How to make your own gas boiler. Advantages and disadvantages of gas heating. Placing the boiler in the garage

The idea of creating a home-made gas boiler is, in principle, interesting, although it has no practical implementation. Simply, no sane inspector responsible for the safe operation of gas-powered devices by citizens will give permission for its operation. And the neighbors will not be delighted with such unsafe experiments. Therefore, what's the point of doing something that will never be used for its intended purpose, that is, for heating. And if you really want to design a heating device with your own hands, you can start with simpler and less dangerous heating boilers operating, say, solid fuel. The more successful examples of the use of solid-fuel units, created by yourself, abound. And after a certain time, something may change, and it will be allowed to use home-made gas boilers for heating. Although, I would like to hope that this will not happen.

Options for heating boilers that you can do yourself

Leaving thoughts about the construction of a gas boiler alone, let's consider what types of units by the type of energy source are used, and which ones are worth the time and effort to try to successfully make their homemade counterpart. So, what types of energy sources, except gas, use heating boilers:

- electricity;

- some types of liquid fuels;

- solid fuel.

Now about the most common types of heating equipment in more detail.

Electric boilers

Today, manufacturers offer consumers three basic types of boilers powered by electricity:

- classical (Tenovy);

- induction;

- ionic (electrolysis).

It is advisable not to undertake the creation of an electrolysis boiler with your own hands, but home-made models of electric boilers with thermoelectric heaters and to do induction heating with your own hands is quite real. Of course, for this you need to have the necessary set of tools, materials and knowledge of the laws by which electricity operates.

The easiest way to do it. The self-made electric boiler is likely to lose in many respects to modern samples of this type of factory production, but you can try, especially with a strong desire to create a boiler with your own hands.

How does a classic electric boiler with a thermoelectric heater? In fact, it is a metal container, hermetically connected on one side to the return of the heating system, and on the other to the hot line of the heating circuit. Inside the tank is placed an electric heater connected to the mains through an interrupter of a more or less complex structure. This is the simplest model of a TEN boiler, which is quite realistic to do with your own hands. If an improvised child successfully passes the first tests, it can be improved to the extent that it is equipped with automatics.

Make it harder, but quite realistic. What is its basis? These are the main details:

- induction coil, which you can get anywhere (remove from your electric motors, for example);

- core; a thick steel or copper rod will be suitable as an improvised version;

- cylindrical housing;

- insulating materials;

- electric current converter (welding inverter).

The device and the principle of operation are simple. Inside the case there is a coil insulated on both sides, connected by conductors to a welding machine. In the middle is the core. When the potential difference is applied to the coil winding, inward electromagnetic vortices arise, quickly heating the steel rod.

If the inlet and outlet for the heat carrier are made from the ends of the cylindrical body, the homemade basic model of the induction type boiler will be ready. Circulating coolant will cool the core, while heating itself.

Ways to build electric boilers, given here are very schematic. More detailed descriptions along with the drawings will be found in large numbers and diversity in the vast world wide web. The only thing you should not forget about, if you still have an overwhelming desire to make an electric boiler with your own hands, this is a safety precaution when working with electric current.

Solid fuel boilers

Now, many citizens, in order to reduce the cost of heating their homes, are returning to the use of boilers operating on various types of solid fuels. In addition to traditional coal and firewood, today pellets, fuel briquettes from peat and wood waste are produced, which are also used in solid fuel boilers as sources of thermal energy.

To minimize the costs associated with heating, many craftsmen create solid fuel boilers with their own hands, so as not to buy expensive factory-made equipment. Serial manufacturers today offer a wide variety of solid-fuel units, such as:

- classic (grate);

- pyrolysis;

- long burning;

- with automatic fuel supply (pellet).

The last three types of boilers have a very complex structure and automation of some processes. Although there are attempts to create such installations in artisanal conditions, they usually do not stand up to scrutiny. But to make a classic water-heating unit with your own hands is quite within the power of many home craftsmen who possess welding skills even in a garage or workshop.

Conclusion

It is clear the desire of homeowners to create home-made models of boilers for heating, because factory samples are not cheap. However, the pros and cons should also be weighed here. In any case, for the construction of homemade equipment will have to incur certain costs, including time. Isn't it better to spend time on finding additional income, which will allow you to quickly save up money for a modern factory model of a heating boiler. As for self-made gas units, it is better not to start this venture. It can cost too much.

How and what to choose a gas boiler

Despite the fact that gas prices are climbing up, the boilers in which it is used as fuel are still very indispensable. Now that most of the dacha plots are already gasified (if you are unlucky and you don’t enter a happy number of these, then see the article), many summer residents want to install a gas boiler for heating in turn already at home. Before you ask yourself the question of where to buy a gas boiler, using the following, try first to determine the choice of what you need.

1 CHOICE - CONVECTION OR CONDENSATION BOILER?

A convection gas boiler is a standard type of device that uses only the energy of combustion of fuel. The layout of these boilers is very simple and they are relatively cheap. The condensing boiler, due to its design, produces more heat at the outlet than it can in principle stand out when burning gas fuel. The so-called conditional efficiency (otherwise called fuel utilization) in such boilers can reach 110 percent. Condensation boilers use the heat of water vapor in flue gases, which are formed during combustion, and give extra energy to the heat carrier during the transition from a gaseous to a liquid state. This boiler has a more complicated device and is somewhat more expensive than the convection one, but its operating costs are lower, as gas consumption decreases by a quarter and sometimes by a third.

