Mini boilers for solid fuel long burning. Choosing a solid fuel boiler for a private house

Solid fuel boilers remain among the most sought after on the market. This is largely due to the availability of such a variant of heating, as well as ease of operation. Therefore, many are interested in how to choose a home for heating in order to purchase an efficient but inexpensive model.

Solid fuel boilers should be chosen not only by the characteristics of the room, but also taking into account the quality of fuel cells. Therefore, the following criteria come to the fore:

1. Type of fuel. Solid fuel boiler is able to operate on wood, coal, industrial waste. Thanks to the versatility, you can significantly reduce heating costs, pick up equipment with optimal characteristics for the needs of a particular object. will not work if there is no place to store a large amount of firewood. Anthracite provides high efficiency, lignite - a little less, firewood - even less.

2. The volume of the combustion chamber. This parameter determines the performance of the process and the comfort of using the heater. After all, a small volume of the chamber will require more frequent replenishment of solid fuel to maintain a certain temperature, which is especially inconvenient with very cold frosts outside the window.

3. Automation. As a rule, a modern solid fuel boiler already has a certain level of automation. If such opportunities are not provided in the design, it is worth figuring out whether it can be done in the future and how much it can cost. If we choose a boiler for heating your house, you should purchase an automated model.

4. The level of safety of the device. At the height should be not only productivity, but also the safety of the heating system. For example, a solid fuel boiler must be equipped with alarm systems and automatic shutdown.

5. Power consumption. As a rule, all modern heating appliances on firewood are autonomous, without the need for power from the electrical network. However, there are some models that run on solid fuel, but need electricity. Therefore, this parameter must be taken into account when choosing.

6. The cost of solid fuel equipment. You should not choose cheap samples, because their heating characteristics may simply not be enough to effectively heat your home. A great option - models of proven manufacturers who have been tested in domestic difficult conditions.

Features of the solid fuel boiler Warmos

Where to begin?

First, it is necessary to determine the solid fuel boiler will be the main or still a backup source of heating. If it complements other options, it is necessary to select a model that is consistent so that all equipment is combined, ensuring the harmonious functioning of the entire system. It should be borne in mind that there are domestic, and there are industrial models for space heating.

Note: If several solid-fuel appliances are used, difficulty may arise with the difference in temperature graphs, so it is not recommended to use such equipment in parallel. The problem can be solved if you use an expansion tank.

Another important parameter that must be taken into account when choosing, is the power of the unit. To determine this indicator should take into account the area of a private house, the level of insulation of rooms that will be heated by a solid fuel boiler. If this parameter cannot be determined independently, it is better to contact a specialist. This will make the calculations correctly, will prompt the best options.

Choosing a solid fuel boiler for home heating, many people forget about the chimney. In case of inadequate draft, it is recommended to use equipment with additional ventilation system.

Power

Of course, it is desirable to perform accurate power calculations so as not to lose out after buying heating equipment. However, there are average indicators that will help simplify the task. It is believed that 1 kW of solid fuel boiler capacity is enough to maintain a comfortable temperature of 10 m 2 of a private house. Therefore, with a building of 100 m 2, it is worthwhile to take care of purchasing equipment with a capacity of 10 kW. With such an indicator, quick heating is ensured, if necessary.

Since pellet heaters have maximum efficiency, the power of such a device may be different. Therefore, when choosing this parameter, it is necessary to take into account the heating of: wood, coal or other type of fuel.

Fuel

The main types of fuel have already been mentioned above, but it is worthwhile to give an extended list:

- anthracite;

Modification of the anthracite boiler

Modification of the anthracite boiler - peat;

- briquettes;

- firewood;

- pellets;

- coke;

- other options.

This parameter is chosen taking into account the region of operation of the device, the level of required power and efficiency, features of storing solid fuel and other nuances of home heating.

Solid fuel boiler

Solid fuel boiler

They are the most popular solid fuel appliances in remote parts of the country where there is no gas supply. They are suitable for those cases where there is no place to store firewood, but you need to provide high power. This is a versatile, inexpensive solid fuel equipment with autonomous operation.

Solid fuel boiler on coal

Solid fuel boiler on coal Pellet and wood boilers - high power and efficiency, while maintaining efficiency. They can be installed in any building: from a private house to a small boiler room. The cost of such fuel remains one of the most affordable. At the same time, high efficiency is ensured - up to 90%. Long burning of firewood, their complete combustion is provided. Installation of the loading bunker is possible.

Pyrolysis devices allow you to burn biofuel. It can be various agricultural, wood waste, the combustion of which produces gas, which provides highly efficient heat transfer and burning duration. High efficiency is preserved - up to 92%. Pyrolysis devices provide complete combustion of fuel. Power may vary widely. Since pyrolysis solid fuel equipment is equipped with injection fans, there are low requirements for the chimney.

However, such heating devices are quite expensive, they require a certain moisture content of solid fuels and water temperature. This can complicate the heating of the house, put forward certain requirements for storing firewood.

By the type of burning equipment is divided into types:

- prolonged combustion;

- with natural or additional bollard;

- pyrolysis.

They are also divided into boilers:

- normal burning;

- pyrolysis types.

