Comb manifolds for radiator heating. Collectors for radiator and underfloor heating systems

Collectors for radiator and underfloor heating systems

Today, the most common way to achieve effective functioning of heating systems is the use of distribution manifolds, whose main task is the proportional distribution of the coolant and the regulation of its parameters: volume, temperature and supply pressure. The efficiency of the heating system depends on the amount of coolant passing through the pipes, the volume and speed of its movement.

According to the Federal Law No. 261 on “Energy Saving and Heat Accounting”, it is necessary to implement heat consumption accounting for each apartment, which is the easiest to implement with systems with a collector distribution of the coolant.  Advantages when installing collector systems:

Advantages when installing collector systems:

- possible to use hidden pipeline.

- convenient for installation, because there are no pipe connections in the floor.

- ease of adjustment of individual hinges of the heating system.

- the ability to turn off the radiator with the supply pipes without turning off the entire heating system, that is, the possibility of replacing a separate section in the operating mode of the system.

- ease of installation of water heat-insulated floors. Heated floor is connected as a separate independent circuit. This is due to the fact that the temperature of the coolant in the floor heating system is lower than in the heating system, which is ensured by installing a special mixing circuit.

The distribution manifold of heating is equipped with a set of leads designed to connect heating devices and consists of two interconnected parts: supply and return collectors combined into a single unit. The first directly controls the flow of hot water to the circuits, and the inverse proportionally distributes the coolant to heat each room in private homes. If the house has two or more floors, then the collectors are installed separately for each. This system is very convenient, because it allows you to adjust the temperature on each floor and in each room, and in case of emergency situations, simply turn off the required circuit without turning off the heating in the rest of the house.

In case of using radiator heating together with underfloor heating, the absence of a distribution manifold may lead to uneven flow of heat to different circuits of the system, for example, there will be a hot floor and cold radiators or vice versa. Thanks to this distribution, the radiators are heated evenly, as each is supplied with a separate supply pipe.

Types of heating collectors

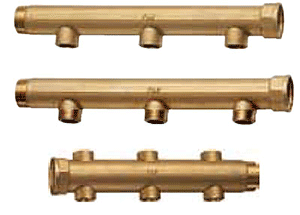

Unregulated manifolds

Unregulated manifolds

When precise adjustment of the flow rate in the heating or water supply system is not required, it is sufficient to simply install the distribution manifold without valves and connect pipes of the required diameter to the outlets. For this purpose, unregulated headers with a diameter of 3/4 ”and 1” can be used with a spacing of 36 mm. Such collectors can be of the through and end type.

End collector

The end collector type is a collector with an entrance on one side only, and the other side does not have an aisle, which eliminates the need to install a plug and the possibility of an additional risk of leakage in this place.  If it is necessary to shut off the flow, it is better to use collectors with a spacing of 50 or 100 mm between the outlets, which will provide the possibility of installing 1/2 ”or 3/4” ball valves. The diameter of the collectors with the distance between the taps 50 can be 3/4 ”, 1” or 1 1/4 ”.

If it is necessary to shut off the flow, it is better to use collectors with a spacing of 50 or 100 mm between the outlets, which will provide the possibility of installing 1/2 ”or 3/4” ball valves. The diameter of the collectors with the distance between the taps 50 can be 3/4 ”, 1” or 1 1/4 ”.

Depending on the size of the outlet

- one tap of a collector with a diameter of 3/4 ”, 1” or 1 ¼ ”with a center distance of 36 or 50 mm has a capacity of 5 to 9 m3 / hour and can provide a flow of ~ 1 m3 / hour at a flow rate of 1 m / s. Such collectors are mainly used for floor-by-floor or apartment-by-apartment distribution;

- one collector outlet with a diameter of 1 ”, 1 ¼”, 1 ½ ”or 2” with a center distance of 100 mm has a throughput of 7 to 17 m3 / hour and can provide a flow rate of 1 to 2 m3 / hour at a flow rate of 1 m / sec.

It is recommended to install the collectors with an increased distance between the outlets (100 mm) on the main distribution sites: in the cottage boiler houses or in the house sections of the water supply. Such collectors have a diameter of 1 ”, 1 ¼”, 1 ½ ”or 2” and the dimensions of the taps ½ ”, ¾” and 1 ”.

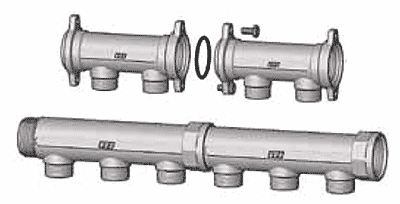

1 ”manifolds may be threaded or flanged. The flange connection of the collectors provides a 100% arrangement of the collector taps in one plane.

1 ”manifolds may be threaded or flanged. The flange connection of the collectors provides a 100% arrangement of the collector taps in one plane.

