Gas boiler closed single-combustion chamber. How to choose a gas boiler with a closed combustion chamber

Heat - this is the most important component of comfort in the house. When building a heating system, they pay a lot of attention, because no matter how good the thermal insulation of the enclosing structures is, it will still be very cold in the house without additional heating. The choice of the ideal heating mechanism will be helped by the rating of gas wall-mounted single-circuit boilers. But before choosing such a heating mechanism, it is necessary to determine its advantages over other models and make sure that it is necessary to install it.

Choosing a heating boiler

In order for the heating system not to cause trouble and not to spend a significant part of the budget, it is necessary to choose it carefully. This will have to understand the differences in the models of heating equipment. In all models, the coolant is not heated in the tank, but by the flow method. This ensures a continuous flow of hot material into the radiators and does not clutter the space.

Fuel

The first thing that distinguishes heating systems from each other is the fuel necessary for their operation:

- Boilers that need solid fuel to operate. Typically, such equipment is installed in homes where there is no other way of heating. Solid fuel has low efficiency. In addition, the work of such a system will have to constantly monitor and put into the furnace a new fuel.

- Diesel and fuel oil. These are large installations designed for heating large spaces. They are not installed in apartments and private homes.

- Electric boilers. They are environmentally friendly, work silently, do not take up much space. It can be left without constant supervision. But in the event of a power outage, the house will remain without heating, which can be very uncomfortable in winter.

- Gas. They are very economical to use, able to work smoothly, even if the owners have left the house. such equipment is environmentally friendly and does not pollute the environment. Utilities very rarely turn off the gas supply, this happens only in emergency cases.

Depending on the communications carried out to the house, each owner independently chooses the option that suits him. Electricity is even in the farthest corner of the planet. Gas held in almost all garden and garden arrays and villages.

The method of installation of the heating boiler

The ideal option for installation in a private house is considered to be wall models. Unlike their floor counterparts, they take up much less space due to small dimensions and installation on the wall. Due to this, the space under them can be used to store various things that do not require special conditions for this. Modern designers successfully make this indispensable element of comfort as inconspicuous as possible and at the same time ergonomic. It can be hung in the kitchen, in the attic and in the bathroom.

The possibility of combining heating and hot water

There is a difference in the number of contours:

- The dual-circuit version of the heater provides for the simultaneous provision of a house with uninterrupted supply of hot water to the taps and heating. It is very convenient, but it has one big minus: such boilers cannot use anything other than vda as a heat carrier. In addition, the priority in this installation is given to the heating of the hot water supply, which leads to a downtime of the heating system during the opening of the hot water tap. This is not critical when the heating process is interrupted for a short time, but over a long period of time the house may cool down a bit.

- Single-circuit mechanism can only provide heating of the building. It is able to heat and distill antifreeze through radiators and batteries.

Tip: The absence of a second circuit, and hence the hot water is easily solved by connecting the water heater. In this case, the heating starts to work smoothly and at the same time the hot water supply system becomes completely autonomous and is always an available resource.

The combustion chamber

There are also open and closed combustion chambers:

- An open camera implies a natural thrust. Air to maintain combustion is taken from the premises, depriving it of a small part of oxygen. The products of combustion, that is, the smoke is removed into the chimney as well under the action of natural draft. Such a design was borrowed from a conventional stove, but it has undergone some adaptation to the modern world and new technologies.

- A closed chamber does not require a chimney, such boilers can be installed even in apartment buildings. Such cameras are equipped with a device that forcibly removes smoke. Smoke is also burned under the action of constant inflation of oxygen and generates additional heat, thereby increasing energy efficiency.

The best solution for heating a private house is a single-wall gas wall boiler with a closed combustion chamber. It meets all the requirements of the owners of the house and at the same time is not difficult to use or install.

Choosing a boiler by comparing models

In order for the heater to be properly selected, compare models from different manufacturers. This method rolls up to see the disadvantages and merits of different options. By rating the gas wall-mounted single-circuit boilers, you can identify the best option for space heating.