Battery life and volume of the combustion chamber

These indicators are interdependent: the smaller the camera, the shorter the battery life.

Note: Therefore, in order to be less likely to approach the boiler for throwing fuel, it is recommended to choose equipment with a large chamber. These indicators are expressed in units of l / kW.

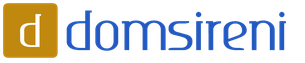

Separately, it should be said about solid fuel boilers with a vertical way to load firewood or other fuel. Such devices have an increased volume of the combustion chamber.

Automation and safety

Many modern heating systems are equipped with devices for the forced circulation of the coolant. Such equipment is easier designed, installed, saves money. Its only drawback - there is a risk of circulating during heating. In this case, the coolant stops moving around the system, but the boiler continues to generate heat. And if the pipes in the system are plastic, they may well not withstand such a temperature load.

Therefore, the developers were forced to install automated solid fuel systems, which independently ensured that the fan did not stop. After all, it is important not only to preserve the integrity and performance of the system, but also to ensure the safety of heating, to prevent the occurrence of fire.

boiler

boiler An inexpensive solid fuel boiler can be equipped with a cooling heat exchanger, which is installed at the outlet of the device. Its input is equipped with a valve that opens if the temperature of the coolant exceeds a critical value. In this case, the cooling water enters the system, lowering the temperature indicator to safe.

Automated systems need electricity supply. Since this may cause interruptions in the operation of equipment, it will not prevent the installation of uninterrupted components.

Demonstration of the solid fuel boiler

Switch to gas

Asking how to choose a solid fuel boiler, many people think about whether it is necessary to switch from solid fuel to gas. If there are interruptions in the supply of any type of fuel, then a universal system is an excellent choice.

Such equipment can be used even if gas has not yet been delivered to the house, but is planned for the near future. Then the season or several seasons can provide heating for the house with wood, and then switch to gas.

Heat exchanger material

Cast iron or steel? Two materials from which solid fuel boilers are made.

Steel endurely withstand temperature changes, heat up faster and cool down. The disadvantage is the possibility of developing corrosion, which makes further exploitation impossible. Models differ in standard indicators:

- material thickness;

- operating time at one solid fuel load;

- design features.

Cast iron solid products are sectional. Therefore, upon failure, only a section can be replaced. The likelihood of corrosion in cast iron samples is much lower than in steel. The main disadvantage is poor resistance to temperature changes, as a result of which the device can be damaged. Pig-iron equipment is inert.

Products exhibit high efficiency when operating on coal. The use of firewood can cause a decrease in the efficiency of cast iron equipment.

How to choose a solid fuel boiler for heating

Not always and not everywhere heating the rooms with gas or electricity is expedient or even possible. As an alternative solution, partially or fully autonomous devices - solid fuel heating boilers - come to the rescue. These devices are designed for high-performance work, both in private homes and on an industrial scale, the capacity in this case can reach 5000 kW. Thanks to their affordable price and high level of efficiency, they gained special attention and numerous positive feedback from consumers throughout the country.

Solid fuel boilers for a private house are presented on the modern market of heating equipment based on the classification of their power characteristics, price category, type of fuel and method of installation. According to user reviews, some of the most popular companies - Stropuva, Protherm, Biasi, as well as domestic ones - Zota, Hephaestus VPR, Prometheus, Teplodar and others are the most popular. Somewhat more, each manufacturer will be discussed below.

Description of products of different brands

1. The German company Buderus is engaged in the production of a line of solid fuel boilers up to 50 kW. In this case, the series of apparatuses includes both classic cast-iron and steel versions, as well as pyrolysis modifications. They differ from their competitors with a decent level of process automation. Allow the use of coal, pellets and coke.

The most remarkable, but at the same time expensive Buderus Logano G221 / A solid fuel model combines the functions of a long-burning pellet boiler and a boiler due to the built-in cast iron contour. Thus, it is not only heating the house, but also supplying it with hot water. An innovative adjustment system provides precise adjustment of the temperature mode of operation for the needs of a particular room, and a large number of electronic sensors makes the operation process as safe as possible. Thanks to automation, and also to a capacious tank, 1 loading allows to provide up to 7 days of uninterrupted functioning.

2. Lithuanian brand Stropuva offers its consumers long-burning solid-fuel boilers. Due to the design features and high level of efficiency, the devices are well adapted to work in Russian conditions. The unique gas distribution scheme allows you to evenly distribute the cold air into the very thickness of the pledged fuel, and the hot, giving off heat to the furnace walls, is discharged into the chimney. The owners of such a boiler note an increase in the burning time of one tab when using coal - up to 8 days.

3. The wide-profile company Zota produces a line of low-cost options for solid-fuel boilers in a steel case, equally well suited for both private houses and industrial buildings with a maximum area of 230 m2.

In particular, the Topol-M solid fuel model is distinguished by a heat-insulated and gas-tight casing thanks to a water jacket covered with basalt cardboard and a mechanized ashpit blowing valve. One load is enough for 10-12 hours. In combination with a horizontal heat exchanger and a three-way gas duct, it gives a maximum level of efficiency for its range of 91%. The device is quite universal and can work both on wood and coal, and with the help of electricity, or on gas when installing the corresponding burner.

