Comparison of boiler heating and brick kiln. Oven with a water circuit: buy or make your own hands? Options, solutions

Lack of available solid fuel in Russia there is not and is not expected. A furnace with a water circuit costs a lot cheaper than a boiler: domestic prices heating stoves with a water register start at 16,000 rubles; averaged over the models, the cost of such a furnace is approx. 40 000 rub. More or less decent boiler on the same thermal power costs three to five times more expensive. Firewood in remote regions is often free - foresters will only be happy if someone cleaves the fallen tree. Wood fuel is environmentally friendly: the time it takes for a tree to grow to suitability corresponds to the flow of natural climatic cycles, and when wood is burned, exactly as much carbon dioxide is released as the tree took it to build itself. If you drown fossil fuels, then the nature “digests” much easier and faster than the volley from a CHP of the same capacity dispersed over a large area and stretched over time, the total emission of greenhouse gases from a variety of house furnaces.

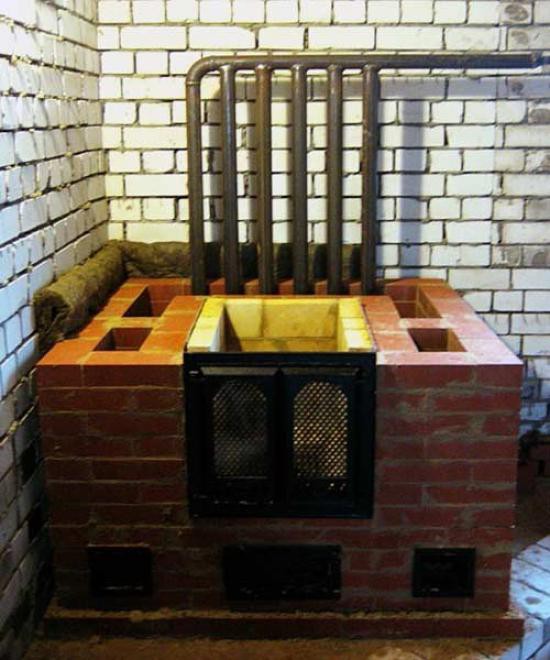

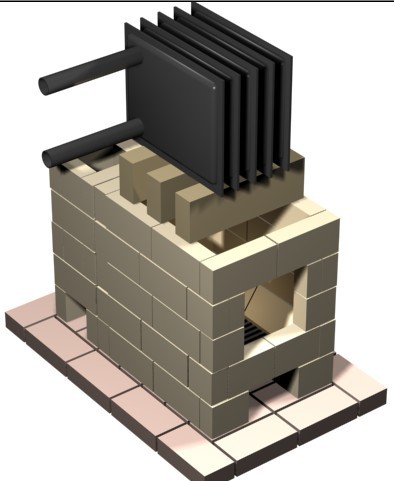

Build a brick or make a metal stove case is quite tricky, but the machinery and industrial conditions does not require. See, for example, a video project of a brick oven with a water heating circuit for a private house:

Video: example of a project of a water circuit furnace for a private house

The purchase of a furnace is relatively inexpensive, but the delivery of a heavy and bulky item to distant places can cost more than it cost: overseas heifer cannon and ruble transportation. In this section, the question: "Is it possible to make a furnace with a water circuit with your own hands?" Is quite legitimate. But, unfortunately, the design of the furnace has developed in those times when they have not even thought about water heating. Modern high-tech stoves work on the same principles as cruise liners float in the same way as the trireme of the time of Archimedes. Build or choose the right to buy a stove with a water heating circuit is possible, but you need to take into account a number of specific pointsabout what this article is written.

Note: The first of these moments is aesthetic. Do not expect that the stove that supplies the heating battery will look like it is shown on the left in fig .:

AT the best you get what's in the center. And maybe the one on the right. Therefore, if you also have a home decoration for the furnace, you need to think three times and think three times - but is it still necessary to supply heating? It will not be a hindrance to him, see at the end.

About the disadvantages and merits of bricks

- Complicated heavy construction, which requires a separate foundation and production of capital construction works in the house. Embedding the water circuit in a brick oven is much more difficult than in, see below. But at the same time:

- The brick oven maintains optimum humidity in the house: it absorbs excess water vapor from the cool air and releases it when heated during heating.

- It also establishes a temperature field optimal for health in the room: everything is warmer from the walls to the center.

- Reduces the heat loss at home: streams of air heated by the furnace create a downward thermal curtain in front of the windows, much more efficient than rising from the registers (radiators) under the windows.

- Aligns the microclimate in the house: in summer it absorbs some of the excess heat and takes it through the foundation to the ground. In winter, in the same way a little warms the house.

- For the reason before. paragraph stabilizes the draft of the building, makes it more reliable, stable and durable.

Note: In the history of construction, there are many cases when strong houses, transferred from the furnace to central heating, after dismantling the furnaces began to collapse.

What is the problem?

The heating boiler was invented precisely in order to replace the stove as a heat generating device in heating systems (CO). The boiler is a continuous device requiring from the user, ideally, only periodic reloading of fuel and seasonal maintenance. Its fundamental difference from the furnace is the automatics that support the combustion mode that is optimal for a given operating mode. Automation is not necessarily electronic; It can be a non-volatile combination of bimetallic plates, springs and levers.

The furnace is a hand-operated batch device, which is why it is cheaper. It's not about the box with automatics. The point is the very basics of the approach to design and production. Specifically, in the methods of organizing complete combustion of fuel. If we continue the shipbuilding analogy, the boiler is no longer a displacement vessel, but a glider. Which can also float like a steamer, but will show its full qualities only when it comes out to the redans. However, planing requires relatively calm water; correctly constructed and adjusted CO, figuratively speaking, for the boiler it is. The furnace (continuing the same analogy) under the control of an experienced crew can go at full speed on considerable excitement. Due to such a margin of operational endurance and it is possible to adapt the furnace under water heating. Full speed (the same analogy) will be quieter than that of a speedboat (maximum thermal efficiency 60-65% versus 80-95%), but, "going at economic speed in calm water", the specific fuel consumption for heating a unit of cubic capacity at home do not exceed that of the boiler.

Note: thermal efficiency of heat-generating devices is a complete analogue of efficiency for internal combustion engines.

Buy or build?

Only metal furnaces with a water circuit are available. The foundation and the defeat in the house for the installation of a metal furnace is not needed, but it does not possess the useful qualities of brick. In an energy efficient house (see below) you can only put a metal stove. Produce such many furnace companies, incl. foreign ABX (Czech Republic), MBS (Serbia), EdilKamin (Italy). Here, firstly, the nuance: do not confuse with the bath stove, equipped with a hot-water heater for hot water supply; for heating bath stoves are unsuitable. Differences, if the specification does not indicate that the stove is a heating stove - a bath stove is always with a heater. The second is the same stove, but with a water circuit, often goes on sale like a boiler. How to distinguish from this boiler? By the presence of the hob and furnace door with a sight glass. The boiler is not intended for gatherings at the lights. Third, EdilKamin is built in a water-jacketed pattern and is not intended to be used as the main heating device; it is actually a fireplace with a water circuit, see below. And, finally, Russian stoves with a water jacket (the sign is “Aqua” in the title) should be installed in a non-residential room or in a separate boiler room, but for giving Brenerrans the most: Breneran Aquatene costs up to 20,000 rubles. (without delivery). About other domestic furnaces with a water circuit, see video reviews:

Video: Water Circuit Reviews

In addition, if you intend to buy a stove for water heating, please note:

- For factory water furnaces, all of the following operating limitations apply;

- If the heating boiler is often sold with a full set of standard strapping, then the furnace is always without it. The selection and installation of strapping is a particularly difficult topic, and its cost can bridge the difference in the price of the furnace or boiler;

- Fireplace inserts with a water circuit are also available. This is by no means a major. heating deviceswhatever they promise in advertising! The fireplace insert with a water jacket (as well as the EdilKamin stove) is included in the existing local (house) CO with a boiler for saving regular fuel or in a CO energy efficient house, see below.

Note: to include additional heat-generating devices in the operating CO it is necessary with several degrees of protection against their undesirable influence on each other, see for example. video below:

Video: about the danger of a fireplace with a water circuit

Basement as a decision criterion

Generally, if your house is with a basement, first of all you need to consider purchasing and installing a boiler. The basement will always be given by the elevation of the registers above the heating device, which is necessary for constructing a simple, inexpensive and non-volatile gravitational CO (see below). Heat from the stove (fireplace) without a water circuit for cooking and / or admiring the fire under the brandy with caviar for free will not be lost: the boiler automation "hears" it and saves regular fuel.