2 CHOICE - OPEN OR CLOSED CAMERA?

Boilers with an open combustion chamber (with a natural burden) take the air from the room in which they are located. In them, the traction does not depend on the power grid and they are cheap. When choosing such a boiler, take care of good ventilation of the room in which it will be installed, and provide the appropriate chimney in the house project

In boilers with a closed combustion chamber, combustion air is supplied and the combustion products are removed by force through a fan through a coaxial chimney (pipe in pipe). Such a device allows you to supply air from the room and from the street. Air is taken along one pipe, and combustion products are taken down the other, which makes it possible to mount the system more compactly. Also, such a boiler can be used in rooms that are not equipped with a stationary chimney. The disadvantage of this boiler is its energy consumption - electricity is needed to operate the fan.

3 CHOICE - WHAT MATERIAL HEAT EXCHANGER?

The heat exchanger is one of the important components of a gas boiler. It is a metal container in which the coolant is heated. In boilers it may differ in the materials of which it is made. In cheap models of mounted gas boilers, steel heat exchangers are often used, the main advantage of which is excellent plasticity. It is of fundamental importance, since the constant direct flame of the burner can cause thermal stresses, which can cause cracks in the heat exchanger. With steel models this will not happen. In addition, they are much lighter than similar cast iron. The minus of steel heat exchangers lies in their susceptibility to corrosion and, therefore, in a shorter service life. "Cast iron" more massive, heavy and much more expensive. They are sensitive to a large jump in temperature (thermal shock), but almost do not rust - the duration of their service may be more than 50 years. Copper heat exchangers, which are used for compact wall-mounted boilers, are lightweight and practically stainless. Most units can be removed from the boiler and cleaned as they are used. But such heat exchangers are considered the most expensive. They require special attention to the operation, because when water leaks burn through faster.

4 CHOICE - WALL OR FLOOR BOILER?

Installing a boiler in a house is related to its qualities and characteristics, such as weight (it is most dependent on the heat exchanger material) and power.

Power and those and others starts from 18 kilowatts.

Floor-standing boilers can have a capacity of up to hundreds of kW or more, and wall boilers, usually 32 kW.

The wall-mounted boiler is usually lighter, more compact and cheaper than the floor-mounted one, but it is not equipped with a cast-iron heat exchanger or an external burner.

Therefore, boilers that use 2 types of fuel (diesel and natural gas) are produced only in the floor solution. Most often floor models are designed for heating houses ranging from 400 meters. So if you are the owner of a cottage with a large area (from 100 to 300 m2), then the wall boiler will suit you best.

5 CHOICE - SINGLE-ORGANIZED OR DOUBLE-CIRCUIT BOIL?

Single-circuit boiler easier and cheaper. But it is suitable only for heating, and you will not receive hot water when using it. The double-circuit boiler has 2 heat exchangers, which are used for both heating and water heating. Therefore, it is possible to solve 2 problems at once. Most of these boilers are made on the principle of the superiority of hot water. This means that when the flow of hot water is turned on, the coolant does not heat up. Therefore, in order to level the fluctuations in the temperature of the coolant, we recommend installing a heat accumulator.

If you already have an electric boiler for heating water, you do not need to install a double-circuit boiler, one-circuit is enough. Using gas, water heating will certainly be cheaper, but installing a double-circuit boiler will require reworking the existing pipeline system.

6 CHOICE - SINGLE-ACCESSOR OR TWO-SPEED BOILER?

Gas boilers can be either single-stage, with one power level, or two-stage, with 2 levels, as well as with modulation (continuously adjustable) power. When choosing a boiler for this characteristic, keep in mind that you will need its full power only in the cold, the rest of the time you can get by with a boiler and lower power. On the other hand, choosing a boiler with less power, it will be possible to find that the temperature in the house in the cold will not be comfortable enough. Therefore, it is more appropriate to consider the option of acquiring a two-stage boiler. It has the following advantages:

Increase the life by reducing the on and off cycles;

Work on the first stage with reduced power and a moderate number of inclusions and shutdowns will save gas, and hence finances;

Less flue gas and toxic substances released to the environment.

7 CHOICE - BOILER FORCED OR NATURAL CIRCULATION?

In units with natural circulation, the heated coolant goes to the radiators by gravity under the influence of a drop in density. Units with forced circulation (coolant supplied by an electric pump) consume 10-15% less gas and better support the thermal regime. Some types of boilers, such as condensation and mounted, have only a forced form of circulation. For heating cottages with an area of more than 100 m2, you should choose this type of boiler.

Installation of a boiler with natural circulation will cost more and will require the use of large-section pipes that may not fit the interior of your home.

Nuances when choosing:

- The boiler with a closed chamber uses the air from the street, which is charged through a special pipe by a fan.

- The boiler with an open combustion chamber takes the air from the room.

- Floor boilers are usually more powerful and are installed in large houses.

- Floor gas boilers are large enough, so they are better to install in the basement.

- The most practical material for the heat exchanger is stainless steel.

Modern gas boiler - what is it?

Connecting a house to the gas mains saves the owners from solving problems with heating and hot water supply of the home. In addition, modern gas boilers can significantly save on the consumption of blue fuel.