4. The Protherm model of the Beaver series produced in Slovakia is a classic low-cost solid-fuel devices suitable for heating a small house or cottage with a capacity from 18 to 45 kW to choose from. The pig-iron case provides reliability, durability, wear resistance and, according to responses from consumers, high-quality heating of rooms. Available for installation in new and even already functioning systems. The devices have a high level of efficiency and a relatively low degree of preventive maintenance. Due to the volume of the combustion chamber, the process of heating a single firewood or coal laying takes more than 2 hours. As a result, combustion products are eliminated naturally.

5. The Russian company Hephaestus VPR produces a line of universal heating units, which, if desired, can operate on both solid fuel and a gas burner. The case also has connections for electrical heating elements. The steel casing of the apparatus, made of metal 3 mm thick, and a copper heat exchanger make it possible to combine the function of space heating and hot water supply in the device. The natural circulation of the coolant in the system is provided by the water-tube design of the heat element. Highly efficient Italian filling ensures the reliability and efficiency of the boiler. The declared level of efficiency is 90%. The powder-polymer outer coating contributes to the long-term preservation of the original appearance, and quiet operation characterizes the device for installation in a country house.

5. The Russian company Hephaestus VPR produces a line of universal heating units, which, if desired, can operate on both solid fuel and a gas burner. The case also has connections for electrical heating elements. The steel casing of the apparatus, made of metal 3 mm thick, and a copper heat exchanger make it possible to combine the function of space heating and hot water supply in the device. The natural circulation of the coolant in the system is provided by the water-tube design of the heat element. Highly efficient Italian filling ensures the reliability and efficiency of the boiler. The declared level of efficiency is 90%. The powder-polymer outer coating contributes to the long-term preservation of the original appearance, and quiet operation characterizes the device for installation in a country house.

6. Prometheus is another domestic manufacturer of durable and inexpensive solid fuel boilers. The technique is simple in installation and maintenance, reliable construction and a long period of combustion. Prometheus is well suited for use in any low-rise suburban construction, having in its arsenal bulk loading tank with a capacity of up to 7 kg. Thus, the burning time is extended to 8–12 hours. A heat exchanger made of heat-resistant steel with a thickness of 4 mm is capable of maintaining the optimum water temperature as quickly and as long as possible without the risk of failure. It is possible to connect electrical equipment for emergency or additional heating. Efficiency with coal heating is 84%, firewood - 78%.

6. Prometheus is another domestic manufacturer of durable and inexpensive solid fuel boilers. The technique is simple in installation and maintenance, reliable construction and a long period of combustion. Prometheus is well suited for use in any low-rise suburban construction, having in its arsenal bulk loading tank with a capacity of up to 7 kg. Thus, the burning time is extended to 8–12 hours. A heat exchanger made of heat-resistant steel with a thickness of 4 mm is capable of maintaining the optimum water temperature as quickly and as long as possible without the risk of failure. It is possible to connect electrical equipment for emergency or additional heating. Efficiency with coal heating is 84%, firewood - 78%.

Views of the owners

Below are some reviews from owners of solid fuel technology.

“We once decided to buy a solid fuel heating boiler ZOTA Topol M. So far, it has been working properly, for 4 years already. Six months after the installation, the water temperature sensor failed, but this did not affect the device. In addition, the manufacturer quickly replaced the spare part under warranty. In principle, it is enough for our weather conditions. Only in the winter in the most severe frosts, if it switches to electricity, it eats a lot, turns out to be a little expensive. Even in addition, they laughed and set a homemade traction control. The temperature stabilizes and the flow rate visibly decreases. "

“We once decided to buy a solid fuel heating boiler ZOTA Topol M. So far, it has been working properly, for 4 years already. Six months after the installation, the water temperature sensor failed, but this did not affect the device. In addition, the manufacturer quickly replaced the spare part under warranty. In principle, it is enough for our weather conditions. Only in the winter in the most severe frosts, if it switches to electricity, it eats a lot, turns out to be a little expensive. Even in addition, they laughed and set a homemade traction control. The temperature stabilizes and the flow rate visibly decreases. "

Larisa Gavrilova, Moscow.

“The owner of the solid fuel boiler Buderus for several years. He put the pyrolysis apparatus in a wooden house of 150 m2. I didn’t want to soil with coal, so now I’m burning firewood, I’m quite satisfied. Even in winter, one bookmark lasts up to 5 days. The size of the installation is compact, it does not take up much space, it works silently, and the house heats up with a bang. There are several safety sensors in the configuration. In addition, always hot water, and the floor heating system here is also connected. The only negative is a narrow opening for loading, it is necessary to chop smaller ones ”.

“The owner of the solid fuel boiler Buderus for several years. He put the pyrolysis apparatus in a wooden house of 150 m2. I didn’t want to soil with coal, so now I’m burning firewood, I’m quite satisfied. Even in winter, one bookmark lasts up to 5 days. The size of the installation is compact, it does not take up much space, it works silently, and the house heats up with a bang. There are several safety sensors in the configuration. In addition, always hot water, and the floor heating system here is also connected. The only negative is a narrow opening for loading, it is necessary to chop smaller ones ”.