Comparison of Bosch heating boilers

This is a company engaged in the production of household appliances for many years. German quality quickly attracted the Russians and earned their respect. Gas boilers of this company are represented by many models of different types. Their price category is also different. All this allows you to choose the perfect option for each house.

WBN 6000-18 C RN S5700

Users rate this device as one of the best, celebrating its efficient and silent operation. Despite the double-circuit type of the boiler, it copes well with multitasking and equally efficiently heats the house and ensures the availability of hot water.

WBN 6000-12 C RN S5700

He is capable not to break silence in the house and to work imperceptibly, but effectively. Users note the ease of installation and modest dimensions of this model. Disadvantages are considered minor and therefore no one mentions them.

WBN 6000-18 H RN S5700

The owners of this boiler note its compactness and energy efficiency, but this boiler has its drawbacks. Sometimes the system gives an error, you can deal with this problem by flashing the equipment. This is a fairly simple measure, but it forces the owners to invite a specialist and undergo some inconvenience.

WBN 6000-35 H RN S5700

Another heating system of compact size. It is able to provide a warm medium-sized house, even in extreme cold. Users note the ease of use and installation. This is due to a well-thought-out and simple design, because the simpler the mechanism is, the less it breaks.

Comparison of the technical characteristics of the boiler company "Chaffoteaux"

A French company founded more than a hundred years ago. Throughout this period, engineers are engaged in the development and implementation of new technologies in the production of household appliances. All products are repeatedly tested, and only immaculately working copies get to the buyers.

ULTRA SYSTEM 25 CF

![]()

People who acquire this mechanism are pleased with the possibility of connecting an external boiler. This solves the problem of single-circuit boilers with hot water supply. The option of the middle price category works well and does not require the hassle of its service.

ULTRA SYSTEM 30 FF

![]()

Users like the pump anti-lock system. It automatically starts working once a day and turns on the pump. It is equipped with other useful properties: temperature sensor, pressure sensor, etc. Especially the owners like the Russified multifunctional display, which allows them to cope with the control of even the person most distant from technology.

ULTRA SYSTEM 25 FF

![]()

This boiler model is distinguished by the ability to perfectly maintain the required fluid temperature in the batteries. The controller almost never fails and does an excellent job with the tasks assigned to it. This variant of the middle class is liked by all people who bought it.

ULTRA SYSTEM 35 FF

![]()

In this model, trapping users note the measured amount of the flame, which allows to regulate energy consumption and adjust the heating intensity of a building to suit their needs.

Comparison of technical characteristics of Vaillant boilers

The history of this company goes back almost one and a half hundred years, but in Russia they learned about this company relatively recently, only two decades ago. Engineers are concerned about the convenience of their customers and therefore are constantly engaged in the installation and development of user-friendly controls. All management principles embodied in the products of this company are based on the so-called “intuitive control”. It helps people who are not familiar with such a mechanism to correctly start using it correctly.

turboTEC plus VU / 5-5

Among the advantages of this boiler emit protection system. It helps people to always correctly set up and use the heating system without the risk of disabling the complex and expensive mechanism. Small size with good performance also deserve respect among satisfied customers. It fits perfectly into the interior and does not catch the eye.

turboTEC plus VU 242 / 5-5

According to buyers, this is one of the easiest to install models of gas boilers. The sensors built into the system do not allow it to fail, thanks to which the heating in the house will be permanent. Management and configuration are also very easy for many users. This is due to the wide and multifunctional display. Powerful enough mechanism. It is suitable for private homes rather big area, but still better to consult with experts.

turboTEC plus VU 282 / 5-5

In the event of a breakdown, this device is able to diagnose its faults on its own. The master, called for their elimination of breakages, it is enough just to make a diagnosis. That is why users mark the speed of repair. Users praise the designers who thought out the look. This copy does not stand out in any interior.

turboTEC plus VU 202 / 5-5

Powerful enough device. He is able to heat a very rather big house. All functions of this heating system are regulated by protective mechanisms designed to prevent errors in operation. This allows you to extend the life of the device and simplify its use. This option is ideal for use in spacious rooms, but the power regulator allows you to install it in a movable small house, only this is irrational.

