8 cubic meters. If a single-circuit gas boiler is used for underfloor heating, for dHW systems will have to install an additional boiler indirect heatingwhich is allowed to be placed in the same room.

For an apartment where every square meter of area is expensive, a wall-mounted gas boiler can be used, which, if properly selected, will also ensure the efficient operation of a water-heated floor. Due to its size, it is easier to pick up a place to place such equipment, wall-mounted gas boilers can be installed even in the kitchen or in the bathroom. Typically, the power of wall-mounted gas boilers varies in the range of 7-30 kW.

Wall autonomous gas appliances in most cases have closed chamber combustion, therefore, for its effective and safe operation, it is enough to equip a coaxial chimney with access to the street or to the central chimney shaft.

An important point when purchasing equipment is to determine the optimal power of the gas boiler, which will have to ensure the operation of the “water heated floor” system, therefore, when choosing a model of a gas boiler, it is necessary to rely on the data of thermal calculations.

For reference: for heating 1 square. m of living space required costs of approximately 100 watts of electricity, subject to good thermal insulation of the room, ceilings with a height of no more than 3 m and the absence of an excessive number of windows.

Most of the premises of a private house have external walls in their designs, heat losses through which may require an increase to 150 W of heat consumption for heating 1 square meter. living space. Therefore, when buying a gas boiler, even having a thermal calculation with an indication of the required power of the unit, it is better to purchase a device that exceeds the calculated value of this characteristic by 15-20%.

In most cases, the capacity of double-circuit boilers is designed for hot water with one or two points of water intake. Therefore, increasing the number of hot water intake points will require an increase in boiler capacity.

In this regard, water heated floor has the advantage - the gas boiler loads in a sparing mode. The principle of the warm floor system in this situation requires the boiler to heat the coolant with minimal energy consumption. Most of the boiler power is released to the hot water system.

Pipes for underfloor heating

Copper, polypropylene, metal-plastic or PEX pipes are used for laying a warm water floor.

Copper pipes (high thermal conductivity, durability) are the ideal material for installing underfloor heating, so their price is high and availability is limited.

Polypropylene pipes are also not very common, but for another reason - their flexibility is insufficient, and the minimum bend radius of the pipe must be equal to 8 of its diameter, which separates the coils from each other.

Metal-plastic pipes are deservedly popular - the internal aluminum coating provides them with good thermal conductivity, and polymer shells protect them from damage. With such characteristics, an affordable price is a good incentive to opt for them.

PEX tubes are made of “cross-linked” polyethylene, that is, with an artificially modified molecular structure, which makes this material strong and durable. The price of PEX pipes is quite affordable, and therefore their use when installing underfloor heating systems is widespread. However, one specific property of this material should be kept in mind: when heating, PEX tubes tend to adopt their original contour, therefore, when laying them on the floor, they must be firmly fixed to the screed reinforcement.

The heating system does not fit on one day, so its reliability, including tightness, and durability must be ensured. For this purpose, the pipes are stacked in a single integral coil, without connections. The task is to get a single, closed loop through the installation process, through which coolant will circulate, the quality of which is better to use water with special additives. This will avoid defrosting the system during severe frosts. Such a measure is relevant for owners of country houses and cottages with non-permanent residence.

Important! When using water in the system, it is necessary to install an additional protective device, a compressor or a can of compressed air for emergency purging of the entire circuit and draining the coolant.

Important!Buying pipes for the heating system, pay attention to the labeling. In products intended for heating systems, there are appropriate symbols and symbols. As a rule, this is a permissible pressure of 10 bar and a heating temperature of up to 95 0 C.

Depending on the characteristics of the room and the type of flooring (thickness of the screed, the height of the room, etc.), pipes with a diameter of 16-20 mm are used to install the system of warm water floors. During pipeline installation, a minimum bending radius of five times the diameter for metal pipes and 8 times for a polypropylene material is allowed.

For completeness, we suggest to familiarize yourself with the video material, which tells in detail and shows how the installation of water heated floor.

Installation of the "water floor heating"

The construction of a water-heated floor system begins with the preparation of the foundation, which includes several operations, which we will now briefly consider. Failure to comply with the requirements for the subfloor, on which the heated floor is mounted, is fraught with at least a decrease in the efficiency of its work, as a maximum - depressurization followed by costly overhaul.

Foundation preparation

The base before laying the pipeline must be prepared accordingly. The surface of the base must be firm, clean and even. Height differences in the range of plus or minus 10 mm per meter of linear length are allowed. If the floor surface does not meet the requirements, has a large curvature and obvious flaws, an alignment screed device is carried out, followed by waterproofing the base in case of system depressurization.

Before laying the pipeline is also insulated subfloor. For these purposes, plates of extruded polystyrene foam or basalt fiber with a thickness of 30-50 mm are used.

