Fireplaces on the wood for the house with their own hands. Wood fireplace do it yourself

To increase the efficiency of the fireplace can be due to a competent choice of place. The main thing is that it is blocked from drafts, so do not install it in front of windows and doors. Optimally build a fireplace against the inner wall of the room. After all, hypothetically placing it on the outer wall, we will heat the "street".

The country house must be in order to keep the heat that gives the fireplace. The room in which the installation is planned must be at least 20 square meters. m. Otherwise, the fire will not have enough air for the furnace, and it will “choke”. In this case, you need to think on additional air supply specially for the fireplace. If the building already has a supply and exhaust air (infrequent guest at summer cottages), then for the time of the fireplace operation it should be adjusted to the mode of excess of air flow over the outflow.

Designers recommend draw the fireplace to the center of the roomto admire the flame. Making the interior, do not place curtains and other flammable objects near the fireplace: one never knows, sparks can escape from the firebox to the outside!

Craft tips

Considering the components of a country house, we almost always insist on the need competent project. This also applies to the fireplace portal. Here you need an exact calculation. After all, if the fireplace is too large, there will be drafts in the house, and if it is small, the room will be heated badly. The numbers below will help you navigate. So, the design takes into account the following requirements:- The size of the basement of the fireplace in depth - about 1.5 m.

- The projection of the pre-furnace platform must be at least 1.5 m in length and 20-30 cm on the sides.

- The walls of the firebox should be inclined (have a negative angle of inclination): this allows better to reflect the radiant heat.

- The hearth area of the firebox should be equal to 70% of the total portal area.

- The inner cross-section of the blower must be at least 200 square meters. cm.

- Portal height - twice the depth of the furnace.

We build a fireplace

The first step is the purchase of building materials. It is better to lay down the fireplace from baked ceramic or fromas the technology is in many respects similar to the laying of a conventional oven. And no innovations like multi-gap brick are needed here. Normal red full-bodied will be just right. White silicate brick is almost never used when laying fireplaces, it is not its scope.

In addition to the traditional red, you will need fire brick for the firebox- chamotte. Mortar for the fireplace body is preparing from clay, quartz sand and water. A foundation should be put on cement-containing mortar.

Attention: the manufacture of dry construction mixtures is one of the most popular counterfeit businesses in this industry, and it is very easy to buy a hack in a bag on the market. But there are also pleasant, one might say, encouraging exceptions. Knauf company marks the bags to the nearest second. Moreover, these figures, the marks are clearly visible. In the same warehouse, in the same market container, all bags must have close timestamps, but all are different.

Fans of avant-garde solutions are ready to build and reinforced concrete fireplace. Justification can be either free cement, or an acute shortage of bricks, or the desire for originality. After all, constructing formwork, knit reinforcement and vibrate the concrete mixture - work for an amateur. And with the worst thermal performance.

Facing the facade of the fireplace performed by a variety of materials: natural or artificial, tiles, ceramic or marble tiles. In the construction markets, you can find ready-made kits for the fireplace, where the kit, in addition to facing materials, includes mortar and all the necessary parts for the work.

In developing the overall concept of room design, you can use the same lining for adjacent surfaces, as was done in the photo. So the fireplace fits well into the interior. But all this must be solved at the project stage, and not at the last moment.

Chimney: Undisputed Truths

There are a few regulatory documentson which construction and installation of smoke channels (pipes) for fireplaces should be carried out. It:- SNiP 2.04.05-86 "Heating, ventilation and air conditioning",

- GOST 9817-82 "Combined household appliances for solid fuels. General technical conditions ",

- PPB 01-03 “Fire safety regulations in the Russian Federation”.

- Wall and root smoke channels must be lined made from full-bodied red ceramic bricks (brand not lower than M100), normal firing, without cracks and impurities.

- The thickness of the seams of masonry should be no more than 10 mm. Loose seams are not allowed..

- From the point of view of fire resistance, the thickness of the walls of a brick smoke channel should be not less than 120 mm.