Manifolds with built-in regulating and locking-balancing valves.

Regulating collectors allow not only to fully open / close the flow, but also to precisely control the flow rate for each consumer. They are installed in hydraulic systems with pressures up to 10 atm and temperatures up to 100 ° C. Collectors with built-in control valves can be placed on the flow and return lines. Flow control is done without the use of special tools. A sealing ring (from EPDM) on the valve seat ensures reliable operation of the valve over a long period of operation.

End control collectors with an entrance on one side only (the second side has no passage) eliminate the need to install a plug and the possibility of an additional risk of leakage at the point of attachment of the plug to the collector.

The valve control knob and the slam-shut closure cap are located on the front surface, providing the user with ease of maintenance without the need for special tools.

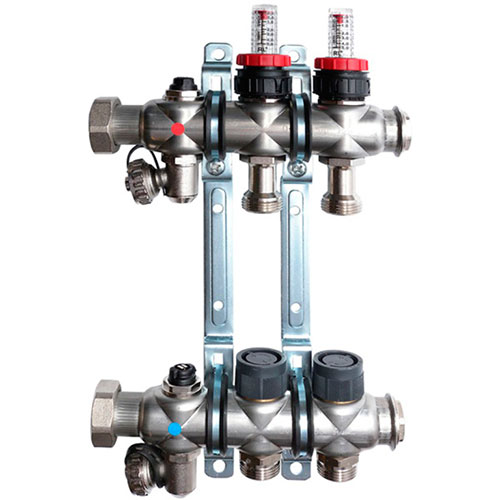

Floor heating collectors

Shutoff balancing manifolds with built-in vertical valves can be put into the water supply or heating system (to the supply and return lines).

Shutoff balancing collectors, equipped with a flow meter, allow you to measure and block the flow of fluid and to carry out balancing of the branches of underfloor heating and cooling. According to the indications of the flow meter, the required flow rate can be set. The flow can be completely blocked by a tight twist on the handle.

Thermostatic manifolds. Installed in the heating system on the return line, if necessary, manual or automatic adjustment of the temperature in the room.

Installed in the heating system on the return line, if necessary, manual or automatic adjustment of the temperature in the room.

Automatic adjustment is provided by installing electrothermal heads instead of adjusting knobs. Electrothermal head, depending on the thermostat signal, provides the value of opening / closing the passage of the coolant and is designed for installation on thermostatic valves as a two-position (open / closed) regulating servo. Electrothermal heads operate on the principle of ON-OFF (open / closed) from an electric signal of a remote thermostat with an AC voltage of 220V or 24V. Automatic maintenance of the required thermal conditions (room temperature, “warm floor” surface, etc.) can be carried out using thermostats. When voltage is applied, the thermal material is heated and the valve stem moves. In the absence of voltage, the valve is in the closed position.

The comb can additionally be equipped with shut-off valves, circulation pumps, thermometers and pressure gauges, deaerators, which together provide full control over the movement of the coolant.

note, if you plan to use collector heating, then note that it will not be able to work without a circulation pump!

When buying a collector, one should pay attention not so much to the material from which it is made, but to its technical parameters: maximum allowable pressure, number of outlets, capacity level, possibility to add additional circuits in case of an increase in the number of radiators, availability of automatic auxiliary devices.

Today, manufacturers offer a variety of models of such devices, among which devices can be found that have a maximum set of elements: flow meters that regulate the flow of heat carrier in each loop can be mounted on the supply side, and thermal sensors can be installed on the return side to automatically control the temperature of each heating device. The price of such a collector will naturally be much higher.

Collectors for radiator heating serve as the main distributor of coolant consumption between all heaters in the circuit. With their help, you can control the heating in each individual room.

Sale of components in the site implies a factory warranty. For the buyer, there are affordable prices for collectors for radiator heating, as we have established our own channels of cooperation with manufacturers.

Construction and types of reservoirs

Distributive combs of radiator heating consist of two main parts - the supply and return manifold a. The first serves to adjust the flow of coolant, and the second - for proportional heating of rooms by balancing the pressure in each branch. The distribution on the species is conditional and implies a complete set of the node:

- automatic air vent devices for water drainage;

- electronic mixers and valves to maintain the set temperature;

- automatic thermostats - maintaining pressure in the system within the framework of the noma;

- control units supply coolant;

- pressure and temperature sensors.

The node price will depend on the configuration and the number of contours. The device is equipped with shut-off valves to block the flow of each branch.

In order for the collector wiring for radiator heating to work, it is necessary. Before making a choice, consult with our experts. They will assist in the selection of optimal models in terms of cost and capabilities.