Comparison of the characteristics of the best models of different manufacturers

To see the full picture and make a rating of wall-mounted single-circuit gas boilers in terms of reliability and quality, it is necessary to compare models of boilers with each other. For these purposes, you can choose boilers with the highest rating from each manufacturer.

For comparison, take the following heating boilers: turboTEC plus VU / 5-5 manufactured by Vaillant, ULTRA SYSTEM 25 CF from Chaffoteaux and WBN 6000-18 C RN S5700, produced by Bosch.

|

Name of the heating boiler model |

turboTEC plus VU / 5-5 |

ULTRA SYSTEM 25 CF |

WBN 6000-18 C RN S5700 |

|

Maximum power (kW) |

|||

|

Min power, (kW) |

|||

|

Efficiency (%) |

|||

|

Natural gas consumption, (m 3 / h) |

|||

|

Consumption of liquefied gas (kg / h) |

|||

|

Nominal pressure of natural gas (mbar) |

|||

|

Allowable pressure of liquefied gas (mbar) |

|||

|

Heat carrier, minimum temperature © |

|||

|

Temperature maximum |

|||

|

Flame modulation |

|||

|

Autodigo |

|||

|

Safety of use (automatic blocking) |

|||

|

Protection against pump blocking |

|||

|

Price (rubles) |

As you can see from this table, cheaper models lack some necessary functions, without them, of course, you can do without, but with these additional options, using the device becomes an order of magnitude easier. Each owner must decide whether he needs these additional functions. Budget models also can not boast of low gas consumption, they spend this valuable resource in large quantities. Safety and the ability to heat the premises remain almost unchanged in all models, which allows us to conclude: Nothing changes in the design of a heat boiler, but the additional functions may fall a lot.

Each manufacturer is responsible for the quality of the goods produced and therefore the boilers work well, but low-end models will have to be installed and configured longer, and during operation it will require more thorough maintenance than expensive models.

| Brand and model name | Evaluation | Type of heating boiler | Power Min / Max (kW) | Consumption of natural gas (m 3 / h) / liquefied (kg / h) | Additional functions | Cost of the device (rubles) |

| Bosch, WBN 6000-18 C RN S5700 | 5 | Double circuit | 5,40/18,00 | 2,1/1,5 | 25 100 | |

| Bosch, WBN 6000-12 C RN S5700 | 4 | Double circuit | 5,40/12,00 | 2,1/1,5 | Panel modulation, lock lock protection, | 24 00 |

| Bosch, 6000-18 H RN S5700 | 4 | Single circuit | 5,40/18,00 | 2,1/1,5 | Panel modulation, lock lock protection, | 25 600 |

| Bosch, 6000-35 H RN S5700 | 3 | Single circuit | 12,20/37,40 | 3,90/2,70 | Panel modulation, lock lock protection, | 37 547 |

| Vaillant, turboTEC plus VU / 5-5 | 5 | Single circuit | 11,20/6,10 | 1,46/4,10 | Weight 44 kg | 65 250 |

| Vaillant, turboTEC plus VU 242 / 5-5 | 4 | Single circuit | 8,00/24,00 | 2,80/0,96 | Weight 41 kg | 49 400 |

| Vaillant, turboTEC plus VU 202 / 5-5 | 4 | Single circuit | 6,10/19,70 | 2,40/0,89 | Weight 40 kg | 45 600 |

| Vaillant, turboTEC plus VU 282 / 5-5 | 4 | Single circuit | 9,40/28,90 | 3,20/1,08 | Weight 42 kg | 54 100 |

| Chaffoteaux, ULTRA SYSTEM 25 CF | 4 | Single circuit | 11,00/25,00 | 3,65/2,72 | 35 500 | |

| Chaffoteaux, ULTRA SYSTEM 30 FF | 4 | Single circuit | 14,40/30,00 | 2,73/2,03 | Wide tank circulation pump | 40 900 |

| Chaffoteaux, ULTRA SYSTEM 25 FF | 4 | Single circuit | 11,00/25,00 | 3,17/2,37 | Wide tank circulation pump | 39 000 |

| Chaffoteaux, ULTRA SYSTEM 35 FF | 5 | Single circuit | 15,00/30,00 | 2,86/2,13 | Wide tank circulation pump | 43 200 |

Thus, it is impossible to find the ideal heating boiler, because such equipment is selected individually depending on the area of the room, its features and customer needs. The conditions in which the mechanism is to be operated are also very important, for a small heating system it is not necessary to allocate an entire room.