Power is the main criterion when choosing a gas boiler (as, incidentally, a boiler unit of another type). But the questions about the future heat generator in the house do not end there. Gas boilers are wall and floor, convection and condensation, single and double circuit (that is, working on heating and hot water). Which unit to purchase depends on the specific situation and personal preferences of the owners, as well as on their financial capabilities. Be that as it may, when choosing a boiler one should be guided not by short-term profit, but by weighty dividends in the future, that is, be guided by efficiency, economy and simplicity of maintenance of the boiler equipment.

Owners of country houses who plan to install a boiler in the kitchen should know that, according to Russian standards, the power of the unit should not exceed 35 kW. If according to calculations the cottage needs more powerful heating equipment, then the boiler should be in a special room with an area of at least 6 m2 with a ceiling height of at least 2.5 m, that is, the volume should be at least 15 m2. When installing a powerful condensing boiler, safe disposal of acid-containing condensate should be considered.

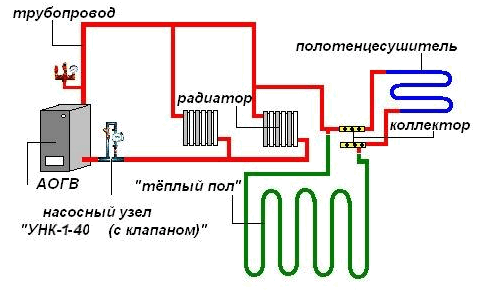

Parts of a whole

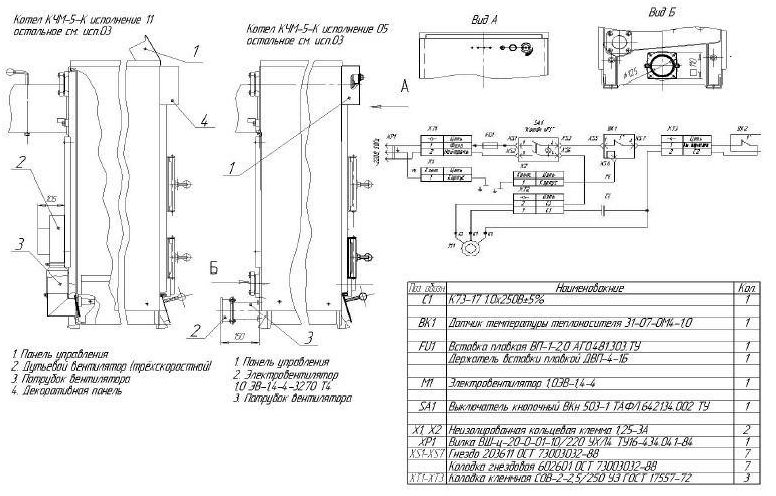

Schematically, the device of a gas boiler can be described in two sentences. Natural gas enters the combustion chamber, or rather the burner - the most important working element of the unit. When burning blue fuel, hot gases are generated, which heat the heat exchanger filled with coolant (water or antifreeze). Next, the heated fluid through the heating pipe rushes to the radiators or water-heated floors.

Performance and to some extent the cost of the boiler depends on the type of burner. In the basic set of boiler equipment usually

simple, reliable, compact, silent and inexpensive atmospheric burners are included. In most models, there is a transition to more efficient fan (pressurized) devices (air is blown into the combustion chamber by a fan). These burners burn gas without residue, fuel is rationally consumed, which increases the efficiency of the boiler. But they are quite noisy and are more expensive than atmospheric counterparts.

Regulation of the flame allows you to change the temperature of the coolant without turning off the boiler. But this “trick” was trained only by “advanced” modulated burners, the combustion of which is controlled smoothly, which has a positive effect on the service life of the unit (by reducing the on and off cycles) and provides almost 15 percent fuel economy.

Off the ground

Modern wall-mounted boilers are optimally suited for heating small cottages. Such units are essentially a mini-boiler room - in addition to the heat generator itself, there are components of the hydraulic piping: a circulation pump, an expansion tank, make-up valves, automatic control devices, temperature sensors, safety devices, and so on. No special room required. The unit is often placed in the kitchen - flush with cupboards for dishes. But it happens that the boiler is mounted in a spacious bathroom or hallway. The latest generation models feature an elegant design. These machines fit perfectly into the modern interior. The class of wall equipment includes both single-circuit and double-circuit units. The second option is great for winter cottages and houses with three to five points of water intake. Double-circuit boilers not only heat the building, but also perform the function of a kind of gas column (equipped with a built-in instantaneous water heater). However, with a large consumption of hot water, it is better to install a single-circuit unit plus a boiler (storage water heater) indirect heating, working from a heat exchanger of the boiler unit.

Power show

In homes with an area of more than 300 m 2 install floor gas boilers. Outdoor units are famous for their reliability and very decent performance. Sometimes such heat generators are blamed for massiveness and heaviness. However, this judgment is only partly true. Modern floor boilers have compact dimensions and do not take up much space.

A relatively large mass of "napolnik" are required to the cast-iron heat exchanger - an important technical "chip" of units of this class. The fact is that in the production of models of the last generation, special eutectic cast iron is used. This metal is durable, homogeneous (has no internal cavities and other defects), resistant to all types of corrosion.