Related Restrictions

Recall the saying "shaggy": free cheese is only in a mousetrap. A heating furnace with a water circuit is built and operated with serious limitations compared to simple:

- The heat exchanger cannot be brickled into the body (structure) of a brick kiln: the difference in TCR (thermal expansion coefficients) of it and the structure of the kiln will very soon disable both;

- If the firebox is equipped with a water jacket, then it is impossible to achieve an optimal stove / fireplace stroke in terms of fuel consumption. Therefore, devices of this type can only serve as additional in the current local CO;

- The heat exchanger of the furnace with a water circuit must be completely wrap around flue or flue gases;

- To start a stove / fireplace with a water circuit with empty CO is unacceptable. If it is a heating-cooking stove used all year round, it should have a winter-summer switch, and the heat exchanger should be installed only in the winter part of the furnace structure;

- Let the water in the bottom CO, i.e. Immediately into the furnace, it is possible only if it (the furnace) is steel and the feed from the bottom is indicated as standard in the manufacturer's specification. CO with brick oven fueled cold water only and above, from the expansion tank;

- Since the heat exchanger in CO with a periodically fired furnace undergoes regular alternating thermal loads, build with a CO furnace closed type with excessive pressure is unacceptable;

- For the reason before. the point of building a CO with a furnace that is constantly filled with antifreeze is meaningless: the expensive heat carrier will even grow old, degrade and disappear before the end of the current heating season;

- At the end of the heating season, the coolant (water) from CO necessarily merges. This is necessary for the formation of a dense iron hydroxide film in the pipes, which prevents their further corrosion;

- Before you start the trail. season, the system is filled with water, pressurized and pressed by pumping air from the expansion tank to 2.2 ATI;

- The system must be filled at an outside temperature not lower than 15 degrees;

- The heater starts not earlier than one day after the system is crimped, but not earlier than the coolant temperature equals the room temperature;

- A wood-burning stove with a water circuit should be heated at intervals of no more than 12 hours between the furnaces, regardless of the heat capacity of the furnace structure and external conditions, i.e. Ovens should not be allowed to cool completely. This is explained by the low calorific value of firewood and the high probability of acid precipitation from wood flue gases.

Note: it is impossible to build with a Leningrad-type CO furnace - over-pressure and forced circulation are needed for Leningrad.

Oven and CO

The main thing you need to know if you decide to build a furnace with a water circuit yourself: to completely burn the fuel in the furnace and achieve its extreme thermal efficiency, the temperature under the roof of the furnace, where the pyrolysis gases burn down, should be at least 1100 degrees. At the same time, for pyrolysis, which completely “sucks out” volatile components from fuel, the temperature is 400–600 degrees, and 600–800 for ignition of residual amorphous carbon fuel. The temperature of the outer surface of the heat exchanger is, in principle, needed higher, this allows you to perform its smaller sizes (see below), but the steel one is not more than 400 degrees, and the pig-iron one is not more than 600 degrees (with a system pressure equal to atmospheric) to prevent boiling of the heat carrier. The characteristic size of the heat exchanger installed in the furnace furnace is 0.3-0.5 m; installed in the smoke ducts - 1-2 m. Another thing: if the temperature in the smoke ducts falls below 200 degrees, the probability of acid precipitation in the furnace is high. If the stove is fueled by waste (non-conforming) fuel that never completely burns out - also increased soot deposition in the stove and chimney.

Knowing these circumstances, and perhaps successfully build a stove with a water circuit for heating the house. The task is as follows: to build in a heat exchanger into the furnace, which takes a sufficient amount of heat, but does not bring down the temperature at the installation site below permissible. The stove for this purpose is designed to be obviously overpriced: 10-15% more than is needed to heat the house. These 10-15% must be given to maintain the correct course (mode of operation) of the furnace, taking into account the heat transfer to the side. Due to a more uniform distribution of heat in the house, its heat losses, depending on the temperature difference between inside and outside, are falling, and fuel savings for the season will be 20-25%; up to 30% in combined WITH (see below). The net gain in fuel costs per season is 10-20%, and the loss compared to heating from a good boiler is 5-10%.

Note: a furnace with a heating circuit makes it possible to build a relatively inexpensive and self-accessible gravity cooling system in a house without a basement, see below. The boiler for gravitational CO must necessarily be in the basement, and if it is not there, an energy-dependent CO with forced circulation, see also below.

More on brick issues

A brick furnace has one, from the point of view of CO, "unfriendly" quality: their thermal time constants (this is what is commonly called thermal inertia) are approximately equal. The thermal inertia of a metal furnace is an order of magnitude less than that of CO. If the system exits the mode, “drive” it back there, possibly by promptly adjusting the furnace stroke. It’s not always possible with a brick stove: it can all get stuck in an uneconomical and even emergency mode (to put it “smart”, to be in a metastable state). Then you have to either freeze, waiting for the next firebox, or even urgently extinguish the furnace. The means to almost eliminate the “looping” is to heat the furnace 3 times a day with an interval of 7-9 hours (early in the morning, and at night), and in the very cold - 4 times with an interval of 6 hours.

About furnaces on corruption

If you search the product catalogs for long-burning heating furnaces with a water circuit, then there are none. About 3-4 years ago a coal stove flashed "Homeless", but now it is not visible. And this is no accident.

A long burning furnace “pulls out” heat from the fuel slowly and gradually. On the other hand, these furnaces are critical to the temperature of gases above the mass of fuel; for different designs, it ranges from 600-1000 degrees. A little lower - the stove is extinguished and the caked mass from it is very difficult to pick out. Above - goes on a fiery burning, for her emergency, and the owners face a great disaster. Fiery stove in either case, just eat more fuel.

In other words, the heat balance in a long-burning furnace should be maintained much more accurately than in a fiery furnace. The “extra” heat (suitable for use) of the “on smoldering” furnace either does not give enough to maintain the minimum required return temperature in CO, or it flashes. Therefore, long burning furnaces with a water circuit and manual adjustment of the mode are suitable as hot water for hot water supply, which also gradually accumulates heat in an insulated supply tank. And in order to adapt a long-burning stove for heating, it must be equipped with at least the simplest automatic control system that quickly regulates the air supply. And it turns out ... boiler long burning. Which have long been produced by industry and successfully exploited. As for the homemade stove on smoldering for heating, then this is exactly the option for which you shouldn’t wring a head or a hand.

Build a stove

It makes sense to undertake the construction of a furnace with a heating circuit itself, if you have enough cheap or free firewood. On a more energetic fuel (for example, on coal), a furnace with significant heat extraction on the side will acquire properties close to a long-burning furnace, see above. To make it work correctly, the project must be carefully calculated, modeled, brought to the prototype and subjected to comprehensive testing. In addition, a wood-burning stove with a water circuit needs to be built brick. Everything is poison, and everything is medicine - its large thermal inertia will make the design not so sensitive to the agreement of the parameters of the heat exchanger and the structure of the furnace. Next, we consider the features of manufacturing of the one and the other, accounting for which will allow to simplify the calculations or to build a furnace without them according to a well-known sample.

Register

The heart of the furnace is a heat exchange register or simply a register. The first thing that begins its manufacture is the calculation of the area of thermal contact. Then select the configuration of the register (see below), its material and location in the furnace. Then, either a furnace or a channel system are designed for the register, and the whole furnace will be used for it. In the latter case, the conventional design of the furnace is broken - from the furnace to the pipe, so you may need to recalculate at the design stage.

Heat contact area

The register must receive as much heat from the furnace as is necessary for heating the house, excluding the room with the furnace. The heat flow into the register is determined at first glance easily: Q = kS (ΔT), where:

Q - heat flux, W / s;

k is the heat transfer coefficient for the material of the heat exchanger of a given thickness;

S is the thermal contact area of the register with the heat-transfer zone of the furnace;

ΔT is the effective temperature difference between the heat-giving zone and the coolant in the register.

The last parameter is the most tricky, because ΔT is a complex function of dependences of the temperature change both in the space occupied by the register and in time during the furnace and the subsequent heat transfer from the furnace. With sufficient accuracy in our case, it is possible to consider when the register is located in the firebox ΔT = 800 degrees, when it is placed in the cap of the bell-burning furnace ΔT = 550 degrees and in the smoke channels channel ΔT = 350 degrees. Then 1 square. m of the register of steel with a thickness of 3 mm will transfer to the coolant 12, 8.25 and 5.25 kW, respectively, and cast iron with walls of 4 mm will be twice as small.

Material and form

In the furnace of the furnace closely, and there is placed a register of fairly good heat conducting steel. The usual constructional thickness of 3-4 mm; in the zone where it is above 1000 degrees, a properly designed heat exchanger will not be present. In the channels you need to put an acid-resistant cast-iron register. It is not necessary to build bell-type furnaces with a heating circuit without exact calculation: gas circulation under the hood is a delicate matter. If at random the register made by it is knocked down, the efficiency of the furnace will drop greatly and it will have to be cleaned very often.