- Its inner surface should be smooth, not plastered.

- From the outside, the brick smoke channel in the attic should be plastered and whitewashed. Wherein it is forbidden to place it near the truss elements.

- The distance from the inner surface of the smoke channel (cutting size) to the protected combustible structure of the building must be at least 250 mm, and to the unprotected one at least 380 mm.

- The free space between the chimney and the roof structures follows cover with apron of roofing steel. This caution alone indicates the limited choice of installation sites for the fireplace itself.

- It is advisable to install smoke channels vertically, without ledges. Although, if the internal layout does not allow this, channels with a ledge are allowed at an angle of not more than 30° to vertical and horizontal deflection no more than 1 m.

- If the smoke channel is of rectangular cross section, its internal dimensions must be at least 140x270 mm. And if a steel sandwich chimney of circular cross section is used, then its internal diameter should exceed 200 mm.

The smoke channel can serve lightweight steel coaxial (pipe in pipe) chimney with a layer of basalt fiber between the shells. Here I would like to warn future users against the use of cheap fakes. You may reasonably ask what the difference is. The fact is that basalt material is different:

- The most common is used for thermal insulation. Adhesive composition, holding basalt fibers, is designed for a temperature of about 250 ° C.

- There is also a fireproof basalt material, where the adhesive composition holds already 750 ° С. Although in fact, and in another case, basalt fibers are used, which begin their own melting at a temperature of 950 ° C.

Summary: coaxial factory-made chimney with high-quality fire-retardant basalt material will completely eliminate the problem of the delivery of exhaust gases during combustion to the atmosphere.

And a few words about the rules of fire safety:

- Check the smoke channels once a year.: what is the condition of their internal walls and is there any soot on them?

- It is necessary to clean the smoke channel pbefore the startheating season and during it - at least once in 2 months.

You can read about how to properly clean chimney chimneys with modern methods in the article.

Premier firebox

Professionals do not advise to heat the fireplace during the first month after its assembly. And this is understandable: cementing solutions gain strength and dry with natural moisture. Why test them at such a crucial moment?

Next stage - trial firebox:

- Within 10 days, 2 times a day, short-term (up to half an hour) ducts with a small amount of firewood are carried out. At the same time, the hole of the blower (on the ash pan facade) should be ajar.

- It is best to lay crumpled paper on the grate, and on top of it - chips and finely chopped wood.

- Then ignite the paper, close the door and slightly open the blower. Although in the presence of difficulties in fueling, you can for some time leave the door of the firebox and ajar.

What kind of wood do you prefer for heating the fireplace?

As practice shows, it is better to use dry hard wood (maple, oak). They will give a steady and calm flame. Birch woods bring a lot of soot. And alder and aspen, on the contrary, will help to burn out soot from the chimney. You can read more about the types of firewood and their pros and cons in the article.

Readers will easily share their experience of giving the fire additional romantic attributes. So, to get a flame of a beautiful pattern, you can add chopped to the logs

In order for the house to feel a truly cozy atmosphere, you need to install fireplaces. Fireplaces are heating systems, like stoves, consisting of a firebox, chimney and cladding. There is a wide variety of fireplaces, but this article will focus on wood. Wood heating systems began to be made long ago, but today it is done with the help of modern technologies, which ensures a long service life and guarantees safety.

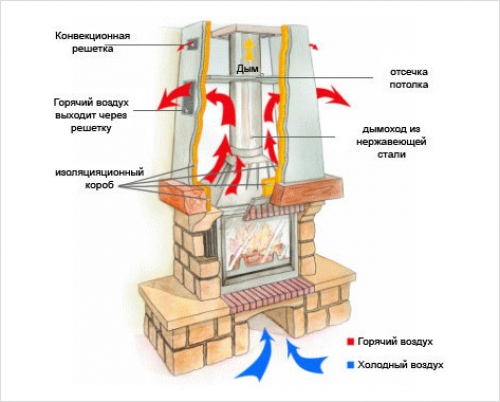

In general, wood-burning stoves can be divided into 2 types: heating systems with an open firebox, and those with a closed firebox. Furnaces with a closed firebox have a special device made of heat-resistant glass, which closes an open fire. Such stoves are recommended to be installed if there are small children or pets in the house.