Eutectic cast iron withstands large and sharp temperature drops, which is very important for successful operation of the boiler (pouring ice water certainly will not cause cracking). The high heat capacity of the metal was involved 8 goals of energy efficiency and resource savings. Heat exchangers of a special design are made from “advanced” cast iron - three-pass channels for the passage of hot gases with an optimal configuration of heat transfer fins. The result is a decrease in the heating temperature of the coolant. Such heat generators are also called low-temperature. That is, the water in the boiler heats up to 60-70 DC (in a traditional unit up to 95 ° C), and when entering from the return pipe it cools to 40-50 ° C. This reduces the workload on the equipment, reduces fuel consumption and reduces the amount of harmful emissions into the atmosphere (nitrogen oxides, etc.). And, of course, the performance of the unit is improved.

skim the cream

Exhaust gases carry with them not only numerous oxides, but also thermal energy. Save each calorie allow condensing boilers. In such units, heat is collected, which is released during condensation of water vapor contained in the smoke (just like in an air conditioner, but with the opposite effect). At the same time, the cooled and purified waste gas goes outside, that is, it is solved

urgent problem of environmental safety of boiler equipment. However, when planning the installation of a condensing boiler, you need to think out a scheme for removing acid-containing condensate (water dissolves oxide compounds). The volume of "caustic" water turns out decent. Judge for yourself. During the combustion of 1 me gas, 9 m3 of air is consumed, resulting in the formation of 2 m3 of water vapor, upon condensation of which 1.6 liters of liquid are formed. A boiler with a power of 40-45 kW consumes 4-5 m3 / h. It is easy to calculate that in an hour more than 6 liters of condensate will flow out of the unit, which cannot be discharged into the sewer system so simply. Fortunately, many models focused on the private consumer, have a system of neutralization and removal of condensation moisture. Technical details can be obtained from the representatives of the manufacturing company (authorized dealers, etc.). The main thing is to specify in advance the key points of proper installation of the equipment.

Solid increase

The heat of condensation significantly increases the efficiency of heating equipment. Here you need to clarify. The efficiency of convection (traditional) boilers is determined by the so-called lower calorific value, that is, the amount of heat generated during complete combustion of the fuel and the subsequent cooling of the combustion products to standard conditions. Efficiency is taken as the ratio of useful heat energy, providing heating and hot water supply and heat of combustion (lower heat). For convection boilers, this figure is 90-93%. The efficiency of condensation units is determined by the highest heat, that is, taking into account the condensation of water vapor (efficiency - 94-98%). But in promotional materials often appear outrageous values in 104-107 and even 111%. And this is quite a reasonable explanation.

In order to compare two types of boiler equipment, the efficiency is calculated according to the same method - according to the lower heat. To the received indicator add percent from heat of condensation and pass for 100% abroad. You can differently related to similar marketing techniques. One thing is clear - condensing boilers are more efficient than convection units. The line of equipment of this class includes wall models with a capacity of up to 60 kW, which is of particular importance for owners of country houses, in which every square centimeter is counted.

The boilers are supplied with built-in thermostats that control the water temperature set by the consumer, as well as the maximum temperature that can trigger an emergency situation.

The room thermostat switches off the boiler burner when a comfortable temperature is reached. But in this case, the system filled with hot water continues to give off heat, and the room warms up to a temperature above the set point.

Increasing the temperature by 2 ° C leads to an over-consumption of fuel by 6%. Synchronize the process allows regulators of smooth action, working with modulated burners.

If the boiler is equipped with a simple single-stage burner, it makes sense to install a programmer, that is, a room controller, which contains various programs that regulate the operation of the boiler (lowering the temperature at night and in the absence of the owners, etc.). The greatest economic effect is achieved when installing integrated automation - a programmer plus a weather-dependent thermostat (its sensor monitors the weather outside). In this case, heating costs are reduced by almost 30%. In a house with underfloor heating, it makes sense to install a wireless collector control system that provides a comfortable mode in the house, and it is customized to the daily schedule and personal preferences of the hosts (Smatrix Retrofit system from Uponor).

the calculation of the required power of the boiler, the consumer can make independently

If you have a compact house with well-insulated walls, then to determine the power of the heat generator, use a simple formula: 1 kW of thermal energy per 10 m7 of area which is suitable for both single-circuit and double-circuit units.

In the second case, the automatism of the boiler is adjusted to the priority of the hot water supply system, that is, as soon as the hot water tap is turned on, the heating medium heating in the heating circuit is suspended. Ш However, the owners of houses of decent size and complex architecture - with panoramic windows, high ceilings and second lights, bay windows, warm balconies and that - should act according to the instructions of professionally executed project documentation (the section of heat supply is included in the general project package of the house).

OUR ADVICE:

The power of the boiler should be determined on the basis of the calculation of the actual heat demand of the house.

If you are guided by rough estimates, it is easy to make a mistake and choose the wrong unit at all.

Low-power boiler in the system will not be able to maintain a comfortable temperature at home.

Excess capacity also creates problems. At low load, the boiler operates in the “stop start” mode.

Gas boiler: operating rules

With the approach of winter, many people are thinking about how to heat a house, properly start equipment that has been preserved for the summer, or which heater to buy. Numerous questions on the operation of gas boilers were answered by the specialists of the "Rusklimat"

The main mistakes when using a gas boiler

Most of the possible problems associated with poor-quality installation of equipment and the first launch. It is impossibletrying to save money, trust installation to specialists without sufficient knowledge, who do not know regulatory requirements and have not undergone specialized training from equipment manufacturers. The first boiler start is allowed only to a technician.(engineer) authorized service center. He will check the correct installation of the entire system:

- connection of HVS and HWS hydraulic systems, heating systems to the boiler;

- the presence of filter-mud filters and the necessary shut-off valves on the connection pipelines. Does calculations and checks:

- cold-water pressure in front of the boiler, in the heating system and compare the data characteristics of the boiler;

- conformity of the quality of cold water and coolant to the requirements of the manufacturer:

- power quality of the boiler and its compliance with the requirements of the ROM;

- correctness of installation of smoke exhaust systems and air ducts, their maximum permissible lengths and diameters;

- flow exhaust ventilation system;

- correct installation and tightness of the pipeline.