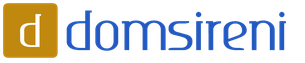

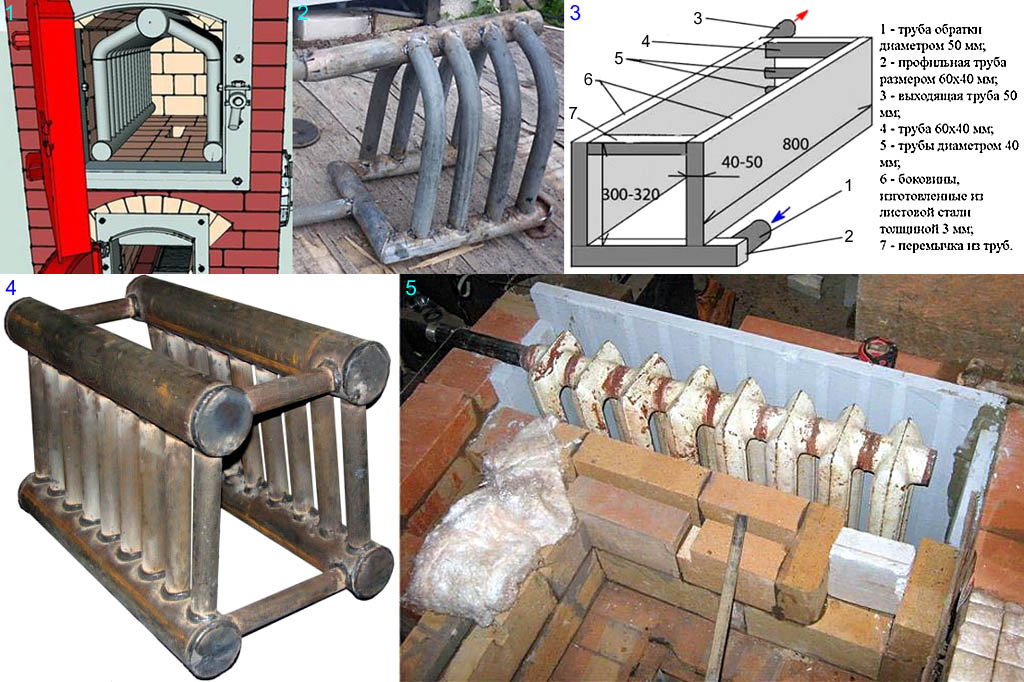

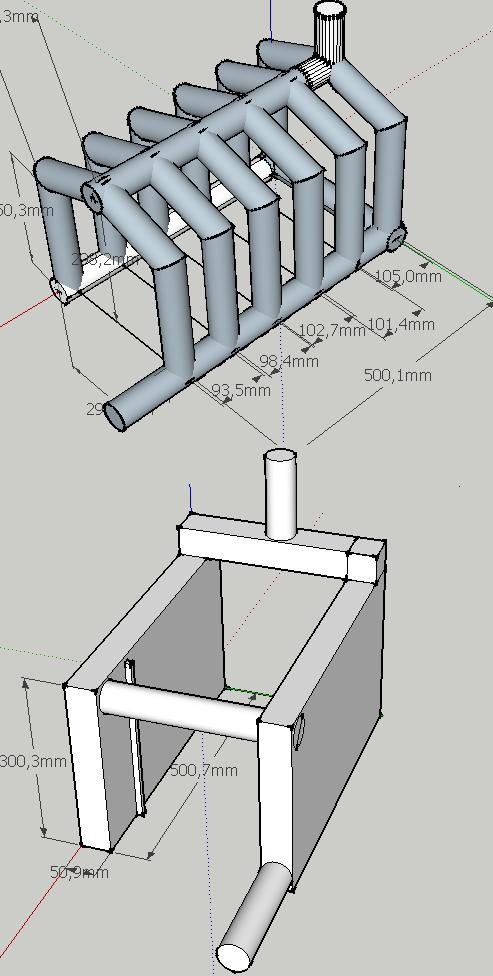

The roof-shaped “house” register (pos. 1 and 2 in Fig.) Has the largest heat-receiving surface with respect to its size and material consumption, but the furnace for it needs high so that the “hot” supply manifold does not cool the afterburner of pyrolysis gases. When designing a furnace with such a register, they take an imaginary plane for the level of the arch of the furnace, which cuts the places of fracture of the vertical branches of the pipes into converging ones. The magnitude of the receiving surface of the register house is considered to be equal to the geometric area of its outer surface.

A register welded from steel sheet (pos. 3) is not an option. Its heat-receiving surface is almost twice less than the geometrical one, and thermal stresses from large planes in contact with the flame will “flow” into the seams and will soon bring the register out of order.

A more metal-intensive box-shaped register (pos. 4) must be placed in the low firebox, and no less than 15 cm should remain from its top to the firebox. A drawing of the box-type register “for all occasions” is given in fig. on right. With its technical design, the calculated value of the receiving surface is multiplied by 1.25.

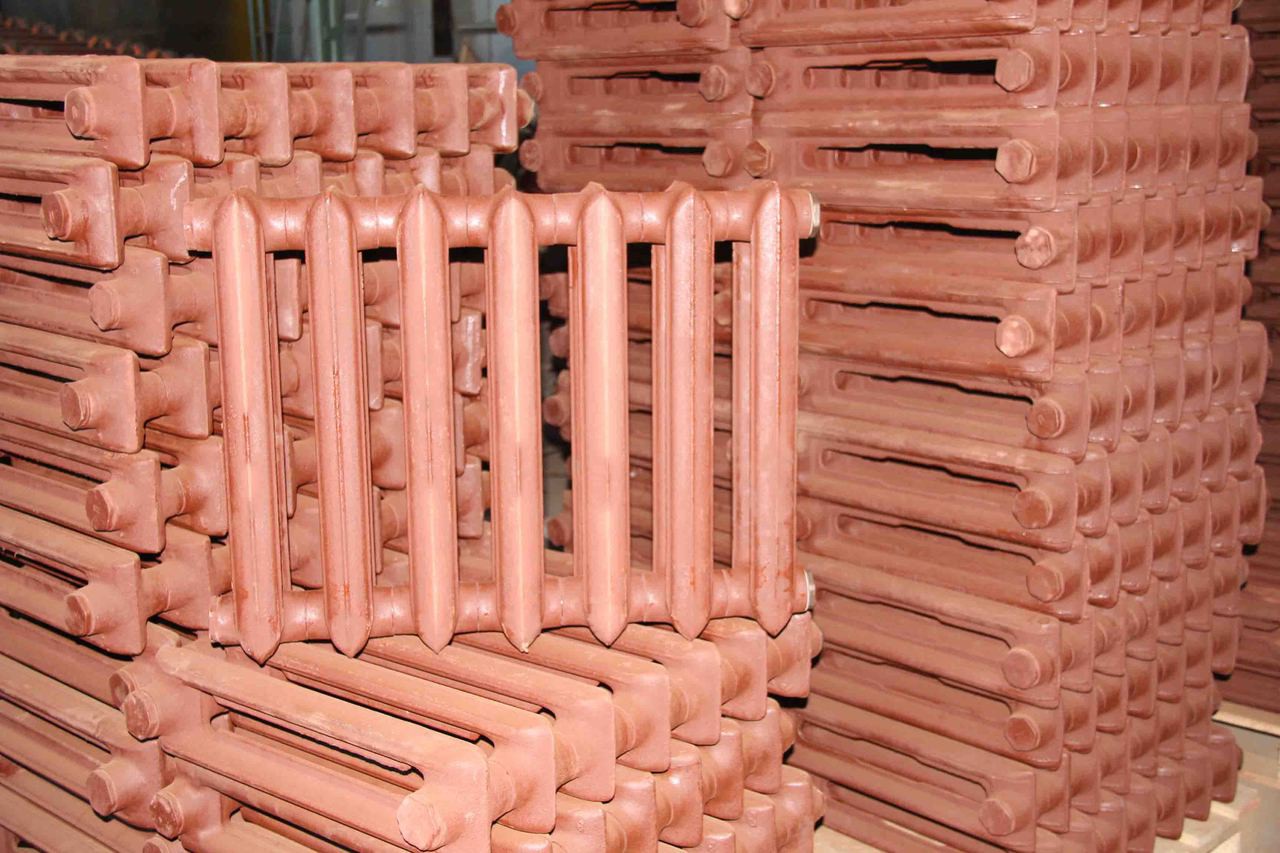

As the cast-iron register, an old battery-accordion, pos. 5 in fig. above. The size of the radiating surface of one section of cast-iron batteries (in this application, the one that receives heat) is in reference books on heat engineering and public utilities. Any search engine will issue a report immediately, you only need to measure what you have and decide on the table, what size it is. And on the surface of one section is either the required number or the total area of the available battery.

Oven building

The firebox of a water circuit furnace must necessarily be fireclay, easily heated and well-kept warm. A stove with a brick furnace register will compel and make you smoke, even if it is somewhere far away in the canals. In the latter case (the cast-iron register in the channel furnace), it is desirable to lay out the entire thermal core of its structure with chamotte, and put the register closer to the hail (exit from the firebox to the first well) so that the temperature at its closest end to the firebox is not lower than 400 degrees.

