Installation of ducts on the pipes on the roof. Chimney box: its design and purpose

Sadly, many private developers, who decided to build a bathhouse on their site, forget about some details and trifles, one of which is the chimney box.

Some builders do not know what it is about. And someone heard, but did not attach much importance to it.

We decided to fill this “gap” and tell why the box on the chimney is needed, because a properly constructed bath is the key to longevity and the health of its owners.

In fact, this is a rather complicated question, since the duct refers to two designs that perform completely different functions.

In the first embodiment, this device is for the passage of the chimney through the roof or ceiling, and in the second - a decorative component, which can serve to hide the ventilation pipe, and the chimney.

Consider each construction in order.

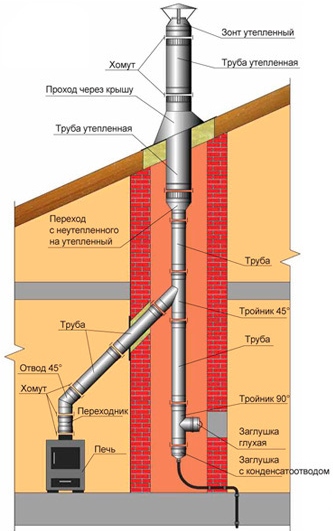

The smoke exhaust pipe can run both inside and outside the room.

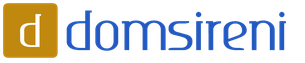

The passage of the pipe through the room of the steam room is more expedient for more heat preservation, but in this case it will pass through the roof. That is what the chimney box is for.

Thanks to such a device, from the chimney to the ceiling rafters, as well as to hydro and vapor barrier films, high temperature will not be transmitted.

It is very good if the opening for smoke removal is designed immediately after the construction of the bath. Then a separate roof system is immediately made for the chimney.

Depending on the type of pipe, the distance from its surface to the surface of combustible materials should be from 15 to 25 cm. Then there is enough space around the chimney to be filled with non-combustible material, such as high density basalt wool, and in this area you can do without additional waterproofing.

Important! In order to prevent the roof from leaking later, the waterproofing of the ceiling should be well fixed around the perimeter of the box to the rafters and additionally pressed with a crate. The vapor barrier on the inside of the room is also nailed to a truss system with nails or staples, after which it is pressed against the finishing material.

Thus, it turns out a beautiful wooden chimney box, which isolates the roofing pie or ceiling in the bath from high temperatures, and at the same time has sufficient waterproofing.

There are also boxes from other non-combustible materials, such as metal or ceramics.

Metal device for insulating the smoke pipe

This device is also a box that can be made of sheet metal, galvanized and stainless steel, 1 mm thick, with a hole for the chimney in the middle.

These devices are sold in almost all specialized stores or building supermarkets, for various chimneys.

An example of a decorative box

The decorative box on a flue, is made of various materials with the subsequent dressing.

Thanks to the decorative finish, you can significantly improve the appearance of chimneys made of metal and brick.

In addition, in the decorative box ventilation can take place, the pipe of which will also be safely hidden from prying eyes and various atmospheric phenomena.

- If the chimney is made of brick, then in this case, the decorative frame for it can be made of plasterboard. After that, carefully plastered and decorated with artificial stone, tiles or tiles.

- If the smoke exhaust pipe is made of metal, then at the beginning it should be wrapped with foiled thermal insulation material. Only after that you can install a decorative box of drywall and decorate it to your liking.

It is important to remember that the passage device for the chimney of the bath is a very important element. And how you make and install it will depend on the fire safety of the entire building.

At present, the frame house is probably the most popular type of building that combines such remarkable qualities as the speed of construction, the budget of construction, the environmental friendliness of the resulting building.

In addition, it is a cozy, comfortable, warm and beautiful dwelling of modern man.

But in order for this wonderful house to fully justify its functional characteristics, it must be competently constructed, including a high-quality chimney.

But in order for this wonderful house to fully justify its functional characteristics, it must be competently constructed, including a high-quality chimney.

When building any frame building, especially from wooden materials, a significant moment is always the correct development of the project, followed by its embodiment by experienced craftsmen.

A special role in the design is given to the choice of model and type of stove, chimney and box for it.

Excellent air traction, complete fire safety, reliability and durability of the building - all these are extremely important moments, necessary requirements for a chimney in a private house , taken into account when developing a building plan.

During the direct operation of an already built house, from time to time there is an urgent need to clean the chimney inside and outside the house. And for this, there must be convenient and secure access to the device itself to remove smoke.

In modern construction, the installation of a chimney in a frame house is usually carried out from steel, brick or ceramics. The choice of material largely determines the final cost of the finished product.

Chimney in the frame house

Of brick

The choice for arranging the chimney in a private house is by far the most popular. This is a well-proven material, time-tested, affordable, reliable and durable, with good refractoriness.

The choice for arranging the chimney in a private house is by far the most popular. This is a well-proven material, time-tested, affordable, reliable and durable, with good refractoriness.

But not everything is so wonderful. A pipe made of this material has such an enormous weight that it requires a separate one. In addition, the surface of the brick has a lot of roughness, which later will cause sedimentation and accumulation of soot on the pipe walls.