If there are no comments, the engineer will proceed to the procedure itself, which includes various checks and settings of the boiler control systems, adjusts its automation, and customer needs, taking into account various factors: the heat output of the building, the type of heating system, the area of heated premises, etc. d.

The second most important problem is the neglect of annual maintenance, because of which, after a while, various failures begin to occur. This may be due to the pollution of the combustion chamber, the fan-removal fan in boilers with a closed combustion chamber, the formation of soot on the ignition electrodes and other natural contaminants arising during operation. If you call a service engineer and fix such problems in a timely manner, the equipment will last a long time.

Work before start

What to do before the heating season, if the house already has a heating system, which in addition to the boiler includes heating devices, supply pipes, stop valves, smoke removal system?

Diagnostics, setting up and first start-up of the boiler must be entrusted to qualified professionals, the rest can be checked and prepared for the upcoming cold weather on your own.

Before starting it is necessary to check the heating system for tightness - whether there are any smudges in the joints, to recheck the shut-off and control valves, to remove and wash the mud filters on the cold water supply and the reverse supply of the heating system, to check the operation of the voltage regulator and the boiler grounding. It is also necessary to check that in the smoke removal system of the bird there are no BARS nests.

When starting the boiler on its own with a closed heating system, it is necessary to make sure that the pressure in the heating system is within the range allowed by the manufacturer. If the pressure drops during equipment downtime, it is necessary to feed the boiler (add heat carrier to the heating system to the appropriate starting pressure), not forgetting to open the Mayevsky valves to remove air. Modern boilers have automatics that independently monitor the state of the boiler. If necessary, informs about possible errors in the operation of the equipment, and subject to annual maintenance, it will work for many years.

Setting up a modern boiler with an electronic control unit, connecting smoke removal systems and any repairs should be carried out only by service organizations. By law, gas equipment can only be repaired by persons authorized to work with gas! The boiler must be serviced annually.

What to do if there is no boiler yet

First you need to determine whether you need a boiler: only for heating or for heating hot water. Choose a model - single or dual circuit. Understand what area, taking into account future extensions, is planned to be heated, where it is planned to divert combustion products, how the boiler should behave in your absence.

Recently, wall gas boilers are very popular. They are a small boiler room - finished) product, which during installation and first start-up must be adapted to a specific heating system. To calculate the power of the heating boiler, use the proportion: 1 kW of power per 10 m 2 of area. With the calculation of power for heating water, you need to consider the number of consumers and points of water intake.

Approximately, to wash the dishes, you need 6-7 liters of hot water per minute, and 11-12 for a shower. There are models on the market that produce up to 20 l / min. Pay attention to the heating rate of hot water supply and the technology by which the boiler runs silently. By the way, the built-in programmer will help to significantly save on energy resources (when you are not there, the boiler automatically lowers the temperature, saving gas).

When choosing smoke removal systems and ensuring the air flow to the boiler, pay attention to the warmed coaxial kits. They have proven themselves at low temperatures: they prevent condensate from icing up and guarantee stable operation of the boiler even at -50 ° C. If the length of the flue pipe is more than 5 m, a heated separate system can also be used, which will also prevent the formation of condensate inside the room.

The choice of boiler equipment entrust professionals. They will make the calculation, will recommend the equipment, will make the project and will ensure the launch of the equipment.

Choosing a coolant for heating systems ...

Approved by an expert

Many people are increasingly thinking about switching to independent heating. In this case, the entire system will cost a large sum. A good alternative is homemade gas boiler. At first glance, such a task may seem overwhelming. But if you look at it, it can be done by people who have experience in installing, repairing and operating gas equipment. Only such professionals can afford to do exactly what the owner needs, and also significantly reduce the cost of purchasing equipment.

There are lots of instructions on how to make a boiler for heating on different types of fuel: solid, liquid, electricity and others. But to build such a structure on gas is not solved by many. The main problem is that the installation will need to be connected only after agreement with the relevant authorities. But first things first.

So, first you need to understand that you can use such a heating unit only at your own risk, the responsibility for the consequences, which can be disastrous, falls entirely on the shoulders of the homeowner.

After realizing this, you need to find suitable drawings. It is desirable that they were described in detail about the boilers of heating, connection, cooling, chimney, baffle and other important points. The master must understand this documentation in full, because even one change will adversely affect operation in the future. It is advisable to see a few photos of ready-made systems. This will help to "assemble the unit in my head."

After that, you need to calculate the amount of all materials per boiler. It should be understood that in no case should the specified metal be replaced by another to reduce the cost of construction, because it can be soft, which will quickly lead to the installation becoming unusable. Then purchase blanks, as well as already assembled individual components (buttons, deflector, cranes, etc.).

It is also important to have your own tool, which is needed for joining metal sheets, their cutting and grinding. You also need to have a soldering iron, a set of screwdrivers and keys, hammers and all sorts of other tools that allow you to work with metal and electrical circuits.

What to do?