The furnace with a water circuit is built "from the register." After laying the foundation of the furnace and laying its bed (the first 2–4 solid rows of the laying of the furnace structure), the register is measured to the place (on the left in the figure), mounted and rigidly fixed in the system, and the furnace is erected around it (center). It is impossible to fix the registers temporarily (on the right) and finally mount the system after the furnace has been built - it is very easy to damage both! It is also unacceptable to fix the register in the furnace in any way: it must be free to lie in it. Outputs of the register pipes beyond the furnace structure are by no means smeared! After the oven is completely dried, they are packed tightly with an asbestos cord to form a gas-tight connection. If the air is “siphoned” into the oven, it will surely smoke, and waste will go out of it. In addition to the construction of a furnace with a roof-shaped register in the furnace see the plot.

Video: brick furnace with a water circuit

The cast-iron register from the old battery is thin. A stove with it is more suitable for dacha heating, for example, with a residential attic. All-season house furnace with a heating circuit will be a very solid construction.

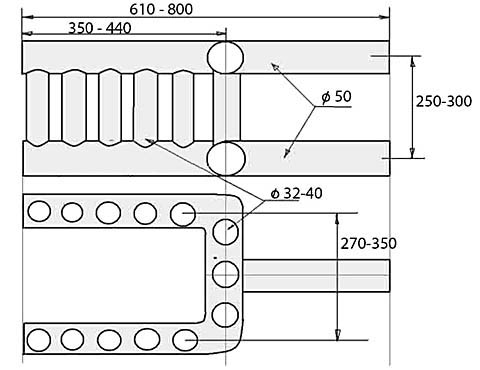

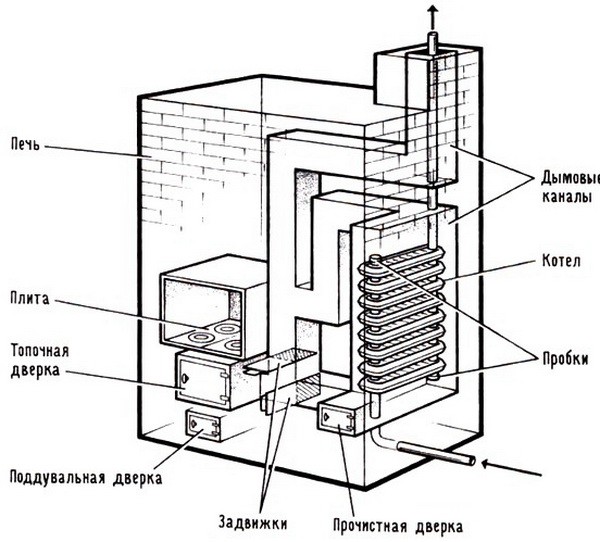

Diagrams of such furnaces are given in fig .:

Left - cottage. Since country stoves are fueled mainly with waste fuel, on which you still cannot achieve the maximum efficiency of the furnace, the stove is entirely brick. To switch to the summer course, the upper valve is opened, and the lower valve is closed. In the house furnace on the right in fig. (switch winter-summer conventionally not shown) steel registers of a large area in channels are applied. In order to prevent acid rain from falling (with proper stoking of the furnace, of course) all its thermal core is made of chamotte, i.e. increased heat capacity. In this design, the probability of the formation of acidic condensate is minimal.

Oven in the system

Correctly to build a heating furnace with a water circuit is not enough. Under it, you also need to properly develop the CO, and properly include a furnace in it.

Let's go briefly on how to organize CO. Whether our system will be one-pipe, 2-pipe, series, parallel or mixed, the question is important, but another - in terms of the efficiency of heat use of the furnace for home heating. From the point of view of possibilities, cost, convenience, simplicity and non-volatility of the furnace and CO interface, it is more important to disassemble the systems:

- Open gravitational (gravity).

- Open with forced circulation.

- Closed without excessive head.

Gravity

There are no purely thermosiphon COs (like the cooling systems of the internal combustion engines of the first cars) - losses in long CO pipelines will suppress the thermosyphon circulation. In order for CO to work, it needs to call upon a certain, quite definite share of gravity (in purely thermosiphon circulation, the proportion of gravitational pressure can be arbitrarily small).

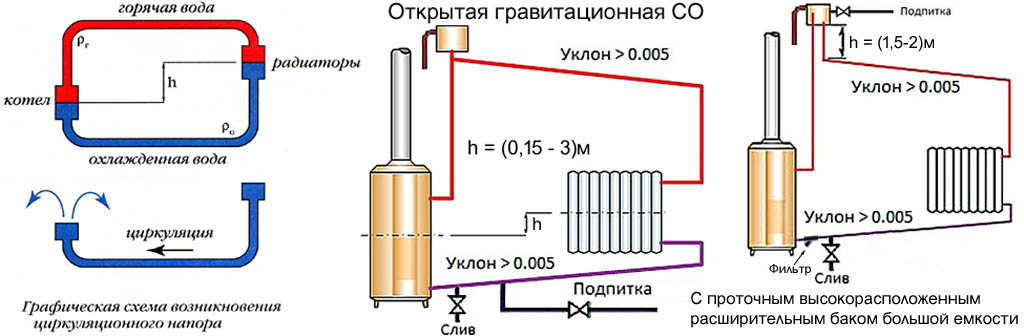

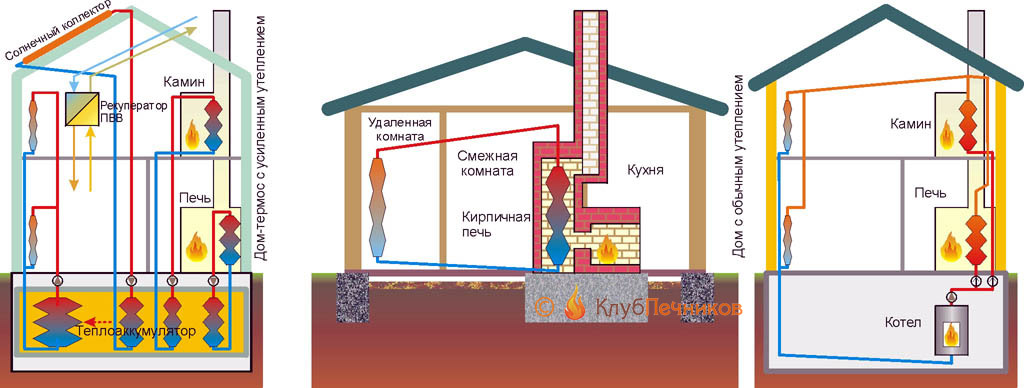

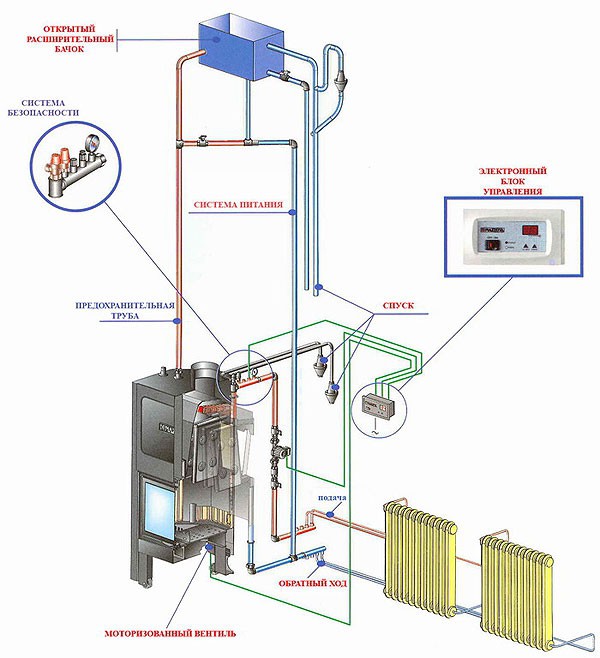

The principle of operation of the gravitational CO is shown on the left in the figure:

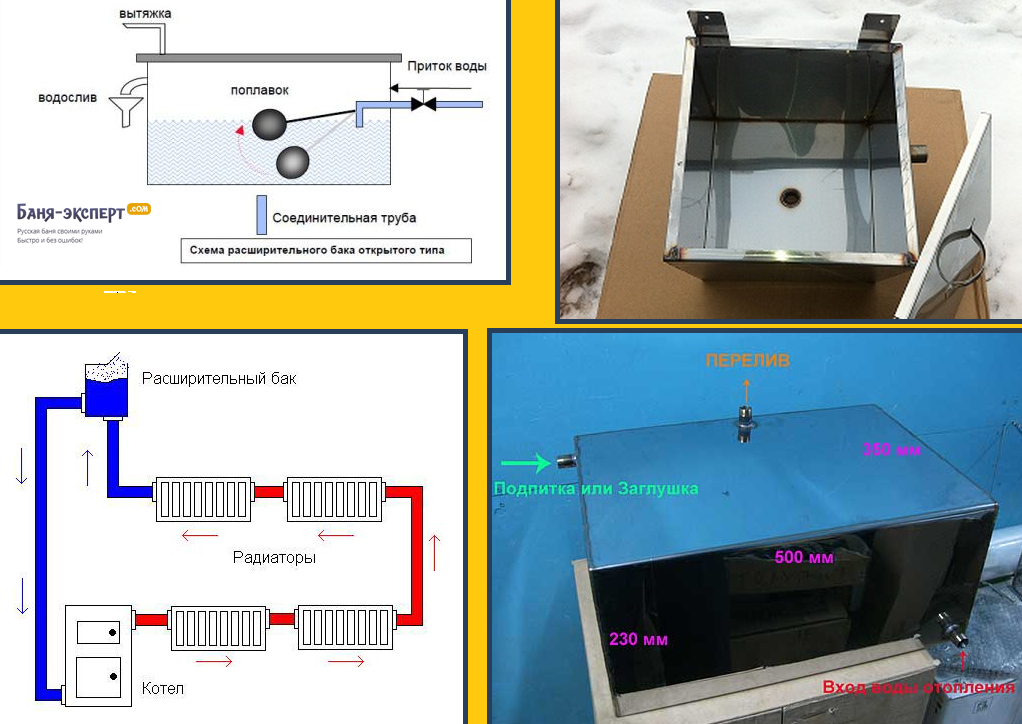

If the system is activated from the stove in the house, it is impossible to fulfill the condition indicated in the center, even if the batteries are hung from the ceiling. In such a case, CO can come from high flow expansion tank (to the right of the figure), it will create the additional pressure necessary for the thermosiphon circulation of the coolant. In centralized CO, a system with a flow dilator is not used, since requires a greater consumption of materials, labor costs for maintenance and, for mass use, gives large losses of the coolant. But in a private house all this is more than offset by the simplicity, cheapness and stability of the work of this SB. Its zest is an expansion tank. The requirements for it are:

- Capacity of 200 liters is enough for the house to 120-150 square meters. m residential.

- It is convenient to make a tank from a barrel placed on the priest, i.e. vertically.

- CO feeding and washing - only the upper ones through the tank.

- The tank must be reliably insulated: in order for the circulation to go, it is enough for the water to cool down only by 1-2 degrees, and the heat losses from the uninsulated tank will be excessively large.

- The tank is half full, as is the usual expansion tank.

- To avoid evaporation of the coolant and clogging it with dust, the tank should be closed with a tight lid with thermal insulation and air drainage.

- The outlet pipe protrudes 5–7 cm above the bottom to avoid clogging of the pipes with sludge.

- The mouth of the inlet nozzle is located not lower than 15 cm above the exit, but not higher than 20-25 to the water mirror at its minimum level, otherwise air can be sucked into the system (water from the inlet is keyed and may be pulled into the exhaust air).

Note: since it is impossible to constantly stoke a brick oven and refill CO with it with antifreeze, and the winter cottage with a stove can also be left for several days, it is highly desirable to include an emergency electric boiler in the system (see the figure on the right). It will maintain the temperature of the water in the system above the freezing point; as a rule - at the level of 5 degrees Celsius. True, the reserve boiler eats a lot of electricity a day.

With pump

Forced circulation CO are built only with metal furnaces, if required by the manufacturer of the furnace. The intensity of heat transfer from the brick furnace is too small for this: it will be cold in the house and the furnace will be heated, and the unused heat will fly off into the pipe in the form of unburned fuel.

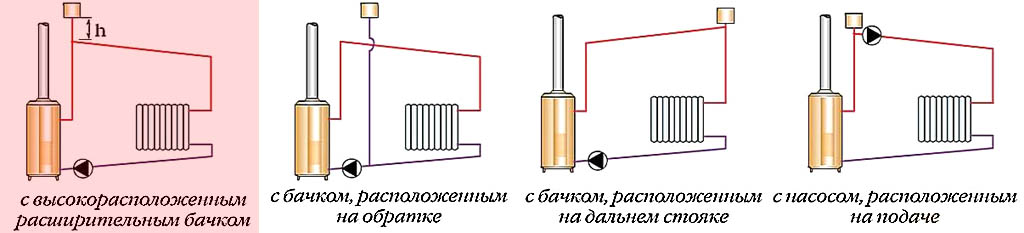

For CO with a furnace, firstly, from the possible schemes of systems with forced circulation of the coolant (see fig.), One should choose a scheme with a high-lying expansion tank (highlighted in red). When the power supply fails, it will provide minimal circulation so that the system does not defrost. If there is no backup electric boiler, the stove needs to be heated all the time, but little by little, so that the water in the system does not boil. Therefore, in such a CO, a water inlet temperature sensor is required.

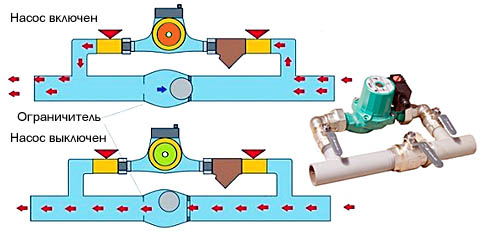

Secondly, the circulation pump must be equipped with a bypass (bypass shunt; bypass in English - bypass) with a check valve, see fig. below. Without a bypass, both the system and the pump will freeze. the tiny thermosiphon pressure does not push water through it.

Closed

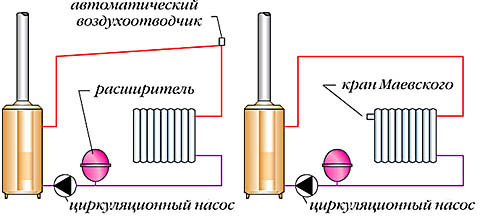

Quite expensive closed CO with membrane expansion tank is used with furnaces quite often, since compact, working with metal and brick ovens and relatively easy to fit into the interior of the house: all CO trim can be placed in a cabinet next to the oven (see the figure at the beginning). The device is closed WITH, involved from the furnace, has no features; It is necessary to have an automatic or manual valve for dewatering the system, see next. rice ..

Use cases

As you can see, there is more than enough work, hassle, and cost to fully heat the house from a water circuit stove. Let's try to figure out in which cases its use may be appropriate.

Option 1: energy saving house with heat accumulator. In such houses, even the ventilation air is carried out through the heat exchanger, so that the exiting one heats the incoming air. The heart of such a house is a heat accumulator. They are short-term (up to 2-3 days) and long-acting. Short-term fill high-boiling heat-absorbing non-flammable liquid; in the long-term are used melts of mineral salts.

This option is very expensive: even the daily heat accumulator alone is more expensive than a good strapping boiler with backup power supply. A 40-50 square meter house with a long-term battery costs a few million USD, but that's not the point. The best of modern heat accumulators on salts keep heat for up to 3-4 months. and at least ever able to pay off only in the regions, where the total annual heat consumption in a house for all needs, except heating, exceeds that for heating a house during the heating season. We are far from them - geographically and climatically. In mid-latitudes, with relatively inexpensive fuel, the heat accumulator can in principle make a house non-volatile if it stores heat for a year or more. Therefore, this option is considered only for common development.

Option 2: there is a rather extensive house without a basement, there is affordable or bestial trash fuel that is unsuitable for boiler quality, but any type of conditional equipment is unavailable or expensive. In this case, it is possible to build a combined CO on the stove with a water circuit (in the center in the figure): the remote rooms are heated to a comfortable temperature with excess heat from the furnace with a cast-iron register. The ability to take the heat of the battery-accordion is enough for 1-3 rooms, because in part, they heat and heat directly from the furnace. For the same reason, the probability of defrosting the system is extremely small. CO itself is the simplest open gravitational.

Option 3: there is an operating CO with forced circulation by a boiler in the basement, but regular fuel is expensive for it, and waste material is available. We include in the system registers of other heat generating devices. In parallel, through check valves (on the right in the figure), so as not to knock each other and the entire system off of the mode. The consumption of regular fuel for the season is sharply reduced: the excess heat from other devices now does not go through the windows and ventilation, but goes into the pipe. Not into the flue, but into the heating one, and it helps the boiler to save regular fuel much more. This is the only to date, always and everywhere justified decision to purchase or build a stove (fireplace, stove) with a water circuit.