Kinds

Wall mounted

This type of furnace is located right next to the wall, which is called the leaning wall. The chimney for such stoves can be erected by leaning it against a wall, or simply connect it with a chimney of another stove, if there is one in the room.

When constructing a wall fireplace, you should know that this type of stoves should take place right in the middle of the wall, while on both sides there should be a place of more than 2 meters. This is done for reasons of fire safety, as well as to make it convenient for guests to be placed near the stove.

If the wall to which the future heating system will lean against is erected from wood, then here it is necessary to observe a number of measures that will allow to avoid fire hazardous situations:

- That part of the wall to which the fireplace will lean against, it is necessary to sheathe steel sheet.

- Next you need to build a brick wall.

- Then take the felt, moisten it in a solution of clay, and put it on the wall.

- After that, you can proceed to the construction of the fireplace.

Angular

Nowadays, this species is considered one of the most common. It is located in the corner of the room. This type of stoves has gained such wide popularity due to the fact that it fits organically into the interior of the room, and the heat emanating from the fire is evenly distributed throughout the room.

Chairs with this arrangement of the furnace usually have a semicircle. The chimney is usually sent to one of the bearing walls. As the positive aspects of such a fireplace, the following characteristics can be noted:

- Small square. This type of stove takes up little space in the room.

- The embodiment of design ideas. Indeed, there are many options on the market for fire chambers designed specifically for corner furnaces.

Of the disadvantages, you can select only one:

- This type of furnace simultaneously adjoins two walls, so you have to isolate two walls at once, and this, in turn, draws additional costs.

By the way, speaking of the corner fireplaces, you should list the options of furnaces, which are designed specifically for this type:

- Shutter with partition. This type is a glass consisting of two parts. One of them is motionless, and the second can be opened and closed.

- Half round flap. This type is considered a classic option and ideally combined with corner stoves.

- Fireplace with two glasses.

Island

Representatives of this group are also called central furnaces. They are usually located in large rooms right in the center of the room. The smoke collector for such furnaces is located directly above the firebox, that is, on the ceiling. Such furnaces can be fenced on all sides, or not fenced at all.

To plan such a fireplace, you need to be under construction, since you need to decide exactly where the chimney will be located. This type also has its pros and cons, which will be discussed later.

So, the pros:

- Openness You can look at the flame and admire it from all sides.

- Heat transfer.The distribution of heat is the same in all directions.

- The lack of a strong foundation. Unlike other types of stoves, it is not necessary to build a strong foundation when erecting island stoves.

- Original appearance. Indeed, the fireplace, located right in the center of the room, is an original sight for the guests.

And now about the shortcomings:

- Lots of space. Unlike corner stoves, this type takes up a lot of space, so it is impossible to build such stoves in small rooms.

- Complexity. As already mentioned, the construction of island furnaces should be designed at the construction stage. But not every section of the ceiling can be installed smoke box, so in any case, it is recommended to consult with a specialist.

- Purpose The main function of such furnaces is not the heating of the room, but the decor. Therefore, even if the room has this type of heating system, you will have to heat the room in an additional way.

Built

Another name for this type of fireplace is end-to-end. Representatives of this group are built into the wall even during the construction of load-bearing walls.

The advantages are as follows:

- Saving space. These heating systems are built into one of the load-bearing walls, as a result of which a lot of space is saved.

- High efficiency. Heat output from these furnaces is quite high.

- Fire safety.

As for the minuses, only one can be singled out - the design must be carried out even in the process of building the bearing walls.

Advantages and disadvantages

Like any other device, a wood burning fireplace also has its positive and negative sides.

First, the advantages will be considered:

- Heating. Wood heating systems can heat a large room in a fairly short time.