Stepan, Kiev.

“I asked the owners of solid fuel pellet boilers about the quality of the heating produced, different opinions. One thing became clear - cost-effective. Pellets are inexpensive, they have more efficiency than firewood, and the places take 10 times less. In the end, he took the full automation. Attention does not require much. I load the tank once a week and use the remote control to adjust the desired mode. Power that is necessary, the big house heats in 2 hours after a long idle time. And the economic benefit on the face: the winter before last spent 40,000 rubles on electric heating, now he bought a pellet machine for 14,000 rubles and had not spent the stock until the end. In general, the choice was not wrong. "

“I asked the owners of solid fuel pellet boilers about the quality of the heating produced, different opinions. One thing became clear - cost-effective. Pellets are inexpensive, they have more efficiency than firewood, and the places take 10 times less. In the end, he took the full automation. Attention does not require much. I load the tank once a week and use the remote control to adjust the desired mode. Power that is necessary, the big house heats in 2 hours after a long idle time. And the economic benefit on the face: the winter before last spent 40,000 rubles on electric heating, now he bought a pellet machine for 14,000 rubles and had not spent the stock until the end. In general, the choice was not wrong. "

Sergey, St. Petersburg.

“We bought a Protherm solid fuel boiler. A good combination of price and quality. The only thing was that I had to tinker with replacing the tank, the built-in painfully small turned out to be for our family. Well, for greater savings, an additional thermostat was installed. And mandatory grounding, of course, on the advice of the master who installed the boiler. In general, the purchase satisfied. At first they tried to use firewood, but they had to be thrown often, so the best thing to do with coal was burning it twice as long. Much more efficient than electric heaters, and cheaper than supplying gas to the house. The device is compact, almost silent during operation. With proper installation, there will be no operational problems. ”

“We bought a Protherm solid fuel boiler. A good combination of price and quality. The only thing was that I had to tinker with replacing the tank, the built-in painfully small turned out to be for our family. Well, for greater savings, an additional thermostat was installed. And mandatory grounding, of course, on the advice of the master who installed the boiler. In general, the purchase satisfied. At first they tried to use firewood, but they had to be thrown often, so the best thing to do with coal was burning it twice as long. Much more efficient than electric heaters, and cheaper than supplying gas to the house. The device is compact, almost silent during operation. With proper installation, there will be no operational problems. ”

Valentin Ponomarev, Kharkov.

“We approached the choice of a solid fuel heating boiler sensibly, having studied reviews from the owners of the network. We stopped at the Stropuva brand; in one of the ratings, it ranked first in terms of reliability and popularity. The price tag bites, but in my opinion it’s not worth saving on heat. The device as a whole is ergonomic, does not require a lot of space. The representatives of the dealer were engaged in the installation, they let everyone down correctly and cleanly. He eats a pot in moderation - is not picky about fuel. First, the remnants of firewood burned, then they decided to switch to coal in order to burn longer. In addition, a little uncomfortable - too narrow door for laying wood. We also want to try pellets - cheap material, I wonder how long it will be enough. ”

“We approached the choice of a solid fuel heating boiler sensibly, having studied reviews from the owners of the network. We stopped at the Stropuva brand; in one of the ratings, it ranked first in terms of reliability and popularity. The price tag bites, but in my opinion it’s not worth saving on heat. The device as a whole is ergonomic, does not require a lot of space. The representatives of the dealer were engaged in the installation, they let everyone down correctly and cleanly. He eats a pot in moderation - is not picky about fuel. First, the remnants of firewood burned, then they decided to switch to coal in order to burn longer. In addition, a little uncomfortable - too narrow door for laying wood. We also want to try pellets - cheap material, I wonder how long it will be enough. ”

Galina Gracheva, Krasnoyarsk.

“I decided to support the domestic manufacturer to purchase a steel solid fuel boiler Hephaestus Siberia. In principle, it works fine. Heats, of course, rather weakly, the power is not enough, but we also do not like the strong stuffiness in the rooms. Throw in the furnace every 5-6 hours. They say that if you switch to coal, it will burn more slowly, it is worth trying. When the fuel runs out, you can turn on the electric heating mode, thanks to the built-in heating elements. Bribes the presence of the hob, and even for such a ridiculous price compared to other firms. For a country house - the perfect solution. In addition, we do not live there in winter, and drown there the rest of the time, when we are not lucky with the weather. Cooking is a pleasure, no worse than an electric cooker. ”

“I decided to support the domestic manufacturer to purchase a steel solid fuel boiler Hephaestus Siberia. In principle, it works fine. Heats, of course, rather weakly, the power is not enough, but we also do not like the strong stuffiness in the rooms. Throw in the furnace every 5-6 hours. They say that if you switch to coal, it will burn more slowly, it is worth trying. When the fuel runs out, you can turn on the electric heating mode, thanks to the built-in heating elements. Bribes the presence of the hob, and even for such a ridiculous price compared to other firms. For a country house - the perfect solution. In addition, we do not live there in winter, and drown there the rest of the time, when we are not lucky with the weather. Cooking is a pleasure, no worse than an electric cooker. ”

Peter Zorin, Yekaterinburg.