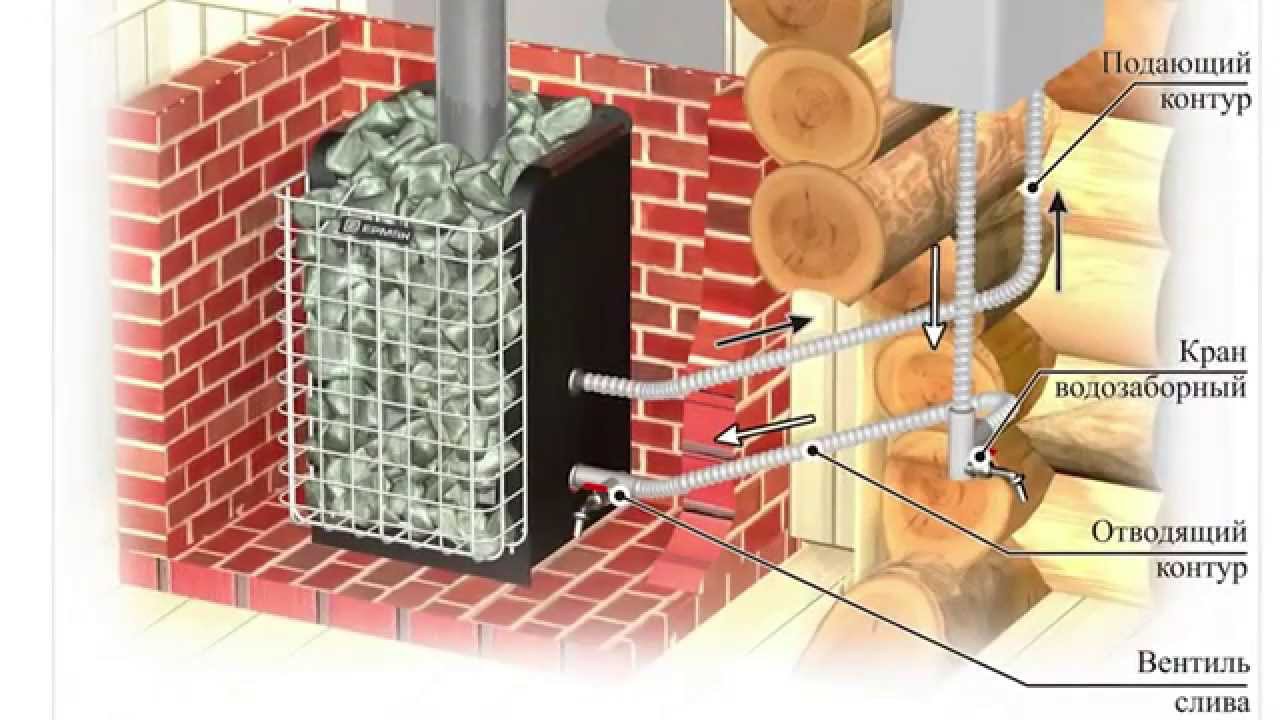

It is advisable to put such furnaces in large saunas, which have a separate shower room, a rest room, a dressing room, etc. They will make it possible to create a comfortable temperature in the rest of the rooms during the heating of the steam room. It is necessary to solve problems with the choice of the type of boiler and its linear dimensions even during the design of the furnace, and all features of its operation and design changes should be taken into account. It is almost impossible to make an exact calculation of the thermal power of an improvised boiler; there are too many individual factors.

Furnaces for the bath can be metal and brick, with a different arrangement of the heater, with the presence of a boiler for heating water for washing. There are no restrictions on the size, specific parameters are selected taking into account the size of the premises, materials for the construction of the bath and the climatic zone of residence. Consider the design features of two types of furnaces with heating boilers.

- Heating boiler built into the chimney. Advantages - a long time of operation, relatively low heating temperatures have a positive effect on the stability of metal structures. In addition, this installation of the boiler does not affect the heating rate of the steam room, the heat from the furnace is completely transferred to the walls of the stove, heat transfer indices do not change. The disadvantage is low productivity and a small area of contact of the heating boiler with hot gases do not allow to effectively heat large rooms.

- The heating boiler is located directly in the furnace.

Advantages - large premises are heated, the heating functions immediately after the start of the furnace heating, it becomes possible to use various types of heat exchangers.

Disadvantages - direct contact with the fire of the metal elements of the heat exchanger negatively affects the indicators of their physical strength. The walls of the heat exchanger have a relatively low temperature, this contributes to the appearance of moisture condensation, and a large amount of soot adheres to wet surfaces. A soot buildup of one millimeter thick reduces the efficiency of the heat exchanger by approximately 10%. You have to clean it often or put up with insufficient heating of the water in the boiler. Another drawback - increasing the size of the furnace and as a result, the overall size of the stove. Not every bath has the ability to install large stoves.

A few words should be said about the types of heat exchangers. This is a very interesting question. Errors during the choice of engineering design can have very sad consequences.

Types of heat exchangers, their advantages and disadvantages

You can independently make two types of heat exchangers: flat and tubular. In order to make it easier to make an informed decision, you need to familiarize yourself with their performance characteristics and features.

Flat heat exchangers

A fairly common form, often used during the construction of furnaces for various purposes, and not only for the bath.

Benefits

The simplest to manufacture, surfaces are easily cleaned of adhering soot, can be installed both vertically and horizontally, have a fairly high efficiency.

Flat boilers, unlike tubular boilers, can have a large volume, which in some cases allows for fence hot water for washing from the heating system.

Set by expansion tank with the increased linear sizes in which water is constantly added after decrease in level below critical.

The option is quite convenient, solves several problems at once. But there is one prerequisite - in the bath in the winter period of time, the temperature in the bath should not drop to minus values. If the condition is not met, then the water should be replaced with a cold-resistant coolant.

disadvantages

It is necessary to dwell upon them in more detail; many builders do not pay them due attention. The main drawback is that the heat dissipation of the walls of the stove is sharply reduced. The fact is that flat heat exchangers are made in the shape of the letter P, installed around the perimeter of the firebox, except for the door. This means that the outer walls of the stove have a low temperature, the heating does not exceed + 40 ÷ 50 °. Such parameters significantly increase the warm-up time of the steam room, preparation for receiving water procedures takes a lot of time. There are even more strange suggestions - to increase the life of the boiler to make a lining between it and the furnace.

We do not argue, an additional row of bricks will protect the heat exchanger from the negative effects of a direct flame. Just at what cost? The start time of efficient operation of the heating system is much longer, and heating with a steam oven will decrease many times. In order to steam in the steam room and warm the rest room and the shower will have to heat the stove for many hours. On conversations that the boiler keeps heat for a long time, do not pay attention, there is no benefit from this. No one can repeal the laws of physics. Once a furnace with a boiler keeps heat for a long time, it means that it heats up just as long. Time spent on heating a large mass of bricks. In addition, the outer walls of the stove remain cold. Such an option can still be imagined during the installation of the furnace for heating residential premises, but for baths we strongly recommend against using it.

In residential buildings, the stove is constantly heated and the increase in the heating time of the premises for several hours does not matter. How, by the way, is the time of cooling water in the boiler.

Practical advice. If you plan on bath stove install a flat boiler on the sides of the furnace, then consider, due to which it will be possible to accelerate the heating of the steam room. There are several options. You can significantly increase the heater, place it directly above the furnace. Another option is to use the chimney for space heating. Make it only metal, slightly increase the length due to the various knees, etc. Immediately, we note that these options, besides the positive sides, have negative ones. It is necessary on the spot to independently navigate and make informed decisions.

Tube heat exchangers

Most successful solutioncan be of various sizes and shapes, from fairly simple to complex.

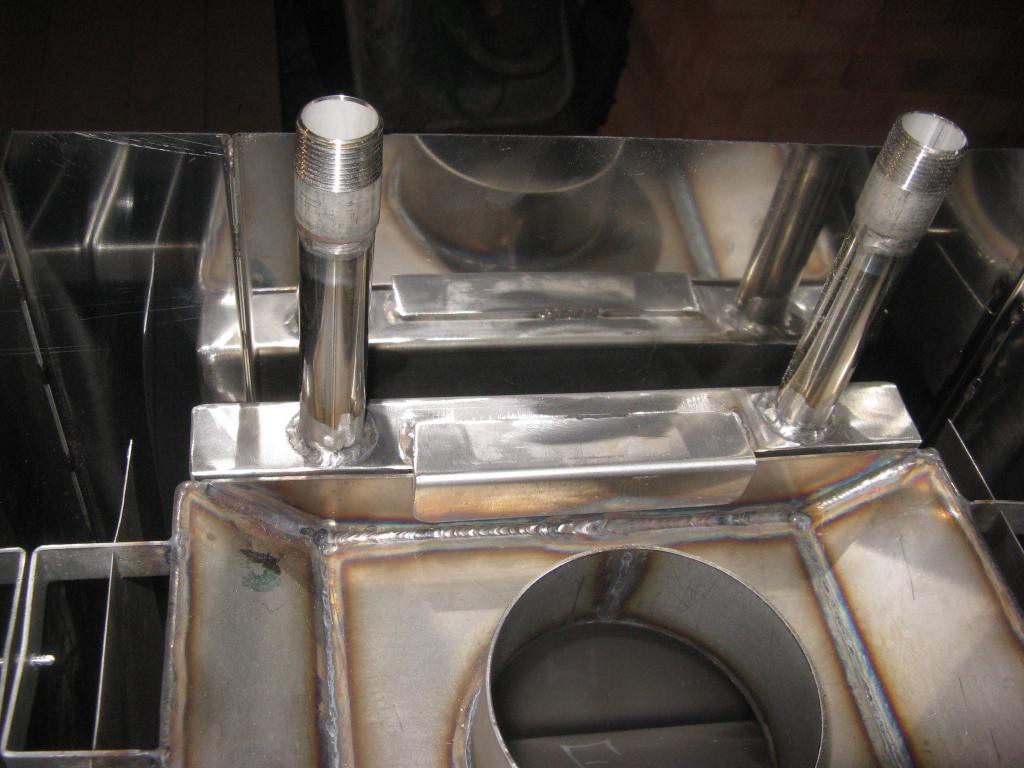

Such registers are made with different sizes, can be installed either on one side of the firebox, or on two or three. Heat exchangers are easily maintained, in case of emergency they can be removed from the furnace without disassembling the brickwork. Practitioners do not advise to pursue too complex designs of heat exchangers, such aspirations often bring the result opposite to what was expected.