Of steel

Often, the owners prefer steel chimneys inside the houses. They do not have separate drawbacks of brick pipes: their weight is rather small, and installation takes much less time and effort. There are steel pipes and disadvantages.

Often, the owners prefer steel chimneys inside the houses. They do not have separate drawbacks of brick pipes: their weight is rather small, and installation takes much less time and effort. There are steel pipes and disadvantages.

They are limited to t (temperature) of smoke: it should not be more than 500 ° C. This rule is quite difficult to follow, especially when it comes to solid fuels. Special requirements are imposed on the quality of stainless steel for the manufacture of the chimney. If it does not match the quality, the chimney pipe will be oxidized and even burned out.

From ceramics

Also today, the use of a ceramic chimney in a wooden house is not uncommon. The technology of its use is called a sandwich. The inner, initial layer is usually made of special refractory ceramics. Its important characteristic is the absence of an acute reaction to the harmful (aggressive) influence of the external environment.

Also today, the use of a ceramic chimney in a wooden house is not uncommon. The technology of its use is called a sandwich. The inner, initial layer is usually made of special refractory ceramics. Its important characteristic is the absence of an acute reaction to the harmful (aggressive) influence of the external environment.

The next layer is presented, which is usually used.

The final, last layer is a kind of packaging, the decorative shell of the previous two. Suitable material for it is artificial or natural stone.

This method is especially good for the high degree of safety of such a chimney, and, consequently, its reliability and durability. The rather high cost of both the chimney itself and its installation, and its high weight are significant drawbacks.

A ceramic device will be lighter than that of brick, but heavier than a stainless steel system.

External chimney

Traditionally, all the usual chimney is located indoors, inside the house. Naturally, passing from the bottom up, he seemed to permeate the whole house, taking away the useful space of his home.

This is not a problem for large housing sizes, but if they are rather limited?

There is, for example, where almost every decimeter of area is valued.

An excellent way out of this, and in other cases, will be the arrangement of an external chimney system..

Through the wall it is brought out, and goes along the outer wall of the building.

One of the main advantages of such a chimney is excellent traction, and, therefore, a remarkable system efficiency.

In addition, the excluded leakage of smoke into the room, the possibility of damage to the floors. External systems are extremely easy to maintain and maintain, the deposition of soot on the walls is insignificant.

All this ensures their reliability and safety. Additional bonuses of the external chimney - its low weight, no need to build a foundation specifically for it, low cost.

Well, as noted above, he does not take away the living space from the dwelling.

Chimney installation procedure

When arranging a chimney through a wall in a frame house, the whole structure is completely processed with special insulating materials.  Its role is played by slag concrete, fiber insulation, and other non-combustible materials.

Its role is played by slag concrete, fiber insulation, and other non-combustible materials.

At the top, the pipe is wrapped with an insulating aluminum foil, securely fastened with tie clips. You can make it easier - use sandwich chimneys with insulation. Their device is extremely simple. Roughly speaking, these are two pipes of excellent diameter, the smaller of which is embedded in the larger one. As a filler space between them serves as a heater.

When choosing the most suitable type of chimney for your home, you need to remember that it will be used for a long time. Therefore, special attention should be paid not only to the material for it, but also to the strength and reliability of the whole structure. After all, its fire safety and efficiency of use will be determined by the type of method chosen and the quality of its implementation.

The chimney provides fresh air and the removal of combustion products from the room, is responsible for the natural draft of the furnace or gas boiler. Installing a chimney is a prerequisite for the operation of heating equipment.

- It is the key to a comfortable microclimate and security inside the house, cottage or bath. In order to save, you can assemble a chimney with your own hands. It is important to correctly calculate and comply with all existing standards for the design and installation of chimneys.

Rules for placing the chimney on the roof

The installation of the chimney should be made in accordance with fire safety requirements. The main points are as follows:

- On a flat roof, the height of the pipe should not exceed the height of the roof by more than 1 m;

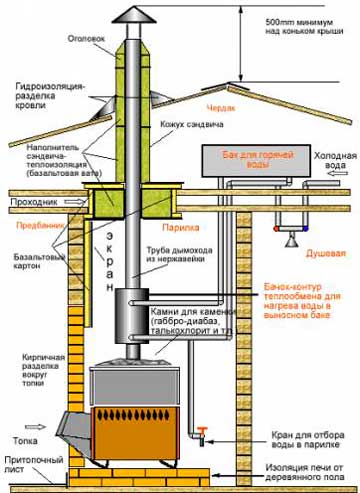

- On the pitched roof, provided the device is placed less than 1.5 m from the ridge, the pipe should rise at least 0.5 m above the ridge;

- If the distance from the ridge is 1.5-3 m, the pipe should be installed on the same level with the ridge;

- The pipe located at a distance of 3 meters or more from the ridge must be at a distance not lower than 10 ° from the horizon of the ridge part. Variants of placement of the internal chimney on the pitched roof are shown in the figure:

- When installing the device, it is recommended to install revision elements for removing condensate and cleaning the structure, as well as a plug with a stainless steel trap;