Advantages and disadvantages

It is worth choosing solid fuel boilers as the main source of heating for a private house, based on a number of their advantages:

1. simplicity - the equipment is able to function successfully on coal, peat, firewood, pellets and some other types;

3. thanks to modern designs, a high level of fire safety is observed;

4. economic benefits versus gas and electricity costs;

5. uncomplicated technology ensures uninterrupted operation of the device and long service life;

6. autonomy of solid fuel equipment;

7. the cost is lower than that of other heating devices;

8. wide range of configurations suitable for various needs;

9. relative ease of installation and operation.

However, there are some downsides:

- low heat transfer rate;

- continuous monitoring of the operation of solid fuel equipment, with the exception of fully automated heating systems;

- the need for a separate, moisture-proof fuel storage area;

- in low-cost devices - the constant need for preventive maintenance - cleaning soot and soot.

What is better to choose?

1. For heating a private house with a solid fuel boiler, it is necessary to choose a model that is primarily suitable for specific premises in terms of power characteristics. It is easy to independently calculate the approximate power of the required boiler - 1 kW for every 10 m2 of living space, while taking into account a satisfactory degree of insulation of walls and a ceiling height of up to 3 m.

2. When choosing a solid fuel heating boiler one should pay attention to the volume, shape and dimensions of the furnace. These characteristics indicate the allowable weight of the fuel being loaded and its dimensions.

3. It would not be amiss to inquire about the material for the manufacture of the boiler, heat exchanger and other components:

- cast-iron options are best suited for wood heating and retain a high temperature for a longer time, the service life is 30-40 years;

- alloy steel is more suitable for solid coal fuels, combines lightness and smaller dimensions of equipment, the service life is 10-15 years; The steel heat exchanger heats up faster, it is not afraid of sudden changes in temperature, but it is also significantly more capricious about the quality of the heat carrier.

4. It is important to pay attention to the level of efficiency of a solid fuel boiler. The normal value is 75-90%. Such equipment can work both on firewood and coal, pellets, etc. However, there are omnivorous plants, and their level of efficiency is somewhat higher. There are some best options that combine wood and electric heating. Thus, during the day heating is carried out by a firebox, and at night TEN is switched on. This is beneficial if the economical night tariff for electricity consumption is connected.

5. If only wood is preferred, then pyrolysis types are better. Gas-generating boilers for heating differ in the concept of operation - wood gas is burning, which is produced by the action of high temperatures on firewood. These equipment options are good with less soot and soot formation and, as a result, the need for rarer preventative maintenance. Efficiency apparatus is 84%, however, the price will be much higher than their fellow tribesmen.

6. In some cases it is worth choosing a durable automated solid fuel boiler to save time and effort on a regular tab. It is more suitable for residential buildings. For the seasonal stay is quite suitable classic heating option.

7. It is advisable to entrust the installation of equipment to professionals. When installing the boiler, it is mandatory to comply with the standards for the height and cross section of the chimney. These values depend on the model and type of specific apparatus and are indicated in the accompanying documentation. Otherwise, there is a risk of smoke from the room.

8. One of the main advantages of solid fuel heating - non-volatility. Most models do not require an additional electrical connection. However, in the absence of electronics in boilers, as a rule, a mechanical system for adjusting the temperature of the coolant is installed - an important component of efficient operation.

9. If it is necessary to provide a house with hot water supply, you should pay attention to the solid-fuel modifications with a double or single circuit and an indirectly connected boiler. Such devices operate both autonomously due to heating, and from electricity.

Cost of equipment

Buy solid fuel heating boilers are available in a wide range of stores at prices, depending on the capacity and type of equipment.

Comfortable and well-heated solid fuel boilers have long been replaced by old stoves, and over time they are improving. Owners of country houses in which there is no permanent central heating system, simply can not do without such equipment. They are used as main or backup heating devices, they do not allow to freeze even in the coldest winter nights. You have already purchased a cottage or a mansion and now you do not know how to heat it? Let's find out how to choose a solid fuel boiler for a private house, what types of them exist, what are their features and what is better to choose.

Types of solid fuel boilers for heating a private house

Before you buy a solid fuel boiler for a private house, you should understand what types they are and what is the difference between them.

In terms of functionality, all such devices can be divided into two types:

- Dual circuit. Used for heating the house and heating the water system in the kitchen and bathrooms.

- Single circuit. During the work they give out heat only for space heating.

- traditional or classic;

- pellet

- long burning;

- pyrolysis or gas generator wood.

Classic, traditional

Such solid fuel boilers are most similar to the usual stove with a window for the supply of coal or wood, chimney and furnace. The main part of such a unit is a heat exchanger, which ensures the transfer of heat energy to the coolant. Depending on the material from which the heat exchanger is made, they are:

- cast iron;

- steel.

Pellet

From a traditional, classic solid fuel boiler, such an apparatus is different in that, in addition to the combustion chamber, it also contains a special bunker, as well as automation, which supplies fuel. The raw materials for the device are granules specially made from various wood waste. They produce heat and are cheaper than coal. The advantages of this type include the fact that they:

- do not require constant attention and time-consuming maintenance;

- The efficiency reaches 85%;

- the duration of operation is limited only by the size of the bunker for the automatic supply of raw materials;

- equipped with a temperature controller and a sensor that monitors the level of heating inside.