Very important. For the manufacture of heat exchangers, use only seamless pipes. To distinguish them from the seam is quite simple - they do not have a longitudinal welding line. When heating the suture tubes can cause cracks, as a result, a complete replacement of the heat exchanger with mandatory disassembly of the furnace.

The first. The pipe circumference is C = π × d.

The formula for the circumference

For example, a pipe with a diameter of 50 mm in the unfolded state has a circumference of 3.14 × 50 = 157 mm. Takes only 50 mm along the length of the place in the furnace, and is heated three times more than the surface. In order for the efficiency of the flat heat exchanger to be the same as that of the tubular heat exchanger, its dimensions must be three times larger. With this, everything is clear, but not everything is unambiguous. Pipes cannot be fixed close to each other, and the gap between them reduces the effective heat transfer area, this substantially eliminates the advantage. But even with such a device, tubular heat exchangers are more efficient than flat ones.

The second. No one remembers this reason, but it is of great importance. Due to the presence of gaps between the pipes of the heat exchanger, it is possible not only to clean the pipes from soot, although this is very important. There is another plus - open fire through the gaps directly heats the walls of the stove, the steam room warms up quickly. Flat heat exchangers completely isolate the walls of the stove from the fire with all the negative consequences.

We hope that we will convince you to make pipe heat exchangers, even if they are much more difficult to manufacture. Do not have enough experience to make it yourself - ask for help from a qualified welder, and you will be busy installing the finished product in the furnace. You can be sure that some increase in the cost of work will pay off in full due to the reliability and efficiency of the boiler.

Video - Solid fuel boiler

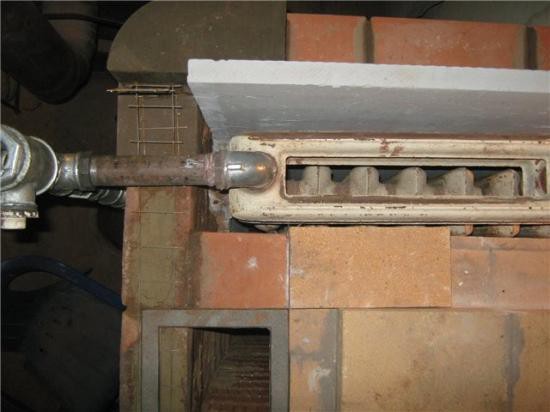

There are such tips. Separate sections of radiators are assembled into batteries, the number of sections is not limited by anything. The batteries are inserted into the firebox and the heating of the sauna is solved. Everything is beautiful and at first glance quite convincing.

What do the professionals say about this?

- First, cast iron radiators are very heavy, a significant increase in the load on small bath stoves.

Some of them are built on floor beams, it is impossible to increase the weight of the structure. We need to make a concrete foundation, and it is expensive.

- Secondly, such radiators can be installed only in stone stoves, and tubular or flat heat exchangers of universal application can be mounted both in brick and metal stoves.

- Thirdly, cast iron reacts extremely negatively to an open flame; it is not recommended for engineers to install boilers made of cast iron radiators in the furnace. Where then to install them in the chimney? The big question.

- Fourth. Cast Iron Radiators have many different edges to increase the heat exchange area, the surface is uneven, etc. Such design features contribute to the accelerated deposition of soot on them, its presence causes a sharp decrease in the efficiency of operation. In addition, cleaning radiator surfaces is not just difficult, but impossible.

Practical advice. If you have after the repair of the old heating system remained cast iron batteries, then hand them over to the scrap metal reception center, and buy metal pipes with the money, do not try to save yourself at a loss.

How to embed a radiator in the oven

We will try to give step-by-step instructions for the laying of the furnace, it is impossible to tell a detailed universal order, there are too many options both in terms of the size and type of heat exchangers and the characteristics of the furnaces. But knowing the general principles, stages and features it will be possible to make the furnace according to individual drawings. Initial data. Brick stove with the upper arrangement of the heater, the boiler is flat or tubular with placement in the furnace, reinforced concrete foundation, brick chimney or combined with a tubular one.

Step 1. Make a boiler (heat exchanger) of the type you like; dimensions should be coordinated with the dimensions of the stove and furnace. Put bricks in the room, the doors of the blower and firebox, gate, elements of the heater. Prepare masonry mortar. For masonry, you can use only clay with sand or add a little more cement for strength. Both options are almost equivalent, but we advise the second - the risks of leaching solution in the furnace joints are reduced due to water ingress.

Cast iron heat exchanger - photo

Step 2. Check the level of the foundation, align it if necessary. Scatter horizontally less than one centimeter - do not pay attention, such errors are eliminated without problems during the laying of bricks due to the difference in thickness of the solution.

Step 3. Lay out the furnace base with bricks without mortar, check once again the correctness of the calculations made. On the order of the base, it is already possible to roughly mark the number of bricks for the fire, the thickness of the walls, the specific location of the boiler.

Step 4. Put the first row on the solution, it will be solid. The second row should already take into account the location and size of the blower.

Practical advice. There are options for modern stoves that can sustain firewood burning for a long time. In such constructions, the ashpit with grates in most cases is not done, the intensity of combustion of the fuel is regulated by the amount of air supplied through special vents. We do not recommend for the bath to use this option. Long burning fuel does not increase its heat transfer, but stretches it in time. The oven will be warm for a long time, but never hot. A steam room to be heated as quickly as possible to a high temperature.

Step 5. For the height of the ashpit, three rows of bricks are sufficient; specific dimensions need to be coordinated with the dimensions of the door. Under the grate, you should choose the sidewalls of the bricks, make it grinder with a diamond disc. The last row under the grate is better to put the refractory bricks. Make the entire inner surface of the furnace and the first few rows of the chimney out of refractory material. If you can not - do not worry. Practice shows that furnaces from ordinary bricks do not fall apart for 5 ÷ 8 years. And this is when the daily fire. About how many times a year will the stove be heated in a bath? Add to this the protection of the walls of the furnace with a boiler, perform simple arithmetic calculations, the result will calm you.

The beginning of the furnace laying - a part of the firebox is lined and a grate is installed

The first rows of the stove made, it's time to start laying the boiler (heat exchanger). This is a more complicated process, requires increased attention.

Laying boiler (heat exchanger)

The firebox of the stove must contain the boiler and allow for the simultaneous making of several bookmarks of firewood.

Step 1. Place the tank on the top row of bricks. Adjust its position so as to cut the minimum number of bricks. If you have made the heat exchanger flat in the shape of the letter P, then try to place it in the maximum proximity to the outer walls. At the same time, look at the position of the inlets / outlets, their length should be about 5 ÷ 10 cm more than the thickness of the firebox. Do not make a flat heat exchanger with a top heating surface; this will make it much more difficult to heat the heater to high temperatures. It will have to do in the chimney, and to achieve a high heating temperature in this place is quite difficult. In addition, the amount of stones is limited, which will certainly reduce the heating rate of the steam room and the duration of maintaining the required temperature.

Step 2. Start laying bricks around the boiler. For a flat boiler you can use ordinary red bricks, the temperature of the walls will be minimal. For tubular heat exchangers it is better to use a refractory material around the perimeter of the firebox. We have already mentioned one of the important advantages of boilers of this type - the external surfaces of the stove can be very hot. This means that the sides of the firebox should be protected from thermal damage.

Step 3. After two rows, begin to leave a hole under the fire door, the dimensions are standard or adjust yourself. The front wall of the firebox should also be made of fireclay bricks.

Step 4. If the stove is large, make channels for cleaning and close them with doors, for small constructions this is not necessary. Periodic cleaning can be done without problems through the installation of the installation of the heater. Stones are removed, the metal plate on which they lay is removed, and access is opened to completely remove the soot from the stove.