Despite the importance of the right choice, the installation process is the most important in the device of the heating system. This should be done exclusively by professionals, only they will be able to comply with all standards of installation of heating equipment.

In the process of comparing models of heating boilers, it was found that the price for them depends not only on the technical characteristics, but also on the brand producing these products. Not always the price is a decisive factor, sometimes you can get a decent machine at a lower cost. So, you should pay attention primarily to the integrity of the manufacturer, and not to the cost and number of functions.

Which model of single-circuit wall gas boilers with a closed combustion chamber did you like the most?

Buy a gas wall boiler prefer many owners of apartments and small houses. We offer models of such famous brands as: Viessmann, Bosch, Baxi, Protherm, Vaillant. The products of the represented manufacturers are in demand in the world market and in Russia.

Characteristics and possibilities of wall gas boilers

Heating equipment that runs on gas, does not require the organization of a place to store fuel, because it comes from the central communications in the required quantity and almost without stopping. Moreover, the gas surpasses other types of fuel in thermal output, and it is easier to automate the operation of gas boilers. That is why the presented models are so in demand in the market of heating equipment.

We offer the following types of wall mounted gas boilers:

- single and double circuit;

- with open and closed combustion chambers;

- with various types of automatic control.

Gidrotop online store is a leader in its market segment. Each buyer is guaranteed to be able to buy a wall-mounted gas boiler, as well as additional equipment for competent organization of the heating system and hot water supply in the house and apartment.

We offer affordable prices and high quality service. You only need to choose the boiler of optimal power, which varies from 10 to 100 kW. Wall gas coppers are a reliable work, profitability and high efficiency.

It is well known that for the installation of most gas heat generators it is necessary to organize a good supply and exhaust ventilation. It also requires a reliable chimney, which provides sufficient traction. It is not always possible to fulfill these requirements; moreover, the installation of a full-fledged chimney is not a cheap pleasure. The question can be solved in a simpler way, for this there are single- and double-circuit gas boilers with a closed combustion chamber. The purpose of this article is to help a homeowner find a heating unit of this type.

What influences the choice of gas boiler?

Consider the process of selecting a heat generator from the point of view of an ordinary user. Then the selection criteria will be as follows:

- thermal power of the boiler;

- its cost;

- profitability;

- installation conditions;

- the complexity of the installation work.

The most important criterion is the required power of the heat source. Ideally, it is determined by calculating heat losses through building structures and for ventilation. Such calculations are usually performed by specialists - designers. If you do not have such calculations, then it is customary to use the method of enlarged calculation. It lies in the fact that for heating 1 m2 of the area of the house you need 100 W (or 0.1 kW) of thermal energy. Accordingly, the total area (of all floors) of the building must be multiplied by 0.1 to get the required heat output in kilowatts.

The second criterion - the cost of equipment - most worries every homeowner. It will depend on the power of the gas boiler, its type and functionality. The more new technical solutions and expensive elements are introduced in the design of the heat generator, the higher its final cost. We will mention this criterion when considering different types of boiler plants with a closed chamber.

It should be noted that the gas boiler with a closed combustion chamber is a high-tech product and burns fuel very efficiently, this determines its efficiency. The efficiency of gas units of this type is in the range of 93-98%, depending on the design.

From where it is planned to place the heat source in the house, will depend on the selection of its execution. When a special room is set aside for this purpose, it is possible to purchase any kind of boiler — wall or floor — which one is more suitable for power and price. If there is no such room and the unit should be placed in the kitchen or in another room, then the choice is limited only to wall units.