Long burning

Such solid fuel boilers are also called top burning devices. This type is characterized by the fact that the air is supplied and the fuel burns only in the upper part. Due to this, a large amount of fuel material can be immediately loaded into the firebox - it will be consumed gradually, which ensures a longer burning time.

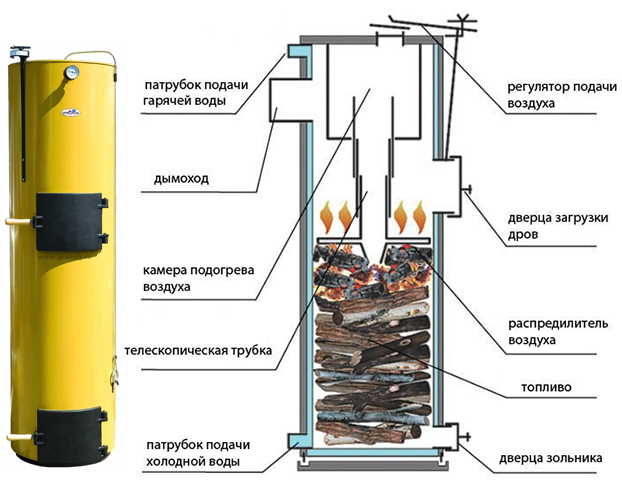

Pyrolysis (gas generator)

This unit produces heat in several phases:

- The first. Drying wood.

- The second. The degassing process, during which, during the combustion of fuel, 85% of the substances go into a combustible gaseous state, and 15% - into charcoal.

- Third. The combustion phase at which the temperature reaches 600 degrees. Combustible gases are oxidized and ignite, resulting in a layer of burning charcoal. When it reaches 900 degrees and up to a threshold of 1000, low gases are actively saturated with carbon and maintain the required temperature so that the charcoal decomposes.

Choosing a heat exchanger material for a solid fuel boiler for a private house

Today, the model range from various manufacturers is represented by devices with steel or cast iron heat exchangers. None of them loses popularity, and manufacturers often specialize in the production of both types. Each of them has its advantages and disadvantages, and therefore even professionals do not take it for granted which material is better. So, if we talk in more detail:

- Cast iron This is a sectional design and therefore each individual section can be easily replaced in case of failure. Also, such a collapsible version of a solid fuel boiler for a private house is more convenient for transportation, maintenance, installation, in case of repair during depressurization. It is possible to clean such devices less frequently, since during operation the cast iron is covered mostly with dry rust, and it is exposed to wet corrosion much more slowly than steel. They have a higher rate of thermal inertia, that is, they warm up longer, but at the same time they cool down much more slowly. The main and rather serious drawback is their instability to sudden changes in temperature. If a hot liquid that has not had time to cool down from the cast iron gets cold liquid, such a thermal shock can cause cracking and your boiler will simply burst. Therefore, you need to be very careful when using and avoid a large temperature difference between the return and flow lines.

- Steel. This one-piece monoblock assembled and welded in an industrial environment. Such a solid fuel boiler for a private house does not understand, therefore, a number of problems may arise with cleaning and maintenance, although the specialists cope with them quite well. Steel raids are not as terrible as cast iron, temperature drops - this metal is much more elastic, therefore it can withstand even feeding with cold water in the return line. Due to such resistance to thermal shock in equipment with steel heat exchangers, automation is widely used. Despite the fact that temperature drops are well tolerated, they should not be abused anyway. After all, if they are large and occur frequently enough, they may appear in places weakened by welding cracks. In case of damages, rusting wall, large deposits of salt, burnout, the whole apparatus becomes unusable, as it is most likely not possible to weld it and there are no sections that can be easily replaced. As for the work itself, such solid fuel boilers heat up faster, but also cool down in less time.

Fuel for solid fuel boiler

When choosing a boiler, it is important to decide which type of fuel will be easier for you to use. For example, you may have a problem with the supply of firewood or there is no place to store them in large volumes. Perhaps you for some reason do not want to use coal or you have a lot of other fuel materials in the public domain. Most modern devices can operate on different raw materials. The main types of fuel used in solid fuel equipment include:

- firewood;

- brown coal;

- anthracite;

- peat;

- coke;

- fuel briquettes.

Usually, in the instructions of the manufacturers indicate which raw materials should be used as the main and additional. Following these recommendations will significantly extend the life of the product.

We determine the power of a solid fuel boiler for a private house

This is one of the main selection criteria, and therefore the question of power is set before each purchase. After all, it is important that you feel warm and comfortable in all the rooms of the house, but you did not have to overpay for the surplus. To calculate the power yourself, you need to know such parameters as:

- The area of the heated room.

- The specific power of the heater per 10 square meters. m. taking into account the amendment to climatic conditions.

- If the area is from 60 to 200 m2, a device up to 25 kW is required.

- To heat a house with a territory of 200–300 square meters, an aggregate up to 35 kW will be needed.