Step 5. Lay the rows of bricks at the height of the boiler, constantly check the level of their position. If you do the dressing correctly and observe the spatial position of the bricks, the seams between them will always be the same in thickness. At the level of the firebox door, you need to put a metal strip for bricks to close its upper part.

Step 6. Start preparing to install the heater. The heater can be placed on a thick (approximately 4 ÷ 5 mm) steel sheet, the dimensions should correspond to the dimensions of the furnace with the heat exchanger installed in it. If it is difficult to get such a metal, you can buy in the store a cast-iron cooking stove with a set of rings for closing the holes.

Important. The sizes of cooking plates are standard, they do not always correspond to the dimensions of the boiler you made. If the slab is a bit larger, then there is no problem; make holes in the bricks through the thickness of the metal and place the slab. If it is smaller, then you need to narrow the gap above the firebox. This should be done for several rows, the specific amount depends on the size of the stove and firebox.

Bricks should not protrude more than one-third of the length, only in such a position can they be securely fixed in the following rows. Can not it? Then use metal plates or rods, brick them into the seam and put some of the protruding bricks on them. During the laying of the side surfaces of the furnace, make holes for the heat exchanger tubes.

Step 7. Get started. The location of its location should be determined before the laying of the furnace. The dimensions of the inner passage are required to provide constant and sufficient traction.

Choice of chimney length

Important. Pay attention that the chimney is not located under the ceiling beams or rafters. This is a big mistake; you have to lose a lot of time to fix it.

In the chimney should be sure to put the gate. If desired, you can not make the entire chimney out of bricks, and after the gate install a metal pipe.

Video - Heating stove

Video - Draft brick furnace for the bath + order

It remains to make the heater. To do this, make a small fence of metal wire around the perimeter of the steel sheet or cooking stove. The height of the fence is about 25 ÷ 30 cm. The more stones there are, the longer the optimum temperature will be maintained in the steam room.

In order not to interfere with the inlet / outlet of the coolant during dismantling, make threaded connections at the ends. Weld to the exits of the heat exchanger the nuts of the corresponding diameter and tighten the nozzles with a gas wrench. Aluminum or bronze washers are recommended for sealing. If not, you can use any other seals. The connection of the pipes with the heat exchanger is performed in a place inaccessible to fire, the temperature of heating of the threaded connection will not exceed + 60 ÷ 70 ° C.

The bath is used periodically, in the winter time the water in the heating system may freeze. To prevent breaks in the heating system, use antifreeze as a coolant. It is strictly forbidden to replace it with diesel fuel.

Heating baths such boilers can not be natural due to the temperature difference, it is imperative to install a circulating pump. By selecting the pump should be approached very carefully. You need to look not only at his specifications, but also on the opportunity to work with antifreeze. The fact is that not all rubber seals can work with such liquids, special oil-resistant rubber is required. Ask this question from implementers.

Two-pipe heating system: its features and installation with your own hands You thought about installing your own heating and the question arose, which of all existing systems to assemble? There are a lot of them, and they all have their advantages and disadvantages that you don’t want with, but you’ll have to figure it out - the truth is learned by comparison, and heating in this regard is no exception. Two-pipe heating system: advantages and disadvantages two-pipe system heating a private house, as they say, more than enough. Among all their many, the following advantages occupy a special place. The most important of all the advantages is that for each individual heating radiator a coolant of the same temperature is supplied. Naturally, if the calculation of the system was made correctly. Everything is important here - the length of the lines, the area of the rooms, the diameter of the pipes, the power of the boiler, and many other factors, including the average air temperature in winter, are taken into account. In contrast, the one-pipe heating system does not allow all the batteries to be supplied with the same temperature as the coolant - as a rule, the last devices of such a system do not get warm. Independence of each individual heating device. If we compare the two-pipe heating wiring system with its one-pipe analogue, then, unlike the second, the first one does not provide for stopping all the heating when at least one heater fails. You simply close a couple of taps on the battery, and the rest of the system continues to function normally. The ability to adjust the temperature in each individual room. This is achieved simply - taps or automatic thermostatic heads are installed on each heater. In any case, opening or closing the taps regulators, or setting the temperature on the thermostatic heads, you can control the comfortable temperature in the room without affecting the operation of all other appliances in the house. In this way, you can even debug the heating operation, ensuring the effective functioning of all batteries. Installation of a two-pipe heating system can be done in any houses and buildings, regardless of their area and number of floors. In general, it is a universal heating system. It does not do without the drawbacks - in most cases they are not technical and do not affect the heating efficiency in any way. The negative aspects of such systems include complex installation (often very extensive heating systems with a large number of equipment) and high cost, which is a consequence of the complexity of the system and the presence of a large amount of equipment in it. Types of two-pipe wiring and their features There are several points according to which it is possible to divide all existing two-pipe heating systems into types. Two-pipe heating system with forced circulation and natural coolant current. The main difference between the two systems is that forced circulation requires participation in the process of heating a circulating pump at home, while the natural one works on its own, thanks to the laws of nature. In the first case, the system is dependent on the availability of electrical energy. If we talk about the effectiveness of one and the other heating systems, then in small areas it is almost the same (the only negative point is that natural heating it warms up longer), but as for large areas, the primacy here, undoubtedly, belongs to the heating system with forced circulation of the coolant. Vertical and horizontal two-pipe heating systems. It is not difficult to guess that we are talking about the location of pipes in space and under the vertical heating system means drains, which often spoil the appearance of the premises. In principle, this is not a problem if their wiring is laid in a hidden way, in the wall. As a rule, there is no pure heating system with vertical distribution of pipes - whatever one may do, and one cannot do without horizontal sun loungers that distribute and collect coolant from vertical risers. Such a system works by the simple principle - a pump or natural circulation squeezes the heated coolant into the attic room, in which it is fed to the risers on the sun beds. After passing through them and giving some heat to the heating devices, he returns to the boiler for the next heating cycle in the central lounger located above the floor or in the basement. This system is quite efficient and in some way even economical - for its work requires less power equipment. In fact, circulation pump you only need to raise the coolant up, and then all the work is done by the laws of nature - the water just flows by gravity downwards. Two-pipe heating system with top and bottom wiring. Such heating systems are classified as horizontal and their main advantage lies in the compact arrangement of pipelines, which allows them to be hidden in one place. Typically, this floor or ceiling - as an option, basement or attic space. Wiring, in which the pipes are located under the ceiling or in the attic, is called the top. If the pipes run in the floor or above the floor or, respectively, in the basement, then this is a two-pipe heating system with lower wiring. Speaking in a more understandable language, then lower wiring provides for the location of pipes under the heating devices, and the top above them. There are combined versions of such systems - for example, the most effective is considered to be a system in which the supply coolant pipe is located above the heating devices (under the ceiling or in the attic), and the return pipeline, respectively, above the floor or in the basement. Fully lower heating wiring is used with a small system length - if we talk about a large house with a large number of radiators and an extensive network of pipes, then it is better to use a combined heating system in them. In general, for large houses, combined heating systems are the best option - by and large, in such houses there are risers and sun beds. The pipes run both under the floor and under the ceiling, and even in the basement and in the attic. Ask why? Yes, everything is simple - each system has its own strengths, using which in one or another part of the system, maximum efficiency and profitability of heating as a whole is achieved. Two-pipe heating system of a private house with their own hands The principle of installation of a two-pipe heating system is quite simple, if you do not take into account the presence of complex equipment and do not take into account large branched pipelines. You simply draw two lines side by side (supply and return) and connect heating devices to the tees. There are in this case their own subtleties, and about them we will talk further. The most important point that determines the efficiency of the system, is the diameter of the pipes used. The principle of their choice is simple - you need to make sure that the coolant is enough for all heating devices. It is for this reason that the main pipelines have a larger diameter, and the linings can be said to be minimal (as a rule, ½ inch). Everything is clear with eyeliners, but you need to sort out the lines. If we talk about small systems two-pipe heatingthen the diameter of their pipes, starting from the boiler, should decrease - first we take an inch and sit on the trunk of this diameter to four radiators, then reduce the diameter to inch and sit on it with the same number of radiators. To the last heater the pipes can be pulled in with a diameter of ½ inch. If your system has more radiators, then wings are created - in fact, these are parallel pipelines connected to each other, to collect them into a single system, a collector is used ( distribution comb). In fact, it is a thick steel pipe with several connections for connecting main wings - as a rule, its diameter is two times larger than the diameter of main pipelines. The presence of valves - this can be called a prerequisite for the normal operation of the system. Without it, you simply can not adjust the heating and achieve its optimal performance. It is installed almost everywhere - on heating and other devices and on the branching of the wings. In general, wherever possible. It should be understood that screwing a faucet in one place, to another place, you serve a greater amount of heat carrier. And, of course, the correct selection of heating equipment power - in principle, this moment is important for all types of heating systems. Power equipment must be selected with a margin and calculate it based not on the area of the room, but its volume. In all other respects, in particular in installation, the two-pipe heating system is practically no different from its other technological counterparts.