- Cheap fuel. A wood burning fireplace works on wood, and today it is a relatively inexpensive type of fuel.

- Convection.Wood heating systems perfectly carry out the process of convection in the room.

- Flame. In a quiet atmosphere, you can sit by the fireplace and admire the beauty of the flame. Thanks to this quality, wood stoves have gained such wide popularity.

And now about the shortcomings:

- Extra bed.When operating wood fireplaces, you need to make room for firewood.

- Troubles. We will have to constantly take care of the cleanliness - to clean the ashes, etc.

- Limitations. Wood-burning stoves can be installed only in private or country houses. In the apartment to have a wood-burning fireplace is impossible.

Temperature

The burning temperature in the furnace of wood stoves is 800-900 degrees Celsius. The temperature of the outgoing smoke should not exceed 350 degrees Celsius.

Sometimes it is observed that the outgoing smoke has a temperature of about 1000 degrees. This is an alarm signal. This means that during the construction of the fireplace, some of the standards were not observed, or the fireplace is not operated properly. This happens because part of the flame falls on the chimney, as a result of which soot begins to burn.

Fireplace styles

There is a wide variety of styles of wood stoves, the main of which will be discussed below:

- Gothick style. Representatives of this style have a rather massive base and a narrow chimney, pointing straight up. The chimney can be fully or partially built into the wall.

- Renaissance style. Renaissance or Renaissance involves a return to ancient Roman architecture. Heating systems built in this style have various kinds of patterns, drawings, inscriptions on the walls. Smooth collector massive.

- Classicism style.Heating systems built on this style have clear geometric shapes on the surface, such as square, circle, rectangle, etc. Such heating systems are made of high-quality materials. Drawing various patterns and pictures is not allowed.

- Eclectic style. Heating systems built according to this style also have various artistic elements. But these elements are chosen in such a way that completely opposite and incompatible patterns can merge into a single whole.

- Rustic style. These heating systems are shaped like a large letter "D". Under the furnace are firewood. Above the firebox on a wooden shelf there are clocks, candles and other decor items.

Fireplace construction technology - step by step instructions

The construction of a wood-burning fireplace is a very time-consuming and responsible process, which must be approached very carefully. Next will be step by step instructions for those who decided to build a wood burning fireplace with their own hands.

- Layout. This stage involves planning on the following points:

- Location

- Dimensions.

- The shape of the chimney.

- Construction material.

- Height.

- Decoration Materials.

- Foundation construction. This stage includes several steps:

- First of all, you need to dig a pit. The dimensions of the pit should be about 10 cm more than the size of the fireplace. The depth should be about 40 cm.

- Then insulate the bottom of the pit. To do this, put a layer of rubble on the bottom and tamp.

- Now formwork is being constructed, the height of which should be just above the floor level.

- Stones are put into the formed dimple and poured with cement mortar on top.

- All this is poured with conventional plastic wrap and left for a period of 1 week, during which the foundation will get stronger.

- Erection of a pig-iron fire chamber. The fireplace is generally made of brick, but it is recommended to make a firebox of cast iron, as in this way it is possible to extend the service life and avoid complex arched brickwork. The outer walls are made of bricks, but from the inside they are covered with iron sheets. It should be noted that a small space should remain between the brick walls and the cast-iron sheets. This is done on the grounds that when heated, the cast iron expands, as a result of which it can simply break the walls.

- The construction of the chimney. First, in the ceiling it is necessary to make a hole of a certain diameter. Chimney can be built of brick, but you can buy ready. Finished chimneys have a special damper. Its main function is to prevent heat from escaping through the chimney while the fireplace is not in use. If the chimney is built of brick, the flap is mounted independently.

- The final stage. On this construction of the fireplace can be considered complete. It remains only to plaster and decorate the surface. But it already decides everyone, proceeding from the imaginations and possibilities.