- An average cottage of 300–600 m2 will need a 35–60 kW appliance.

- To make it warm even in the most severe frosts in a mansion ranging from 600 to 1,200 square meters, it will be necessary to install equipment with a capacity of 60–100 kW.

Net volume of a loading chamber of a solid fuel boiler for a private house

The useful chamber volume is one that you can fully use to load combustible raw materials. This characteristic is also very important when choosing a solid fuel boiler for a private house, as it shows the ratio of the volume of fuel laid during one load to the power. That is, to say in simple words - how often you will need to fill the chamber to maintain a comfortable temperature. On average for:

- Cast iron - 1.1 liters of fuel goes to 1.4 kW.

- Steel - 1.6 liters at 2.6 l / kW.

On average, the burning time of one filling at pyrolysis boilers is 6–10 hours, while the efficiency level is 90%, the main fuel is wood, and the size of the chamber is larger than that of traditional ones.

When choosing the size of the chamber of a solid fuel boiler for a private house, many are guided by the principle that the more the better, because less often you will have to load firewood or coal. However, everything is entirely individual, because the longer the battery life, the higher the price.

An interesting solution would be to purchase an automatic pellet aggregate, since it will require a minimum of intervention from you. All you need to heat the room is to load the pellets into the bunker, and the device will automatically feed them into the burning zone with the help of an auger. Burning time varies by camera size.

Electricity consumption by solid fuel boilers for a private house

Depending on whether the device consumes electricity or not, they are divided into:

- Non-volatile. Such devices are ideal for heating systems that do not have the need for a circular pump and the whole process takes place in a natural way. Non-volatile are the classic, traditional units and some models of long burning. They are very convenient for use in areas where electricity is often cut off, they can also play the role of an auxiliary or backup solid fuel boiler for a private house.

- Volatile. These are the devices in which there is a fan that feeds air into the combustion chamber, and a control panel on electronics. These include pyrolysis, pellet and most models of long burning.

The presence of buffer capacity in a solid fuel boiler for a private house

The best way to use this type of heating equipment is to use it in conjunction with a thermally insulated water tank. Such a tank is installed between the boiler and the heating system. This buffer (heat accumulator) performs the following basic functions:

- Protective. It protects the heating system from overheating of the apparatus by absorbing the entire excessively heated coolant and mixing it with a sufficient amount of warm water.

- Accumulating. It collects the necessary heat from the unit and, as necessary, supplies it to the system.

- Binder. It allows you to easily connect in a single chain different gas, solid fuel and electrical devices, as well as function normally in the same system.

Choosing a buffer, you should calculate its capacity, based on the fact that about 25 liters are required per 1 kW of boiler power. That is - the more powerful our unit is, the larger the heat accumulator it needs.

Additional criteria for choosing a solid fuel boiler for a private house

In addition to all of the above, before buying a solid fuel boiler for a private house should pay attention to:

- How good is your chimney draft. If it is insufficient, it is better to stop on models with an additional ventilation system.

- Do you need the ability to switch to gas. If you have frequent interruptions in electricity and gas, or you already need to go to a new house, but have not yet conducted gas there, but promise it soon, then a device with the possibility of changing the fuel is what you need. For work on gas, classic units are perfectly converted by installing an inflatable heater.

- What is the weight and cost of installation. A solid fuel boiler for a private house made of steel weighs about 20% less than a cast-iron one, and therefore its delivery and installation will cost you less.

- What guarantees durability. The longer the guarantee of the company, the better. On average, it is about ten years.

- How high is the safety of use. More expensive equipment has more levels of protection against burns and injuries.

More about the features of choosing a solid fuel boiler for a private house, see below:

Almost everyone cherishes the dream of their own country house, where you can spend your free time or just live in the summer months. When buying, including a wooden house or during its construction, the question of heating necessarily arises. If there is an option to connect to the gas distribution network, there is no problem, but what about if there is no such opportunity.

You can heat the house with a conventional stove or fireplace, but they have low heating efficiency and need constant monitoring. An alternative and economically feasible solution to this rather complicated task is to heat a country house with a solid fuel boiler.

In Scandinavia, for example, 40% of brick and wooden private houses are heated with solid fuel boilers, using natural fuel. Such boilers are environmentally friendly equipment. If all requirements are met during installation, this is a safe solution for heating a private house, and the solid fuel used is considered the cheapest.

Fig. one Solid fuelsfor heating a private house

Solid fuel:

- firewood;

- peat;

- briquettes;

- coal;

- pellets (wood pellets);

- biofuels.

The main determining factors for choosing a solid fuel boiler

In order to purchase a heating boiler for solid fuel for the house of the necessary power, which is the main characteristic when buying, it will be necessary to take into account various factors.

If the ceiling height is less than three meters, the required power is determined from the proportion of 1 kilowatt per 10 square meters. m

Be sure to take into account the presence of wall insulation, air temperature and the duration of cold months.

The calculation takes into account the number of windows and doors and their placement. The inner walls retain heat well, so their number also needs attention. The use of additional heat sources (electric heaters, fireplace) is taken into account.

It is necessary to determine the dependence of equipment on electricity, if at the location of your home there is a tendency of frequent outages or power failures.