Installation conditions and the type of equipment chosen will also affect the complexity of its installation and ultimately the total cost of the project. It is necessary to understand that it is simpler to install the floor gas boiler in a separate room and to make its binding, rather than to mount the wall double-circuit unit in the cramped conditions of the kitchen. In the second case, the case is complicated by the fact that the equipment must be entered into the interior of the room, and hence the cost of such installation will be significantly higher.

Note. To select a double-circuit boiler, there is an additional criterion - the necessary flow of hot water. If an alternative source of water for the needs of the DHW is not planned in the house, then this obligation will fall entirely on the heat generator, which should be taken into account when purchasing it. Often, to ensure the required flow of hot water, it is necessary to acquire a boiler of greater power than is needed to heat the house.

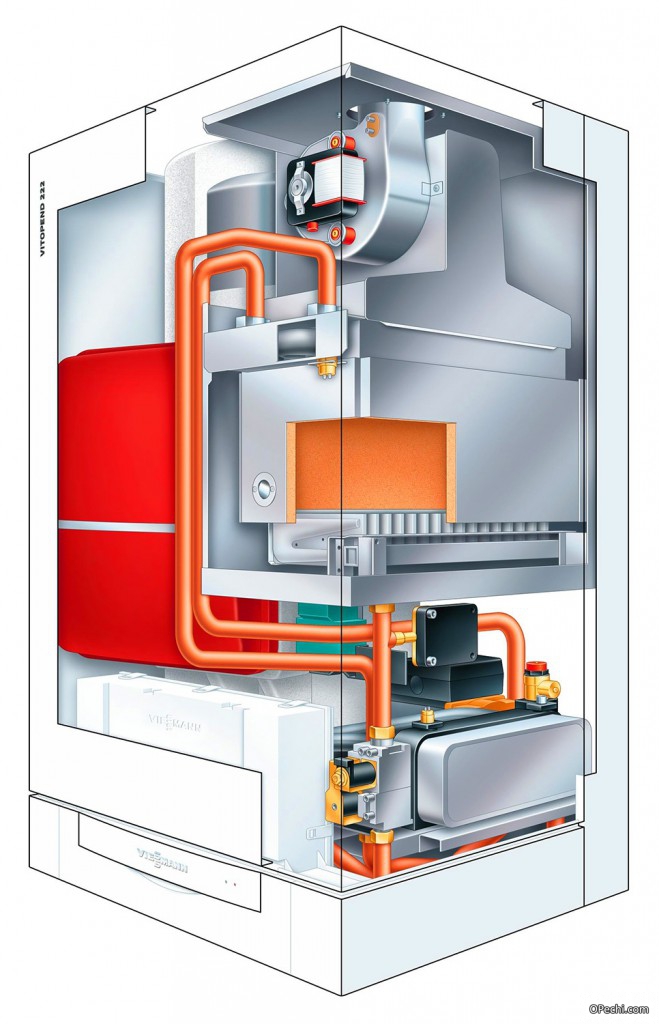

Types of boilers with a closed chamber and their features

Heat generators of this type have a number of advantages over conventional boilers, namely:

- the closed combustion chamber of the gas boiler does not require the supply of air from the room where the unit itself is located;

- no need to make a traditional chimney and provide traction;

- all major processes, including ignition, are fully automated.

In short, the principle of operation of the boiler is that the combustion of the fuel takes place in a closed chamber, to which air is supplied with the help of a blower-blower fan. In the same way, flue gases are removed from the furnace, and they pass out through the pipe of a coaxial chimney, which is led out horizontally through the wall. Ignition, attenuation, and gas burner operation are controlled by the controller; all these processes are not visually visible, but are only displayed on an electronic display.

In addition to conventional units with a closed chamber, where the burner heats the heat exchanger, there are so-called condensing heat generators. As a rule, this is a two- or single-circuit boiler, where a cylindrical coil surrounding the burner of the same shape plays the role of a heat exchanger. The trick is that on the coil, inside of which the coolant moves, condensate is formed, which is formed during the combustion of methane. At the same time, it transfers thermal energy of condensation to water.