Necessary tools and materials

Before proceeding to the construction of the furnace, you should make sure that the following tools and materials are available:

- Trowel. This tool resembles a miniature spatula and serves to apply a mortar.

- Hammer pickaxe. It is needed for cutting bricks.

- Level. This device is necessary to check the horizontal masonry.

- Plumb. This tool allows you to make the corners strictly vertical.

- Ruler. This tool is needed to verify the straightness of the masonry.

- Cement mortar. The solution can be prepared by yourself.

- First you need to mix the usual construction cement with sand in the ratio of 1: 8.

- Then to the resulting mass is added clay solution.

- Now all this mass is thoroughly mixed.

Important: in no case can not use the solution, which contains lumps. If this is observed, then the mass is not sufficiently mixed.

Cost of

If you look at the cost of wood-burning stoves, it should be noted that the wall and corner heating systems are cheaper. Their cost varies from 50,000 rubles to 110,000 rubles.

Island heating systems have a very high price, with an average price of 170,000 rubles. But the cost depends not only on the type of fireplace, but also on the type of lining, and on what materials were used in the manufacture.

Contemplation of the open fire never bored. The flame causes ambiguous feelings that have been asleep in a person for many years since the times when our ancestors spent winter evenings in front of the hearth. If the process of setting up a fireplace in a city apartment will create certain difficulties even for a professional craftsman, then the owners of country estates and cottages will have to create a wood fireplace with their own hands. But first you have to find out what kind of fireplaces are there, what functional load this structure carries in the interior, and what material is better to make a bet. And directly the construction technology can be found in our subsequent articles.

Wood fireplaces in the interior

Wood foci in private homes are different from gas and electric “brothers”, which help to create a special atmosphere in a heated room that is close in spirit to the natural warmth, with the help of which many generations of people were heated.

Distant relatives of wood-burning fireplaces served faithfully in the era of Tiberius, Nero and Caesar and warmed the desolate and gloomy halls of medieval palaces with their warmth. Fireplaces at the dawn of the Renaissance were transformed into stucco-decorated and glittering works of art.

Therefore, we can say with confidence that modern fireplaces are classic examples of the design of the interior space of a country house and are not inferior to other important design elements of their own value.

The wood fireplace will turn out to build with own hand if to follow certain rules. In apartments of typical high-rise buildings, it will be difficult to construct such a product, because it will be necessary to obtain permission to build a hearth.

This type of fireplace should be more accurately called solid fuel, not wood, because logs, lignite and hard coal, pellets (briquettes or pellets of compressed wood waste) and peat can be used as fuel. This fuel combines the high temperature of combustion, which is significantly higher than that produced when burning biofuel or gas.

Fireplace design

Wood fireplaces are ordinary stoves with an open firebox. The room is heated only with radiant heat energy. The heat, which gives the fireplace, reaches 10-20%, and the rest of the heat comes out through the pipe. Thus, a similar fireplace for home heating is not suitable, but it will be just the way to create comfort.

The length of the firebox itself should have a large width, but the fireplace should not be excessively deep, and its fencing (side and top) should expand towards the room. This design allows you to get from the fireplace as much heat transfer.

In the internal niche of the building, where the chimney will dock with the firebox, a protective threshold should be put, which has a knee-like shape. This design is needed to eliminate the risks of sparks that are generated during combustion and prevents the creation of air currents that lead to the emission of soot and smoke.

The width of this threshold should correspond to the dimensions of the smoke channel, and the protrusion must be made flush with the front wall of the pipe (a small protrusion of about 1-2 centimeters is allowed). The threshold design assumes the presence of an exclusively horizontal surface. It should not narrow the chimney pipe.

Fireplaces of this type with fireplaces are distinguished by a small burden, so they need to arrange the so-called sump shafts or caps for the accumulated carbon smoke. When you have a ready-made channel for the removal of smoke, you should buy the simplest model of the fireplace made of cast iron, which is realized through the installation of fuel cassettes.