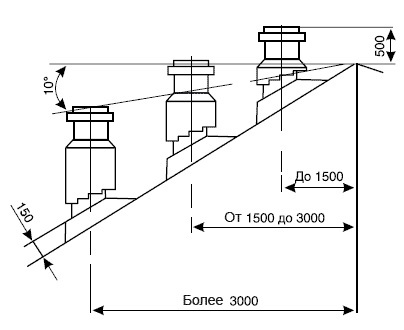

- Installation of a chimney at a height of at least 1.5 m from the roof of adjacent structures;

- The chimney pipe with a height of more than 1.5 m must be additionally secured with braces. An example is shown in the figure:

- If the roof is made of combustible materials, it is recommended to mount it on a spark-proofer;

- The joints of the chimney should not coincide with the passage through the ceiling, or the roof of the wall;

- Installation of the knee and tees must be done in such a way that they do not carry the load from the flue pipe located above;

- Horizontal patches should be avoided. Their maximum length can be 1 m.

Choice of chimney depending on the type of heater

The installation of the chimney must take into account not only the design features of the roof, but also the type of heater for which it will be used later. For stoves and wood fireplaces, the installation of a brick chimney is recommended, but in the case of gas equipment the brick does not resemble, since it is destroyed by the acids contained in the smoke. For gas boilers, stainless steel chimneys are best used.

Features of the installation of a brick chimney

For the chimney, it is recommended to use clay bricks and lay out each wall not less than 12 cm wide. Brick laying for weak power kilns is made in four rows, for medium power kilns - in five rows and for high power kilns - in six rows. However, any brick is destroyed by soot, soot and condensation, in order to avoid this, the brick box should be strengthened by adding a metal pipe. The space that is formed between the pipe and brick walls must be filled with non-combustible insulating material, thus performing additional insulation of the chimney.

Stages of chimney construction:

- Brick chimney with their hands begin to install from the neck. This part of the chimney, which immediately follows the nozzle tube of the furnace. In this place it is necessary to make a smoke valve, or, as it is also called, a view that overlaps the pipe after processing the fuel.

- Further, the outer diameter of the masonry expands, the so-called raspuska is performed, and the internal smoke channel does not change in size.

- After passing the chimney through the ceiling, the pipe riser is laid, which is the same size as the neck.

- The next time the outside masonry size increases during the passage of the chimney through the rafters of the roof. This extension is called otter. It is necessary to mount each otter wall with a minimum width of 0.1 m in order to successfully complete the protection against moisture penetration into the attic space through the existing gaps between the chimney and the roof.

- After cutting the otter, the outer diameter again narrows - the laying of the neck of the pipe is made.

- After the neck of the chimney masonry expands again - it is the tip of the pipe.

- A special metal cap, an umbrella that protects the chimney from rain and other precipitations, is installed on the tip.

In addition to the main function, the umbrella also holds back strong gusts of wind that can break the draft in the smoke channel and serves as an ornament to the chimney and the entire building, giving it a finished look. - Insulation of the visible part of the chimney can be performed using the box.

Brick laying should be done in such a way that the internal size of the smoke channel is the same in any place.

Sometimes, with a lack of experience, the chimney is laid out of the same size from the neck to the tip, and then expanding the wall outside, adding fluff and otter made of concrete. Laying a brick chimney is not easy and requires certain skills. However, you can do it yourself if you study the diagrams and drawings in detail.

We build a brick chimney according to the scheme shown in the figure:

Installation of metal chimney

There are various options for mounting a metal chimney both inside the building and outside. In order to properly make a chimney out of a metal pipe, you must follow some rules:

- The diameter of the chimney pipe must be equal to or greater than the diameter of the outlet pipe of the heater;

- Pipes without insulation are used exclusively indoors;

- If the chimney is located outside the building, it is necessary to insulate the pipe, or to use a so-called. chimney-sandwich;

- Smooth vertical chimney can be used without a support site;

- If the design of the smoke channel has bends, it is necessary to strengthen it with the help of the supporting platform;

- To collect condensate you need to install special tees with plugs;

- In the places of construction passage through the ceiling, it is necessary to use the “Passage through the ceiling” element and to carry out insulation of free space;

- If the smoke channel passes through the wall, the pipe is removed at an angle of 45 °. You will also need additional insulation and insulation of the space between the wall and the pipe;

- In the places of passage of the chimney through the roof, the element “Passage through the roof” is used;

- Completion of construction is carried out with the help of the protective element “Umbrella” or “Umbrella warmed”;

- It is necessary to carry out warming of all joints of the pipe with the help of heat-resistant sealant and clamps;

- Installation should be from the bottom up;

- On the main chimney pipe can be installed at will box.

The box or casing covers part of the chimney rising above the roof and performs a number of important technical tasks:

- Thermal insulation of the main pipe, which in turn improves traction;

- Strengthening of the chimney, in case the duct is installed on the permeable wall of the flue duct;

- Decorative design. If there are several gas ducts on the roof, the duct is installed on each of them.

The chimney box can be made of various materials, be solid metal or consist of corrugated flooring elements. If a duct is installed on the roof, the umbrella is mounted directly on it.