Condensing boilers are the most economical of all gas heaters. Their efficiency is up to 98%, while the efficiency of a conventional unit is no higher than 92-93%. But, as you understand, for the costly "stuffing" of such a miracle of technology, it will be necessary to lay out considerable means, which is not available to everyone. In addition, there is another point concerning all boilers with a closed chamber.

The fact is that a floor or wall-mounted boiler of this type for work necessarily requires the presence of electricity. A prolonged power outage in the middle of winter will cause the equipment to stop, the house to cool down, or even to defrost the system. Therefore, if shutdowns are not uncommon in your area, you will have to buy an uninterruptible power supply unit or even a gasoline generator together with a high-tech boiler. It is worth considering whether you need this, perhaps it is easier and cheaper to take an atmospheric non-volatile heater.

Installation of a boiler with a closed combustion chamber

Compared to other gas appliances, the installation of a wall-mounted boiler with a closed combustion chamber is somewhat simplified. Of course, it must be placed and fixed on the floor (if the option is floor standing) or attached to the wall. There are no differences in the connection of the heat generator to the heating system, the binding is carried out exactly according to the scheme. Simplicity - in the device coaxial chimney, used instead of the traditional.

Coaxial chimney canal is made of metal on the principle of "pipe in pipe". The combustion products induced by the supercharger move along the inner tube, heating the outside air drawn in through the outer tube. As a rule, the channel is released on the street in the shortest way, horizontally. At the same time, a small slope in the direction opposite to the boiler is observed. In some cases, when the heat generator is in a room that does not have an outer wall, the pipe is allowed to lead up through the roof.

In fact, for the installation of the chimney you only need to make a hole in the outer wall and install a metal sleeve in it. Further, a pipe is passed through it, the lumen is compacted with a non-combustible insulation. Inside the chimney is connected to the boiler in accordance with the instructions, on this installation is over.

Conclusion

It turns out that the choice of a gas heating installation with a closed chamber largely depends on the budget allocated to the project. When there is an opportunity and desire to purchase an economical condensing boiler - you should not hesitate, you just need to choose a manufacturing company. If the budget is limited, then you can take the usual supercharged unit, whose efficiency is slightly lower, but there will still be nothing to compare it with.

Comfort in the room in winter is largely determined by the quality of the heating system. Therefore, for example, wall or floor boilers should be chosen as responsibly as possible. They must meet the current operating conditions, the requirements of the owner, etc. This is the only way to achieve efficient operation of heating equipment.

By the number of circuits, there are two types of boilers:

1. Single circuit. Provide space heating.

2. Double circuit. The second circuit is used to heat the water.

wall gas boiler

wall gas boiler Such devices with chimneys can be floor or wall. And they and others can run on different fuels: gas, electricity, etc.

These devices are different performance, performance, efficiency and technical parameters. Many consumers install floor gas models in their homes. They are more productive, convenient to use, can provide heating for industrial facilities. The difference between wall and floor single-circuit models consists in price.

Single or double boiler?

Gas boilers

Floor gas heaters have good technical characteristics, small hydraulic resistance.

Note: Single boiler can heat up to 400 m 2.

It is made of cast iron with good insulation qualities, fire-resistant burners, equipped with the possibility of pre-mixing, closed chamber and equipped with a chimney for the output of combustion products.

An important characteristic of floor models is the possibility of circulating coolant without the use of pumping equipment. This increases the efficiency of devices. The design provides protective elements, eliminating the need to limit the temperature regimes. Due to the use of modern automated control systems, high efficiency of combustion and cost-effectiveness of heating, safe removal of combustion products through are ensured.

in outdoor performance

in outdoor performance Single-circuit gas boilers are used only for space heating; they cannot provide hot water. Such devices are built in two versions:

- Economical type of heating. In addition to the heating appliance, a water heater is installed. Provides minimal gas consumption during the operation of two devices.

- The optimal type of heating. In this case, the heat exchanger is installed in. Provides increased hot water flow. It is important to coordinate the power of the two devices. If the gas boiler will have less power than that of the boiler, the normal level of hot water consumption will be difficult. Then an electric water heater can be used.