Finding out what kind of solid fuel in your region will not be a problem in the acquisition. Taking into account all the above factors, you can choose the best option for a solid fuel boiler for the house.

What determines the cost of the boiler

The cost of the heating system for solid fuels depends primarily on its configuration. Coppers of this kind can have an automatic fuel supply system, which, of course, increases its cost. This mechanism allows you to automatically load the fuel from once a week to three times during the entire heating season. For the latter, they use such convenient fuel as pellets, they have the appearance of wood pellets and are one of the best fuels.

Of great importance for the cost of equipment is the material from which one of the most important components is made - the heat exchanger. It is through it that heat is released from the entire system. Steel heat exchangers can serve up to 20 years, are resistant to sudden temperature changes and have a low weight. The disadvantage is condensate sensitivity. Cast iron heat exchangers serve more than 45 years and have a high resistance to corrosion, but when the temperature drops, due to the fragility of the material, cracks may appear in them.

Principles of heating systems of private housing

According to the principle of action, two types of boilers are distinguished: classical and pyrolysis. In the first case, the fuel heats the water during combustion, and it is the coolant. Heating of the rooms occurs with hot water filling the pipes.

Pyrolysis boilers work as a dry gas distillation system (gas generator). They provide combustion of fuel almost completely. Under the influence of a very high temperature of burning and due to insufficient oxygen, wood decomposes and releases a gas called pyrolysis. When in contact with oxygen, the gas begins to burn and emit a greater amount of heat than when burning fuel in a classic boiler.

The efficiency of the solid fuel pyrolysis boiler reaches 90%. But if the fuel is not advanced, its performance will fall by more than 50%. Therefore, it should be stored in a completely dry place.

According to safety precautions, solid fuel boilers for heating a private one, especially a wooden country house, are not allowed to be installed directly in a residential area. The boiler is mounted on a concrete substrate with a height of at least 50 mm. Installation work on its installation is simple. The main thing - to withstand all the technology installation. All work on the heating of a private home solid fuel boiler can be performed within one, maximum two days.

Fig. 2

Fig. 2The room where the solid fuel boiler will be installed must be equipped with ventilation. In no case should it contain flammable or explosive substances.

Benefits

Advantages of a solid fuel boiler:

- availability of the acquisition;

- small sizes;

- easy installation and use;

- high degree of safety during operation;

- the possibility of long-term operation of automation in accuracy with the settings without human intervention;

- low cost;

- low cost and no shortage of solid fuels;

- environmental friendliness (it has no components harmful to humans);

- possibility of use in any region, even the most remote.

Disadvantages in operation

The main disadvantages of the heating system include:

- The need to load fuel on average from 2 to 6 times.

- The need for regular cleaning of residual fuel.

- Difficult start after a long idle.

- The inability to instantly stop work.

- The presence of a large area for storing fuel.

Specificity of heating a wooden house with a solid fuel boiler For proper and full heating of housing it is necessary to take into account some features. The heating system does not have full autonomy. In all solid fuel boilers, it is necessary to load the fuel itself in time to avoid a sharp decrease in temperature in the heat exchanger.

If you install a cumulative buffer tank, then in the event of a cooling down of the boiler or a temporary power outage, the system will itself maintain a predetermined heating temperature for some time. For the same purpose, you can use the principle of "warm floor".

Safety issues of heating in a country house

The system of general heating safety in a country house is a priority.

Wood is a flammable material and therefore there should be several options for protection against fire when the house is heated with a solid fuel boiler:

- Availability of coolant pressure sensors to avoid pipe gusts.

- Installed fire extinguishing system with sensor response to smoke and sudden temperature changes.

- Overheat protection, installed in the equipment itself, blocking, if necessary, the operation of the heater.

Key points for installation

Installation of a solid fuel boiler for heating must be carried out exclusively in accordance with the installation rules. The safety of all tenants in the future depends on this.

Fig. 3 Placement option solid fuel boiler

Fig. 3 Placement option solid fuel boiler in a wooden house

It is obligatory to cover the heat-resistant material of the walls, floor and ceiling of the room where it is planned to organize the boiler room. In a rare case, it is possible to do with the impregnation of the wooden surfaces of the room with special solutions to increase the temperature resistance. Solid fuel boilers for home heating are subject to increased danger.

The installation of equipment close to the wall, as well as the installation of fasteners strapping on a wooden surface is excluded. In a high-rise wooden country house need interchanges on each floor. This reduces the number of common risers. Mandatory installation of expansion tanks and compensation equipment.

It is necessary to use only high-quality pipes and radiators, pay special attention to their quality connection. If the wooden structure does not have a basement or basement room, where solid fuel boilers are usually mounted, it can be installed in a separate extension or a designated place on the first floor, taking into account the necessary space to accommodate the fuel.

The popularity of heating wooden houses with solid fuel boilers is very high. Qualitatively heated wooden house can store heat for almost two days.

According to statistics, the heating of a private house with a solid fuel boiler, and even more so a wooden house today is the most profitable and highly efficient. Eliminating many problems associated with maintaining a comfortable temperature in the room and in the presence of inexpensive fuel, solid fuel boilers have a good future outlook.