When all the necessary components for the process are assembled, you can take the first steps to create heating with your own hands. Thus, according to the drawings, sheets are cut out, tubes, angles, and internal parts are prepared. It should be noted that some components do not have to be created independently. For example, a deflector that will be easier to buy and put on the end of the chimney.

After that, you can start the assembly according to the drawings. In no case can not hurry. It is important to understand that misplaced components can simply lead to device malfunction. It is advisable to even watch the video, which will be told the main points.

After everything is connected to a single system, you need to clean the edges well and paint the unit. This is necessary because during operation in cold weather condensate will appear, and the uncoated metal will simply start to rust.

What's next?

We must immediately say that for a gas boiler there are a number of requirements. For example, you must have a special exhaust gas outlet, which will be on top of the deflector. In addition, everything should be perfectly connected. In other words, it is prohibited to use heating systems operating on this type of fuel at the legislative level without the necessary checks and obtaining relevant documentation. Therefore, before you install a gas boiler, created by yourself, you need to call a specialist involved in the above.

The fact is that such equipment relates to devices that have an increased risk. And it is necessary to get permission for installation in the service dealing with gas for the boiler created by yourself. And she, in turn, must provide a certificate for the product, moreover, the original, not a copy or photo.

You need to understand that getting such paper is not easy, and most often it costs a large amount of money. In addition, the minimum deviation from all prescribed standards leads to a complete ban on the use of improvised installations. This is a strong argument in favor of the fact that the manufacture of a gas boiler with its own hands can only be done by a person who has extensive experience in the installation and maintenance of such units. This refers to the assembly and assembly of the system from separate units, each of which is manufactured in compliance with GOST, and the use of parts made by hand is minimized and is permissible only in non-critical areas.

When all moments with the relevant services are settled, the boiler can be installed. Unfortunately, there are rare cases where homeowners manage to do this without coordination with the technical oversight bodies, which is a gross violation of the law and is fraught with unpredictable consequences.

Calculations for a homemade gas heating boiler

Gas boilers with their own hands need to do, just to calculate everything. If this is done correctly, the equipment will save the owner not only one-time costs, but also maintenance.

It is necessary to make the unit, taking into account the heat loss in each room where heating will be carried out. It should be understood that even if the rooms are the same, the heat transfer in each will be different. It is best to carry out the calculations with a small margin. In this case, the layout of the room will not work, it is better to build on the actual size. It is important to check everything several times in order to precisely exclude the possibility of an error, because it can lead to fuel overspending and increased costs in the future.

In order for self-made gas boilers to work as expected, you need:

- calculate the entire hydraulic system;

- consider the costs of the chimney, including the deflector;

- pre-determine the diameter of the pipe;

- set the required pump power;

- and calculate the resistance of the system.

If everything is calculated correctly, there should not be any failures.

Many people think about creating autonomous heating with their own hands. This is mainly due to the price of boilers. There is a mass of drawings, which indicate how to do everything yourself. But in the case of gas equipment, you need to remember that all of it must undergo mandatory certification.

Gas is one of the most popular sources for home heating. And if the housing is located in close proximity to the gas pipeline, the device for gas heating the house is the best option.

Before introducing a heating system, it is necessary to take into account many factors and carry out all the procedures in the correct sequence:

- develop project documentation and obtain permission;

- purchase appropriate materials and equipment;

- carry out the installation of all elements of the system;

- check its performance;

- start up heating.

In addition, attention should be paid to the following nuances:

- installed equipment capacity;

- technical characteristics of radiators;

- availability of swimming pools, jacuzzi and other structures;

- the possibility of combining with additional elements (water heating, "warm floor").

All calculations are carried out at the design stage. To select a more suitable heating method, the following are also taken into account:

- dimensions of the house;

- structural features of the roof;

- wall thickness;

- the presence of thermal insulation materials.

Based on all this information, the choice is made:

- boiler;

- pipes;

- radiators;

- wiring type;

- the direction of movement of the coolant;

- quantities of household appliances.

Among the advantages of gas heating should be noted:

- availability of automatic temperature control;

- silent operation;

- no waste;

- cleanliness in the house;

- minimally occupied room space;

- possibility of arbitrary installation of heating communications;

- affordable cost.

The only thing to consider when installing gas heating is the explosiveness of the fuel. Therefore, it is necessary to observe a number of requirements concerning the placement of equipment:

- The source of heat generation (boiler) is preferably located in a separate room (boiler room).

- The room should be ventilated and have a spare entrance from the street.

- The optimal dimensions of the boiler room are: minimum height - 2.5 m, area - 4-8 m².

- The minimum width of the entrance door is 0.8 m.

- The material from which the boiler room is being built must be non-combustible. The brick room is plastered and covered with water-based paint. The wooden room is sheathed with asbestos sheets with a thickness of 3 mm or roofing steel.

- The distance from the boiler to the walls should be between 30-50 cm.

- The chimney has a small number of bends and is 0.5 meters higher than the ridge.

- Do not install the boiler in the basement.

Boiler selection

If a country house is characterized by a sufficiently large area or a complex configuration of rooms and corridors that impede the free movement of heated air, then the most appropriate solution would be to install a heating boiler.

Gas heating boilers are:

- floor and wall;

- c pig-iron and steel heat exchangers;

- single and dual;

- with electric ignition or piezoelectric element;

- with fan and atmospheric burner;

- with the natural and forced movement of the coolant;

- with closed and open combustion chamber.