Dual-circuit gas boilers include the following components:

- heat exchanger;

- burner;

- pump;

- expansion tank;

- chimney - sometimes referred to as the ventilation system.

The tank is connected to the heating and water supply system. The heating device operates with the priority of hot water supply. When the tap opens, the heating coil is turned off. Only the hot water circuit is heated, and the water is heated in a flow-through mode.

Note: If the water flow is high, it is recommended to use a single-circuit boiler with a built-in boiler, otherwise hot water will be provided and the house will be heated poorly.

Appliance prices are different. Some domestic models have increased weight and increased overall dimensions, uncomfortable chimneys. Therefore, they may require a separate chimney for the removal of gas combustion products.

About connecting the gas boiler

Operating principle

The principle of operation of floor devices with closed and open combustion chamber is quite simple. The gas during combustion gives off heat to the heat exchanger inside the structure. Fluid passes through it, is heated and fed into the heating system. For proper functioning, a high-quality heat exchanger is required:

1. Cast iron elements are durable, because the material is resistant to burning and is not subject to corrosion. As a result, the design can function for more than 50 years. But there is one drawback - fragility, which means that a sharp temperature drop or strong mechanical effects can cause damage to the body.

2. The steel heat exchanger is characterized by increased mechanical strength to allow it to effectively resist damage. The element has less weight than the cast iron body. However, there is also a minus - susceptibility to corrosion, which causes a fairly rapid burnout during heating. The operational period is about 5–15 years.

3. Copper elements are now rarely used.

Features of floor boilers Thermomax

equipment requirements

To ensure the most effective work must meet the requirements:

- Maximum power and endurance. The performance of the boiler is determined by the power. The higher it is, the more comfortable the living conditions. It is better to use single-wall or floor models with a closed or open chamber, oriented specifically to heating rather than water heating.

- Maximum heat at low cost. Due to the presence of an automated control system and automatic arson, effective combustion of gas is ensured, which creates the optimum ratio of the ingredients of the mixture in the combustion chamber.

- Heating of any room. Wall models have limited use. Single-stage boilers of floor execution can provide heating not only for small areas, but also for huge industrial premises.

- Full compliance with safety criteria. Otherwise, the operation of single-circuit boilers can turn into a dangerous event.

Benefits

Single-circuit boiler floor execution with chimney has the advantages:

- High performance. Single-stage floor models, like wall-mounted boilers, models use technological methods in combustion chambers.

- Heat transfer efficiency. Single-circuit boilers wall or floor execution provide efficient transfer of heat from a closed or open combustion chamber to the heating system.

- Automated control system of single-circuit models provides economical fuel consumption.

- Single-circuit devices allow you to organize the heating of large areas. Additional chimneys may be required.

- Large functionality: several temperature regimes (you can equip a warm floor), a standby mode and automatic switching on when the gas supply is restored, the use of modern monitoring tools.

- To control the temperature in single-boiler boilers, sensors and coaxial cables for electronic control can be used.

- Trouble-free and long-term operation, ease of maintenance with a closed or open combustion chamber.

- Single-circuit boiler provides low noise.

- Minimum selection of combustion products through the chimney.

- Availability. Prices for single-circuit models allow you to acquire such devices. And it can be wall or floor models with a closed or open chamber and chimney.

The single-circuit boiler is equipped with a cast-iron heat exchanger, which ensures good thermal insulation. A burner allows the device to operate on liquefied or natural gas.

Both double-circuit and single-circuit boiler require installation in a separate room, holding a chimney. Installation of wall options is easier than outdoor. Also single-boiler is characterized by energy dependence. All this makes the device popular in the market.

Boiler with a closed combustion chamber

Choosing a gas boiler for their homes, each consumer is faced with a huge number of models of such heating equipment. All of them differ from each other in a large number of parameters. And your choice, as always, will depend on the priorities that you put at the forefront. The market offers you to choose a model that will exactly match the characteristics of the house and the climatic specifics of the area where you live. We recommend a wall mounted gas bypass boiler with a closed combustion chamber.