If you heat your fireplace with coal or wood, then it should be equipped with a grate and ash pan to remove the ash. For active admission to the air furnace, the hearth is equipped with a blower. The final touch in the creation of the hearth is the installation with the protective purpose of a spark-arresting grid and the preparation of a wood basket and a set of tools for the fireplace.

Types of wood foci

All types of fireplaces that work with solid fuel, according to the generally accepted classification, differ in architectural design, installation place in the room and in the form of the furnace. According to their stylistic design, there are fireplace designs made in the style of "classicism", "high-tech", "modern" and "country".

Wood fireplaces of the classical type with a portal are made in the shape of the letter “P”. Granite, marble or talcchloride are commonly used to decorate such foci. In the form of decorations and ornaments used sculptural compositions and wrought metal products. Pockets made in the classical style, called the English.

Brick stoves of fireplaces in the "country-style" are characterized by unusual forms of the portal, which are made in the shape of the letter "D", and have a beam of wood on top. Different types of natural stone are used as decoration, it is best to take calcareous rocks.

Fireplaces, equipped in the style solution "modern", have smoother lines in the design and flexible forms of elements of decoration. Such products focus all attention on themselves and the cup, therefore they are the basis, not the subject of decor.

Wood-burning fireplaces of cutting-edge hi-tech style are made using modern materials - fireproof plastic materials, glass and steel. Often, television screens or waterfalls are “implanted” into such fireplaces.

According to the version of the installation is known the following classification. Closed fireplaces are usually installed during the construction of a dwelling house; the chimney channel is a part of the wall. Closed brick hearths have compact dimensions, and therefore occupy a small area in the room.

Semi-open models can be installed in the finished or under construction premises, a channel for smoke exhaust is attached to the wall. Wood-burning fireplaces of this type also take up little space. A kind of half-open type is an angular brick fireplace, which is able to heat two adjacent rooms at the same time.

Open fireplaces are the most exotic option for the location of a brick fireplace. Wood construction with an open hearth is placed in the middle of the room as a central element of the interior. The inconvenience of working with a similar design include large dimensions and high fire risk.

Material for wood burning fireplace

Wood fireplaces come in all shapes, different sizes, and are made from many materials. The price of wood fireplaces also varies. In private homes, fireplaces are often found in offices or living rooms. Mainly brick is used for their laying.

The main point of building a brick fireplace is the observance of the correct proportions between the depth and height of the firebox - one to two. At violation of the ratio of the fireplace will weakly give heat and smoke.

Many developers choose metal as the material for the future fireplace. These products began to be in demand with the advent of Hi-Tech industry. Such foci are currently manufactured by well-known companies and professional handicraftsmen of various designs and shapes. Metal fireplaces are made disassembling, which can be removed by the summer, and in the winter again to establish in place.

Pig-iron wood-burning fireplaces look extremely fashionable. Making a fireplace, they usually buy an ordinary cast-iron firebox, which is edged with a portal from a cast iron fireplace. Such fireplaces provide designers with the opportunity to display their creative abilities. For example, you can create a cast-iron fireplace with a back wall of glass and access to the street.

Thus, today, the fireplace is experiencing the peak of popularity among customers who want to see at their country house or in a country house a stylish hearth, which for centuries has been considered a symbol of home comfort, a place of atmosphere of peace and happiness. In addition, do not forget that the fireplace is a practical element of the interior, which will warm the home. How to build a fireplace? You can make it yourself without any problems; you only need to prepare in advance and study the process of building this structure. To do this, read the following articles on our website.

Probably everyone dreamed of sitting on a fireplace in his country house or in a country house on cold winter or autumn evenings, sipping hot chocolate, listening to the crackle of firewood and watching the fiery flames flicker. All this creates a special atmosphere of calm and comfort. Modern stove devices are considered not only a means of heating the room, but also a place of pleasant pastime and prestigious attribute of the interior.

Building a brick fireplace is not cheap, so many owners of a cottage or a country house prefer to build a fireplace with wood. Building a wood-burning fireplace with your own hands takes a long time and requires the craftsman much strength and perseverance. For a more visual representation of the construction of the heating device in the country or in a country house, you can see the many videos that available on the Internet.