Now on sale there are various heating boilers. It is worth noting that the equipment of foreign manufacturers is designed for a nominal pressure in the gas pipeline, which is in the range of 18-20 mbar.

A decrease in pressure can lead to negative consequences, as a result of which, on cold winter days, it is possible to remain without heat. It happens that in normal conditions the boiler can heat a room up to 300 m², and if the pressure drops, effective heating will be reached on an area of only 150 m².

Wall and floor equipment

To install a modern wall boiler does not need a separate room. Thanks to the horizontal coaxial tube, the boiler elements can be brought out through any of the walls of the house. The boiler itself can be placed in a convenient place where it will not disturb anyone. The only caveat is that it is recommended to purchase wall equipment with a capacity of up to 24 kW.

Installation of floor boiler, it is desirable to carry out in the back room. Be sure to construct a concrete stand (you can use asbestos blocks). The contact points of the gas equipment elements with the surface are sealed with a solution of clay, which will prevent the occurrence of cracks.

Heat exchanger

The material for the manufacture of the heat exchanger can be:

- cast iron;

- steel.

Cast iron products are quite heavy. They need to be very carefully transported and installed. But cast iron heat exchangers have an undoubted "plus" - they almost do not corrode.

For this reason, the operating period of the cast iron heat exchanger is about 50 years. That exceeds the service life of steel products more than 3 times (15 years). This difference is due to the fact that steel heat exchangers are not resistant to corrosion.

The occurrence of corrosion in gas equipment is associated with:

- the presence of air in the coolant;

- the appearance of condensate, which during cooling settles on the steel walls.

Boiler contour

When choosing equipment for this criterion, the following are taken into account. If there is no need to consume hot water, then a gas boiler is purchased for heating a single-circuit house.

But in modern conditions it is difficult to imagine comfortable living in a house without hot water supply. Naturally, the best option (although more expensive) would be to purchase a gas boiler, which has two circuits.

Burner, ignition method and power

The gas pressure in the main pipelines is subject to sharp drops, and in winter it can even drop to 13 mbar. This is fraught with a decrease in the flame in the burner, which causes it to quickly burn out. For this reason, the best option would be to use a boiler equipped with a fan burner.

As for the method of ignition, the main criterion for selection is the need for gas savings. Electric ignition method will significantly reduce gas consumption. Switching the boiler on and off is automatic. But there is one caveat - when there is a power outage, there is a high probability of being left without hot water and heating.

If ignition is carried out using a piezoelectric element, the gas consumption will be slightly higher. This is explained by the fact that a small igniter is constantly burning in the boiler, waiting for the heating of hot water or the heating system to turn on.

As for the power of the boiler, its optimal value is determined on the basis of the area of the heated room. On average, for heating 10 m² of housing will require 1 kW of energy. In the presence of ceilings with a height of over 3 m, the power of the boiler should be twice as large. Also note that ¼ part of the power goes to water heating.

Automatic system

The greatest problem of gas heating is a high probability of fuel leakage. The causes of this phenomenon may be different:

- a sharp decrease in pressure in the pipeline;

- involuntary attenuation of the burner or igniter;

- poor traction in the chimney;

- power failure

All these factors (with the exception of the latter) are difficult to identify manually. To identify the problems of gas heating are various automatic devices:

- sensors that control the force of the torch and the flame level of the burner;

- a device that stops the operation of the boiler during a power outage;

- sensor monitoring the coolant level in the heating system;

- a device that blocks the boiler with a sharp drop in pressure in the pipeline;

- descaling and diagnostic systems;

- safety valve for the heating circuit;

- appliances that protect the boiler from freezing.

Due to the explosion hazard of gas equipment, it is necessary to acquire only such a boiler, which is equipped with automatic equipment that diagnoses any non-standard situation. Among the innovative developments that will make the work of the boiler safer, mention should be made of the programmers. Thanks to this new product, the owner of the house will see all the faults of the heating boiler on the digital display.

Assembly work

To install the elements of gas heating at home with your own hands, you must obtain permits. Only after visiting the relevant services (BTI, fire and gas supervision) proceed to the installation work.

Fastening of the boiler is carried out on the slats. Installation height is 0.9-1.5 m from the floor. The wall where the equipment will be located should be flat and durable. If it is made of combustible material, it is protected from the boiler with a heat-resistant gasket up to 3 mm thick. Fixing the boiler progresses so that there is a distance of 4-5 cm between it and the wall.

At the next stage, the boiler is connected to the gas pipeline:

- the boiler nozzle is connected to the gas pipe element where the valve with the valve is located;

- a filter is mounted on the crane, which will regulate the flow of fuel and protect the system from debris;

- the joints of the elements of the boiler with the gas pipeline are sealed with paint or tow;

- filters are mounted with a flexible connection (do not use rubber hoses that dry up and crack over time);

- with the help of flare nuts and paronit gaskets, the connections and the hose are connected.

It should be noted that only a metal pipe is used to connect the boiler to the gas pipeline. To achieve the maximum hard connection, it is recommended to use the "American" or special sgonom.

- The main distinctive feature is the use of pipes of different diameters and different taps (as compared to connecting the boiler to the heating system).

- Cold water distributing provides for the presence of strainers that prevent clogging of the gas boiler.

- To shut off the water supply, install valves that have detachable connections. It is necessary for easy replacement of the crane in case of its failure.