It is clear that there are units on the market with an open combustion chamber. Their model range is many times more, because it is the usual type of boilers in which the fuel is burned with the help of air entering through the door of the firebox and blowing. Each of these types has both pros and cons. We will be interested in the unit with a closed combustion chamber.

Features

The heating gas boiler equipped with a closed-type combustion chamber is an easy-to-use unit, which is also very practical. If you decide to purchase it, then the mass of inconveniences and problems that are usually encountered when operating the unit with an open chamber, will bypass you.

First of all, such boilers do not require an equipped boiler room. For them, you do not need to strictly adhere to fire safety requirements and create a specially equipped room. This is especially true of such a unit as a wall-mounted double boiler. It is compact and convenient. Therefore, it is often installed directly in the kitchen, sometimes in a combined bathroom.

Of course, one should not think that the fire safety rules are completely ignored. In no case. But there is relief. This type of boiler equipment is perfect for city apartments or small private houses, where the problem of free space is acute. It is enough for him to find a place in a couple of square meters, and you can forget about the problems of heating and hot water.

Many consumers, who for the first time meet boilers with a closed combustion chamber, cannot understand where the air comes from to maintain the combustion of fuel, and where its combustion products go. For all other models, this is problem number one, and a good chimney is the only solution for the efficient operation of the heater. In the case of a closed camera, the situation is completely different. For such a boiler does not require a high vertical chimney that goes beyond the roof of the building.

In order for a wall-mounted double-gas gas boiler with a closed chamber to work efficiently, it is only necessary to install a short horizontal coaxial-type chimney. That is why it is so important that the place of installation is the external wall of the house.

Today, many models of double-circuit gas boilers are equipped with fans for the outflow of combustion products. In fact, this is a common ventilation system, which means that this type of boiler is a volatile unit. And this is a big disadvantage of boilers with a closed combustion chamber. After all, it is no secret that in suburban settlements blackouts are commonplace. Now you can imagine what can happen if you suddenly turn off the light in the winter. A couple of hours, and your house will turn into an ice hut.

Coaxial chimney solves the problem of energy dependence. In fact, these are two pipes of different diameter, inserted into each other. Combustion products are discharged through the inner pipe, and fresh air enters the firebox through the gap between the pipes. If the fan turns off, the chimney will still work in natural mode. True, the effectiveness of its functioning is sharply reduced.

And one moment. It can be attributed to the shortcomings, but this is a controversial issue. Wall-mounted and floor-mounted gas-fired boilers with a closed combustion chamber are more expensive than their counterparts with an open hearth. But if we take into account all the listed advantages, then it can be argued that the design with an isolated firebox is an economically sound solution. Moreover, this option is more practical.

Advantages of the coaxial chimney

This type of chimney is a rational result of engineering. Its installation allows you to abandon the complex system of exhaust and ventilation.

Here are its advantages:

- This is the safest chimney. Please note that the exhaust gases passing through the internal diameter are immediately cooled by fresh air in the gap between the pipes. At the same time, the smoke cools down and does not extend over a long distance. Plus, this is the reason for the increase in thrust.

- Efficient entry of oxygenated air into the furnace ensures better combustion of the fuel, that is, gas. This increases the release of thermal energy, and decreases the percentage of combustion products in the exhaust gases. And this savings and environmental protection.

- Comfortable conditions. This indicator is that, firstly, the air is not taken from the living quarters, and, secondly, the exhaust gases do not enter the rooms.

Let's sum up

How to choose a gas heating boiler

Considering everything that was said, we note four important points:

- Coppers with the closed fire chamber possess high efficiency due to receipt of fresh air from the outside directly to the combustion chamber.

- Be sure to have a coaxial chimney. Any other design will aggravate the situation and dramatically reduce the characteristics of the unit.

- You should not use boilers of this type in regions where the problem of power supply is relevant.

- This type of boiler equipment works more noisily than analogs with an open chamber.

So, we have considered the advantages and disadvantages of a boiler with a closed firebox. Given all this, you can make the right choice by sorting out the variety of the model range represented on the modern market of heating equipment.