If you weigh the pros and cons and are determined to build modern device in the country or in your country house you need to independently consider and properly think through each stage of construction.

Preparatory stages during construction

The choice of location - initially you should decide where in your country house or cottage will be located. The prerequisite here is the size of the room, in which will be a fireplace. The room must be spacious. Otherwise, there will not be enough air in the room, as the fireplace takes up most of the oxygen during the combustion process. Thus, in the process of long-burning furnace can lead to sad consequences. Details of the choice of the location of the furnace are described in the video.

You should also decide in which part of the room the building will be located. Brick fireplaces on the wood can be, or near the wall, and in the center of the room. It depends on the your preferences.

- Development of the project - when building a long-burning furnace in the country, it is necessary to make preliminary drawings of the device that will help in the future during construction. The drawings also need to paint the number necessary building materials.

- Type Definition - wood fireplaces for giving happen closed and open, attached, built-in and island. In a separate category includes fireplaces with a water heating circuit.

Closed furnaces have in which burning process occurs. Such boilers are called the base. The base can be made of brick or stone. In front of the fireplace is a glass door that allows you to watch the fire, without opening the firebox. The advantage of a closed type furnace is to save on fuel consumption and to keep oxygen in the room. Open type long burning stove with nothing outside does not close.

An island fireplace is more suitable for large spaces. For smaller spaces, a corner or built-in oven should be installed, which considered and more economical. Today are popular water circuit ovens. Such a device evenly distributes heat to all rooms, and the effect itself acts for a long time. Many argue that water heating the system is considered the best.

A distinctive feature of heating is a steel or cast iron heat exchanger, which is located in the zone of the combustion chamber. From the heat exchanger come two pipes: the lower one is connected to the reverse heating circuit, and the upper one with supply circuit heating. Inside the heat exchanger is the coolant water heating system. There are also differences in the design of the furnace. Water circuit device heated by wood.

Similarities and differences, the advantages of heating devices with a water heating circuit, as well as features of the work are shown in numerous videos on the Internet.

- The choice of materials for construction - the brick wood-burning fireplace is considered the most durable and reliable. When choosing a brick, you should decide on the one that can withstand high temperatures, formed in during long burning fuel.

Wood fireplaces with their own hands can also be built of concrete or stone. Such options will be more economical..

- Dimensioning - the facility must fit the size of the room. Before construction, it is necessary to calculate the dimensions between the width of the portal, the depth of the firebox and the height of the firebox. The firelighter should not be made very deep, otherwise it will be broken. fireplace heat output.

The progress of the construction of a wood fireplace

Having worked out all the nuances of building a long-burning furnace on the drawings, calculating its parameters and choosing materials, you can proceed to the most important thing - the construction of a wood-burning fireplace in your country house or cottage. Details of the construction can be seen on numerous videos in the network, ibid you can find ready-made drawings.

Having worked out all the nuances of building a long-burning furnace on the drawings, calculating its parameters and choosing materials, you can proceed to the most important thing - the construction of a wood-burning fireplace in your country house or cottage. Details of the construction can be seen on numerous videos in the network, ibid you can find ready-made drawings.

First you need to perform a long burning. Laying make of fire-resistant bricks. Pre-brick must be kept for at least a day in water solution.

After that, a pipe is laid out of bricks - a chimney: first the corners, then the outer walls, the latter are laid out by the inner walls. Be sure to the inside of the walls must be laid out metal refractory plates. Such a process called lining. With the features of masonry and fireplace order should be previewed on video. Next you will need skills in welding. Made of metals, pipe and stove.

It is necessary to follow all the rules for the construction of the furnace device. Despite, what type of stove will you choose: a traditional fireplace or a device with a water heating circuit, only if you meet the requirements, it will serve you and your home for a long time. Today, there are many video lessons on the construction of furnaces that will help you during construction.