With sufficient budget justified the use of plates, shielded with foil and equipped with special projections for easy pipe installation. Such measures are used to reduce heat losses through the floor in the first floor premises - a warm floor with a gas boiler of any capacity will work with increased load while heating the floor to heat the basement room or someone else's apartment on the floor below.

Important! Before pouring the laid pipes of the system of warm floors with cement mortar, it is necessary to glue a strip of damper tape 5 mm thick and the width equal to the thickness of the layer of mortar to the walls along the perimeter of the room. The tape will compensate for thermal expansion of the screed and reduce its pressure on vertical structures.

Installation

Water floor heating systems are divided into 2 types according to their design and, accordingly, the installation method:

- concrete (filler);

- flooring

In the first case, we are talking about pouring concrete laid under the prepared base of the system of water-heated floors. This operation is preceded by a breakdown of the base into sections and the laying of reinforcing mesh.

The following types of laying pipes of thermal water are used:

- snake;

- double snake;

- spiral;

- offset helix;

- combined method.

The diagram shows how the heating circuit is installed in a room with increased heat loss - two or more external walls.

Important! After the installation of the underfloor heating system is completed, it is pressed under a pressure of 5 Bar within 24 hours.

Concrete screed is an additional element of the heat distribution process. Given the poor performance of concrete in tension, it is placed at a pressure of 3 bar in the heat supply system, reducing the tensile load during the further supply of water to the system to the working pressure.

For the screed mortar, cement of a grade not lower than M-300 is used, and its thickness should be 30-50 mm, while the mortar layer over heat pipes should not be more than 2 cm.

When constructing a water-heated floor system, a technological limitation should be taken into account - a clean floor covering should have a high thermal conductivity coefficient in order to transfer heat to the room air with minimal losses. That is, laying on the warm floor of linoleum, laminate, parquet, boardwalk is impractical because of the high insulating properties of these materials. And laying on top of the tile system, especially with high density - porcelain stoneware, natural stone, broomstick, is not only justified, but also advisable because of the constantly cold surface of such a finish.

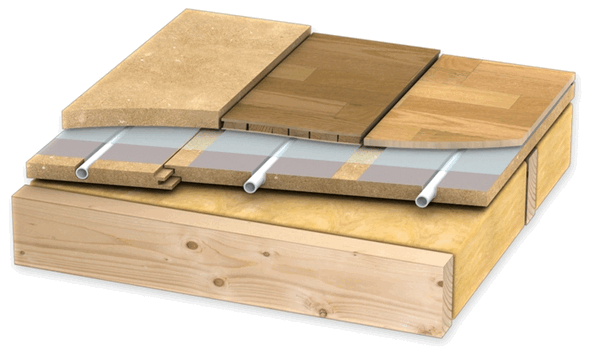

The laying method of laying is used in rooms where the use of a screed is undesirable due to low ceilings, or the production of concrete works is fraught with leakage of moisture into the lower or adjacent rooms. Restriction may be a seasonal factor or be associated with the structural features of the building. The main advantage of flooring systems is their high speed of installation. Warm water floors of the flooring type of laying according to the materials of the device system is divided into:

- polystyrene;

- wooden:

- modular;

- rack

All these types of flooring systems are less labor intensive and lack of significant pollution of the housing during installation.

Polystyrene heated floors

This system is a set of heat insulating coating of extruded foam (polystyrene foam), pipes, teplovodov and heat distribution aluminum plates.

Plates of polystyrene are laid on the supporting base, on top of which heat conductor pipes are mounted on aluminum plates with special grooves.

On top of the aluminum plates, the floor is finished with a material with a high thermal conductivity coefficient (for example, ceramic tile with 2-component epoxy glue).

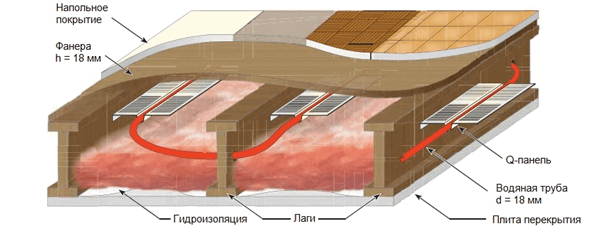

Wooden floor heating systems

These devices are mounted on existing wooden floors or logs of wood.

In a modular variety, plates (modules) with channels and grooves are used for heat-distributing plates and pipes.

In the rack subfloor warm floors installation of modules is made between existing on the hard rough floor lags, or lags are preset for this. These structures play the role of stiffener edges of a heated water floor and its subsequent finishing, the list of structural elements does not differ from the modular type.

After the termination of laying the warm floors of the flooring type, the system is also crimped and commissioned (leak test, tightening of the joints).

The laying way of the device of system of heat-insulated floors is universal and applicable practically in all buildings and constructions. However, its advantages are reflected in the cost, which is quite high.

Conclusion

Competent project in combination with qualified installation of equipment - a guarantee of a positive result. Water floor heating, which you will use as additional system house autonomous heating, will be the effective, economic and practical device considerably increasing comfort of housing.