- Before connecting the boiler to the water supply pipe, protective plugs are removed from the pipes. The pipes themselves are arranged in this way: on the left - for cold water, on the right - for hot water supply.

In the process of installing equipment for home heating, the following rules should be followed:

- observance of a small slope of pipes;

- prevention of narrowing of the elements of the input / output on the boiler;

- a device for draining the coolant between the boiler and the riser;

- all types of expansion tanks and radiators must comply with the standards for the use of coolant;

- installation of the expansion tank is carried out at the highest point;

- the separation of all elements of the heating system taps;

- the boiler must provide efficient heating of the entire area.

After installation, the heating system is filled with coolant. There should be no air in the boiler, which can cause ignition or disruption of the working cycle. To prevent the formation of air "pillows", the filling system is carried out from the bottom up.

At the final stage, the equipment quality check is carried out. As a result, correctly performed installation work should not be:

- gas emissions;

- water flow;

- distortions of a copper in the vertical and horizontal planes.

It is clear that the presence of a leak is determined by visual means. To detect the leakage of gas, you should use a soap solution that moisten the pipes. If after some time there are no air bubbles, then the communications are connected qualitatively. Only after a thorough check of the quality of the work performed is the final launch of the heating system.

Nuances of the chimney device

Installation of the boiler is accompanied by the mandatory device effective chimney. This process is carried out after the purchase of a gas boiler, since the size of the chimney is directly dependent on the size of the equipment.

The size of the useful section of the pipe (the length of the chimney multiplied by the inner perimeter of the pipe) must exceed the internal area of the boiler. If the chimney dimensions are smaller than the boiler area, then it is necessary to increase the length of the pipe.

When constructing a chimney, the following requirements should be considered:

- There should be no branches larger than 1 m, and the number of bends or knees should not exceed three units.

- Some elements of the chimney are installed at an angle of not more than 30º.

- In cross sections there should be no tapering areas and ledges.

- Rotation points of the chimney are equipped with a hatch through which the removal of condensate.

- The absence of gaps between the individual parts of the chimney.

- The inner side of the pipe should be without rough edges.

- When installing the horizontal parts of the chimney, their length is in the range from 3 to 6 m.

- Tight pipe connection.

- Lack of the bending elements and connections in places of contact with a roof.

- Warming of pipes at their placement in not heated places.

Coaxial tubes

There is an option when it is not necessary to equip the chimney to connect the gas boiler for removal of combustion products. To do this, use a horizontal pipe, which is displayed on the street through any of the walls. It is called a coaxial pipe.

When using this system, not only removal of exhaust gas occurs, but also fresh air. In fact, a coaxial pipe consists of two pipes that are inserted into each other:

- the first pipe displays the products of combustion;

- the second pipe supplies the system with fresh air.

If the choice fell on a coaxial pipe, then you should purchase one of two types of double-circuit boilers:

- parapet (for heating buildings up to 150 m²);

- with forced air vent (for heating of premises over 150 m²).

A few words about autonomous gas heating

If the country house is located away from the highway, then for the device of autonomous gas heating, you can use cylinders or. To heat a small house will need 3-4 bottles (40 liters) per month.

Gas convectors can be used as heating equipment. They are attached to the walls in the rooms where space heating is planned. Depending on the size of the rooms, convectors with a certain power are purchased.

The main advantages of gas convectors are:

- unnecessary electrical power;

- heating the room as soon as possible;

- solid gas savings.

Video about the nuances of the gas heating device:

Among the population of Russia, gas boilers are becoming more and more popular. When choosing a boiler, consider several aspects. It can be steel or cast iron. The steel boiler is 2 times lighter than the lighter cast iron, has the same capacity and volume. But, its service life is 12/15 years, the cast-iron counterpart - 50 years.

Steel heat generator rust, especially when the system is turned off or a sharp drop in temperature. Pay attention to the resistance of the furnace. We are talking about excess pressure at which it is necessary to supply gas to the firebox. A good unit has a fire resistance of 1 / 1.5mBar, a bad one - up to 8mBar. In other words, an imperfect firebox requires greater gas pressure. It is worth recalling that in our gas networks, pressure often drops sharply.

The choice of gas boiler depends on whether it is floor or wall mounted.. The second type is a mini-boiler room, in the case of which there is not only a heat exchanger and a burner, but also an expansion tank, a circulation pump, a thermometer, a pressure gauge, and a security system.

Gas boiler installation

Choose an installation location. When this is determined, engage in punching holes for the chimney. Please note that the installation conditions of gas boilers are such that they require good traction in the chimney - it is a guarantee of safe and economical operation of the unit.

If the boiler is wall mounted, hang it on an anchor or hooks. Next, start collecting exhaust hood. When it is collected, blow out the hole with foam. When it is dry, rub it in with a cement-based solution. Next, you need to connect the heating main heating, if the boiler is a double-circuit, then the hot and cold water. On the return pipe, put a filter for the rough cleaning of the water so that the dirt from the radiators does not get into the unit.

Important information, how to install a gas boiler for home heating with your own hands: equip it with shut-off valves, so in case of repair you will not have to drain the water.

Connect the boiler to the outlet. Take care in advance of its protection against voltage surges. Put a voltage regulator or an electronic circuit breaker, which will operate for low and high voltage.

Complete system installation by hydraulic testing.. Fill it with water through the return heating pipe. If the pressure in the system is about 1.5 bar, then everything is fine.

see also