Where to buy a radiator collector in Moscow

In ours, you can cheaply order collectors for radiator heating from leading manufacturers Oventrop, Stout, Tiemme, Watts. We strive to make customer service as comprehensive as possible. Therefore, we will deliver your order to any address in Moscow and the region. If you decide to buy a collector from us, you get the opportunity to use the services of professional installation.

The company website offers to buy collectors for home heating (technical information and prices are listed in the catalog). Discounts are provided for regular customers and a guarantee of quality for the goods. We offer services of delivery, installation of equipment and its maintenance during operation.

Appointment and scope of the heating comb

This equipment is considered auxiliary and is used most often in the "warm floor" systems, but is also found in the case of a radial (two-pipe) radiator heating system. Comb for heating (collector) is designed to distribute, control and adjust the flow of coolant in the house.

The device consists of two main blocks:

- serving,

- reverse.

From the first go pipe for supplying hot coolant from the boiler to the heating devices. The return unit receives the used liquid, which is sent for heating.

Such a collector for heating radiators is mounted, as a rule, in a hidden place at home:

- under the stairs;

- in a special closet;

- in the technical room.

According to the current rules, the supply unit is placed on top, and below - for receiving the return flow. In order to avoid heat losses, the pipes are enclosed in special thermal insulation of red and blue colors.

Design features and collector price for heating

This device is a pipe made of brass, stainless steel or plastic, with taps welded to it perpendicular to the longitudinal axis. The latter are equipped with thread or collet connectors for connecting pipes of the heating system. The number of taps on the comb must match the number of mounted radiators (one for each). There may be two or more, depending on the model.

Flow valves are installed on the supply manifold for the heating system - one for each outlet. They are designed to adjust the amount of coolant and its even distribution between the connected batteries.

Thermal heads (thermoelectric actuators) are mounted on the back heating comb - one for each pipe. By means of this equipment it is possible to change the section through passage. This regulates the heat transfer to each battery.

The price of the comb for heating depends on several factors:

- the number of taps and diameter of the connected pipes;

- availability of auxiliary valves;

- material (brass, stainless steel);

- protective (decorative) coating;

- brand.

The principle of operation of the collector of water heating

This equipment is positioned as auxiliary. The coolant flows from the boiler to the feed comb in one stream, where it is distributed through the pipes of the heating circuits. Flow can be controlled for each “loop” (battery) using a flow valve.

After passing through the radiator, the cooled water is delivered to the return manifold of the heating system. Its quantity is regulated with the help of thermal heads and other accessories.

Benefits of the collector system

Connecting radiator heating through a comb allows you to make each battery an independent zone, to regulate the degree of heating of each battery (or room) in a building. For example, you can disable non-residential rooms on the second floor from heating and save energy. In other rooms, on the contrary, it is possible to increase the intensity of heat transfer.

In the event of an accident, using a comb, you can easily turn off only one problem battery without shutting off the entire heating system. This is especially important in the winter, in the event that repairs will be delayed for a long time.

Planning to buy a brand collector for underfloor heating of a private house ?.

Collectors are designed to dispense fluid from the main line through additional circuits, to mix and evenly distribute flows from parallel pipelines, as well as to recover the flow during circulation. Manifolds for radiator heating improve the properties and characteristics of heating systems in buildings for various purposes.

Collector design

The design of the collector for the heating system is quite simple: it is a piece of pipe with a certain number of end and side taps for connecting separate circuits. There are devices equipped with a safety group, a mixing unit, an air vent, automatic or manual flow controls. Such equipment is used only in circulating closed heating systems and provides automated management of them.

Variety of collectors for heating systems

Depending on the design and purpose, the collectors are divided into 4 types:

Distribution manifold

The most common type separating the flow of coolant for heating devices. It consists of 2 distributors (combs), at the ends of which devices are installed for connecting to the supply and return lines. Along the body there are fittings for heating devices (contours or underfloor heating, heating radiators). In the first distributor, the coolant flows to the heating devices, and in the second - it is diverted back to the boiler. Radiator-type heating is connected through a distribution manifold in parallel, rather than in series, as in single- and two-pipe circuits.

Hydrocollector or thermo-hydraulic distributor

Designed for hydrodynamic balancing of a complex type of heating system (with several heating circuits). Aligns the temperature and pressure of the coolant in different circuits, while the flows can be mixed to the extent necessary. This ensures a stable temperature in the premises, as well as gentle operation of the equipment.

With pump

The thermo-hydraulic distributor allows you to achieve optimal operation of the heating system in a large building in the case when each circuit is equipped with a pump. Such a collector has a large diameter and is installed vertically in the boiler room.

Solar

Directs solar energy to household needs. As the main source of heating is suitable for heating water in water pipes located in areas with a sufficient level of solar lighting. The valves of this type differ in construction from the usual collector and, often, serve as a heat exchanger.

Installation of a collector for radiator heating will allow using the system as efficiently as possible, which will ensure efficient heating of the rooms.